Академический Документы

Профессиональный Документы

Культура Документы

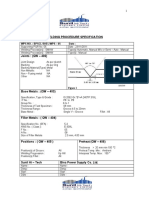

Prequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .

Загружено:

Midhun K Chandrabose0 оценок0% нашли этот документ полезным (0 голосов)

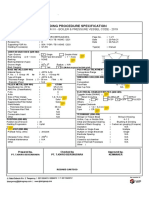

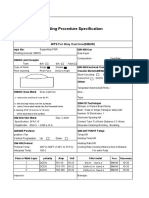

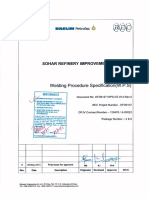

49 просмотров2 страницыThis document summarizes a welding procedure specification (WPS) for shielded metal arc welding (SMAW) of 3/8-inch thick ASTM A36 steel in the 3G position. The WPS uses E-7018 electrodes in multiple passes with a root opening of 1/4-inch and a 45-degree groove angle. Post-weld heat treatment is not required. The WPS was qualified by ATC Qatar and authorized on October 25, 2018.

Исходное описание:

Welding Procedure Qualification

Оригинальное название

Welding Procedure Qualification

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document summarizes a welding procedure specification (WPS) for shielded metal arc welding (SMAW) of 3/8-inch thick ASTM A36 steel in the 3G position. The WPS uses E-7018 electrodes in multiple passes with a root opening of 1/4-inch and a 45-degree groove angle. Post-weld heat treatment is not required. The WPS was qualified by ATC Qatar and authorized on October 25, 2018.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

49 просмотров2 страницыPrequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .

Загружено:

Midhun K ChandraboseThis document summarizes a welding procedure specification (WPS) for shielded metal arc welding (SMAW) of 3/8-inch thick ASTM A36 steel in the 3G position. The WPS uses E-7018 electrodes in multiple passes with a root opening of 1/4-inch and a 45-degree groove angle. Post-weld heat treatment is not required. The WPS was qualified by ATC Qatar and authorized on October 25, 2018.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

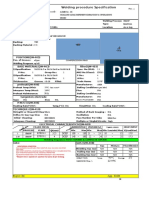

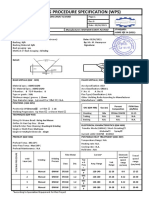

(AWS D1.1/1.1M)WELDING PROCEDURE QUALIFICATION (WPS) YES…X...

PREQUALIFIED…………X………… QUALIFIED BY TESTING…………………

PROCEDURE QUALIFICATION RECORDS (PQR) YES…..

Identification # ATC/WPS/001

Revision # 00 Date: 25/10/2018 By: Contractor QC person

Company Name: ATC Qatar Authorized by: Imam Hussain Date: 25/10/2018

Welding Process(es): SMAW Type: Manual: Yes Semi-Automatic: NA

Supporting PQR No(s): Pre qualified B-U2a Mechanized: NA Automatic: NA

JOINT DESIGN USED POSITION

Type: Butt Position Of Groove: 3G Fillet: -

Single weld: Yes Double-Weld: NA Vertical Progression: Up: Yes Down: -

Backing: Yes: Yes

Backing Material: ASTM A36 ELECTRICAL CHARACTERSTICS

Root Opening: ¼’’ Root Face Dimension: - Transfer Mode(GMAW)

Groove Angle: 45° Radius(J-U): - Short Circuiting: NA

Back Gouging: No Method: NA Globular: NA Spray: - NA

Current: AC: - DCEP: Yes DCEN: NA

BASE METALS Pulsed: NA

Material Spec: ASTM A36 Power Source:

Group No #, P #: Group 1 , P1 CC: Yes CV: NA

Thickness: 3/8’’ Groove: Yes Fillet: NA Others: NA

Diameter (Pipe): NA

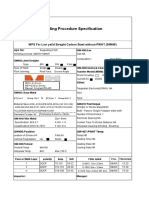

FILLER MATERIALS TECHNIQUE

AWS Specification: A 5.1 Stringer or Weave Bead: Stringer or Weave

AWS Classification: E-7018 Multi pass or Single pass(per side): Multiple

F No # , A No : F4 , A-1 Number of Electrode(s): 01

SHEILDING Electrode Spacing: NA Longitudinal: NA

Flux: NA Gas: NA Lateral: NA

Composition: NA Angle: NA

Electrode Flux (Class): NA Contact tube to Work Distance: NA

Flow Rate: NA Peening: NO

Gas Cup Size: NA Inter-pass Cleaning: Chipping, Grinding

PREHEAT POST WELD HEAT TREATMENT

Preheat Temp. Min: 50° Temperature: NA

Interpass Temp. Min: 50° Max: 350° Time: NA

WELDING PROCEDURE

Pass/Weld Process Filler Filler Current Current Volts Travel Joint

Layers Class Dia Type & Amps/Wire Speed(mm/Min) Details

Polarity Feed Speed

Root SMAW E- 3/32’’ DCEP 70-110 9-12 40-100 See

7018 below

Hot SMAW E- 3/32’’ DCEP 70-110 9-12 40-100 picture

7018

Fill SMAW E- 1/8’’ DCEP 90-130 8-11 40-100

7018

Cap SMAW E- 1/8’’ DCEP 90-130 8-11 40-100

7018

45°

5 6 7

3 4

t 2

1

¼’’

Prepared by, Reviewed and Approved by,

Contractor QA/QC TPI Inspector:

Name & Signature: Date:

Date:

Вам также может понравиться

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Документ20 страницWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaДокумент5 страницBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaОценок пока нет

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateДокумент3 страницыJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanОценок пока нет

- WPS For Different Materail by BhelДокумент176 страницWPS For Different Materail by Bhelsaisssms911691% (46)

- Welding Procedure Specification: Page 1 of 1Документ2 страницыWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Method Statement - STOP-LOGSДокумент7 страницMethod Statement - STOP-LOGSMohammad Bader Al-DeinОценок пока нет

- WPS 8 To 1-3-1 Rev2 (10-1-13)Документ5 страницWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Chem-1 Sadara Chlorine & Brine Project Nasser S. Al Hajri CorporationДокумент1 страницаChem-1 Sadara Chlorine & Brine Project Nasser S. Al Hajri CorporationMidhun K ChandraboseОценок пока нет

- WPS BhelДокумент2 страницыWPS BhelpradhankruhsnaОценок пока нет

- WDI-WPS-072 Rev.00 SMAW 2Документ4 страницыWDI-WPS-072 Rev.00 SMAW 2MohamedОценок пока нет

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkДокумент10 страницWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateДокумент2 страницыWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanОценок пока нет

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Документ2 страницыPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- WPS 03 GtawДокумент3 страницыWPS 03 GtawBiswajit DeyОценок пока нет

- WPS E6013+e7018Документ2 страницыWPS E6013+e7018Anvesh Vaddi100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewДокумент4 страницы(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaОценок пока нет

- Welding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Документ1 страницаWelding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Lipika GayenОценок пока нет

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Документ2 страницыWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- WPS-PQR RepairДокумент16 страницWPS-PQR RepairmohammedetaОценок пока нет

- Aic Asf PQR 0120Документ2 страницыAic Asf PQR 0120AHMED MEDANYОценок пока нет

- WPS PQRДокумент126 страницWPS PQRBuditama ChandranegaraОценок пока нет

- Aic Asf PQR 0121Документ2 страницыAic Asf PQR 0121AHMED MEDANYОценок пока нет

- WPS-IOT-005 REV.0 Welding Procedure Specification (IOTPG) - For Proposed OnlyДокумент10 страницWPS-IOT-005 REV.0 Welding Procedure Specification (IOTPG) - For Proposed OnlyUripTobingОценок пока нет

- PIPING WPS and PQRДокумент5 страницPIPING WPS and PQRshibaprasad0115Оценок пока нет

- Procedure Qualification SpecificationДокумент4 страницыProcedure Qualification Specificationriyas.hvacworkОценок пока нет

- WPS-2 InchДокумент2 страницыWPS-2 InchKarthikeyan MpОценок пока нет

- Tz.O.R.C R.O. Project: Second and OtherДокумент5 страницTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiОценок пока нет

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel Without PWHT (SMAW)Документ1 страницаWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel Without PWHT (SMAW)Lipika GayenОценок пока нет

- Mechanical Engineering M.Abdul GhoziДокумент4 страницыMechanical Engineering M.Abdul GhoziRizaldy PhoenksОценок пока нет

- JOINTS (QW-402) : Groove Design of Test CouponДокумент2 страницыJOINTS (QW-402) : Groove Design of Test CouponbeyОценок пока нет

- PhuBia-WPS-AWS D1.1-8-6-2011Документ2 страницыPhuBia-WPS-AWS D1.1-8-6-2011poulmackОценок пока нет

- WPS PQR CompleteДокумент49 страницWPS PQR CompleteGulfam HussainОценок пока нет

- Manual Joints (QW - 402) : Page 1 of 12Документ12 страницManual Joints (QW - 402) : Page 1 of 12miteshpatel191Оценок пока нет

- Aic Asf PQR 0122Документ2 страницыAic Asf PQR 0122AHMED MEDANYОценок пока нет

- Pessing Libya INC: Weld Detail Preparation MethodДокумент1 страницаPessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagОценок пока нет

- Welding Proposed Pwps For Our Jubail WorkДокумент2 страницыWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Final WPS - ItdcДокумент2 страницыFinal WPS - ItdcsarancivilrajОценок пока нет

- WPS CuNiДокумент1 страницаWPS CuNiDieter Huaman ToscanoОценок пока нет

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CДокумент1 страницаPessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagОценок пока нет

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Документ1 страницаWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenОценок пока нет

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Документ3 страницыWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanОценок пока нет

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingДокумент3 страницыDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyОценок пока нет

- PhuBia-WPS-AWS D1.1-8-6-2011Документ3 страницыPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CДокумент1 страницаPessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagОценок пока нет

- Wps - Eni-Ci - Enife-ci-A (Gray Cast Iron)Документ1 страницаWps - Eni-Ci - Enife-ci-A (Gray Cast Iron)AminОценок пока нет

- WPSДокумент2 страницыWPSAlam MD Sazid100% (1)

- WPS PQR ProcedureДокумент31 страницаWPS PQR Proceduresudeesh kumarОценок пока нет

- WPS PQR Procedure PDFДокумент31 страницаWPS PQR Procedure PDFsudeesh kumarОценок пока нет

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Документ2 страницыBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduОценок пока нет

- WPS 10Документ2 страницыWPS 10Arab WeldersОценок пока нет

- WPS - 600 MW ChampaДокумент7 страницWPS - 600 MW ChampaAmjad PathanОценок пока нет

- Welding Procedure Specification: JOINT (QW-402)Документ10 страницWelding Procedure Specification: JOINT (QW-402)Lipika GayenОценок пока нет

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDДокумент2 страницыWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobiniОценок пока нет

- WPS No. ST-CS-02-2Документ1 страницаWPS No. ST-CS-02-2Hussein JassimОценок пока нет

- Aic Asf PQR 0119Документ2 страницыAic Asf PQR 0119AHMED MEDANYОценок пока нет

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- Ofd0137 WPS GT 013 Rev 0Документ22 страницыOfd0137 WPS GT 013 Rev 0Midhun K Chandrabose100% (1)

- Ofd0137 WPS GTSM P4 002 Rev 1Документ6 страницOfd0137 WPS GTSM P4 002 Rev 1Midhun K Chandrabose100% (1)

- Ofd0137 WPS GT P43 003 Rev 1Документ6 страницOfd0137 WPS GT P43 003 Rev 1Midhun K Chandrabose100% (1)

- Ofd0137 WPS GT 013 Rev 0Документ5 страницOfd0137 WPS GT 013 Rev 0Midhun K Chandrabose100% (1)

- WPS P45 GTSMДокумент16 страницWPS P45 GTSMMidhun K Chandrabose100% (1)

- Revised Weld Map (23!07!2015)Документ15 страницRevised Weld Map (23!07!2015)Midhun K Chandrabose100% (1)

- Ofd0137 WPS GTSM P5a 011 Rev 0Документ29 страницOfd0137 WPS GTSM P5a 011 Rev 0Midhun K Chandrabose100% (1)

- Ultrasonic Testing: NDT Training & CertificationДокумент29 страницUltrasonic Testing: NDT Training & CertificationMidhun K Chandrabose100% (1)

- Ofd0137 WPS GT P8 005 Rev 1Документ25 страницOfd0137 WPS GT P8 005 Rev 1Midhun K Chandrabose100% (1)

- Aramco QuestionsДокумент72 страницыAramco QuestionsMidhun K ChandraboseОценок пока нет

- Arc Weldability of Alloy SteelsДокумент2 страницыArc Weldability of Alloy SteelsMidhun K ChandraboseОценок пока нет

- Design Criteria: Internal CorrosionДокумент48 страницDesign Criteria: Internal CorrosionMidhun K ChandraboseОценок пока нет

- Ferrite Content Testing Procedure PDFДокумент11 страницFerrite Content Testing Procedure PDFMidhun K Chandrabose83% (6)

- Filler Metal SelectionДокумент7 страницFiller Metal SelectionMidhun K ChandraboseОценок пока нет

- Ultrasonic Testing: NDT Training & CertificationДокумент48 страницUltrasonic Testing: NDT Training & CertificationMidhun K ChandraboseОценок пока нет

- Ultrasonic Testing: NDT Training & CertificationДокумент21 страницаUltrasonic Testing: NDT Training & CertificationMidhun K ChandraboseОценок пока нет

- 4P&IDДокумент8 страниц4P&IDMidhun K ChandraboseОценок пока нет

- A Piping Tutorial-1Документ53 страницыA Piping Tutorial-1Midhun K ChandraboseОценок пока нет

- Training & CertificationДокумент52 страницыTraining & CertificationMidhun K ChandraboseОценок пока нет

- PWHT (QC Exam, Procedure Review)Документ2 страницыPWHT (QC Exam, Procedure Review)Midhun K ChandraboseОценок пока нет

- Process Industry Practices Piping: PIP PNSC0001 Fabrication and Examination Specification For ASME B31.3 Metallic PipingДокумент17 страницProcess Industry Practices Piping: PIP PNSC0001 Fabrication and Examination Specification For ASME B31.3 Metallic PipingMidhun K Chandrabose100% (2)

- A LTM at Welder QualДокумент13 страницA LTM at Welder QualMidhun K Chandrabose100% (1)

- ASME P Material NumbersДокумент3 страницыASME P Material NumbersTeodor EzaruОценок пока нет

- S 000 13A0 102 Wrapping and CoatingДокумент17 страницS 000 13A0 102 Wrapping and CoatingMidhun K Chandrabose100% (1)

- Din 931Документ1 страницаDin 931Showkath Ali100% (2)

- Penomoran Ordner QC Head Office ContohДокумент2 страницыPenomoran Ordner QC Head Office ContohGultom Juliana LiliesОценок пока нет

- NG - CD - HD16 9 1939SX P080 - A - PDF - hd16 9 1939sx p080 - 605159Документ2 страницыNG - CD - HD16 9 1939SX P080 - A - PDF - hd16 9 1939sx p080 - 605159O mecanicoОценок пока нет

- Screw Threads, Bolts and NutsДокумент10 страницScrew Threads, Bolts and NutsSayphone HoungbounyuangОценок пока нет

- FW12 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020Документ2 страницыFW12 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020Muhammad firdaus rusliОценок пока нет

- Application of Plasma MIG Hybrid Welding To Dissimilar Joints Between Copper and SteelДокумент6 страницApplication of Plasma MIG Hybrid Welding To Dissimilar Joints Between Copper and SteelKaushik SenguptaОценок пока нет

- TWI CSWIP 3.2 WIS 10 Senior Welding Inspection Terminology: World Centre For Materials Joining TechnologyДокумент16 страницTWI CSWIP 3.2 WIS 10 Senior Welding Inspection Terminology: World Centre For Materials Joining TechnologyJithuJohnОценок пока нет

- Stick or MSAW Welding: Process Characteristics of Shielded Metal Arc Welding (SMAW/Stick)Документ3 страницыStick or MSAW Welding: Process Characteristics of Shielded Metal Arc Welding (SMAW/Stick)senthil4youОценок пока нет

- Tig Flow ChartДокумент1 страницаTig Flow ChartNiranjan khatuaОценок пока нет

- Zoznam NoriemДокумент4 страницыZoznam NoriemPeter TvardzíkОценок пока нет

- 400 Complete Advanced Devices CatalogДокумент24 страницы400 Complete Advanced Devices CatalogJeyson AguilarОценок пока нет

- Welder Operator TrainingДокумент22 страницыWelder Operator TrainingsniperiОценок пока нет

- IRS Concrete Bridge Code - CS 9 PDFДокумент3 страницыIRS Concrete Bridge Code - CS 9 PDFfaumijkОценок пока нет

- Hitch Guide PDFДокумент3 страницыHitch Guide PDFLucas WiddekindОценок пока нет

- Automobile Skills, Communication, Interpersonal SkillsДокумент14 страницAutomobile Skills, Communication, Interpersonal SkillsvigneshОценок пока нет

- Arc Welding ProcessesДокумент153 страницыArc Welding Processespratap biswasОценок пока нет

- WI - 7 5 022 Warman Pump Tolerances - r7Документ2 страницыWI - 7 5 022 Warman Pump Tolerances - r7munhОценок пока нет

- Aramco CBT Questions-Answere For QAQC WeldingДокумент10 страницAramco CBT Questions-Answere For QAQC WeldingAbdul HafeezОценок пока нет

- FCAW Overlay WPSДокумент2 страницыFCAW Overlay WPSAsad Bin Ala Qatari100% (1)

- User Manual DP323C: Issue 2Документ30 страницUser Manual DP323C: Issue 2Ajmaster.ltОценок пока нет

- Ethernet Cable Colour - Code Standards & Methods of CrimpingДокумент15 страницEthernet Cable Colour - Code Standards & Methods of CrimpingSajjad Najum ShakirОценок пока нет

- WPSДокумент2 страницыWPSAlam MD Sazid100% (1)

- Consumables Control ProcedureДокумент13 страницConsumables Control ProceduremominОценок пока нет

- Cement Type Early Age Properties 23 Jun 11 PDFДокумент3 страницыCement Type Early Age Properties 23 Jun 11 PDFJoãoPauloAzevedoОценок пока нет

- Field VesselsДокумент1 страницаField Vesselssaeed ghafooriОценок пока нет

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldДокумент27 страницSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalОценок пока нет

- Welding On Sheet MetalДокумент1 страницаWelding On Sheet MetalDebabrata Misra [DME6369]Оценок пока нет

- Metrc Thread-Extended Thread Size RangeДокумент17 страницMetrc Thread-Extended Thread Size RangeMitsakis MitsarasОценок пока нет

- VXN150 Vixion Intake PDFДокумент2 страницыVXN150 Vixion Intake PDFHarris Jum'aniandaОценок пока нет

- ASI Connection Design Guide 2 WeldingДокумент68 страницASI Connection Design Guide 2 Weldingshashank sharma100% (1)