Академический Документы

Профессиональный Документы

Культура Документы

Shoring and Reshore PDF

Загружено:

ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Shoring and Reshore PDF

Загружено:

ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Авторское право:

Доступные форматы

Shoring and

Reshoring for

Multistory

Concrete Buildings

Formwork economy and safety must go together

BY PERICLES C. STIVAROS

A re three levels of reshoring needed? Or will two suffice?

Is it safe to strip? These simple questions require a

complex answer. The recently published document by

how do we evaluate the safety of a construction schedule

that incorporates two levels of reshores? An engineering

analysis is needed, and this analysis must consider both

ACI Committee 347, “Guide for Shoring/Reshoring of the construction load distribution and the early-age load

Concrete Multistory Buildings (ACI 347.2R-05),”1 can help carrying capacity of the supporting structure when the

construction professionals and engineers answer these shoring/reshoring schedule is developed. If the provided

questions by providing methods for developing safe and support is insufficient, the best that can be expected is a

economical construction schedules. This article outlines series of deflected slabs and beams with radial cracks

the new guide and highlights some of the many factors around columns (Fig. 1); the worst outcome is a local

that must be considered. collapse that triggers a progressive collapse through the

Economy in concrete formwork construction requires whole height of the building.

maximum reuse of forms and shoring materials, as well

as adequate, but not excessive, formwork design. This CONSTRUCTION LOAD DISTRIBUTION

is particularly true for multistory buildings, where The question of how construction loads are distributed

standardized dimensions and repetition result in the least between the formwork system and the newly cast

number of forms needed to ensure a smooth workflow. supported concrete members has been the subject of

To maximize reuse, workers must strip the forms as soon debate in the construction industry. The most significant

as possible, and reinstall them for the floor that follows. work on construction load distribution was published

The relocated forms must then be supported by the in 1963 by Grundy and Kabaila.2 This landmark paper

structure below. presented a simple method of calculating the construction

Shores carry forces from the formwork, concrete, and loads carried by slabs and shores during the construc-

construction loads above, and reshores—installed after tion of multistory flat plate and flat slab concrete build-

the original forms and shores have been removed— ings. The method is known as the simplified method. The

distribute loads over several floor levels. One level of fundamental assumptions of the method include:

shores and two levels of reshores may permit placement Elastic deformation of the concrete slabs (creep and

of one story per week in the most economical manner, but shrinkage are neglected);

Concrete international / FEBRUARY 2006 33

elasticity, respectively. The load capacity of an early-age

slab is also determined by the total service load for which

the slab has been designed. The reserve strength of the slabs

to carry service loads is called upon during construction

to carry the imposed temporary construction loads.

The same strength reduction factors, load factors, and

load combinations used for the original design of the

structure should also be applied during the strength

evaluation of the partially completed structure. It’s also

recommended that the loads and load factors discussed

in SEI/ASCE 377 be considered for construction loads not

covered in ACI 318-05.8

When the applied construction load on a slab exceeds

the early-age strength of the slab, there are two basic

Fig. 1: Typical radial concrete cracking around columns due to alternatives: either reduce the load on the slab at the

premature removal of shores and reshores critical concrete age, or change the concrete mixture. The

first alternative can be achieved by modifying the type of

Infinitely stiff shores relative to the supported slabs; shoring system or the number of shored/reshored floor

Uniformly distributed shore reactions; levels to reduce the applied construction load to an

Shores and reshores supported on a rigid foundation acceptable level. The second alternative can be achieved

at the beginning of construction; and by using high-early-strength concrete, controlling curing

Load distribution between the supporting slabs in temperatures, increasing the construction cycle to permit

proportion to their relative flexural stiffnesses. the concrete to gain strength, or a combination of these

Obviously, the assumptions of the simplified method measures. Under no circumstances, however, should the

are not precisely true. Several analytical studies by other factored construction load exceed the factored design load.

researchers, however, have verified the method’s validity Traditionally, field-cured cylinders have been used to

by comparing the predicted values with field measurements. determine early-age concrete compressive strength. The

Most of the available field observations were found to be testing of concrete cylinders, however, can become

in fair agreement with the predicted values. The most cumbersome (mainly due to the large number of cylinders

controversial assumption is the infinite stiffness of the required). Other, nondestructive methods for estimating

shoring/reshoring system, as compared with the flexural in-place concrete strength, such as rebound-hammer

stiffness of the supported slabs. ACI 347-043 warns that tests, penetration resistance, pulse-velocity measurements,

caution should be taken when a compressible system is pullout tests, or maturity methods, may be more desirable.

used. With a more compressible shoring/reshoring These methods require careful calibration based on

system, the structural system tends to shift as much as cylinder tests of the same concrete mixture to be used

15% of the slab loads to the uppermost interconnected on the project.

floors as compared with rigid shores/reshores.4-6 The At an early age, concrete is susceptible to tensile

floors immediately below the level to be cast may have cracking. A concrete failure due to deficiency in tensile

limited strength and are more sensitive to possible strength, and consequently low shear resistance, is the

overload. The estimated construction loads at the upper most serious type of slab failure, because most shear

floor may be increased to compensate for the error in failures are preceded by little, if any, advance warning.

calculating the construction loads when using the simplified Furthermore, tensile cracks caused by excessive

method. Alternatively, the relative stiffness between construction loading of early-age concrete can contribute

the shoring/reshoring system and the supported slabs to unanticipated nonrecoverable deflections.

should be considered while calculating the construction For flat-slab and flat-plate structures, one of the critical

load distribution. strength parameters during construction is usually

punching shear strength at columns. Also, punching

STRENGTH REQUIREMENTS shear forces due to loads from shores and reshores can

Although detailed calculations can be used to show a be critical in cases of very thin slabs, especially when

greater rate of strength gain, the flexural, tensile, shear, they are not aligned from one level to another, or at the

and bond strengths of early-age slabs can be conservatively bottom level of reshores. In such cases, an analysis

assumed to be proportional to the concrete compressive should be made to ensure that the maximum punching

strength at that age. Cracking and deflections are dependent shear force is within code limits. In most cases, however,

on the early-age concrete tensile strength and modulus of the shore/reshore axial strength will govern over the

34 FEBRUARY 2006 / Concrete international

punching shear strength of the slab. Beam shear may also to the shoring system, construction rate, concrete

control in a one-way slab when shore loads are placed strength development, and slab design loads. The

near a concrete beam. scenarios considered in the example include:

A shoring system with one level of shores and two or

SERVICEABILITY REQUIREMENTS three levels of reshores;

Excessive construction loads at an early age, in Construction cycles of 7, 10, or 15 days per floor;

combination with normal shrinkage and many other 40, 60, or 80 °F (4.4, 15.5, or 26.7 °C) concrete curing

factors, can cause higher creep deflection and more temperatures; and

extensive cracking than anticipated and adversely affect Service live loads of 50 and 100 lb/ft2 (2.4 and 4.8 kPa).

the long-term serviceability of the structure. Excessive

construction loads are usually the result of an inadequate Construction load distribution

number of shored/reshored levels, early stripping, The construction load distribution between the

or both. concrete slabs and the shoring/reshoring system is

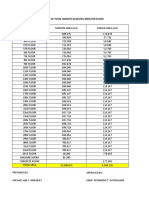

Early-age nonrecoverable deflections and cracking are evaluated using the simplified method. It is assumed that

primarily due to the initial low concrete strength. Early the compressibility of the shoring/reshoring system does

loading of concrete members having a low modulus of not significantly impact construction load redistribution.

elasticity and stiffness will cause larger nonrecoverable The resulting load distributions for construction of the

long-term deflections. A low modulus of elasticity produces fourth and fifth slab levels using the shoring system with

relatively large immediate deflections, and a low modulus one shore level in combination with three reshore levels

of rupture promotes cracking, which in turn reduces the are shown in Table 1. Load distributions for the steps

slab stiffness and also increases slab deflections. The leading up to the construction of these floors are provided

extent of initial concrete cracking depends on the in the guide.

magnitude of early-age shrinkage, the magnitude of Table 1 shows that the maximum slab load first occurs

construction loads, and the age of the concrete when the on the fourth slab level during placement of the fifth slab

loads are applied, which in turn affects the shoring and level (refer to Step 3). The fifth slab level is the first level to

reshoring schedule. Furthermore, long-term creep be placed after the reshores have been removed from the

deflections are increased because creep effects depend first floor, thus removing the direct path of the construction

on the magnitude of the stress resulting from the applied loads to the ground. The maximum slab load is repeated

loads relative to the concrete strength. Most of the early- for all floors above the fifth level each time the shoring

age creep deflections are not recoverable. Deflection due system is installed at the active level and the new slab is

to a combination of higher creep and premature cracking placed. The maximum slab construction load is1.38D

caused by excessive construction loads can be several (where D is the slab selfweight), or 155 lb/ft2 (7.42 kPa),

times the normal elastic, creep, and shrinkage deflection. for the system with three reshore levels. The maximum

The ACI 318-05 requirements for minimum slab thickness slab construction load would increase to 1.5D, or 169 lb/ft2

do not consider the effects of early-age construction (8.09 kPa), if only two reshore levels were used.

loads on long-term deflections; therefore, slab thickness The maximum shoring/reshoring construction load

can’t be used as a safeguard against excessive deflections occurs during the placement of the top floor level and

and cracking when large construction loads are improperly includes the slab selfweight of 112.5 lb/ft2 (5.39 kPa), the

applied to an early-age concrete slab. After the concrete form weight of 6.5 lb/ft2 (0.31 kPa), and the construction

members are cracked during construction, they will live load of 50 lb/ft2 (2.4 kPa) during the concrete place-

remain cracked throughout the life of the structure, ment. The maximum shore and reshore construction load

unless repairs are made. Therefore, coordination between is 1.5D, or 169 lb/ft2 (8.09 kPa), for both the three- and

the design engineer and the formwork engineer is recom- two-reshore systems.

mended for checking slab deflections during construction. The upper shoring level and all reshore levels carry

the same maximum construction load as long as the

TWO-WAY SLAB CONSTRUCTION EXAMPLE shoring/reshoring system is supported on the ground (refer

Two construction examples are presented in the to Step 1). After the removal of the lowest level of reshores

ACI 347.2R guide: one for a two-way flat plate building, from the ground, the maximum applied construction load

and one for a post-tensioned multistory building. The on the reshores decreases at the lower reshored levels.

reader is referred to the guide for details of the flat Therefore, the lower reshored levels will require fewer

plate construction example that are not included in the reshore posts than the upper floors.

following discussion. The floor slabs of this example have equal thickness

The flat plate construction example is designed based and approximately equal flexural stiffness. Thus, the

on ACI 318-05 and covers various scenarios with respect construction load is distributed equally between the

Concrete international / FEBRUARY 2006 35

TABLE 1:

LOAD DISTRIBUTION TO SLABS AND SHORES/RESHORES FOR CONSTRUCTION EXAMPLE USING ONE LEVEL OF SHORING AND

THREE LEVELS OF RESHORING

36 FEBRUARY 2006 / Concrete international

interconnected floor slabs. In cases where the floor slab

thickness and slab weight varies, the slab stiffness should

be considered when calculating the slab, shore, and

reshore construction loads.

Available early-age slab load capacity

The concrete slabs for this example have been

designed for a slab dead load of 112.5 lb/ft2 (5.39 kPa),

and a superimposed dead load of 20 lb/ft2 (0.96 kPa).

Live loads of 50 and 100 lb/ft2 (2.4 and 4.8 kPa) are

considered in the following discussion. If live load

reduction was taken by the engineer, the factored design

loads of the structure would need to be reduced

accordingly. Because the building design is based on Fig. 2: Concrete compressive strength development for various

curing temperatures

ACI 318-05, load factors of 1.2 for dead load and 1.6 for

live load are used. The resulting factored design loads The construction loads and maximum allowable slab

for the slab are 239 and 319 lb/ft2 (11.44 and 15.27 kPa) loads are summarized in Table 2. For a 7-day cycle with a

for the 50 and 100 lb/ft2 (2.4 and 4.8 kPa) live load 50 lb/ft2 (2.4 kPa) live load, two levels of reshoring will be

scenarios, respectively. The specified concrete strength adequate only if the slab is cured at 80 °F (26.7 °C). For

is 4000 psi (27.6 MPa). the 40 °F (4.4 °C) curing environment, the table shows

Based on the previous discussion, both the flexural that only the slab designed for a 100 lb/ft2 (4.8 kPa) live

and shear strengths of the young concrete slabs can load with a 15 day cycle is adequate when only two floors

be conservatively assumed to be proportional to the of reshores are used. This condition can be avoided by

compressive strength development. Figure 2 shows the changing the mixture proportions, increasing the ambient

ratio of early-age concrete compressive strength to curing temperatures, or by increasing the number of

the 28-day design compressive strength based on the reshore levels.

maturity method for the concrete mixture assumed for

this example. The ratios of 7-day strength to 28-day Slab deflections

strength are 0.49, 0.75, and 0.89 for the 40, 60, and 80 °F Though the slabs may have enough flexural strength

(4.4, 15.5, and 26.7 °C) curing environments, respectively. to carry the high construction loads, they may lack the

The concrete strengths given in Fig. 2 are valid only for concrete tensile strength and stiffness required to prevent

the concrete mixture used in this example and the extensive cracking and excessive deflections. Deflection

assumed curing conditions. The early-age slab strength is calculations for service load conditions should be based

obtained by multiplying these ratios by the factored on the least effective moment of inertia determined from

design loads calculated above. either the construction loads with partial concrete

strength or the service loads with full concrete strength.

Slab evaluation According to ACI 318-05, the contractor is required to

For the system with three levels of reshores, the produce structural calculation and concrete strength

maximum slab load during construction occurs on data used in planning shoring and reshoring operations.

Level 4 during placement of the fifth level slab. The total Such data and information should be furnished to the

construction service load on Level 4 is 1.38D or 155 lb/ft2 engineer who should evaluate the effects of construction

(7.44 kPa), consisting of a construction dead load, loads on immediate and long-term deflections. A team

Dc = 142.5 lb/ft2 (6.82 kPa), and a construction live load, effort between the contractor and the engineer is

Lc = 12.5 lb/ft2 (0.60 kPa), (1/4 of the 50 lb/ft2 [2.4 kPa]) required to avoid deflection problems associated with

construction live load shared by each level). Using the construction procedures.

same load factors as for the design loads, the factored

construction load is 191 lb/ft2 (9.15 kPa). SAFETY AND ECONOMY

Similarly, for the system with two levels of reshores, The ACI 347.2R Shoring/Reshorting Guide provides

the maximum slab load during construction occurs on practical guidance for developing safe and economic

Level 3 during placement of the fourth level slab. The construction schedules involving shoring/reshoring

total load is 1.5D or 169 lb/ft2 (8.09 kPa), consisting of operations. It can be used by contractors and engineers

Dc = 152 lb/ft2 (7.27 kPa) and Lc = 17 lb/ft2 (0.82 kPa), to plan shoring/reshoring schedules and make critical

(1/3 share at each level). The factored construction load decisions regarding formwork removal. Such decisions

is 210 lb/ft2 (10.05 kPa). affect both the safety and the economy of construction.

Concrete international / FEBRUARY 2006 37

TABLE 2:

CONSTRUCTION LOAD DISTRIBUTION AND SLAB CAPACITY SUMMARY

Ultimate slab load capacity Maximum factored slab

at selected temperatures, construction load,

Design live lb/ft2 (kPa) lb/ft2 (kPa)

Construction load, lb/ft2 40 °F 60 °F 80 °F Two reshore Three reshore

Cycle, days (kPa) (4.4 °C) (15.5 °C) (26.7 °C) levels levels

50 117 179 213 210 191

(2.4) (5.60) (8.57) (10.20) (10.5) (9.15)

7-day cycle

100 156 239 284 210 191

(4.8) (7.47) (11.44) (13.60) (10.5) (9.15)

50 146 206 237 210 191

(2.4) (6.99) (9.86) (11.35) (10.5) (9.15)

10-day cycle

100 195 274 316 210 191

(4.8) (9.34) (13.12) (15.13) (10.5) (9.15)

50 177 234 239 210 191

(2.4) (8.47) (11.20) (11.44) (10.5) (9.15)

15-day cycle

100 236 312 319 210 191

(4.8) (11.30) (14.94) (15.27) (10.5) (9.15)

It’s possible to economize in construction time and Institute of Standards and Technology, Washington, D.C., 1984, 53 pp.

formwork material, while still maintaining site safety and 5. Gross, J.L., and Lew, H.S., “Analysis of Shoring Loads and Slab

the performance of the structure. Capacity for Multistory Concrete Construction,” Proceedings of the

The avenue to reach higher levels of safety and Second International Conference on Forming Economical Concrete,

economy is through education, training, and knowledge SP-90, American Concrete Institute, Farmington Hills, MI, 1986,

dissemination. Recognizing this, ACI Committee 347 has pp. 109-130.

developed the Shoring/Reshoring Guide to bring together 6. Stivaros, P.C., and Halvorsen, G.T., “Shoring/Reshoring

the collective knowledge of contractors, manufacturers, Operations for Multistory Buildings,” ACI Structural Journal, V. 87,

designers, and academia. No. 5, Sept.-Oct. 1990, pp. 589-596.

7. SEI/ASCE 37-02, “Design Loads on Structures During Construction,”

Acknowledgments American Society of Civil Engineers, Reston, VA, 2002, 36 pp.

This article is based on the ACI 347.2R “Guide for Shoring/ 8. ACI Committee 318, “Building Code Requirements for Structural

Reshoring of Concrete Multistory Buildings” developed by ACI Concrete (ACI 318-05) and Commentary (318R-05),” American

Committee 347, Formwork for Concrete. We are very grateful to the Concrete Institute, Farmington Hills, MI, 2005, 430 pp.

committee members who shared their expertise during the

preparation of the Reshoring Guide, particularly D. W. Johnston, Selected for reader interest by the editors.

who chaired the committee during much of that time.

References

1. ACI Committee 347, “Guide for Shoring/Reshoring of Concrete

Multistory Buildings (ACI 347.2R-05),” American Concrete Institute, ACI member Pericles C. Stivaros is a

Farmington Hills, MI, 2005, 18 pp. principal with Feld, Kaminetzky & Cohen,

2. Grundy, P., and Kabaila, A., “Construction Loads on Slabs with P.C., Consulting Engineers, Roslyn Heights,

Shored Formwork in Multistory Buildings,” ACI JOURNAL, Proceedings V. NY. He is the Chair of ACI Committee 347,

60, No. 12, Dec. 1963, pp. 1729-1738. Formwork for Concrete, and is the principal

3. ACI Committee 347, “Guide to Formwork for Concrete (ACI 347-04),” author of the Reshoring Guide. He is a

American Concrete Institute, Farmington Hills, MI, 2004, 32 pp. member of ACI Committee 362, Parking

4. Gross, J.L., “Implementation of Compressible Shoring Analysis Structures, and the ACI TAC Tolerances

for Multistory Concrete Construction,” NBSIR 84-2964, National Coordinating Committee.

38 FEBRUARY 2006 / Concrete international

Вам также может понравиться

- Reshore Design For Concrete BuildingsДокумент7 страницReshore Design For Concrete BuildingsJason Toralde100% (1)

- Reshoring Aci 3472R - 05 PDFДокумент22 страницыReshoring Aci 3472R - 05 PDFEdwin Ramos Policarpio100% (1)

- Form Pressure Generated by Fresh ConcretДокумент15 страницForm Pressure Generated by Fresh ConcretDarren ThoonОценок пока нет

- Some Technical Aspects of Open Pit Mine Dewatering: Section2Документ11 страницSome Technical Aspects of Open Pit Mine Dewatering: Section2Thiago MarquesОценок пока нет

- Adapt PT SuppДокумент208 страницAdapt PT SuppLau Kim HwaОценок пока нет

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966От EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullРейтинг: 5 из 5 звезд5/5 (1)

- RCC Chairs Design ProcedureДокумент6 страницRCC Chairs Design ProcedureS N satyanarayanaОценок пока нет

- Mechanical vs. Lap SpliceДокумент4 страницыMechanical vs. Lap SpliceEricson M. GonzalesОценок пока нет

- C11Документ6 страницC11Fredy SierraОценок пока нет

- Case Studies of Some Concrete Structural FailuresДокумент96 страницCase Studies of Some Concrete Structural FailuresBandilung TzОценок пока нет

- ARTICLE - Well Drilling & Completion Design and BarriersДокумент34 страницыARTICLE - Well Drilling & Completion Design and BarriersNathan RamalhoОценок пока нет

- Lintel DesignДокумент7 страницLintel DesignDan AielloОценок пока нет

- EM 1110-2-2002 - Evaluation and Repair of Concrete Structures 1Документ185 страницEM 1110-2-2002 - Evaluation and Repair of Concrete Structures 1PDHLibraryОценок пока нет

- P-H Agua PDFДокумент1 страницаP-H Agua PDFSarah B. LopesОценок пока нет

- State-of-the-Art Report on Deformations from Deep ExcavationsДокумент166 страницState-of-the-Art Report on Deformations from Deep ExcavationsMelissa PallaresОценок пока нет

- Ultimate Load Capacity of Reinforced Concrete SlabДокумент8 страницUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- HOARDINGS – A guide to good practiceДокумент42 страницыHOARDINGS – A guide to good practiceshujah1106853Оценок пока нет

- Seiasce37 2Документ3 страницыSeiasce37 2Lê Ngọc-HàОценок пока нет

- ACI E-706 Spall Repair of Horizontal Concrete SurfacesДокумент6 страницACI E-706 Spall Repair of Horizontal Concrete SurfacesmirzaОценок пока нет

- Slab ToleranceДокумент1 страницаSlab TolerancejoanarchОценок пока нет

- Data Sheet Tolerance For Concrete SurfacesДокумент10 страницData Sheet Tolerance For Concrete SurfacesPedro RYОценок пока нет

- Anchorage Strength and Behavior of Headed BarsДокумент12 страницAnchorage Strength and Behavior of Headed BarsProfessor Dr. Nabeel Al-Bayati-Consultant EngineerОценок пока нет

- 2014 SGN 08Документ35 страниц2014 SGN 08Sajoyan HaqueОценок пока нет

- Temp Works 2Документ3 страницыTemp Works 2Vasileios Manginas100% (1)

- C ProgrammingДокумент205 страницC ProgrammingSrinivasan RamachandranОценок пока нет

- Concrete Pipe, Manhole Sections, or Tile: Standard Test Methods ForДокумент14 страницConcrete Pipe, Manhole Sections, or Tile: Standard Test Methods ForOmer Taj-eldinОценок пока нет

- Pour StripsДокумент2 страницыPour StripsChetan Tolia100% (1)

- Astm D420 - 18Документ8 страницAstm D420 - 18ArnoldОценок пока нет

- A Short Guide To Reusing FoundationsДокумент4 страницыA Short Guide To Reusing FoundationsMartillo SaavОценок пока нет

- Microscopes Open Up An Entire World That You Can't See With The Naked EyeДокумент4 страницыMicroscopes Open Up An Entire World That You Can't See With The Naked EyeLouie Jane EleccionОценок пока нет

- Design Two-Way Floor Slab Using Direct Design MethodДокумент47 страницDesign Two-Way Floor Slab Using Direct Design MethodMohammed SalemОценок пока нет

- twf2014.02 Client Guide 26 January 2015 Final PDFДокумент40 страницtwf2014.02 Client Guide 26 January 2015 Final PDFKovacs Zsolt-IstvanОценок пока нет

- Tensile TestДокумент23 страницыTensile TestHazirah Achik67% (3)

- How2 Deflections FINALДокумент8 страницHow2 Deflections FINALDiep TuОценок пока нет

- On Vertical Formwork: Concr Ete PressureДокумент7 страницOn Vertical Formwork: Concr Ete PressureatiОценок пока нет

- PRACTICAL ENGINEERING: LATERAL-FORCE COLLECTORSДокумент11 страницPRACTICAL ENGINEERING: LATERAL-FORCE COLLECTORSx620Оценок пока нет

- Racial Bias in Pulse Oximetry Measurement: CorrespondenceДокумент2 страницыRacial Bias in Pulse Oximetry Measurement: CorrespondenceYony Gutierrez100% (1)

- Wind Tunnel Testing Guide for Tall BuildingsДокумент7 страницWind Tunnel Testing Guide for Tall BuildingsSilver Olguín CamachoОценок пока нет

- Architectural Precast JointsДокумент28 страницArchitectural Precast JointsFalgun HindochaОценок пока нет

- Concrete Slump TestДокумент6 страницConcrete Slump TestHussein BeqaiОценок пока нет

- ACI 550.1R-01 Emulating Cast-In-Place Detailing in Precast Concrete StructuresДокумент16 страницACI 550.1R-01 Emulating Cast-In-Place Detailing in Precast Concrete StructuresnoijpОценок пока нет

- Temp Works Part 4Документ4 страницыTemp Works Part 4aliengineer953Оценок пока нет

- Early Striking and Improved Back Pro PingДокумент2 страницыEarly Striking and Improved Back Pro PinglawkkОценок пока нет

- Concrete Pressures - Formwork PDFДокумент4 страницыConcrete Pressures - Formwork PDFAleksiey PellicciaОценок пока нет

- DIN Standard On Formwork Pressures UpdatДокумент3 страницыDIN Standard On Formwork Pressures UpdatTùng HìОценок пока нет

- Predicting Axial Shortening of Vertical Elements in High Rise Buildings by Using Pca MethodДокумент8 страницPredicting Axial Shortening of Vertical Elements in High Rise Buildings by Using Pca MethodOscar Zúñiga CuevasОценок пока нет

- Series 1600 PDFДокумент49 страницSeries 1600 PDFDavidОценок пока нет

- Astm e 754Документ8 страницAstm e 754Mauricio RiquelmeОценок пока нет

- Concrete Pressure UsaДокумент12 страницConcrete Pressure UsaAmila KulasooriyaОценок пока нет

- Minimum design loads for hotel buildingДокумент3 страницыMinimum design loads for hotel buildingJoanne DawangОценок пока нет

- Steel Reinforcement Manufacturing Process & Quality StandardsДокумент1 страницаSteel Reinforcement Manufacturing Process & Quality StandardsJahid HasnainОценок пока нет

- Seismic Info KnaufДокумент20 страницSeismic Info KnaufVarga Zoran100% (1)

- Anchorage of Large-Diameter Reinforcing Bars Grouted into DuctsДокумент148 страницAnchorage of Large-Diameter Reinforcing Bars Grouted into DuctsAntonette Marie ElgarioОценок пока нет

- Flexible Vs RigidДокумент1 страницаFlexible Vs Rigidsilvereyes18Оценок пока нет

- Chapter 3 FormworkДокумент11 страницChapter 3 FormworkSue IlaОценок пока нет

- Checklist For Forensic Structural Engineering InspectionДокумент1 страницаChecklist For Forensic Structural Engineering InspectionAmanda SmithОценок пока нет

- Civil Engineering Concrete Formwork SpecificationДокумент18 страницCivil Engineering Concrete Formwork SpecificationRaj MaОценок пока нет

- Ac308 - 15 - Concrete Anchor Manufacturers AssociationДокумент127 страницAc308 - 15 - Concrete Anchor Manufacturers AssociationPaulo HenriqueОценок пока нет

- Piling GuideДокумент3 страницыPiling GuidesandycastleОценок пока нет

- A Five Story Precast Concrete Test Building For Seismic Conditions - Design DetailsДокумент8 страницA Five Story Precast Concrete Test Building For Seismic Conditions - Design Detailswrite2eddyОценок пока нет

- As 3600-2001 Amdt 1-2002 Concrete StructuresДокумент5 страницAs 3600-2001 Amdt 1-2002 Concrete StructuresmmОценок пока нет

- Behavior of Braced FramesДокумент12 страницBehavior of Braced FramesJaime MercadoОценок пока нет

- SplicesДокумент2 страницыSplicesAwais Safder Malik100% (1)

- Number Cement Length (M) Width (M) Height (M) Thickness Per Sq. M. Class Mixture40 Kg./BagДокумент3 страницыNumber Cement Length (M) Width (M) Height (M) Thickness Per Sq. M. Class Mixture40 Kg./Bagᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- Product Key - MS - Project - 2010 - ProfessionalДокумент1 страницаProduct Key - MS - Project - 2010 - Professionalᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- PMM Customs Brokerage & Freight Services: Copper Sulphate PentahydrateДокумент2 страницыPMM Customs Brokerage & Freight Services: Copper Sulphate Pentahydrateᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- Mec Logo: Request For Painting WorksДокумент2 страницыMec Logo: Request For Painting Worksᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- Book 1Документ2 страницыBook 1ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- August 26, 2011Документ4 страницыAugust 26, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- Slab Area Per FloorДокумент239 страницSlab Area Per Floorᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- Total floor area and smooth/rough breakdownДокумент4 страницыTotal floor area and smooth/rough breakdownᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔100% (1)

- August 24, 2011Документ4 страницыAugust 24, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- Structural dimensions multi-floor buildingДокумент24 страницыStructural dimensions multi-floor buildingᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- Slab Area Per FloorДокумент239 страницSlab Area Per Floorᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- PMM Customs Brokerage & Freight Services: Copper Sulphate PentahydrateДокумент2 страницыPMM Customs Brokerage & Freight Services: Copper Sulphate Pentahydrateᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- August 24, 2011Документ4 страницыAugust 24, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 3, 2011Документ4 страницыSeptember 3, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- August 30, 2011Документ4 страницыAugust 30, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 2, 2011Документ4 страницыSeptember 2, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 6, 2011Документ4 страницыSeptember 6, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- August 24, 2011Документ4 страницыAugust 24, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 3, 2011Документ4 страницыSeptember 3, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 6, 2011Документ4 страницыSeptember 6, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 3, 2011Документ4 страницыSeptember 3, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 1, 2011Документ4 страницыSeptember 1, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 3, 2011Документ4 страницыSeptember 3, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 5, 2011Документ4 страницыSeptember 5, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 3, 2011Документ4 страницыSeptember 3, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 2, 2011Документ4 страницыSeptember 2, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 2, 2011Документ4 страницыSeptember 2, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 3, 2011Документ4 страницыSeptember 3, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- T-1 ScheduleДокумент2 страницыT-1 Scheduleᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- September 7, 2011Документ4 страницыSeptember 7, 2011ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Оценок пока нет

- Regional Office X: Republic of The PhilippinesДокумент2 страницыRegional Office X: Republic of The PhilippinesCoreine Imee ValledorОценок пока нет

- Reg OPSДокумент26 страницReg OPSAlexandru RusuОценок пока нет

- ReadingДокумент6 страницReadingakhyar sanchiaОценок пока нет

- Calculate Capacity of Room Air Conditioner: Room Detail Unit Electrical Appliances in The RoomДокумент2 страницыCalculate Capacity of Room Air Conditioner: Room Detail Unit Electrical Appliances in The Roomzmei23Оценок пока нет

- Mod. 34 Classic Compact T06Документ4 страницыMod. 34 Classic Compact T06Jaime Li AliОценок пока нет

- Arts and Culture An Introduction To The Humanities Combined Volume 4th Edition Benton Test Bank Full Chapter PDFДокумент22 страницыArts and Culture An Introduction To The Humanities Combined Volume 4th Edition Benton Test Bank Full Chapter PDFoutscoutumbellar.2e8na100% (15)

- Chapter 63 Standard Integration: EXERCISE 256 Page 707Документ9 страницChapter 63 Standard Integration: EXERCISE 256 Page 707Khaerul UmamОценок пока нет

- Teaching and Learning in the Multigrade ClassroomДокумент18 страницTeaching and Learning in the Multigrade ClassroomMasitah Binti TaibОценок пока нет

- EMB 690-1 SM Course Outline Spring 21Документ8 страницEMB 690-1 SM Course Outline Spring 21HasanОценок пока нет

- Arsh Final Project ReportДокумент65 страницArsh Final Project Report720 Manvir SinghОценок пока нет

- Import Sample 2Документ63 страницыImport Sample 2akkyОценок пока нет

- 09 Bloom Gardner Matrix Example 2009Документ2 страницы09 Bloom Gardner Matrix Example 2009Ellen Jaye BensonОценок пока нет

- De Thi Thu Tuyen Sinh Lop 10 Mon Anh Ha Noi Nam 2022 So 2Документ6 страницDe Thi Thu Tuyen Sinh Lop 10 Mon Anh Ha Noi Nam 2022 So 2Ngọc LinhОценок пока нет

- The Standard 09.05.2014Документ96 страницThe Standard 09.05.2014Zachary Monroe100% (1)

- Coca Cola Live-ProjectДокумент20 страницCoca Cola Live-ProjectKanchan SharmaОценок пока нет

- Phenolic Compounds in Rice May Reduce Health RisksДокумент7 страницPhenolic Compounds in Rice May Reduce Health RisksMuhammad Usman AkramОценок пока нет

- Electronic Throttle ControlДокумент67 страницElectronic Throttle Controlmkisa70100% (1)

- Cases 39 45 PDFДокумент11 страницCases 39 45 PDFYvette Marie VillaverОценок пока нет

- Adjective: the girl is beautifulДокумент15 страницAdjective: the girl is beautifulIn'am TraboulsiОценок пока нет

- On-Chip ESD Protection Design For IcsДокумент14 страницOn-Chip ESD Protection Design For IcsMK BricksОценок пока нет

- Going to the cinema listening practiceДокумент2 страницыGoing to the cinema listening practiceMichael DÍligo Libre100% (1)

- Physics Force and BuoyancyДокумент28 страницPhysics Force and BuoyancySohan PattanayakОценок пока нет

- A Final Project For The Course Title "Monetary Policy and Central Banking"Документ11 страницA Final Project For The Course Title "Monetary Policy and Central Banking"Elle SanchezОценок пока нет