Академический Документы

Профессиональный Документы

Культура Документы

Scheduled Oil Sampling Report: Customer Information Unit Information

Загружено:

Muhammad AriefИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Scheduled Oil Sampling Report: Customer Information Unit Information

Загружено:

Muhammad AriefАвторское право:

Доступные форматы

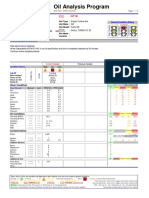

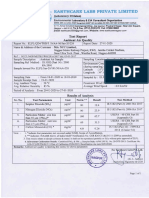

Laboratorium S.O.S PT.

Trakindo Utama

Scheduled Oil Sampling Report

JI. Cilandak KKO Raya No. 1, Jakarata 12560

PO Box 2282/JKT - Indonesia Telp No. (62-21) 7822373

Fax. (62-21) 7822357, 7822379

Customer Information Unit Information

PENTA PRIMA SEJATI PT. Category Oil Equip Make Hino Received Date: 12/30/2016 3:00:00PM

ATTN: Penta Prima Sejati / novi (N) Lab No A17A020918 Equip Model FL235TI Reported Date: 1/3/2017 1:11:21PM

Indonesia Unit Number B9096TEU Location PUNINAR Sample Note

Equip Serial B9096TEU Jobsite 10 - JAKARTA Evaluation Code A No Action is Required.

Compartment Engine Job No

Sample Point Interpreted by: Trakindo HO EMS / Misbakhul Umam (A)

Label No 10

Phone

Element Reading (mg/kg = ppm) - ASTM D-5185

Lab No. Sample Date Eval CMU SMU HOO Oil Added Fluid Filter Oil Type Oil Grade

Wear Metal Contaminant Additives

Date Process Chg Chg

Cr Pb Fe Cu Al Sn * Ni * B* K* Na Si Ca * P* Zn Mg Mo

A17A020918 30/Dec/16 30/Dec/16 A 546236 0 0 SHELL : 0 0 23 2 5 0 0 282 1 0 15 3197 878 1007 8 39

RIMULA R4 X

Element Reading (mg/kg = ppm) Oil Condition (JOAP) ASTM E2412 Physical / Chemical Test Particle Count (Counts / ml) - ASTM D 4464

Lab No Ba * Ti * Ag * V* ST OXI NIT SUL FP (P/N) DF (%) * V100 V40 VI * TBN TAN * W (P/N) * W(%) PQ * Visual * PC 04 * PC 06 PC 14 ISO 04* ISO 06 ISO 14

(cSt) * (cSt) * (idx)

A17A020918 26 14 6 23 N 13.0 8.3 N 5.0 -

Lab No. Tendency (5' Tendency (5' Tendency (5' Stability (10' Stability (10' Stability (10' Milipore Sludge

aeration) Seq 1 * aeration) Seq 2 * aeration) Seq 3 * aeration) Seq 1 * aeration) Seq 2 * aeration) Seq 3 * Test *

A17A020918

Recommendation ** Rekomendasi **

ALL TEST RESULTS APPEAR ACCEPTABLE. TAKE OIL SAMPLES AT 250 HOUR INTERVALS TO MONITOR CONDITION. Sample SEMUA HASIL TES DALAM BATAS NORMAL. AMBIL SAMPEL OLI PADA INTERVAL 250 JAM UNTUK MEMONITOR KONDISI.

Notes:

This analysis provided is indicative of conditions based upon sample information received and the quality of sample supplied. Any decision relating to repair of components is entirely at the descretion of the customer.

A17A020918 Page 1 of 2

* Not Include on scope of Accreditation

** The evaluation / Recommendation made by Equipment Management PT. Trakindo Utama

Glossaries

Elements P=Phosphorus (LoD=0.74) Water Criteria ISO6=ISO Code 6 V100=Viscosity 100°C (WIN.MP.05)

Si-Silicon (LoD=0.26) B=Boron (LoD=0.40) W=Water - ASTM D 4928 / ASTM D 4377 ISO14=ISO Code 14 V40=Viscosity 40°C - ASTM D445

AI=Aluminum (LoD=0.12) Mo=Molybdenum (LoD=0.20) % =Percentage Oil Condition cSt=Centistokes

Cr=Chromium (LoD=0.12) Zn=Zinc (LoD=0.17) N=Negative ST=Soot DF(%) - ASTM D 3524

Fe=Iron (LoD=0.11) Ti=Titanium P=Positive (0.5 - 0.8%) OXI=Oxidation Visual

Pb=Lead (LoD=0.82) V=Vanadium T=Trace (Cloudy but < 0.5%) NIT=Nitration LQ = Low Quantity

Cu=Copper (LoD=0.01) Ag=Silver E=Excessive (> 0.8%) SUL=Sulfation MQ = Medium Quantity

Sn=Tin (LoD=0.25) Note: Results = 0 < LoD (Limit of Detection) Particle Count Physical / Chemical HQ = High Quantity

Ni=Nickel (LoD=0.38) ppm=Parts Per Million (ASTM D 4464 & ASTM D 7596) PQ=Particle Quantifier (Idx=Index) Met = Metallic

Mg=Magnesium (LoD=0.01) FP Criteria PC04=Particle Count at 4 micron TBN=Total Base Number - ASTM D 4739 Non Met = Non Metallic

Ca=Calcium (LoD=0.05) FP=Flash Point (ASTM D 3828 - Method A) PC06=Particle Count at 6 micron (mg KOH /g) F = Fine

K=Potassium (LoD=0.64) P=Positive PC14=Particle Count at 14 micron TAN=Total Acid Number - ASTM D 664 C = Coarse

Na=Sodium (LoD=0.42) N=Negative ISO4=ISO Code 4 (mg KOH /g) Granul = Granular

General Analysis Guide ***

Primary Element Secondary Element Potential Wear Problem area & causes Primary Element Secondary Element Potential Wear Problem area & causes

Si Al Piston, Rings, Liner Air induction, breathers, dirt. Cr Mo Piston ring Blow by, oil consumption

Liner, piston, valve, Dirt, abnormal temperature, lack of lubricant, Na Si, B Cooling system Water Pump, Cyl Head, Liner seal, Oil Cooler,

Fe - Anti Freeze

gear train, crankshaft storage (rust)

Al Cr Piston & Rings Blow-by

Pb, Sn Cu, Al Bearing Dirt contamination, lack of lubricant.

Fe Cr Piston ring Abnormal operating temperature

Al or Cu Sn, Pb Bearing Low or fluctuating oil pressure. Fe Al Liner Restricted air induction system

*** THIS CHARTS ARE FOR GENERAL USE ONLY, AND DO NOT INDICATE DEFINITE LIMITS OF WEAR METALS FOR ANY SPECIFIC MAKE OR MODEL.

TABEL INI HANYA DIGUNAKAN UNTUK ANALISIS SECARA UMUM DAN TIDAK MENGINDIKASIKAN SUATU BATASAN UNTUK MODEL DAN MEREK TERTENTU

KINDLY ADVISED YOU TO CONTACT US PRIOR 7 DAYS AFTER REPORT RELEASE SHOULD YOU NEED FURTHER DISCUSSION ABOUT THIS SAMPLE.

DISARANKAN AGAR DISKUSI LEBIH LANJUT MENGENAI SAMPLE INI HARUS DILAKUKAN SEBELUM 7 HARI DARI TANGGAL LAPORAN DI TERBITKAN

Wear Metal Contaminant Oil Condition Viscosity

24 28 24 14

24 12

20 20

20 10

16 16

Al 16 K 8

NIT

Cr Na OXI V100

12 Fe Si 12

SUL

Pb 12 ST TBN 6

PQ

8 8

8 4

4 4 4 2

0 0 0 0

12/30/2016 12/30/2016 12/30/2016 12/30/2016 Approved by

Mukhlisin

Manager S•O•S Laboratory

A17A020918 Page 2 of 2

Вам также может понравиться

- Workshop Manual Automatic Transmission 30 40leДокумент2 страницыWorkshop Manual Automatic Transmission 30 40leDony TedyantoОценок пока нет

- EPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Документ20 страницEPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Ion IonutОценок пока нет

- Is 7098 P-1 (1988) PDFДокумент21 страницаIs 7098 P-1 (1988) PDFAmar PatwalОценок пока нет

- 02whole PDFДокумент313 страниц02whole PDFAme Ra100% (1)

- Oil Analysis Report: Test DetailsДокумент1 страницаOil Analysis Report: Test DetailsdnoaisapsОценок пока нет

- Learn PowerShell Core 6.0Документ800 страницLearn PowerShell Core 6.0Felippe Coelho100% (2)

- Scheduled Oil Sampling Report: Customer Information Unit InformationДокумент2 страницыScheduled Oil Sampling Report: Customer Information Unit InformationKorneliusОценок пока нет

- SOS Sampling ReportДокумент2 страницыSOS Sampling ReportAsaisan AsaisanОценок пока нет

- Sos Sampling ReportДокумент2 страницыSos Sampling Reportomar solimanОценок пока нет

- A20J120618 Valuable Customer 0Документ2 страницыA20J120618 Valuable Customer 0Chandra Hermanto SinagaОценок пока нет

- Scheduled Oil Sampling Report: Customer Information Unit InformationДокумент2 страницыScheduled Oil Sampling Report: Customer Information Unit InformationDharmaNugrahaОценок пока нет

- B14B052339 - Hanurata Ahmad Zarkasi (A) - 0Документ1 страницаB14B052339 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiОценок пока нет

- Scheduled Oil Sampling Report: Customer Information Unit InformationДокумент2 страницыScheduled Oil Sampling Report: Customer Information Unit InformationARI WIJAYANTOОценок пока нет

- Scheduled Oil Sampling Report: Customer Information Unit InformationДокумент2 страницыScheduled Oil Sampling Report: Customer Information Unit InformationHeri KiswantoОценок пока нет

- PT Petrolab Services: Grease Analysis ReportДокумент1 страницаPT Petrolab Services: Grease Analysis Reportvictor josuaОценок пока нет

- Pdf24 MergedДокумент9 страницPdf24 MergedauliaadyaksaОценок пока нет

- 01 EngineCheckReport802Документ5 страниц01 EngineCheckReport802phutthawongdanchai041215Оценок пока нет

- Sterntube - Man. AstaДокумент1 страницаSterntube - Man. AstacahyoОценок пока нет

- B14A243506 - Hanurata Ahmad Zarkasi (A) - 0Документ1 страницаB14A243506 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiОценок пока нет

- BED - IPAL Cap 50 CMPD - PT Balikpapan Enviromental ServicesДокумент3 страницыBED - IPAL Cap 50 CMPD - PT Balikpapan Enviromental ServicesSalman RatoОценок пока нет

- DT 41Документ1 страницаDT 41Ridha IkhsanОценок пока нет

- Oil Analysis Report: PT Petrolab ServicesДокумент1 страницаOil Analysis Report: PT Petrolab ServicesJon HermanОценок пока нет

- Oil Analysis Program: Subrptpage1 - 7captionДокумент6 страницOil Analysis Program: Subrptpage1 - 7captionChristian CoboОценок пока нет

- Noise Report Jan-20Документ4 страницыNoise Report Jan-20rohith eticalaОценок пока нет

- OJ10639 UO 23 QRДокумент1 страницаOJ10639 UO 23 QRSubastianОценок пока нет

- DTHW 005Документ1 страницаDTHW 005Angga 99Оценок пока нет

- Fastners MTCДокумент18 страницFastners MTCmaheshmalaichamy007Оценок пока нет

- OJ10641 UO 23 QRДокумент1 страницаOJ10641 UO 23 QRSubastianОценок пока нет

- 7test Report of Petroleum Coke Dated 13.07.2020Документ1 страница7test Report of Petroleum Coke Dated 13.07.2020Abhinav BansalОценок пока нет

- Oil Analysis Report: PT Petrolab ServicesДокумент1 страницаOil Analysis Report: PT Petrolab ServicesJon HermanОценок пока нет

- Battery 17 AhДокумент1 страницаBattery 17 AhBroh UtunОценок пока нет

- Mycom #1Документ1 страницаMycom #1Rifky Windya NОценок пока нет

- HGR3098 Engine 23augДокумент1 страницаHGR3098 Engine 23augIndo BemlОценок пока нет

- Oil Analysis Report: PT Petrolab ServicesДокумент1 страницаOil Analysis Report: PT Petrolab ServicesJon HermanОценок пока нет

- 6:: Ff-Hna$Ufa (Ra:::: TLW - Psbol .Co"Id LnilДокумент1 страница6:: Ff-Hna$Ufa (Ra:::: TLW - Psbol .Co"Id Lnilkingpin182Оценок пока нет

- HGR3100 Engine 23augДокумент1 страницаHGR3100 Engine 23augIndo BemlОценок пока нет

- Motor Gasoline Specifications and Trend in IndiaДокумент2 страницыMotor Gasoline Specifications and Trend in IndiavivekagОценок пока нет

- Adt-03 Engine 3112 Ob1922568Документ1 страницаAdt-03 Engine 3112 Ob1922568abdul rahmatОценок пока нет

- Adt-03 Engine 1001 Ob2000450Документ1 страницаAdt-03 Engine 1001 Ob2000450abdul rahmatОценок пока нет

- CCR JN 5646488-Sis-C9 Engine en Mbd09063-High BlowbyДокумент15 страницCCR JN 5646488-Sis-C9 Engine en Mbd09063-High Blowbyahmat ramadaniОценок пока нет

- IMIR - 067 - G1 For - CS - Seamless - Pipe - 300 - NB - Pipe - For - Group - IДокумент1 страницаIMIR - 067 - G1 For - CS - Seamless - Pipe - 300 - NB - Pipe - For - Group - IFredin FrancisОценок пока нет

- VR1241 - 8116610659 - Rev. 00 D-25.04.2023Документ9 страницVR1241 - 8116610659 - Rev. 00 D-25.04.2023Agni DuttaОценок пока нет

- Oil Analysis Report: PT Petrolab ServicesДокумент1 страницаOil Analysis Report: PT Petrolab ServicesJon HermanОценок пока нет

- PT Atlas Petrochem Indo (Indoseiki)Документ3 страницыPT Atlas Petrochem Indo (Indoseiki)QA LAB ISMОценок пока нет

- DT 118Документ1 страницаDT 118Ridha IkhsanОценок пока нет

- OJ10642 UO 23 QRДокумент1 страницаOJ10642 UO 23 QRSubastianОценок пока нет

- Indian Oil Corporation Limited: ASTM/IP/IS1448)Документ3 страницыIndian Oil Corporation Limited: ASTM/IP/IS1448)Arvind DhakaОценок пока нет

- Sahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportДокумент3 страницыSahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportPrakash kumarTripathiОценок пока нет

- OJ10640 UO 23 QRДокумент1 страницаOJ10640 UO 23 QRSubastianОценок пока нет

- Coa GlobalДокумент3 страницыCoa Globalnur wahyu dewi kusriniОценок пока нет

- 2 Turbin 0511 Ob2123174Документ1 страница2 Turbin 0511 Ob2123174BennyОценок пока нет

- Scheduled Oil Sampling Report: Eval CodeДокумент1 страницаScheduled Oil Sampling Report: Eval CodePutra JawaОценок пока нет

- PT Centa Brasindo Abadi-Aircol MR 46Документ2 страницыPT Centa Brasindo Abadi-Aircol MR 46azmiazfarОценок пока нет

- KLJ Hdpe BK 9606 Arat AratДокумент1 страницаKLJ Hdpe BK 9606 Arat AratDinesh SinghОценок пока нет

- OJ10643 UO 23 QRДокумент1 страницаOJ10643 UO 23 QRSubastianОценок пока нет

- Unit ID: WP D P1801 A De: 25040: .: Unit Type: Unit Make: Unit Model:: Site: Location: Name CodeДокумент1 страницаUnit ID: WP D P1801 A De: 25040: .: Unit Type: Unit Make: Unit Model:: Site: Location: Name CodeFraz AhmadОценок пока нет

- Sky Mqap1Документ1 страницаSky Mqap1Kumara SubramanianОценок пока нет

- Supreme Roa02Документ1 страницаSupreme Roa02MUDI SOBARHADIОценок пока нет

- BTG 11.12.22-11.18.22 T-1 PDFДокумент1 страницаBTG 11.12.22-11.18.22 T-1 PDFKimberly DayoОценок пока нет

- A545-101-PA-MR-5001-1072-5099-FOA - 905139-LS - 02 - LUBRICATION SCHEDULE - Multiple TagsДокумент3 страницыA545-101-PA-MR-5001-1072-5099-FOA - 905139-LS - 02 - LUBRICATION SCHEDULE - Multiple Tagsmahesh.easwaran3609Оценок пока нет

- Pt. Tekenomiks Indonesia: Fuel Analysis ReportДокумент1 страницаPt. Tekenomiks Indonesia: Fuel Analysis Reportfirman manaluОценок пока нет

- Process Specification For: Middle East Kimiaye Pars Company 5,000 MTPD Methanol Plant Bandar Assaluyeh, IranДокумент6 страницProcess Specification For: Middle East Kimiaye Pars Company 5,000 MTPD Methanol Plant Bandar Assaluyeh, IranHammad LalaОценок пока нет

- Qap 900000236 R0Документ4 страницыQap 900000236 R0meet bhavsarОценок пока нет

- Decrypt SSL and SSH TrafficДокумент5 страницDecrypt SSL and SSH TrafficMinh Luan PhamОценок пока нет

- Introduction To Turbomachinery Final Exam 1SY 2016-2017Документ1 страницаIntroduction To Turbomachinery Final Exam 1SY 2016-2017Paul RodgersОценок пока нет

- Artemis Data SheetДокумент2 страницыArtemis Data SheetmahmoudОценок пока нет

- 010 Frank Sealing Systems 700BR01Документ28 страниц010 Frank Sealing Systems 700BR01Handy Han QuanОценок пока нет

- Reporte ReservasДокумент184 страницыReporte Reservasjair coronadoОценок пока нет

- Commissioning Template RevДокумент17 страницCommissioning Template Revelif maghfirohОценок пока нет

- Amces 2020Документ1 страницаAmces 2020Karthik GootyОценок пока нет

- Brochure Otis Gen360 enДокумент32 страницыBrochure Otis Gen360 enshimanshkОценок пока нет

- Vaas Head Office DetailsДокумент8 страницVaas Head Office DetailsDanielle JohnsonОценок пока нет

- S5 ManualДокумент39 страницS5 ManualAleena ShajuОценок пока нет

- Proposal For Voice AppДокумент3 страницыProposal For Voice Appavneet1993Оценок пока нет

- Anothr System Definition FacilityДокумент90 страницAnothr System Definition FacilityllllllluisОценок пока нет

- CH 01Документ28 страницCH 01Deepu MaroliОценок пока нет

- Summer SLS 1103 SyllabusДокумент22 страницыSummer SLS 1103 SyllabusJay100% (1)

- I Know Many BeginnersДокумент5 страницI Know Many BeginnersOsmar Tavares JuОценок пока нет

- O I - LT3 - HP3 - User - 02Документ14 страницO I - LT3 - HP3 - User - 02Francisco AvilaОценок пока нет

- NS2 Simple Simulation ExampleДокумент5 страницNS2 Simple Simulation ExamplepradeepОценок пока нет

- Checklist of E/OHS Activities For Asbestos Management: Name of Publication DateДокумент20 страницChecklist of E/OHS Activities For Asbestos Management: Name of Publication DateidahssОценок пока нет

- A Photovoltaic Panel Model in Matlab - FinalДокумент7 страницA Photovoltaic Panel Model in Matlab - FinalLeela KrishnaОценок пока нет

- Wilf Book FlyerДокумент4 страницыWilf Book FlyerEduardo Manuel Chávarry VelaОценок пока нет

- Summary Key ParameterДокумент18 страницSummary Key ParameterAndry JatmikoОценок пока нет

- Shot PeeningДокумент5 страницShot Peeningcaddcentre velacheryОценок пока нет

- Sunil Bhatia ResumeДокумент5 страницSunil Bhatia Resumepravin gamareОценок пока нет

- JournalДокумент13 страницJournalAnonymous 1uwOEpe5w8Оценок пока нет

- Water Cooled Flooded Vertical Screw ChillersДокумент96 страницWater Cooled Flooded Vertical Screw ChillersaftabОценок пока нет