Академический Документы

Профессиональный Документы

Культура Документы

Modelos e Padrões

Загружено:

AndersonDosSantosАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Modelos e Padrões

Загружено:

AndersonDosSantosАвторское право:

Доступные форматы

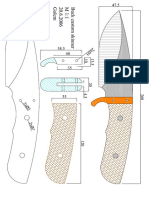

Gen 2 table holder plans

An attachment for the 2x72” tilting belt grinder

Some important notes:

1. To use this attachment, you will first have to build my 2x72” tilting belt grinder. Plans for it

and the platen attachment (the grayed out parts shown above) are available here: http://

etsy.me/2sm5uvg Plans & Sketchup models for all other attachments & jigs are available on

my website, here: http://jerswoodshop.com/2x72-tilting-belt-grinder/

2. It is assumed that you will build and use the belt grinder and this attachment in a safe

manner, therefore, few safety precautions are set forth in these plans. Build and use at your

own risk. I am not responsible for any injuries caused by the manufacture and use of the belt

grinder or this attachment.

3. Building assumptions: It is assumed that you have a basic knowledge of fabricating and

metalworking. These plans will give you a few pointers and what techniques worked best for

me, but they will not tell you how to set your welder, etc., since I assume you already know

how to do that. All welds on the build may be ground & touched up for looks, so long as you

don't grind away the structure of the weld. Everything should be checked with a square prior

to welding, and all parts should be built with good precision, for best results.

4. Painting should be left to the end of the build, after testing is complete. Some parts may

need to be modified slightly, so it’s best to leave painting for after that’s done.

5. If you haven't seen the YouTube build video for this attachment, please watch it prior to

building the attachment: https://youtu.be/6lbUuRWsiFg

6. If you have any questions, or if you find any errors in these plans, you can contact me at

jerswoodshop@gmail.com.

Page 1 Gen 2 table holder plans © 2018 Jeremy Schmidt

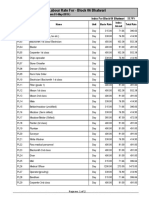

Parts list:

“Used in…” indicates which step(s) in the plans use this part. Refer to that step or steps for

more information about that part.

Part/material name Size Quantity Used in…

Steel flatbar 3/8” x 1-1/2” 20” Steps 1 & 9

Steel flatbar 3/8” x 2” 16” Steps 1, 8, &10

Steel plate 3/8” thick 5” x 8” minimum Step 5

Steel square bar 1-1/2” x 1-1/2” 16-1/2” Steps 2 & 6

Steel plate for tables 3/8” thick recommended Approx. 8” x 8” for each Making tables, page 9

Steel tube for tables 1-1/2” square, 1/4” wall Approx. 9” for each Making tables, page 9

Grade 8 nut 3/8"-16 1 Step 4

Grade 8 bolts 3/8”-16 x 3/4” 4 Step 13

Flat washers 3/8" 4 Step 13

Bolt or handle 3/8”-16 x 1” 1 Step 13

Nomenclature: Table

Tool arm

Table holder

Mounting

plate

Locking Table

handle

Connecting

structure

Support

structure

Table post

Table tube

Page 2 Gen 2 table holder plans © 2018 Jeremy Schmidt

Step 1 1-1/4” 3/4”

Start by cutting out the parts to make the table tube. The

left and right sides of the tube are made from 3/8 x 2”

flatbar, and the front and back of the tube are 3/8 x 1-1/2” 45°

flatbar. Cut out the sides according to the drawing on the 1:1 scale

right. This drawing may be printed and used as a template,

but be sure to confirm the dimensions after printing. After

tapping the holes in the left side plate, remove any burrs

from them so the surfaces are perfectly flat. The back plate

of the tube is 4-1/2” long, and the front plate is 4” long

overall, with the end beveled to 45°.

4-1/2”

3/8”-16

tapped holes

3”

(left plate only)

1/2”

1/2” 1”

Step 2 2”

Set the tube up to be welded together. Clamp the four parts around

a piece of 1-1/2” square bar, using a 0.030-0.050” thick shim on

two sides, so the inside dimensions of the tube will be at least 1.53

x 1.53”. I used utility knife blades as shims. Tack weld each edge in

3 or 4 places, but do not weld it solid yet. Remove the clamps and

slide the tube off the 1-1/2” bar (this will take significant force). 0.030”

Once it is removed from the bar you can finish welding it solid. To shims

prevent the tube from warping into a rhombus shape, you should

only weld about 1” per edge before moving to a different corner.

This will cause the whole tube to heat up more evenly, rather than

getting a build-up of heat in one area.

Offset leaves

space to fill

with weld

Page 3 Gen 2 table holder plans © 2018 Jeremy Schmidt

Step 3

Tables will be secured in the table tube by a locking handle

installed in the right front corner of the tube, so you need to weld

in a nut to accept that locking handle. Start by grinding/filing a flat

spot on a 45° angle into the corner of the tube. The center of the

flat spot should be 2-1/4” up from the bottom of the tube, and the

flat area should be about 3/4” square. Note: because of the

angled weld on

the corner of

the tube, the

flat spot may

appear to be at

the wrong

angle even if

it’s right, so ~3/4”

trust your

protractor,

not your 2-1/4”

eyes.

Step 4

Find the center of the flat spot,

and drill a 7/16” hole through

the corner of the tube at a 45°

angle. Use caution when

drilling, since the bit may catch

in the corner of the tube.

Remove any burrs from the

hole. Place a 3/8”-16 nut in the

center of the flat spot, and

carefully weld it in place. The

table tube is now complete.

Tip: You can use a bolt to hold

the nut in place while you weld. Nut

Use a 3/8”-16 x 1” bolt with a Washer

washer, threaded into the nut

from inside the tube. The bolt

also keeps weld spatter from Bolt

getting in the nut.

Page 4 Gen 2 table holder plans © 2018 Jeremy Schmidt

Step 5

Get started on the connecting structure by cutting

out the left & right sides from 3/8” thick steel

plate, according to the template below. The left

side is identical to the right, except that it lacks

the 1-3/4” bit that extends forward, as shown.

3/4” 1-1/4”

45°

2-1/2”

Ri

Le

gh

ft

7/8”

2”

si

t

si

de

de

1:1 scale

45°

1-3/4”

1”

1-3/4”

45°

5/8”

2-3/8” 2-3/8”

Step 6

Cut your 1-1/2” solid square bar to 16-1/2” length to use for the tool arm. Cut a 45° bevel on

the end, as shown below.

Tool arm 45°

16-1/2”

overall length

1/4”

1-1/4”

Page 5 Gen 2 table holder plans © 2018 Jeremy Schmidt

Step 7

The sides of the connecting structure will be welded to the tool Chamfers

arm as shown on the right, but before welding, you need to

chamfer the edges of the tool arm and the side plates to create

a “V” to fill with weld. Once the chamfers are created, remove

any burrs and make sure the mating surfaces are clean. Then

clamp the two side plates to the tool arm, make sure they’re

square, and tack them in place. Don’t weld them solid yet.

V to fill

with weld

Step 8

Tack weld a 1-3/4” long

piece of 3/8 x 2” flatbar

into the front of the

connecting structure,

angled to join both of the

sides together as seen in

the pictures on the right.

Don’t weld it solid yet.

Step 9

Fill in the top and bottom

of the connecting structure with small pieces of steel to create a tube. I used 3/8 x 1-1/2”

flatbar for this since I had it on hand, but thinner material would work as well. These pieces

close in the structure, which helps it resist twisting forces, and makes it look nicer. The exact

placement of the pieces is not critical as long as they close up the tube. Once all the pieces are

tacked in place, you can finish welding all of the seams on the

connecting structure, including welding the sides onto the tool arm.

Page 6 Gen 2 table holder plans © 2018 Jeremy Schmidt

Step 10 2”

Cut out the mounting plate from 3/8 x 2” flatbar, according

to the template on the right. Drill the 7/16” holes and

remove any burrs left by the drill.

Step 11 1/2” 1”

The mounting plate will be Shim

welded to the right side of the

connecting structure, but it

needs to be spaced away from

the connecting structure by

1/8”. Cut a 1-1/2 x 1-3/4”

1:1 scale

4”

shim, from 1/8” thick steel.

3”

Make sure the shim doesn’t

have any burrs or bumps that

prevent it from sitting flat.

Place the shim on the 7/16”

right side of the holes

connecting structure

with a ~1/8” reveal

on 3 sides, as

shown below.

Step 12

Place the mounting plate centered on top of the shim

and clamp it lightly. The mounting plate should be centered

~1/8” vertically on the end of the connecting structure and the front

reveal edge of it should be flush with the front edge of the connecting

structure. Be sure it is square to the tool arm, then tack the mounting

plate in place on all four corners. Then weld the mounting plate

solidly to the connecting structure on all four sides.

Vertically

centered

Page 7 Gen 2 table holder plans © 2018 Jeremy Schmidt

Step 13

Assemble the table tube onto the connecting structure

using four 3/8-16 x 3/4” bolts and flat washers. With the

bolts loose, you should be able to rock the tube back

and forth a couple degrees. Thread a 3/8”-16 locking

handle or bolt into the corner of the table tube, and be

sure you can slide a piece of 1-1/2” square tube into the

tube and lock it in place. If everything works as designed,

you can disassemble and paint the parts. Mask off the

tool arm and the inside of the table tube, as well as the

threaded holes.

Reassemble, but leave

the bolts loose for now.

Step 14

Your new table holder

attachment is now

complete, but it needs

to be adjusted so the

table tube is parallel to

the platen. Secure a

piece of 1-1/2” square

tube in the table holder

as shown below, and

use a scrap of wood or

metal as a feeler gauge to check the gap between the square tube and the platen. Slide the

block up and down the platen, adjusting the angle as needed until the square tube is parallel to

the platen. Once parallel, tighten the four bolts securely.

Note: you’ll see in the photo that I left the belt on the

grinder during this

operation. This

keeps the platen

“preloaded” to be

sure it is in its 1/2” thick

normal use “feeler gauge”

position. This may

not be necessary,

but that explains

why I did it. Your

table holder is

now complete and

ready to use.

Page 8 Gen 2 table holder plans © 2018 Jeremy Schmidt

Making tables

The purpose of the table holder is to allow you to

cheaply and easily make whatever sort of tables you

want, therefore this section is only a few guidelines &

pointers to help you make your tables. The table post

is made from 1-1/2” thick-walled square tubing, and

in most cases 9” length seems to work about right.

Too far; may

I made my primary table from 3/8” steel plate, 8”

cause chatter

square. Ideally, the table post should be close to

the belt. If the post is too far from the belt, the thin

table that spans that distance will flex minutely and

cause chatter. You can also help prevent chatter by

adding a support structure under the table, such as a few

pieces of flatbar standing on edge, welded to the table post.

You can make tables at any angle, and since the table

holder’s vertical tube is parallel to the belt, the angle just Tube is close to

needs to be correct relative to the table post. Be careful belt; prevents

when welding the table to the post to prevent excessively chatter

warping the table. Of course, there is really no limit to what

can be mounted in the table holder; it is not restricted to just

tables. Get creative, and I’ll be interested to see what kind of

jigs you can come up with!

Support structure

Page 9 Gen 2 table holder plans © 2018 Jeremy Schmidt

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Bob Engnath Knife PatternsДокумент43 страницыBob Engnath Knife Patternsherpaderpadood100% (13)

- Circular Work in Carpentry and Joinery PDFДокумент145 страницCircular Work in Carpentry and Joinery PDFcaf_desknote100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Modelos e PadrõesДокумент9 страницModelos e PadrõesAndersonDosSantos50% (4)

- Ece 612Документ3 страницыEce 612AndersonDosSantosОценок пока нет

- Tsuda ArquivoДокумент48 страницTsuda ArquivoAndersonDosSantosОценок пока нет

- Kai Kitchen Knives Catalogue en PDFДокумент116 страницKai Kitchen Knives Catalogue en PDFAndersonDosSantosОценок пока нет

- Fighting KnivesДокумент63 страницыFighting KnivesAndersonDosSantosОценок пока нет

- Full Tangl PDFДокумент1 страницаFull Tangl PDFAndersonDosSantosОценок пока нет

- Full Tangl PDFДокумент1 страницаFull Tangl PDFAndersonDosSantosОценок пока нет

- B Uck Custom Skinner PDFДокумент1 страницаB Uck Custom Skinner PDFAndersonDosSantosОценок пока нет

- Activacion de Office 2016Документ1 страницаActivacion de Office 2016Luz VasquezОценок пока нет

- Activacion de Office 2016Документ1 страницаActivacion de Office 2016Luz VasquezОценок пока нет

- Activacion de Office 2016Документ1 страницаActivacion de Office 2016Luz VasquezОценок пока нет

- CH 7 Wood WorkДокумент44 страницыCH 7 Wood WorkSubhash SinhaОценок пока нет

- Carpentry 1Документ159 страницCarpentry 1Shena Mae SamarroОценок пока нет

- Machining and CNC: CAD/CAM Is Said As Two WordsДокумент4 страницыMachining and CNC: CAD/CAM Is Said As Two WordsIvan Mario VillcaОценок пока нет

- Metal LatheДокумент25 страницMetal Lathebogesz68Оценок пока нет

- Popular Woodworking No 80 September 1994Документ84 страницыPopular Woodworking No 80 September 1994aleksandar.omasystemsОценок пока нет

- How To Make A Colt Western Pistol I 3 4 HoursДокумент5 страницHow To Make A Colt Western Pistol I 3 4 HoursWAGNER JOEL DELNEROОценок пока нет

- BDT JHS 3Документ5 страницBDT JHS 3Emmanuel AgbavorОценок пока нет

- Slider Crank Power Hammer Mechanism Project ReportДокумент33 страницыSlider Crank Power Hammer Mechanism Project ReportYemmina Madhusudhan80% (15)

- Sandpaper Grit Chart & Guide - Grainger KnowHowДокумент11 страницSandpaper Grit Chart & Guide - Grainger KnowHowAnushree DuttaОценок пока нет

- Lathe and Capstan & TurretДокумент13 страницLathe and Capstan & TurretNishit Parmar100% (1)

- Merni TrougaoДокумент9 страницMerni TrougaoNeven BausОценок пока нет

- Fine Woodworking 234 August 2013Документ92 страницыFine Woodworking 234 August 2013Scott Campbell100% (10)

- Defects in Lumber: 16 - Page Ce16: Structural Timber DesignДокумент14 страницDefects in Lumber: 16 - Page Ce16: Structural Timber DesignCzelsi Carlos NavarroОценок пока нет

- 18" Doll House Plans 4 Room OptionДокумент26 страниц18" Doll House Plans 4 Room OptionKelly KerchiefОценок пока нет

- A2 Graphic Products CourseworkДокумент5 страницA2 Graphic Products Courseworkafjwdbaekycbaa100% (2)

- Wood Notes PDFДокумент8 страницWood Notes PDFAleyna ErolОценок пока нет

- Catalog BipicoДокумент20 страницCatalog Bipicoalingutan100% (1)

- Sura 200 350-201803Документ8 страницSura 200 350-201803TharunОценок пока нет

- Untitled 1Документ3 страницыUntitled 1AmanОценок пока нет

- Mold Machining Methods, Part 1Документ22 страницыMold Machining Methods, Part 1Edenilson FadekОценок пока нет

- Chapter 2 Milling FixturesДокумент15 страницChapter 2 Milling FixturesTamirat NemomsaОценок пока нет

- Homemade Ripstik WaveboardДокумент10 страницHomemade Ripstik WaveboardmfdbОценок пока нет

- Planting My Mango TreesДокумент1 страницаPlanting My Mango TreesAPRIL RHOSE ALBITOОценок пока нет

- Arki Ale Building Technology and MaterialsДокумент2 страницыArki Ale Building Technology and MaterialsiloilocityОценок пока нет

- Hgu56 ManualДокумент86 страницHgu56 ManualRedgy Geryl0% (1)

- 103 - Table Saw Panel SledДокумент2 страницы103 - Table Saw Panel SledRob PierceОценок пока нет

- Tolerances Spec PDFДокумент3 страницыTolerances Spec PDFkhai ruleОценок пока нет

- Block 06 Bhatwari - ResourceRate - LabourДокумент2 страницыBlock 06 Bhatwari - ResourceRate - LabourManojОценок пока нет

- Machining Process Video PresentationДокумент1 страницаMachining Process Video PresentationK HОценок пока нет