Академический Документы

Профессиональный Документы

Культура Документы

104 09 Controllable Diaphragm Pumps C4xx 2

Загружено:

PAUL LIMAОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

104 09 Controllable Diaphragm Pumps C4xx 2

Загружено:

PAUL LIMAАвторское право:

Доступные форматы

Controllable diaphragm pumps

C 409.2, C 410.2

The 4 C-designs

intelligent, multifunctional, versatile, economic...

sera controllable diaphragm pumps ...further features of performance

of serie C 409.2 and C 410.2 are electronically con- directly controllable

trolled dosing pumps which can be used for many ap- PROFIBUS DP - Interface

plications. They are designed for industrial use and high dosing accuracy

*

guarantee highest operational reliability. long service live of diaphragms

Performance range between 0,8 l/h and 1450 l/h, high-quality materials

pressures up to max. 10 bar. linear control characteristic

low maintenance

Application low operating expenses

leakagefree

Liquid chemicals with aggressive, odorous, unlimitedly safe to run dry

abrasive, flammable, viscous or toxic properties. easy to operate

low weight

* compared to common conventional diaphragms

Controllable diaphragm pumps

C 409.2, C 410.2

Functions of the

control electronics

Function

Manual operation

Manual stroke frequency adjustment

PROFIBUS DP - Interface

External ON

External STOP

Pulse operation

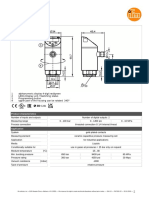

Controllable diaphragm pump, type C 409.2

Fractionation

Cycle delay

Analogue operation (PROFIBUS)

1)

Analogue operation 0 – 20 mA

1)

Analogue operation 4 – 20 mA

1)

Analogue operation standardization

Charge manual 1)

External charge START

Charge with timer 1)

Speed control / Slow mode

3 LEDs for status indication

Multiline illuminated text display

Operating messages in plain text

Fault indication in plain text

Menu - driven parameterization

Controllable diaphragm pump, type C 410.2 (0,37 kW) Flow indication

Calibration

Working hour meter

Password protection

4 – key operation

2 digital outputs (PLC) 1)

1)

1 digital input (PLC or contact signal)

1)

2 analogue / digital inputs (optionally reversible)

1)

Programmable input-/output functions

Connection / evaluation 2-stage level monitoring

Connection / evaluation diaphragm rupture monitoring

Connection / evaluation flow monitoring

Connection / evaluation flow metering

Operating panel for wall mounting (option)

Controllable diaphragm pump, type C 410.2 (0,75 ... 1,5 kW)

1)

inapplicable when supplied with PROFIBUS DP-interface

Controllable diaphragm pumps

C 409.2, C 410.2

Technical data

Pump type Nominal capacity

max. counter- max. suction Inlet-/Outlet- Driving power Nominal stroke-

pressure height size (motor) frequency

50/60Hz Qstroke p2 max. DN PM 50/60Hz

C 409.2 [l/h] [ml/Stroke] [bar] [mWC] [mm] [kW] [l/h]

C 409.2 – 0,8e 0 – 0,8 0 – 0,13 10 2 5 0,18 100

C 409.2 –1,6e 0 – 1,6 0 – 0,27 10 3 5 0,18 100

C 409.2 –2,4e 0 – 2,4 0 – 0,27 10 3 5 0,18 150

C 409.2 –4,0e 0 – 4,0 0 – 0,67 10 3 5 0,18 100

C 409.2 –7,0e 0 – 7,0 0 – 0,78 10 3 5 0,18 150

C 409.2 –12e 0 – 12 0 – 3,0 10 3 10 0,18 67

C 409.2 – 18e 0 – 18 0 – 3,0 10 3 10 0,18 100

C 409.2 – 25e 0 – 25 0 – 2,8 10 3 10 0,18 150

C 409.2 – 50e 0 – 50 0 – 8,3 10 3 10 0,18 100

C 409.2 – 75e 0 – 75 0 – 8,3 10 3 15 0,37 150

C 409.2 – 90e 0 – 90 0 – 15,0 8 3 15 0,37 100

C 409.2 – 115e 0 – 115 0 – 19,2 4 3 15 0,37 100

C 409.2 – 140e 0 – 140 0 – 15,6 8 3 15 0,37 150

C 409.2 – 180e 0 – 180 0 – 20,0 4 3 15 0,37 150

C 409.2 – 250e 0 – 250 0 – 41,7 3 3 15 0,37 100

C 409.2 – 350e 0 – 350 0 – 38,9 3 3 15 0,37 150

C 410.2

C 410.2 – 260e 0 – 260 0 – 48 4 5 15 0,37 90

C 410.2 – 280e 0 – 280 0 – 46 8 5 15 0,75 97

C 410.2 – 510e 0 – 510 0 – 94 3 5 15 0,37 90

C 410.2 – 570e 0 – 570 0 – 98 6 5 15 0,75 97

C 410.2 – 850e 0 – 850 0 – 157 2 3 20 0,37 90

C 410.2 – 900e 0 – 900 0 – 155 5 3 20 1,5 97

C 410.2 – 1450e 0 – 1450 0 – 245 5 3 25 1,5 97

Controllable diaphragm pumps

C 409.2, C 410.2

Electrical data (electronics)

Operating voltage (50/60 Hz): 1~115 V 2); Permitted

1~230 V; ambient temperature: +2°C to +40°C

3~400 V/N/PE

3) Permitted humidity: approx. 90%

Inlet voltage

control input: 5...30 V DC

Minimale contact signal time : 55 ms 4)

Option PROFIBUS

4)

Analogue input resistance : 100 Ω PROFIBUS DP-V0 Slave Interface

4)

Digital Output : PNP, Tranmission rate: 9,6 kbit/s … 12 Mbit/s

internal supply:

Connection socket M12x1, 5-poe, B-coded

max. 15V DC, 50 mA

external supply:

max. 30V DC, 350 mA 2)

Series C 410.2 is not available for 115V-voltage

Pump protection type: IP 55 3)

for series C 410.2 with driving power 0,75 and 1,5 kW

4)

inapplicable when supplied with PROFIBUS DP-interface

Insulation class: F

Materials Drive

The high quality of the materials ensures continuous and Each drive unit consists of a proven motor

5)

reliable operation. We have the optimum material for coupled to a stroke mechanism in a robust aluminium

each requirement. housing.

sera – aluminium housings can cope with

Pump body and valves:

even extreme operating conditions due to

PVC, PP, PVDF, 1.4571,

the thickness of the material and the surface treatment.

PP-FRP, PVDF-FRP

Valve balls: Accessories

Glass, PTFE, 1.4401

Control cable

Valve seals: Diaphragm rupture monitoring

EPDM, FPM, FEP-covered, FFKM

6) Flow controller

Flow meter

Working diaphragm:

EPDM, FPM, PTFE-faced

PROFIBUS Y - connector

Intermediate diaphragm: PROFIBUS T - connector

CSM, PTFE, PTFE-faced PROFIBUS termination resistor

Manual vent valve :

6) For the optimum installation of a dosing pump

PP-FRP, PVDF-FRP we can supply all the necessary accessories such

as valves, pulsation dampers, injection fittings,

5)

please ask us for any material required but not mentioned here dosing tanks etc. against your order.

6)

only with pumps in FRP-execution, 0,8 l/h - 2,4 l/h

Subject to technical modifications!

Local sera - Representative:

sera GmbH

104-09 en / 07.13 / PM

sera-Straße 1

34376 Immenhausen

Germany

Tel. +49 5673 999-00

Fax +49 5673 999-01

www.sera-web.com

info@sera-web.com

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Technical service manual EM 9980 Code 4-117248AДокумент48 страницTechnical service manual EM 9980 Code 4-117248AIrimia MarianОценок пока нет

- Hcia Lte GeralДокумент48 страницHcia Lte Geralvictor kudidissaОценок пока нет

- Generator Set Data Sheet: Fuel ConsumptionДокумент3 страницыGenerator Set Data Sheet: Fuel ConsumptionJohn CardonaОценок пока нет

- Rolls-Royce: 250-C30 Series Operation and MaintenanceДокумент6 страницRolls-Royce: 250-C30 Series Operation and MaintenanceJosé Edwin RoldánОценок пока нет

- Uygulama 211130 160308Документ5 страницUygulama 211130 160308Joao Nogueira ClementeОценок пока нет

- Cisco Catalyst 6500 Series Switch DatasheetДокумент12 страницCisco Catalyst 6500 Series Switch DatasheetJoannaОценок пока нет

- Battery DesulfatorsДокумент4 страницыBattery DesulfatorsAlex MaianoОценок пока нет

- 3GPP TS 36.101: Technical SpecificationДокумент223 страницы3GPP TS 36.101: Technical SpecificationsomberriОценок пока нет

- PSC WP Energising Ireland A Guide To Grid Code Compliance K.YumakДокумент14 страницPSC WP Energising Ireland A Guide To Grid Code Compliance K.Yumakp61466365Оценок пока нет

- Spec25051 - Teck CableДокумент4 страницыSpec25051 - Teck Cablecrfg2003Оценок пока нет

- S Cubed DatasheetДокумент2 страницыS Cubed DatasheetGulf JobzОценок пока нет

- Atmega644Pa: 8-Bit Avr MicrocontrollersДокумент16 страницAtmega644Pa: 8-Bit Avr MicrocontrollersAngel Luciano Ramon GomezОценок пока нет

- Generator Governor Frequency Response Webinar April 2015Документ31 страницаGenerator Governor Frequency Response Webinar April 2015Jeans GonzalezОценок пока нет

- 800xa Outline - IO Systems - S800 IOДокумент20 страниц800xa Outline - IO Systems - S800 IOKourosh52Оценок пока нет

- Esquema Eléc. Frigo CarnesДокумент154 страницыEsquema Eléc. Frigo CarnesIgnacio Vives RicartОценок пока нет

- CH 05Документ14 страницCH 05Abdul Shokor Abd TalibОценок пока нет

- PN7092 Pressure Sensor DisplayДокумент5 страницPN7092 Pressure Sensor DisplayEslam YehiaОценок пока нет

- Fundamentals of Control SystemsДокумент18 страницFundamentals of Control SystemsShiva Sai BuraОценок пока нет

- 1482267279amasadoras Univex Greenline FichaДокумент2 страницы1482267279amasadoras Univex Greenline FichaAdriana GalindoОценок пока нет

- 1280-060 DatasheetДокумент43 страницы1280-060 DatasheetRamesh RautОценок пока нет

- Reply Daly BattrixxДокумент40 страницReply Daly Battrixxyogesh kumar jaiswalОценок пока нет

- Foundry Technologies 180-Nm Cmos, RF Cmos and Sige Bicmos: High-Performance Devices For A Wide Range of ApplicationsДокумент4 страницыFoundry Technologies 180-Nm Cmos, RF Cmos and Sige Bicmos: High-Performance Devices For A Wide Range of Applicationssandeep_sggsОценок пока нет

- 70 Series Maintenance Training Manual - MitsuДокумент299 страниц70 Series Maintenance Training Manual - Mitsuboystudy83100% (1)

- Nivotemp NT 64: Level and Temperature Switch With Display NV64DДокумент6 страницNivotemp NT 64: Level and Temperature Switch With Display NV64DSamad A BakarОценок пока нет

- Technical Data: High Pressure Solenoid ValveДокумент4 страницыTechnical Data: High Pressure Solenoid Valvechigurla ajayОценок пока нет

- Arduino 4 Relays Shield Drives High Power LoadsДокумент2 страницыArduino 4 Relays Shield Drives High Power LoadsBinОценок пока нет

- M.tech CPLD & Fpga Architecture & ApplicationsДокумент2 страницыM.tech CPLD & Fpga Architecture & Applicationssrinivas100% (1)

- DSP Simulation Assignment Using OctaveДокумент33 страницыDSP Simulation Assignment Using Octaveapi-19320842Оценок пока нет

- 487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing TransformersДокумент55 страниц487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing Transformersjose eduardo mejia sanchezОценок пока нет

- TeSys K Control Relay 4 NO 24V DC Data SheetДокумент2 страницыTeSys K Control Relay 4 NO 24V DC Data Sheetsherub wangdiОценок пока нет