Академический Документы

Профессиональный Документы

Культура Документы

Hyflux Kristal Membranes PDF

Загружено:

PRABHU MAXОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hyflux Kristal Membranes PDF

Загружено:

PRABHU MAXАвторское право:

Доступные форматы

Filtration | Separation | Purification

Hyflux KRISTAL K600

™

Polyethersulfone Hollow Fiber Membranes

The KRISTAL K600 hollow fiber ultrafiltration (UF) membranes are

constructed of specially formulated hydrophilic polyethersulfone

materials to provide outstanding flux rates with consistent and reliable

filtration. The KRISTAL K600 membrane is manufactured using a

proprietary process to produce a unique asymmetrical pore structure to

provide enhanced filtration and withstand backwashing for prolonged

service life. Each module is integrity tested at the factory to ensure

filtration performance at system start-up.

High Flux Rate and Consistent, Reliable Filtration

With KRISTAL K600, you’ll benefit from a robust membrane that

delivers better permeate quality, higher permeate flux and throughput,

and greater system recovery. The low pressure membrane operates with

minimal attention, yet meets the strictest permeate quality requirements.

Its simple, compact module design offers more membrane area per unit

volume in a smaller footprint to lower your capital and installation costs.

Global Experience

KRISTAL K600 membranes are ideal for a wide range of applications

including municipal water and wastewater, RO pretreatment and

industrial wastewater. With numerous successful installations worldwide,

you can count on KRISTAL K600 membranes to provide cost-effective

solutions for your ultrafiltration needs.

Seletar NEWater plant in Singapore – 24,000 m3/day Applications

wastewater treatment of secondary effluent

RO Pretreatment Filtration

• Seawater desalination pretreatment

• RO and NF pretreatment for UPW streams

Industrial Wastewater

• Recycle industrial process wastewater

• Zero discharge of process waste streams

Municipal Water & Wastewater

• Removal of turbidity, bacteria, viruses and cysts

• Reduction of iron, manganese, organics and color

• Reclamation of wastewater

Water Purification

• Mobile water purification systems

Jurong Industrial Water – 2,000 m3/day reuse for

high grade industrial and DI water

KRISTAL K600 Polyethersulfone Hollow Fiber Membranes

FEATURES BENEFITS

Polyethersulfone Ultrafiltration Membrane Provides high flux, high permeate quality, excellent

chemical compatibility and reliability

Circular Hollow Fiber Geometry Greater filtration surface area improves flux rate

and reduces membrane cleaning time

High Membrane Packing Density Increases membrane area per unit volume for smaller

footprint to reduce capital and installation costs

Low Operating Pressures Reduces life cycle costs

Effective Backwashing and Maintains optimal operating performance and

Air-Scour Cleaning provides effective system recovery

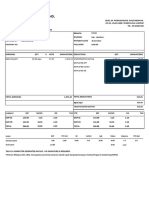

Module Specifications

PRODUCT SPECIFICATIONS

Membrane Chemistry Proprietary Polyethersulfone

Flow Path Outside to Inside

Nominal MWCO 60,000 Dalton

Membrane Surface Area 753 ft2 (70 m2)

Fiber Dimensions, OD/ ID/ Wall Thickness 0.045" (1.15mm) / 0.024" (0.6mm) / 0.011" (0.27mm)

Module Nominal Dimensions, Diameter x Length 8.5" (216mm) x 84" (2130mm)

Housing Construction PVC

Feed and Permeate / Reject Connections 1.5" NPT Female / 1.0" NPT Female

Shipping Weight 121 lbs (55 kg)

PERFORMANCE

Initial Clean Water Flow Rate 39.5 gpm (9 m3/h) ±10% @14.5 psi (1 bar), 77°F (25°C)

Typical Process Feed Flow Rate 26 – 35 gpm (6 – 8 m3/h)

Typical Permeate Flow Rate 18 – 31 gpm (4 – 7 m3/h)

Typical E. Coli Reduction 5 – 6 log

Typical Filtrate Turbidity ≤ 0.1 NTU

Typical Filtrate SDI <3

Typical TOC Reduction 15 – 20%

OPERATING PARAMETERS

Maximum Operating Temperature 104°F (40°C)

pH Range – Operating 2 – 11

pH Range – Cleaning 2 – 12

Maximum Feed Pressure 37 psig (2.5 bar)

Transmembrane Pressure (TMP) 3 – 29 psi (0.2 – 2 bar)

KRISTAL membranes are manufactured under an ISO 9001:2000 certified Quality Management System.

For more information

Graver Technologies Customer Service: 1-800-249-1990

E-mail us at info@gravertech.com

KRISTAL ™ is a trademark of Hyflux LTD.

Graver Technologies, LLC. is licensed as the exclusive supplier of Hyflux products for North America.

200 Lake Drive 302- 731-1700

Glasgow, DE 19702 800- 249-1990 e-mail: info@gravertech.com

U.S.A. Fax 302-731-1707 web site: www.gravertech.com

A member of The Marmon Group of companies GTX- 312 7- 08

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Case 5Документ8 страницCase 5Thuy Tien NguyenОценок пока нет

- Management System Certificate: Thyssenkrupp Bilstein S.AДокумент2 страницыManagement System Certificate: Thyssenkrupp Bilstein S.AsmokefieldОценок пока нет

- Assessing Industrial Energy Transition in Pakistan's Textile SectorДокумент37 страницAssessing Industrial Energy Transition in Pakistan's Textile SectorKamran AhmedОценок пока нет

- Nuñez, Cobacha & Rubio Law Offices: To: Mr. Dennis A. Bautista THRU: Its Representative Annabel BautistaДокумент2 страницыNuñez, Cobacha & Rubio Law Offices: To: Mr. Dennis A. Bautista THRU: Its Representative Annabel BautistancrlawofficesОценок пока нет

- PT Sponsorship LetterДокумент7 страницPT Sponsorship LetterRoselyn AcbangОценок пока нет

- Disney Case StudyДокумент3 страницыDisney Case StudyRuslan AdibОценок пока нет

- Memorandum of AgreementДокумент23 страницыMemorandum of AgreementCza VerwinОценок пока нет

- Expanding Hor Izons: Annual ReportДокумент79 страницExpanding Hor Izons: Annual ReportMohammed AbdelrahmanОценок пока нет

- Jarantilla v. Jarantilla, GR No. 154486, December 1, 2010Документ3 страницыJarantilla v. Jarantilla, GR No. 154486, December 1, 2010Aphrobit CloОценок пока нет

- The Influence of Talent Management and Work Life Balance On Employee Performance With Employee Engagement As Intervening MediaДокумент6 страницThe Influence of Talent Management and Work Life Balance On Employee Performance With Employee Engagement As Intervening MediaInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Airtel Broadband PresentationДокумент25 страницAirtel Broadband Presentationranga_83100% (2)

- Email Address ListsДокумент5 страницEmail Address ListsgebbiepressОценок пока нет

- ABM MODULE D OliveboardДокумент114 страницABM MODULE D OliveboardASHUTOSHОценок пока нет

- Cir V. Lancaster G.R. NO. 183408 JULY 12, 2017 FactsДокумент3 страницыCir V. Lancaster G.R. NO. 183408 JULY 12, 2017 FactsVian O.Оценок пока нет

- My Payslip - A4Документ1 страницаMy Payslip - A4Pie AlarifОценок пока нет

- Acknowledgment ReceiptДокумент2 страницыAcknowledgment ReceiptTish BahjinОценок пока нет

- SAP S/4HANA Finance For Group Reporting 2021 Feature DeckДокумент61 страницаSAP S/4HANA Finance For Group Reporting 2021 Feature DeckSri DeviОценок пока нет

- Swisstek (Ceylon) PLC Swisstek (Ceylon) PLCДокумент7 страницSwisstek (Ceylon) PLC Swisstek (Ceylon) PLCkasun witharanaОценок пока нет

- Testing Business IdeasДокумент7 страницTesting Business IdeasmanuelaОценок пока нет

- Download ebook Essentials Of Investments 12E Ise Pdf full chapter pdfДокумент67 страницDownload ebook Essentials Of Investments 12E Ise Pdf full chapter pdfjanet.cochran431100% (20)

- Lithium Battery Development Manager in Allentown PA Resume Larry SchappellДокумент2 страницыLithium Battery Development Manager in Allentown PA Resume Larry SchappellLarrySchappellОценок пока нет

- Fixed Deposit / Recurring Deposit Payin Slip (FD/RD)Документ2 страницыFixed Deposit / Recurring Deposit Payin Slip (FD/RD)Manoj MudunuriОценок пока нет

- Auditing Gray 2015 Chapter 7 Systems Work Basic Ideas 1Документ37 страницAuditing Gray 2015 Chapter 7 Systems Work Basic Ideas 1Mario GiovanniОценок пока нет

- E-Auctions - MSTC Limited-SiliguriДокумент6 страницE-Auctions - MSTC Limited-SiligurimannakauОценок пока нет

- MAHUSAYLAW211 REFLECTIVE ESSAY - Module 3Документ3 страницыMAHUSAYLAW211 REFLECTIVE ESSAY - Module 3Jeth MahusayОценок пока нет

- Smart Bangladesh ICT Master Plan 2041 Draft PDF 1Документ172 страницыSmart Bangladesh ICT Master Plan 2041 Draft PDF 1riponcseОценок пока нет

- Customer Onboarding TemplateДокумент6 страницCustomer Onboarding TemplateAshley FrancisОценок пока нет

- OSE Annual Report 2012Документ29 страницOSE Annual Report 2012FrasnusОценок пока нет

- Financial Modeling - 4 DaysДокумент8 страницFinancial Modeling - 4 Dayshnhn94Оценок пока нет

- Foa Ii Individual AssignmentДокумент3 страницыFoa Ii Individual Assignmentyosef mechalОценок пока нет