Академический Документы

Профессиональный Документы

Культура Документы

SAMUR KD Tanks Project PDF

Загружено:

Wan RidhwanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SAMUR KD Tanks Project PDF

Загружено:

Wan RidhwanАвторское право:

Доступные форматы

10th July 2014

!

TO WHOM MY CONCERN

!

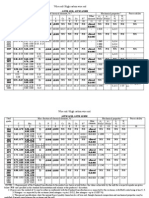

SAMUR KD TANK - PTS 16A & 16B

6.3.4 ! Diesel

6.3.4.1

Reference is made to the above mentioned, Tankguard HB is a high-build admin adduct

Coating System No. 16a : Initial painting, Maintenance Painting for Blast Cleaned Surface and

Power Tool Cleaned Surface.

epoxy coating with

Surface preparation : highto ISO

Blast cleaning resistance

8501-1 : 1988, Sa 2.5,to a wide

or Power

cleaning to ISO 8501-1 : 1988, St 3 for minor touch-up

tool range of chemicals and solvents.

painting

According to PTSRoof

Surface to be painted

Service Temperature Up No

:

: to 60 ºC30.48.00.31-P coating System No. 16a & 16b, the generic of the

and Shell plate

product which been requested for internal

Coating system DFT lining was Amine Adduct Epoxy. Therefore, we

1st coat Amine Adduct Epoxy 125 µ

confirm

2nd coat the

Amine paint system have excellent

Adduct Epoxy 125 µadhesion and performance in line Petronas

Total 250 µ

requirement.

Note :

Floating roof tank shell plates which are subjected to excessive abrasion and wear shall be

uncoated. However, if the Owner considers otherwise, suitable coating systems may be

specified. 6.3.4 Diesel

6.3.4.2 Coating System No. 16b : Initial painting, Maintenance Painting for Blast Cleaned Surface and 6.3.4.1 Coating System No. 16a : Initial painting, Maintenance Painting for Blast Cleaned Surface and

Power Tool Cleaned Surface. Power Tool Cleaned Surface.

Surface preparation : Blast cleaning to ISO 8501-1 : 1988, Sa 2.5, or Power tool Surface preparation : Blast cleaning to ISO 8501-1 : 1988, Sa 2.5, or Power tool

cleaning to ISO 8501-1 : 1988, St 3 for minor touch-up cleaning to ISO 8501-1 : 1988, St 3 for minor touch-up

painting painting

Surface to be painted : Bottom plate and Vessels

Surface to be painted : Roof and Shell plate

Service Temperature : Up to 60 ºC

Service Temperature : Up to 60 ºC

Coating system DFT Coating system DFT

1 st coat Amine Adduct Epoxy 100 µ 1st coat Amine Adduct Epoxy 125 µ

2 nd coat Amine Adduct Epoxy 100 µ 2nd coat Amine Adduct Epoxy 125 µ

3 rd coat Amine Adduct Epoxy 100 µ Total 250 µ

Total 300 µ Note :

6.3.4.3 Coating System No. 16c : Alternative System for Bottom Plate

Surface preparation

Surface to be painted

:

:

Blast cleaning to ISO 8501-1 : 1988, Sa 2.5

Bottom plate and Vessels

! Floating roof tank shell plates which are subjected to excessive abrasion and wear shall be

uncoated. However, if the Owner considers otherwise, suitable coating systems may be

specified.

! Service Temperature

Coating system

1 st coat Epoxy Primer

: Up to 60 ºC

DFT

50 µ

6.3.4.2 Coating System No. 16b : Initial painting, Maintenance Painting for Blast Cleaned Surface and

Power Tool Cleaned Surface.

Surface preparation : Blast cleaning to ISO 8501-1 : 1988, Sa 2.5, or Power tool

2 nd coat Epoxy Glassflake 200 µ cleaning to ISO 8501-1 : 1988, St 3 for minor touch-up

Trust all is in order; should you need any further clarification, please feel free to contact us.

3 rd coat Epoxy Glassflake 200 µ painting

Total 450 µ

Surface to be painted : Bottom plate and Vessels

Service Temperature : Up to 60 ºC

Yours faithfully,

JOTUN (M) SDN BHD (16434-U) Coating system

1 st coat Amine Adduct Epoxy 100

DFT

µ

2 nd coat Amine Adduct Epoxy 100 µ

3 rd coat Amine Adduct Epoxy 100 µ

Total 300 µ

!

!

6.3.4.3 Coating System No. 16c : Alternative System for Bottom Plate

Surface preparation : Blast cleaning to ISO 8501-1 : 1988, Sa 2.5

Surface to be painted : Bottom plate and Vessels

Nicholas Ng Hon Chung Service Temperature : Up to 60 ºC

Deputy Area Manager Coating system

1 st coat Epoxy Primer

DFT

50 µ

Protective Coatings Division 2 nd coat Epoxy Glassflake 200 µ

! 3 rd coat

Total

Epoxy Glassflake 200

450

µ

µ

Вам также может понравиться

- Melo That Is Exclusively Planted in Terengganu and Have Been Recognized As Terengganu'sДокумент14 страницMelo That Is Exclusively Planted in Terengganu and Have Been Recognized As Terengganu'sWan RidhwanОценок пока нет

- RKCGJДокумент2 страницыRKCGJWan RidhwanОценок пока нет

- BPS7277 D15200-2Документ7 страницBPS7277 D15200-2Wan RidhwanОценок пока нет

- Jotun Resist 86Документ5 страницJotun Resist 86Ansar AliОценок пока нет

- Svvq8ym7 PDFДокумент2 страницыSvvq8ym7 PDFWan RidhwanОценок пока нет

- SVVQ8YM7Документ2 страницыSVVQ8YM7Wan RidhwanОценок пока нет

- ND Cash Rebate T CДокумент4 страницыND Cash Rebate T CWan RidhwanОценок пока нет

- Motorcycle Insurance Receipt PDFДокумент1 страницаMotorcycle Insurance Receipt PDFWan RidhwanОценок пока нет

- Finology Sdn Bhd Motorcycle Insurance ReceiptДокумент1 страницаFinology Sdn Bhd Motorcycle Insurance ReceiptWan RidhwanОценок пока нет

- Ile 99 Atwith 12 Months ContractДокумент2 страницыIle 99 Atwith 12 Months ContractWan RidhwanОценок пока нет

- Motorcycle Insurance ReceiptДокумент1 страницаMotorcycle Insurance ReceiptWan RidhwanОценок пока нет

- Motorcycle Insurance Receipt PDFДокумент1 страницаMotorcycle Insurance Receipt PDFWan RidhwanОценок пока нет

- FAQ - Unifi - Mobile - 99 PDFДокумент15 страницFAQ - Unifi - Mobile - 99 PDF42523317Оценок пока нет

- Data Sheet Sandisk Ultra Dual Usb Drive 3 0Документ2 страницыData Sheet Sandisk Ultra Dual Usb Drive 3 0Wan RidhwanОценок пока нет

- Photoshop Cs4 Tools ExplainedДокумент29 страницPhotoshop Cs4 Tools ExplainedManjot Singh100% (1)

- FHGДокумент8 страницFHGWan RidhwanОценок пока нет

- Certificate of Achievement: Wan Mohd Ridhwan Bin Wan ZakiДокумент1 страницаCertificate of Achievement: Wan Mohd Ridhwan Bin Wan ZakiWan RidhwanОценок пока нет

- Timesheet Inspector - PGB GTRДокумент2 страницыTimesheet Inspector - PGB GTRWan RidhwanОценок пока нет

- SAMUR KD Tanks ProjectДокумент1 страницаSAMUR KD Tanks ProjectWan RidhwanОценок пока нет

- Certificate of Achievement: Wan Mohd Ridhwan Bin Wan ZakiДокумент1 страницаCertificate of Achievement: Wan Mohd Ridhwan Bin Wan ZakiWan RidhwanОценок пока нет

- Timesheet Inspector - PGB GTR PDFДокумент2 страницыTimesheet Inspector - PGB GTR PDFWan RidhwanОценок пока нет

- Painting Procedure TemplateДокумент15 страницPainting Procedure TemplateMohd Fadzle93% (70)

- Timesheet Inspector - PGB GTR PDFДокумент2 страницыTimesheet Inspector - PGB GTR PDFWan RidhwanОценок пока нет

- Timesheet Inspector - PGB GTR PDFДокумент2 страницыTimesheet Inspector - PGB GTR PDFWan RidhwanОценок пока нет

- SAMUR KD Tanks ProjectДокумент1 страницаSAMUR KD Tanks ProjectWan RidhwanОценок пока нет

- Cheat SygДокумент3 страницыCheat SygWan RidhwanОценок пока нет

- FHGДокумент8 страницFHGWan RidhwanОценок пока нет

- Contoh CVДокумент12 страницContoh CVWan RidhwanОценок пока нет

- Share SlideДокумент111 страницShare SlideWan RidhwanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Nature of Acidity and Lime Requirement in Acid Soils of ManipurДокумент8 страницNature of Acidity and Lime Requirement in Acid Soils of ManipurIJASRETОценок пока нет

- Water Steam Chemistry OptimizationДокумент4 страницыWater Steam Chemistry OptimizationAshish ParasharОценок пока нет

- 2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)Документ4 страницы2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)AnnafiОценок пока нет

- Wellhead Corrosion and Trim SelectionДокумент34 страницыWellhead Corrosion and Trim SelectionGuillaume Boyer100% (3)

- Physics I ProblemsДокумент1 страницаPhysics I ProblemsbosschellenОценок пока нет

- English Literature Syllabus BreakdownДокумент35 страницEnglish Literature Syllabus BreakdownKirti PathakОценок пока нет

- ELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinДокумент2 страницыELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinLeductoan LeОценок пока нет

- Manometer Pressure DifferenceДокумент5 страницManometer Pressure DifferenceBlue SkyОценок пока нет

- Everything About Alkynes - Q&AДокумент22 страницыEverything About Alkynes - Q&AJoostGoОценок пока нет

- Mahatma Jyotirao Govindrao PhuleДокумент12 страницMahatma Jyotirao Govindrao PhuleSagar V. ThakkarОценок пока нет

- Motor Oil ENGДокумент64 страницыMotor Oil ENGNicolai BelocosovОценок пока нет

- CentralTexas What Is Theta JA-CTEAДокумент38 страницCentralTexas What Is Theta JA-CTEASai Santhosh ManepallyОценок пока нет

- Ethanol Production by Fermentation and DistillationДокумент3 страницыEthanol Production by Fermentation and DistillationChris WarnerОценок пока нет

- High Carbon Wire RodДокумент9 страницHigh Carbon Wire Rodninganray6316100% (1)

- Welding Guide For Rina-EngДокумент75 страницWelding Guide For Rina-EngReaz UddinОценок пока нет

- Liquid-Liquid Equilibria For The Systems Water-Alcohols-Acetic AcidДокумент10 страницLiquid-Liquid Equilibria For The Systems Water-Alcohols-Acetic AcidAleska Guzman SantamariaОценок пока нет

- Sodium Alginate TestingДокумент2 страницыSodium Alginate TestingImran Anwar0% (1)

- BC7068 E-TdsДокумент3 страницыBC7068 E-TdsHoài NguyễnОценок пока нет

- Decolorization and Organic Removal From Palm Oil Mill Effluent by Fenton's ProcessДокумент5 страницDecolorization and Organic Removal From Palm Oil Mill Effluent by Fenton's Processagungtiyo21Оценок пока нет

- Lipids Classification and FunctionsДокумент4 страницыLipids Classification and FunctionsThalia PacamalanОценок пока нет

- Principles of Hemodialysis: Module No: - 02 - Module TitleДокумент10 страницPrinciples of Hemodialysis: Module No: - 02 - Module TitleIan LelisОценок пока нет

- Chemistry 9 Chap 1 Long QAДокумент17 страницChemistry 9 Chap 1 Long QAAkbar Ali AhmedОценок пока нет

- SF 6Документ16 страницSF 6dennyyusuf100% (1)

- Flexible PavementsДокумент13 страницFlexible PavementsAhmad NajiОценок пока нет

- Organic Chemistry: Basic Principles & TechniquesДокумент4 страницыOrganic Chemistry: Basic Principles & TechniquesHasan shaikhОценок пока нет

- Sat Vocabulary 6000 Words PDFДокумент151 страницаSat Vocabulary 6000 Words PDFUman100% (1)

- Ground Slab CourseДокумент36 страницGround Slab CoursezainalharrisОценок пока нет

- 17-Oil Centrifuge PDFДокумент89 страниц17-Oil Centrifuge PDFUmangtarangОценок пока нет

- ACI 207.1R-05 Guide To Mass ConcreteДокумент31 страницаACI 207.1R-05 Guide To Mass ConcreteLukusa Badimuena100% (3)