Академический Документы

Профессиональный Документы

Культура Документы

Failure Mechanism of Concrete Under Fatigue Compressive Load

Загружено:

mohammedelshafieОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Failure Mechanism of Concrete Under Fatigue Compressive Load

Загружено:

mohammedelshafieАвторское право:

Доступные форматы

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/245307996

Failure Mechanism of Concrete under Fatigue Compressive Load

Article in Journal of Materials in Civil Engineering · December 2004

DOI: 10.1061/(ASCE)0899-1561(2004)16:6(566)

CITATIONS READS

16 506

3 authors, including:

Kolluru Subramaniam Surendra P. Shah

Indian Institute of Technology Hyderabad Northwestern University

150 PUBLICATIONS 1,708 CITATIONS 625 PUBLICATIONS 20,952 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Improving sulfate-resistivity of concrete with nanoSiO2 View project

Seismic Assessment of Masonry Structures View project

All content following this page was uploaded by Kolluru Subramaniam on 31 August 2014.

The user has requested enhancement of the downloaded file.

Failure Mechanism of Concrete

under Fatigue Compressive Load

Bin Mu1; Kolluru V. Subramaniam2; and S. P. Shah3

Abstract: In this paper, the behavior of concrete under static and fatigue compressive load is studied. Cylindrical specimens were

subjected to static cyclic and constant amplitude fatigue loading. The static cyclic tests were performed by unloading and reloading the

specimen at three different points in the postpeak period of the static loading response. Low cycle, high amplitude fatigue tests were

performed to failure using three load amplitudes. It is found that under the term of structural compliance the static compressive response

of concrete can be used as an envelope for the fatigue failure compressive response. The change rate of stiffness or compliance under

fatigue loading follows a two-stage process: a deceleration stage followed by an acceleration stage up to failure. The failure mechanisms

for both static and fatigue loading are explained by the band damage zone model and found to be consistent in the term of an inelastic

displacement. The results agree well with the previous research work.

DOI: 10.1061/(ASCE)0899-1561(2004)16:6(566)

CE Database subject headings: Concrete; Failures; Compression; Fatigue; Loads.

Introduction for a given design case followed by statistical analysis. The re-

sulting information is not directly applicable to other design cases

Fatigue is a process of progressive and permanent material dam- with different loading configurations or boundary conditions.

age under repeated loading. Conventionally, a distinction has Mechanistic understanding of damage evolution due to re-

been made between low and high amplitude fatigue. The former peated loading is still evolving. The mechanistic approaches are

is characterized by greater number of cycles of low stress ampli- based on applying the concepts of fracture or damage mechanics

tude. Repeated cycles at high stress amplitude, where the material to model the accruing damage in the material due to repeated

response is nonlinear results in severe damage in a relatively loading. In tensile loading where the primary damage mechanism

small number of cycles. Such loading is encountered in situations is crack growth, early attempts to model crack growth included

such as airport pavements where the concrete is subjected to re- applying the Paris Law to describe the fatigue crack growth (Bal-

peated loading of high stress amplitude due to passing aircrafts. uch et al. 1987; Perdikaris and Calomino (1987); Bazant and Xu

Biaxial high amplitude fatigue response of concrete is of interest (1991); Bazant and Schell 1993). More fundamental approaches

in such situations for developing rational design procedures, as- to understand the damage growth in fatigue have been developed,

sessing the service life of existing pavement, and predicting the which have included a careful interpretation of the fatigue re-

service performance of existing pavements to increased loading in sponse using parameters obtained from the static load response.

the future. Using this approach the evolution of damage under fatigue is

Current approaches to evaluate fatigue performance of con- interpreted by considering the mechanisms that influence growth

crete are empirical. Fatigue equations based on the well-known of damage in static loading. Hordijk and Reinhardt (1993) and

S – N concept have been developed and reported in the literature. Gyltoft (1983) used the cyclic cohesive zone constitutive relation-

(ACI 1982; RILEM Committee 36-RDL 1984; Oh 1991; Paskova ship for concrete obtained from the static test response to numeri-

and Meyer 1994). Oh (1991) demonstrated that the probabilistic cally simulate the crack growth in fatigue loading. Li and Matsu-

distributions of fatigue life of concrete depend on the level of tomo (1998) developed a cyclic constitutive law for frictional

applied stress. Thus, implementation of the conventional S – N bond degradation at the fiber–matrix interface and used it to pre-

approach requires time-consuming experimental data collection dict the fatigue response of fiber-reinforced cement composites.

Recently, it was shown that the different stages in the fatigue load

1

Research Associate, Center for Advanced Cement Based Materials, response of concrete could be interpreted in terms of the different

Northwestern Univ., Evanston, IL 60208-4400. mechanisms that influence the static response (Subramaniam

2

Assistant Professor, Dept. of Civil Engineering, City College of the 2000). A fracture-based mechanistic model, which provides a

City Univ. of New York, New York, NY 10031. clear understanding of the various mechanisms that influence the

3

Walter P. Murphy Professor and Director, Center for Advanced Ce- crack propagation in fatigue, was also proposed (Subramaniam

ment Based Materials, Northwestern Univ., Evanston, IL 60208-4400 1999).

(corresponding author). E-mail: s-shah@nortwestern.edu The damage evolution and the failure of concrete in uniaxial

Note. Associate Editor: Zhishen Wu. Discussion open until May 1, compression are more complex. The failure has been shown to be

2005. Separate discussions must be submitted for individual papers. To

caused by localization of damage into a zone of finite dimensions.

extend the closing date by one month, a written request must be filed with

the ASCE Managing Editor. The manuscript for this paper was submitted

The damage localizes at or close to the peak load. After the dam-

for review and possible publication on February 13, 2003; approved on age localizes, the strain distribution is not uniform along the

February 23, 2004. This paper is part of the Journal of Materials in Civil length of the specimen. After localization, the load–deformation

Engineering, Vol. 16, No. 6, December 1, 2004. ©ASCE, ISSN 0899- response of the specimen is dominated by the continued damage

1561/2004/6-566–572/$18.00. accrual in the damage zone. The deformation of the damage zone

566 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2004

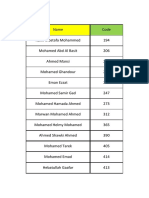

Table 1. Test Data at Peak Loads in Static Compressive Test

Peak load Axial displacement Normalized compliance

Specimen (kN) (mm) 共Cr / Ci兲

1 338.5 0.89 1.13

2 335.1 0.81 1.04

3 337.4 0.86 1.09

Average 337.0 0.85 1.05

Fig. 1. Biaxial C – T region

however been shown to compare favorably with that at the cor-

responding load in the postpeak part of the static response of a

specimen.

continues to increase while the material outside the damage zone The work presented in this paper focused at developing a

unloads (Jansen and Shah 1997). A mechanistic model of the mechanistic understanding of the fatigue response of concrete in

observed damage growth has been developed using the band- uniaxial compression. This uniaxial compression represents a

damage approach and has been successfully used to describe the boundary point in the biaxial compression–tension loading region

observed length independent response in axial compression (Jan- (C – T region), where the signs of the two principal stresses are

sen and Shah 1997). While considerable data have been reported different (Fig. 1). Static and fatigue compressive tests were con-

in the literature on the compressive fatigue of concrete, most of ducted and compared. The band-damage zone model was em-

the previous studies have been confined to generating the S – N ployed to explain the fatigue mechanism of specimens in both

curve (Oh 1991; Pakova and Meyer 1994). A mechanistic under- tests.

standing of damage growth and failure of concrete subjected to

fatigue loading in compression is still lacking.

The concept of envelope curve is often used to establish fail- Experimental Program and Test Results

ure criterion for concrete subjected to fatigue loads. According to

this concept, parameters assessed from the static response of the The experimental program was aimed at determining the com-

specimen provide a bound for fatigue response. There is however pressive static cyclic and constant amplitude fatigue response of

little agreement regarding the choice of parameters. Deflection- concrete. Concrete cylinders 共100⫻ 200 mm兲 were used in the

based criterion has been proposed for the fatigue failure of fiber- study. The average age of the cylinders used in the static and

reinforced concrete, wherein the static response provides a bound fatigue tests was 42 days. The mixture proportions by weight of

for the strain or deflection values for the specimens subjected to the constituents were, cement: water: fine aggregate: coarse

compressive cyclic/fatigue loading (Otter and Naaman 1988). aggregate= 1.0: 0.5: 2.0: 2.0. Commercially available Type I Port-

However, the deflection-based criterion was found not applicable land cement was used. The coarse aggregate was 9.5 mm pea

for fatigue of fiber-reinforced concrete in flexure or tension gravel, which was used in the air-dried state. The water required

(Zhang et al. 1999). The deflections at fatigue failure for plain for effective absorption was determined by the guidelines given in

concrete have been also shown to be significantly different from ASTM C 127 (1994) and was accounted for in the mix. After

the corresponding deflections in the postpeak part of the static demolding at 24 h, the specimens were cured in a fog room at

response (Shah and Chandra l970; Hordijk 1991; Subramaniam et 98% relative humidity (RH) and at 23° C for 28 days. The speci-

al. 1999). The total reduction in the stiffness at fatigue failure has mens were then placed in the laboratory environment until tested.

Fig. 2. Load–displacement response of cylinder in compressive test: (a) static test and (b) fatigue test

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2004 / 567

Table 2. Postpeak Normalized Compliance 共Cr / Ci兲 and Axial Displacement in Static Compressive Test

Prepeak 90% postpeak load 80% postpeak load 70% postpeak load

Specimen 共Ci / Ci兲 Cr / Ci (displacement, mm) Cr / Ci (displacement, mm) Cr / Ci (displacement, mm)

1 1.0 1.21 (0.97) 1.43 (1.02) 1.56 (1.04)

2 1.0 1.12 (0.92) 1.39 (1.02) 1.59 (1.09)

3 1.0 1.18 (1.02) 1.43 (1.09) 1.56 (1.14)

Average 1.0 1.16 (0.97) 1.41 (1.04) 1.56 (1.09)

Note: The axial displacement at x% postpeak load was measured at the starting unloading point in the load–displacement curve.

The average 28 day compressive strength was equal to 35 MPa. cycled between the upper and lower load limits up to failure. In a

typical test, data was acquired for seven load cycles every time

the stiffness of the specimen changed by a certain threshold value.

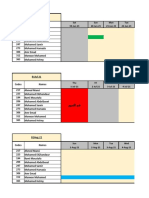

Static Compressive Response

Within each load cycle, data was acquired at time increments of

Static compressive tests were performed by unloading the speci- 0.05 s. Data processing, which involved filtering and analyzing

mens at different load levels in the postpeak part of the load the collected data to determine the change in stiffness at different

response. Specifically, each specimen was unloaded at load levels stages in the fatigue life of a specimen, was performed using a

corresponding to 90, 80, and 70% of the peak load for that speci- computer program.

men and reloaded to the load envelope. The specimens were ini- Typical load response from a constant amplitude fatigue test is

tially loaded in circumferential control using a closed-loop test shown in Fig. 2(b). There is a steady increase in the axial com-

machine (see Table 1). The load was applied to the cylinders such pliance of the specimen with repeated loading as seen by the

that the circumferential expansion of the cylinder measured using decreasing slope of the load–unloading curves. Secant stiffness

an extensometer mounted around the circumference of the cylin- was measured. The change in stiffness during fatigue loading for

der increased at a constant rate. Once the load reached 90% of the the same specimen is shown in Fig. 3. The normalized stiffness

peak load in the postpeak part of the load response, the test was represents the secant stiffness computed between the minimum

switched to displacement control and the load was decreased until and maximum load levels, which has been normalized with re-

it reached a value of 44.5 N. Further testing was performed in spect to the initial stiffness in the first fatigue cycle. The number

displacement control, i.e., the load was applied/reduced such that of load cycles 共N兲 has been normalized with respect to the total

the load–point displacement of the specimen increased/decreased number of fatigue cycles to failure 共N f 兲 for a given specimen. It

at a constant rate. The specimen was reloaded up to the load can be seen that the damage evolution in concrete during com-

envelope and unloaded each time the load reached the specified pressive fatigue, in term of the measured stiffness, is a S-shaped

fraction of the peak load. The load point axial displacement was curve (Fig. 3). The damage evolution appears to follow a three-

measured at the starting of the unloading process. A total of three stage trend. There is measurable drop in the axial stiffness during

specimens were tested to determine the static response in com- the first a few cycles (Region I), which is followed by a region of

pression. The average static peak load determined from the three gradual, almost linear change (Region II). The linear rate of de-

specimens was 337.0 kN. crease in Region II suggests that the damage accrues at a constant

A typical static response obtained by unloading the specimen rate in the material in this stage. This is subsequently followed by

at different points in the postpeak part of the axial load– a large and rapid decrease in stiffness prior to failure (Region III).

displacement response is shown in Fig. 2(a). Ci, and Cr are initial The rates of change in axial compliance at different stages of

and reload compliances, respectively, defined as the most linear the fatigue life for all the specimens are shown in Fig. 4. The rate

parts of the loading curves. The axial compliance increases with of axial compliance increase has been plotted as a function of the

every additional unloading–reloading cycle. This is indicated by percentage increase in the axial compliance of the specimen. The

the progressive decrease in slope of the unloading–reloading rate of compliance increase follows a two-stage process: a decel-

curves. The percentage increase in axial compliance as a function eration stage, which is followed by an acceleration stage up to the

of the percentage decrease in load in the postpeak is shown in failure. There is a distinctive inflection point in the rate of com-

Table 2. The percentage increase in axial compliance has been pliance increase marking a critical value of compliance where the

computed with respect to the initial axial compliance. The in- rate of increase in compliance changes from deceleration to ac-

crease in compliance with continued loading is an indicator of celeration. All specimens tested at the three load ranges showed

accruing damage in the material and the percentage increment in

compliance shows the level of damage in the material.

Table 3. Results from Fatigue Tests for Load Cycle of 90– 5% of Aver-

Fatigue Compressive Response age Static Compressive Strength

Fatigue tests were performed at three different load ranges. At all At fatigue failure At inflection

the three load ranges tested the lower limit in the fatigue load Cycles to Axial displacement Normalized Normalized

cycle was kept fixed at 5% of the average static peak load. Three Specimen failure (mm) compliance compliance

different upper load levels corresponding to 90, 80, and 76% of

1 3,621 0.97 1.30 1.03

the average static peak load were used for the three load ranges

(See Tables 3–5). At least three specimens were tested at each 2 338 0.86 1.22 1.03

load range. Load was applied between the upper and lower load 3 66 0.79 1.25 1.02

levels in a sinusoidal waveform at a frequency of 2 Hz. The fa-

tigue tests were performed in load control, i.e., the load was Average 1,342 0.87 1.26 1.03

568 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2004

Table 4. Results from Fatigue Tests for Load Cycle of 80– 5% of

Average Static Compressive Strength

At fatigue failure At inflection

Cycles to Axial displacement Normalized Normalized

Specimen failure (mm) compliance compliance

1 1,966 0.88 1.32 1.05

2 1,390 0.87 1.24 1.06

3 3,984 1.00 1.35 1.10

Average 2,447 0.92 1.30 1.07

consistent behavior. Similar conclusions were drawn by other re-

searchers in the fatigue flexural tests. Stang and Zhang (1994) Fig. 3. Relationship of normalized stiffness and normalized cycles

presented evidence that the relation between fatigue crack length 共76– 5 % 兲

and fatigue cycles was a S-shape curve. This S-shape curve actu-

ally implies that the crack growth rate follows a two-stage pro-

cess. Their conclusions were again verified by fatigue flexural postpeak period response is obtained. This suggests that the com-

experiments conducted by Subramaniam et al. (2000). pliance at fatigue failure can be obtained from the static response.

Hence, it can be concluded that the static response acts like an

envelope to the fatigue response when framed in terms of com-

Fatigue Failure Criterion pliance.

A comparison of the compliance at the inflection point in the

A comparison of the axial displacement at fatigue failure and fatigue response, where the rate of change in compliance changes

static load displacement response is shown in Fig. 5(a). Each data from deceleration to acceleration, and the compliance at the peak

point in the figure represents a different specimen tested in fatigue load in the static response is shown in Fig. 6. The compliance at

and different symbols correspond to different fatigue load ranges. the peak load in the static response was calculated by the

It can be seen that the axial displacement at fatigue failure, which interpolation/extrapolation as show in Fig. 7. The first extrapola-

is judged as the maximum displacement at the higher fatigue tion based on the load–displacement, points, O2, O3 and O4 to get

loading level, is not comparable to displacement obtained from cross point O0, which was the cross point of the fitting curve

the static response; the axial displacement at fatigue failure are O2 – O3 – O4 and the initial compliance OO0 共Ci兲. Then interpola-

considerably smaller than the axial displacement at the corre- tion was employed to get the unload compliance at the peak load

sponding load in the static postpeak. Therefore, a failure criterion 共Crpeak兲, based on the load–unload compliance relationship of Ci,

based on static deflections may not be suitable for plain concrete Cr90%peak, Cr80%peak, and Cr70%peak. The critical compliance in the

subjected to uniaxial compressive fatigue. Similar observations fatigue test is found to correspond to the compliance at the peak

have been reported from the previous research in the biaxial load in the static test (Fig. 6).

t – C – T region.

A comparison of the compliances (inverse of stiffness) at the

fatigue failure and at the corresponding load in the postpeak static

Prediction of Fatigue Life from Fatigue Response

response is shown in Fig. 5(b). The compliance at the fatigue

failure was determined by the smallest compliance in the load– Fig. 8 shows a plot of the slope of the decrease in compressive

displacement curve. The compliance at a static test was obtained stiffness dK / dN, in Stage II of fatigue response versus the fatigue

from the unloading response at a given load level. Each solid life N f for all the specimens (where K, N, and N f are stiffness,

symbol corresponds to a different specimen tested in fatigue and cycle, and fatigue life, respectively). The response of all the fa-

the hollow symbols correspond to the compliance obtained from tigue specimens tested at three different loading ranges follows a

static load response. It can be seen that a favorable comparison linear trend. This suggests that a larger slope in Region II is

between the compliance at fatigue failure and that obtained at the

load corresponding to the maximum fatigue load in the static

Table 5. Results from Fatigue Tests for Load Cycle of 76– 5% of

Average Static Compressive Strength

At fatigue failure At inflection

Cycles to Axial displacement normalized normalized

Specimen failure (mm) compliance compliance

1 15,256 0.93 1.39 1.04

2 15,906 0.97 1.52 1.04

3 18,656 0.97 1.54 1.03

4 11,174 0.88 1.43 1.04

Average 15,248 0.94 1.47 1.04 Fig. 4. Compliance change rate versus compliance

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2004 / 569

Fig. 5. Comparison of static and fatigue response: (a) load–displacement and (b) load–compliance

associated with a smaller number of cycles to fatigue failure 共N f 兲. of concrete (Stang and Zhang 1994). The applicability of Eq. (1)

A larger rate of damage accrual results in decreased fatigue life. for different minimum load levels needs to be studied.

The relationship between the slope of Stage II and the number of

cycles to fatigue failure obtained using least squares approxima-

tion is given as Fatigue Failure Mechanism

log共N f 兲 = − 0.9444* log共dK/dN兲 + 2.5134 共1兲 In static compression, the damage zone of specimen has a non-

It is interesting to find that the relationship between the slope uniform distribution as shown in Fig. 9(a). From previous study

of Stage II and fatigue life is independent of the load range (Fig. (Jansen and Shah 1997), this damage zone can be modeled as a

8). This suggests that the fatigue life can be determined or pre- band damage zone [Fig. 9(b)]. Using the band damage zone

dicted from Eq. (1) for any load range if the slope in Stage II of model, two distinct areas of the concrete sample can be described;

the fatigue response is known. In practice, Stage I may represent bulk concrete and damage zone. Localization initiates at the peak

the first few months and the Stage II may represent a long time stress or just prior to the peak stress. In either case, the shape of

before the airport pavement needs to be repaired. Since Stage I is the stress–strain curve up to the peak can be considered approxi-

quite short and the slope of Stage II shows almost a linear trend, mately the same in the bulk concrete and the eventual damage

engineers are able to predict the fatigue life of the airport pave- zone. During prepeak the same amount of energy per unit volume

ment by conducting the fatigue test with just a few cycles. When-

ever Stage II and the stiffness change rate in stage II are deter-

mined, Eq. (1) can be employed. However, it should be noted that

Eq. (1) is only applicable for a certain range of load level, for

example, higher than the threshold load level of the materials. In

addition, the minimum load level also influences the fatigue life

Fig. 6. Comparison of compliance at fatigue inflection point and that Fig. 7. Interpolation/extrapolation for compliance at peak load in

at static peak load static test

570 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2004

Fig. 8. Relationship between decrease rate of stiffness in stage II of

fatigue response and fatigue life

Fig. 10. Comparison of static and fatigue response: load–postpeak

dissipated in bulk concrete and damage zone due to microcrack- inelastic displacement in damage zone

ing [Fig. 9(c)]. During postpeak, the bulk concrete unloads. Ad-

ditional energy is dissipated in the damage zone. If assuming that

the total strain in the damage zone is composed of two parts

linearly: one similar to the bulk concrete b and the additional compression, govern the fatigue failure mechanism. The fatigue

inelastic strain in the localized damage zone, one can write failure under compression is also a localized phenomenon. The

relationship of load–postpeak inelastic displacement obtained

z = b + ␦/l 共2兲 from the static test acts as the envelope curve for the fatigue test.

where the length of the damage zone l is independent of the

length of specimen L and the postpeak inelastic displacement ␦

that substracts the prepeak response of concrete from the postpeak Discussion

displacements can approximately describe the inelastic, localized

The static load–response can be visualized as a failure envelope

deformations occurring during strain softening. This means that

curve, where each point in the postpeak region is an equilibrium

no matter how long the specimens the postpeak behaviors in com-

point representing the maximum load that can be supported for a

pression are the same. The postpeak energies are essentially inde-

given level of damage in the damage zone. Therefore every point

pendent of the specimen length. This independence of the post-

on the postpeak load envelope can be characterized by a given

peak compressive fracture energy again confirms the occurrence

damage level in the damage zone. Further, it can be implicitly

of localization as modeled.

assumed that the change in compliance of a specimen in the post-

This band damage zone model is employed to explore the

peak is due to accruing damage in the specimen and the increase

fatigue failure mechanism of concrete airport pavement. Fig. 10

in compliance is indicative of the increase in the level of damage

gives a comparison of these postpeak inelastic displacements at

in the damage zone.

different loading levels from the static test and the fatigue test. In

The favorable comparison between the compliance at the in-

the fatigue test, the postpeak inelastic displacement is calculated

flection point in the fatigue response and the static peak load

by the failure displacement which substracts the displacement at

indicates that the damage level is comparable for the two load-

the compliance rate inflection point (Fig. 4). A good agreement is

ings. A similar conclusion can also be drawn from the favorable

found. This means that the static postpeak displacements, which

comparison between the percentage decrease in stiffness in fa-

approximately describe the localization displacements in static

tigue and static postpeak.

As can be seen from Fig. 1, uniaxial compression and uniaxial

tension represent two boundary points of the biaxial C – T region,

respectively. Within this biaxial region the mode of failure

changes from a highly localized cracking associated with a tensile

loading to a crushing type of failure due to compressive stresses.

Previous research on high amplitude fatigue response of concrete

subjected to biaxial stresses in the tensile–compression–tension

共t – C – T兲 region, where the principal tensile stress is larger in

magnitude than the principal compressive stress (Fig. 1), sug-

gested the following: (1) the structural compliance in constant

amplitude fatigue loading was a two-phase process: a deceleration

phase followed by an acceleration stage; and (2) static load enve-

lope was shown to predict the crack length or structural compli-

ance at fatigue failure. The primary mode of failure in this biaxial

stress region was shown to be crack propagation. The observed

trends in fatigue crack growth were explained based on the

Fig. 9. Band damage zone model for localization behavior in com- mechanisms that influence crack growth in static loading. The

pression: (a) distributed damage, (b) band-damage distribution, and fatigue crack growth models were developed using fracture-based

(c) bulk concrete behavior and damage zone behavior parameters. Details of the experimental work and the analytical

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2004 / 571

model for the material response are available in Subramaniam et Brill is the Project Manager at the FAA Airport Technology R&D

al. (1998, 1999, 2000, 2002) and Subramaniam (1999). Branch. The writers acknowledge the support from the NSF Cen-

The experimental results in uniaxial compression are qualita- ter for ACBM, Northwestern University during the course of this

tively in agreement with those obtained from the t – C – T region. investigation.

Thus it appears that the findings from previous research can be

extended to this point of the c – C – T region (Fig. 1), except for

the terms related to the length of crack. As to the crack informa- References

tion, there is no simple way to characterize such information in

the compressive test, because the cracks are not distinctly local- American Concrete Institute (ACI). Committee 215. (1982). “Fatigue of

concrete structures.” SP-75, S. P. Shah, ed., Detroit.

ized as that in tension. However, using the concept of the post-

Baluch, M. H., Qureshy, A. B., and Azad, A. K. (1987). “Fatigue crack

peak inelastic displacement and band damage zone, the fatigue

propagation in plain concrete.” Proc., SEM/RILEM Int. Conf. on

failure mechanism can still be modeled based on the static results.

Fracture of Concrete and Rock, S. P. Shah and S. E. Swartz, eds.

Houston, 80–87.

Conclusion Bazant, Z. P., and Schell, W. F. (1993). “Fatigue fracture of high strength

concrete and size effect.” ACI Mater. J., 90(5), 472–478.

The concrete airport pavement subjected to static and low fre- Bazant, Z. P., and Xu., K. (1991). “Size effect in fatigue fracture of

concrete.” ACI Mater. J., 88(4), 390–399.

quency, high amplitude fatigue compressive loading was studied.

Gyltoft, K. (1983). “Fracture mechanics models for fatigue in concrete

This loading case is a special point in the biaxial c – C – T region. structures.” PhD thesis, Lulea Univ. of Technology.

The experimental results are shown to be very similar to those in Hordijk, D. A. (1991). “Local approach to fatigue of concrete.” PhD

the t – C – T region from the previous research. The fatigue infor- dissertation, Delft Univ., Delft, The Netherlands.

mation can be obtained from the corresponding static results Hordijk, D. A., and Reinhardt, H. W. (1983). “Numerical and experimen-

under the term of structural compliance. This implies that the tal investigation into the fatigue behavior of plain concrete.” Exp.

method, theory, and model proposed in the t – C – T region are Mech., 83(4), 278–285.

verified and can be extended to this special point (point iv) in the Jansen, D. C., and Shah, S. P. (1997). “Effect of length on compressive

c – C – T region. Future study will focus on a general point in the strain softening of concrete.” J. Eng. Mech., 123(1), 25–35.

c – C – T region, i.e., point v, where the principle compressive Li, V. C., and Matsumoto, T. (1998). “Fatigue crack growth analysis of

fiber reinforced concrete with effect of interfacial bond degradation.”

stress is larger, in magnitude, than the principle tensile stress.

Cem. Concr. Compos., 20, 339–351.

Based on the results presented in this paper, the following main

Oh, B. H. (1991). “Fatigue-life distributions of concrete for various stress

conclusions can be drawn: levels.” ACI Mater. J., 88(2), 122–128.

1. a deflection based failure criterion is not suitable for concrete Otter, D. E., and Naaman, A. E. (1988). “Properties of steel fiber-

subjected to compressive fatigue loading; reinforced concrete under cyclic loading.” ACI Mater. J., 85(4), 254–

2. the response of the load–postpeak inelastic displacement/ 261.

structural compliance obtained from static loading acts as a Paskova, T., and Meyer, C. (1994). “Optimum number of specimens for

failure envelope curve for fatigue loading; low-cycle fatigue tests of concrete.” J. Struct. Eng., 120(7), 2242–

3. structural compliance change rate has two stages: a decelera- 2247.

tion stage followed by an acceleration stage up to failure. Perdikaris, P. C., and Calomino, A. M. (1987). “Kinetics of crack growth

The compliance at the rate inflection point in the fatigue test in plain concrete.” Proc., SEM/RILEM Int. Conf. on Fracture of Con-

corresponds to the compliance at the peak load in the static crete and Rock, S. P. Shah and S. E. Swartz, eds., Houston, 64–69.

RILEM Committee 36-RDL (1984). “Long term random dynamic load-

test.

ing of concrete structures.” Mater. Constr. (Paris), 17(9), 1–28.

4. the damage evolution in concrete during compressive fa- Shah, S. P., and S. Chandra. (1970). “Fracture of concrete subjected to

tigue, in terms of the measured compliance, follows a three- cyclic and sustained loading.” J. Am. Concr. Inst., 67(9), 816–825.

stage trend. Fatigue life can be predicted by the slope of the Stang, H., and Zhang, J. (1994). “Experimental determination of fatigue

stiffness in Stage II and the relationship between the slope of crack growth in fiber reinforced concrete.” Recent advances in experi-

Stage II and fatigue life is independent of the fatigue load mental mechanics, J. F. Silva Gomez et al., eds., A. A. Balkema,

range. Rotterdam, The Netherlands, 1347–1352.

5. the fatigue failure mechanism can be explained by the band Subramaniam, K. V. (1999). “Fatigue of concrete subjected to biaxial

damage zone model and agrees with that of the static com- loading in the tension region.” PhD dissertation, Northwestern Univ.,

pressive test. The postpeak inelastic displacement and the Evanston, Ill.

length of the damage zone are independent of the length of Subramaniam, K. V., O’Neil, E., Popovics, J. S., and Shah, S. P. (2000).

the specimen. “Crack propagation in flexural fatigue of concrete: Experiments and

theoretical model.” J. Eng. Mech., 126(9), 891–898.

Subramaniam, K. V., Popovics, J. S., and Shah, S. P. (1998). “Testing

Acknowledgments concrete in torsion: Instability analysis and experiments.” J. Eng.

Mech., 124(11), 1258–1268.

The paper was prepared from a study conducted at the Center of Subramaniam, K. V., Popovics, J. S., and Shah, S. P. (1999). “Fatigue

Excellence for Airport Pavement Research. Funding for the Cen- behavior of concrete subjected to biaxial stresses in the C – T region.”

ACI Mater. J., 96(6), 663–669.

ter of Excellence is provided in part by the Federal Aviation Ad-

Subramanian, K. V., Popovics, J. S., and Shah, S. P. (2002). “Fatigue

ministration under Research Grant No. 03-128/DOT-95-C-001/ fracture of concrete subjected to biaxial stresses in the tensile C – T

Al 8. The Center of Excellence is maintained at the University of Region.” J. Eng. Mech., 128(6), 668–676.

Illinois at Urbana-Champaign and is in partnership with North- Zhang, J., Stang, H., and Li, V. C. (1999). “Fatigue life prediction of fiber

western University and the Federal Aviation Administration. Pa- reinforced concrete under flexural load,” Int. J. Fatigue, 21(10),

tricia Watts is the FAA-COE Program Director and Dr. David 1033–1049.

572 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER/DECEMBER 2004

View publication stats

Вам также может понравиться

- Deformation of Progressively Cracking Reinforced Concrete BeamsДокумент11 страницDeformation of Progressively Cracking Reinforced Concrete BeamsCE19D506 Shaik Farooq AhamedОценок пока нет

- Misurata UniversityДокумент11 страницMisurata UniversityDustin EllisОценок пока нет

- Valliappan1996 PDFДокумент27 страницValliappan1996 PDFDaniel EscobarОценок пока нет

- Discusion A Ju 2000bДокумент4 страницыDiscusion A Ju 2000bFreddy GonzalesОценок пока нет

- ACEPS-2015 Simulation of Low Cycle FatigueДокумент9 страницACEPS-2015 Simulation of Low Cycle FatigueRabindraSubediОценок пока нет

- 1 s2.0 S1359836816310939 MainДокумент8 страниц1 s2.0 S1359836816310939 MainRavindu ChavindaОценок пока нет

- Experimental and Theoretical Dynamic System Identification of Damaged RC BeamsДокумент11 страницExperimental and Theoretical Dynamic System Identification of Damaged RC BeamsKy Visoth SambathОценок пока нет

- 1 s2.0 S0142112308001539 Main PDFДокумент9 страниц1 s2.0 S0142112308001539 Main PDFHARSHVARDHAN SINGHОценок пока нет

- Paper 29Документ10 страницPaper 29Rieza Zulfahmi TaftazaniОценок пока нет

- Gokhale - Effect of Loading History On Axial Cyclic Behaviour of RC Prisms Representing Wall Boundary Zones PDFДокумент21 страницаGokhale - Effect of Loading History On Axial Cyclic Behaviour of RC Prisms Representing Wall Boundary Zones PDFKamirã Barbosa RibeiroОценок пока нет

- BazantДокумент11 страницBazantHernan David Florez OlivaresОценок пока нет

- Abdullah 2021 IOP Conf. Ser. Mater. Sci. Eng. 1144 012033Документ8 страницAbdullah 2021 IOP Conf. Ser. Mater. Sci. Eng. 1144 012033GenОценок пока нет

- Review Papers Fatigue Behavior of Fiber-Reinforced Polymer Composites-A ReviewДокумент8 страницReview Papers Fatigue Behavior of Fiber-Reinforced Polymer Composites-A ReviewNeelkant PatilОценок пока нет

- 2 Fatigue Crack Growth Prediction in Concrete SlabsДокумент9 страниц2 Fatigue Crack Growth Prediction in Concrete Slabsmohammed abrahimeОценок пока нет

- Paper 3 - 2011Документ10 страницPaper 3 - 2011Halyna HafiychukОценок пока нет

- Organizedby Centro Internazionaledi Aggiornamento SperimentaleДокумент18 страницOrganizedby Centro Internazionaledi Aggiornamento SperimentaleFernando SmithОценок пока нет

- Blast Load Analysis and Simulation of Unreinforced Concrete MasonryДокумент13 страницBlast Load Analysis and Simulation of Unreinforced Concrete MasonryJuanОценок пока нет

- Fatigue Analysis of Steel Jacket Platform in Shallow Water Depth in The Gulf of GuineaДокумент12 страницFatigue Analysis of Steel Jacket Platform in Shallow Water Depth in The Gulf of GuineaAlireza Asgari MotlaghОценок пока нет

- Dey Et Al. (2019)Документ12 страницDey Et Al. (2019)MOHIT SHARMAОценок пока нет

- Findingr Factor0Документ8 страницFindingr Factor0Laxmith ShettyОценок пока нет

- Fatigue of Concrete Under Uniaxial Compression Cyclic LoadingДокумент7 страницFatigue of Concrete Under Uniaxial Compression Cyclic LoadingHCStepОценок пока нет

- Cyclic Loading AdalahДокумент13 страницCyclic Loading AdalahsyaniliffaОценок пока нет

- Concrete Cracking inДокумент9 страницConcrete Cracking inmutiaralfiantiОценок пока нет

- Stress-Strain Model For Concrete Under Cyclic LoadingДокумент14 страницStress-Strain Model For Concrete Under Cyclic LoadingRory Cristian Cordero RojoОценок пока нет

- Stress-Strain Model For Concrete Under Cyclic Loading Aslani PDFДокумент14 страницStress-Strain Model For Concrete Under Cyclic Loading Aslani PDFEnggHabibUlAlamОценок пока нет

- NAOSITE: Nagasaki University's Academic Output SITE: This Document Is Downloaded At: 2016-09-13T03:52:09ZДокумент31 страницаNAOSITE: Nagasaki University's Academic Output SITE: This Document Is Downloaded At: 2016-09-13T03:52:09ZponjoveОценок пока нет

- Tabeshpour A 10 57 1 77f3196Документ9 страницTabeshpour A 10 57 1 77f3196Irfan KhanОценок пока нет

- Seismic Design and Performance of An High RCC Dam: A. Aldemir, U. Akpınar, Y. Arıcı & B. BiniciДокумент10 страницSeismic Design and Performance of An High RCC Dam: A. Aldemir, U. Akpınar, Y. Arıcı & B. BiniciManuel SueroОценок пока нет

- Jgge01 Embankment StabilityДокумент10 страницJgge01 Embankment StabilityEric ChanОценок пока нет

- Dymitis Et Al.Документ10 страницDymitis Et Al.fsimaОценок пока нет

- Faria - Oliver - Cervera (1997) - Modeling Material Failure in Concrete Structures Under Cyclic ActionsДокумент9 страницFaria - Oliver - Cervera (1997) - Modeling Material Failure in Concrete Structures Under Cyclic ActionsSalvatore MirandaОценок пока нет

- Concrete Cracking in Tension Members and Application To Deck Slabs of BridgesДокумент9 страницConcrete Cracking in Tension Members and Application To Deck Slabs of BridgesTardzenyuy GlenОценок пока нет

- Behaviour of Reinforced Concrete Frame Structures With Construction Joints Under Lateral Loads (1998) (10.1680 - Macr.1998.50.2.133) - LДокумент13 страницBehaviour of Reinforced Concrete Frame Structures With Construction Joints Under Lateral Loads (1998) (10.1680 - Macr.1998.50.2.133) - Losvaldo contrerasОценок пока нет

- Seismic Design of Composite Metal Deck and Concrete Filled Diaphragms A Discussion Paper Cowie Hicks Macrae Clifton FussellДокумент11 страницSeismic Design of Composite Metal Deck and Concrete Filled Diaphragms A Discussion Paper Cowie Hicks Macrae Clifton Fussellmongkol_1001Оценок пока нет

- Fatigue Strength of ConcreteДокумент59 страницFatigue Strength of ConcreteElango PaulchamyОценок пока нет

- Li Jun 2013Документ233 страницыLi Jun 2013hahaerОценок пока нет

- Analytical Stress-Strain Model and Damage Index FoДокумент11 страницAnalytical Stress-Strain Model and Damage Index Fomhmdwalid95Оценок пока нет

- Final Project PDFДокумент6 страницFinal Project PDFabatharОценок пока нет

- Final Year Project Proposal: UET Peshawa R Campus IiiДокумент14 страницFinal Year Project Proposal: UET Peshawa R Campus IiiJehangeer Alam 17bnciv0912Оценок пока нет

- Elastic Plastic Response Spectra For Exponential Blast LoadingДокумент21 страницаElastic Plastic Response Spectra For Exponential Blast LoadingNanny LeeОценок пока нет

- Metal Fatigue OverviewДокумент59 страницMetal Fatigue OverviewMahesh RajaОценок пока нет

- Fatigue Analysis of Fixed Jacket Platform Using FEMДокумент11 страницFatigue Analysis of Fixed Jacket Platform Using FEMsaulolmОценок пока нет

- Omae2008-57 148Документ10 страницOmae2008-57 148ahmadОценок пока нет

- Building Pounding State of The Art Identifying STRДокумент10 страницBuilding Pounding State of The Art Identifying STRROLANDO PUMAОценок пока нет

- Concrete Damage Assessment For Blast Load Using Pressure-Impulse DiagramsДокумент10 страницConcrete Damage Assessment For Blast Load Using Pressure-Impulse DiagramsaomareltayebОценок пока нет

- ARABICДокумент33 страницыARABICAamir BalochОценок пока нет

- Dynamic Increase Factor For Pushdown Analysis of Seismically Designed Steel Moment-Resisting FramesДокумент19 страницDynamic Increase Factor For Pushdown Analysis of Seismically Designed Steel Moment-Resisting FramestirursachinОценок пока нет

- Developing A Track Model For Testing The Road Pavement Under Repeated Decelerations of VehiclesДокумент9 страницDeveloping A Track Model For Testing The Road Pavement Under Repeated Decelerations of VehiclesRaja RajanОценок пока нет

- Seong Et Al. - Inelastic Performance of High-Strength Concrete Bridge Columns Under Earthquake Loads - Unknown - 2011Документ16 страницSeong Et Al. - Inelastic Performance of High-Strength Concrete Bridge Columns Under Earthquake Loads - Unknown - 2011Heber Jorge ValenzuelaОценок пока нет

- A Study of Dynamic PullДокумент8 страницA Study of Dynamic PullHEMANTH KUMAR CОценок пока нет

- 2011 - 1 s2.0 S0142112311002866 MainДокумент11 страниц2011 - 1 s2.0 S0142112311002866 MainMd MehtabОценок пока нет

- CaldIn-plane Strength of Unreinforced Masonry PiersДокумент25 страницCaldIn-plane Strength of Unreinforced Masonry PiersDaniele Di LucaОценок пока нет

- Raghavan-Failure Analysis of Lattice Tower Like StructuresДокумент9 страницRaghavan-Failure Analysis of Lattice Tower Like StructuresRm1262Оценок пока нет

- Numerical Prediction of Concrete Slab Response To Blast LoadingДокумент15 страницNumerical Prediction of Concrete Slab Response To Blast LoadingOmer PolatОценок пока нет

- On Fatigue Failure Prediction With Damage Mechanics: Theory and ApplicationДокумент239 страницOn Fatigue Failure Prediction With Damage Mechanics: Theory and ApplicationMona AwadОценок пока нет

- Woo Chanjo 2017Документ14 страницWoo Chanjo 2017Said HaggagОценок пока нет

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesДокумент18 страницJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321Оценок пока нет

- PIIS2352012414000034Документ10 страницPIIS2352012414000034Miguel MОценок пока нет

- Study and Analysis of Crane Hook in Loading AreaДокумент2 страницыStudy and Analysis of Crane Hook in Loading Areamukeshsonava076314Оценок пока нет

- Book 1Документ3 страницыBook 1mohammedelshafieОценок пока нет

- Modeling of Human Structure Interaction in Vibration AnalysisДокумент1 страницаModeling of Human Structure Interaction in Vibration AnalysismohammedelshafieОценок пока нет

- Structure Vacations - 2022Документ20 страницStructure Vacations - 2022mohammedelshafieОценок пока нет

- Structure Vacations - 2023Документ1 страницаStructure Vacations - 2023mohammedelshafieОценок пока нет

- CodesДокумент1 страницаCodesmohammedelshafieОценок пока нет

- SLS Check - Ec2 - General SectionДокумент7 страницSLS Check - Ec2 - General SectionmohammedelshafieОценок пока нет

- Structure VacationsДокумент15 страницStructure VacationsmohammedelshafieОценок пока нет

- Modeling of Human Structure Interaction in Vibration AnalysisДокумент1 страницаModeling of Human Structure Interaction in Vibration AnalysismohammedelshafieОценок пока нет

- SoilMech Ch8 EC7 RequirementsДокумент10 страницSoilMech Ch8 EC7 RequirementsarslanpasaОценок пока нет

- FEM 5node 5memДокумент7 страницFEM 5node 5memBhaskar NandiОценок пока нет

- 5.col Spiral Square, Core SquareДокумент2 страницы5.col Spiral Square, Core SquaremohammedelshafieОценок пока нет

- 4.col Spiral Square, Core CircularДокумент2 страницы4.col Spiral Square, Core CircularmohammedelshafieОценок пока нет

- 3.col Spiral CircularДокумент2 страницы3.col Spiral CircularmohammedelshafieОценок пока нет

- BaseplateДокумент3 страницыBaseplateDushyantha JayawardenaОценок пока нет

- Euro Steel Beam Load and Restr On Bottom FlangeДокумент2 страницыEuro Steel Beam Load and Restr On Bottom FlangeMario FeghaliОценок пока нет

- 1Документ2 страницы1mohammedelshafieОценок пока нет

- 2.col Tied CircularДокумент2 страницы2.col Tied CircularmohammedelshafieОценок пока нет

- Kyoto UniversityДокумент21 страницаKyoto UniversitymohammedelshafieОценок пока нет

- Design of Members: Rui SimõesДокумент53 страницыDesign of Members: Rui SimõesciposОценок пока нет

- (Designers' Guides To The Eurocodes) Gulvanessian, H. - Calgaro, Jean-Armand - Holický, Milan - Designer's Guide To EN 1990 - Eurocode - Basis of Structural Design (2002, Thomas Telford Publi PDFДокумент235 страниц(Designers' Guides To The Eurocodes) Gulvanessian, H. - Calgaro, Jean-Armand - Holický, Milan - Designer's Guide To EN 1990 - Eurocode - Basis of Structural Design (2002, Thomas Telford Publi PDFmohammedelshafieОценок пока нет

- The Complete MARILLION Discography V2 PDFДокумент13 страницThe Complete MARILLION Discography V2 PDFtotalmenteprovisorioОценок пока нет

- Viaje Del SolДокумент3 страницыViaje Del SolJanella UmiehОценок пока нет

- Pepperdine Resume Ico William Kong Updated BДокумент1 страницаPepperdine Resume Ico William Kong Updated Bapi-278946246Оценок пока нет

- ABB - Composite Station Post InsulatorsДокумент6 страницABB - Composite Station Post InsulatorsDominic SantiagoОценок пока нет

- Examples and Non-ExamplesДокумент5 страницExamples and Non-ExamplesslidegaeОценок пока нет

- SCCA2103 Leadership CommunicationДокумент6 страницSCCA2103 Leadership CommunicationsarahОценок пока нет

- Jeeves in The SpringtimeДокумент14 страницJeeves in The SpringtimearavindpunnaОценок пока нет

- TEST Unit 5Документ5 страницTEST Unit 5Giang Nguyen Thi ThuОценок пока нет

- Surge CounterДокумент2 страницыSurge CounterJavier CuzcoОценок пока нет

- MC68 HC05 B4 UДокумент253 страницыMC68 HC05 B4 Uflo724Оценок пока нет

- Paket B Listening Ujian Sekolah Bahasa Inggris SMK Tahun Pelajaran 2022-2023Документ3 страницыPaket B Listening Ujian Sekolah Bahasa Inggris SMK Tahun Pelajaran 2022-2023Nadiah PutriОценок пока нет

- Lecture 12 Public Administration and Development 2017Документ23 страницыLecture 12 Public Administration and Development 2017Raheel Joyia100% (1)

- Evaluation - Chemical Pit - 0Документ8 страницEvaluation - Chemical Pit - 0Aiman AmirullahОценок пока нет

- Stulz C7000R 01 PDFДокумент198 страницStulz C7000R 01 PDFNarciso Torres0% (1)

- DLL - English 5 - Q3 - W8Документ8 страницDLL - English 5 - Q3 - W8Merlyn S. Al-osОценок пока нет

- Lesson4 1515Документ14 страницLesson4 1515gm hashОценок пока нет

- Sharp Service Manual Models Lc-40sh340k and Lc-40sh340e With Chassis 17mb60Документ106 страницSharp Service Manual Models Lc-40sh340k and Lc-40sh340e With Chassis 17mb60murtibing100% (1)

- JRX118SP SpecsheetДокумент2 страницыJRX118SP SpecsheetLuisОценок пока нет

- Topic 2 Evidencias Clase 7 L Reading - Young PilotsДокумент4 страницыTopic 2 Evidencias Clase 7 L Reading - Young PilotsJam C. PoloОценок пока нет

- Cop4600 Exam1 sp13Документ2 страницыCop4600 Exam1 sp13chavОценок пока нет

- PT2 Exam CLASS XI CS 2023Документ2 страницыPT2 Exam CLASS XI CS 2023Aditya AurangeОценок пока нет

- C79 Service Kits and Parts List: CAP179 - C79 Aug 2017 - Rev AДокумент32 страницыC79 Service Kits and Parts List: CAP179 - C79 Aug 2017 - Rev Arobert100% (2)

- Tutorial 4 Chapter 4 - CorrosionДокумент2 страницыTutorial 4 Chapter 4 - CorrosionHafizatul AqmarОценок пока нет

- Michael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972Документ13 страницMichael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972earthcrosserОценок пока нет

- Symposium's Platonic LoveДокумент10 страницSymposium's Platonic LovezkottОценок пока нет

- Equinoxes and Solstices: UttarayanamДокумент2 страницыEquinoxes and Solstices: UttarayanamRahul SharmaОценок пока нет

- STIGA - Vue Eclatée Moteur BRIGGS & STRATTONДокумент32 страницыSTIGA - Vue Eclatée Moteur BRIGGS & STRATTONregis.petitjeanОценок пока нет

- English Is The Window To The World. MimieДокумент2 страницыEnglish Is The Window To The World. MimieFARAH NADIAОценок пока нет

- Grieving The Loss of A Life You WantedДокумент11 страницGrieving The Loss of A Life You WantedNiftyОценок пока нет

- Belbin's Team ModelДокумент2 страницыBelbin's Team Modelsonu_saisОценок пока нет