Академический Документы

Профессиональный Документы

Культура Документы

Cipro - MFR 500r1

Загружено:

Anonymous IVUj0uiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cipro - MFR 500r1

Загружено:

Anonymous IVUj0uiАвторское право:

Доступные форматы

FOURRTS (INDIA) LABORATORIES PVT.

LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 1 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

Master Formula Record

Product : Ciprofloxacin 500 mg tablets

Batch size : 7,50,000 Tablets

Product code: C15T

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 2 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

TABLE OF CONTENTS:

S.No. Contents Page No.

1.0 General Information 03

2.0 Bill of materials for product manufacturing 05

3.0 Potency Calculation

06

4.0 Raw Material Storage Condition for batch manufacturing 07

5.0 Equipments/Utilities to be used 08

6.0 Material safety data 09

7.0 Instructions 10

8.0 Process Flow Diagram 11

9.0 Manufacturing / Processing Area Environment Conditions 12

10.0 Manufacturing procedure 13

11.0 Film Coating 17

12.0 Physical parameter of Film Coated Tablet 17

13.0 Inspection 18

14.0 Storage instructions 18

15.0 Attachment to the MFR 19

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 3 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

1.0.General Information

1.1 Generic Name Ciprofloxacin 500 mg tablets

1.2 Type of formulation Film coated tablet

White to creamish white capsule shaped film coated tablets debossed

1.3 Product description

“CPR500” with breakline one side and “BL” on the reverse.

1.4 Product Code C15T

1.5 Product licence PL17907/0015

1.6 Shelf life 48 months

Optimization Batch Record – IM19CB/OB/001, C15T/OB/001

1.7 Reference Documents

Process Optimization Protocol – FD/PRO/POP-054

Each film coated tablet contains: Ciprofloxacin hydrochloride EP

1.8 Label Claim

equivalent to Ciprofloxacin 500mg

Proposed Market /

United kingdom / Bristol

1.9 Customer

1.10 Product related information

Pharmacotherapeutic Second generation fluoroquinolone antibiotic (Quinolone antimicrobial

classification agent)

Pharmacopoeial status Ph.Eur

Physicochemical properties of API

Ciprofloxacin hydrochloride

Description A pale yellow, crystalline powder

Molecular formula C17H18FN3O3

1-cyclopropyl-6-fluoro-4-oxo-7-piperazin-1-ylquinoline-3-carboxylic

Chemical name

acid

Molecular Weight 331.347 g/mol

Melting Point 255-257 °C

Molecular Structure

Solubility Soluble in dilute (0.1N) hydrochloric acid; practically insoluble ethanol

Biopharmaceutical Class III

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 4 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

Usual

Infection Severity Dose Frequency

duration

Urinary Tract Acute 250mg Every 12 h 3 days

Mild 250mg Every 12 h 7-14 days

Severe 250mg Every 12 h 7-14 days

Posology and

Chronic Mild/Moderate 500 mg Every 12 h 28 Days

administration

Bacterial

Prostatitis

Lower Mild 500 mg Every 12 h 7-14 days

Respiratory Severe 750 mg Every 12 h 7-14 days

Tract

Mechanism of action The bactericidal action of ciprofloxacin results from inhibition of the enzymes

(brief) topoisomerase II (DNA gyrase) and topoisomerase IV, which are required for

bacterial DNA replication, transcription, repair, strand super coiling repair, and

recombination.

Pharmacokinetic parameters

Rapidly and well absorbed from the gastrointestinal tract after oral

Absorption

administration. The absolute bioavailability is approximately 70% with no

substantial loss by first pass metabolism.

Half life

4 hours

Hepatic. Four metabolites have been identified in human urine which together

Metabolism account for approximately 15% of an oral dose. The metabolites have

antimicrobial activity, but are less active than unchanged ciprofloxacin.

Approximately 40 to 50% of an orally administered dose is excreted in the urine

Elimination

as unchanged drug.

Storage condition Do not store above 25°C. Store in the original package

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 5 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

2.1 Indent of active pharmaceutical ingredient Batch Size: 7,50,000 tablets

Quanti Quantity to be dispensed in Kg

Std Qty/ Qty for

S. Name of active Item ty per

Batch the batch Lot 1 Lot 2 Lot 3

No pharmaceutical ingredient code tablet

(Kg) (Kg)

(mg)

Ciprofloxacin hydrochloride *

1 A064 582.000 436.500 436.500

Ph.Eur

2.2 Indent of excipients

Quanti Quantity to be dispensed in Kg

Std Qty/ Qty for

S. Item ty per

Name of ingredient Batch the batch Lot 1 Lot 2 Lot 3

No code tablet

(Kg) (Kg)

(mg)

Dry mix Materials

1 Maize starch BP/Ph.Eur E030 96.200 72.150 75.757# **

Colloidal Anhydrous Silica

2 E026 3.800 2.850 2.850 0.950 0.950 0.950

BP/Ph.Eur

Binder solution ingredient

3 Purified water Ph.Eur E005 q.s 81.840 83.33 27.770 27.770 27.770

Extra granular materials and Lubrication

Microcrystalline cellulose

4 E132 40.000 30.000 30.000 30.000

PH102 Ph.Eur

Sodium starch glycolate

5 E029 22.800 17.100 17.100 17.100

(Type A) BP/Ph.Eur

Colloidal Anhydrous Silica

6 E026 7.600 5.700 5.700 5.700

BP/Ph.Eur

7 Magnesium Stearate Ph.Eur E016 7.600 5.700 5.700 5.700

Total 760.00 570.000 570.000 -

Coating materials

Hydroxy propyl methyl

8 E161 7.600 5.700 6.840 6.840***

cellulose 15cps BP/Ph.Eur

9 Purified talc BP/Ph.Eur E045 4.560 3.420 4.104 4.104***

10 Titanium dioxide Ph.Eur E020 2.280 1.710 2.052 2.052***

Polyethylene glycol 4000

11 E205 0.760 0.570 0.684 0.684***

BP/Ph.Eur (Macrogol 4000)

12 Purified water BP/Ph.Eur E005 q.s q.s q.s 114.630***

Coated tablet weight 775.200 581.400 581.400 -

* Actual quantity of Ciprofloxacin hydrochloride Ph.Eur to be dispensed based on Actual assay (as is basis) and

Water content.

**The amount of maize starch has to be adjusted to compensate for additional quantity of Ciprofloxacin

hydrochloride Ph.Eur # Does not exist in the final product.

#

5% extra Maize starch added to compensate for loss in moisture of Maize starch after drying

***20% extra coating solution can be taken to compensate losses during coating.

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 6 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

3.0 Calculation:

Calculate the actual quantity of Ciprofloxacin hydrochloride Ph.Eur as per the following formula:

Standard quantity Ciprofloxacin hydrochloride Ph.Eur (If 100% m/m Assay) = kg

Note: If the Assay is greater than 100%, Assay to be rounded to 100% for calculation.

NOTE: If the potency is greater than 100%, potency to be rounded to 100% for calculation.

3.1 Potency Calculation for Ciprofloxacin hydrochloride Ph.Eur:

Quantity of Ciprofloxacin Ph.Eur

required for batch (P) (kg) = Std qty per batch x 100 x 100 ___________________

Assay (on anhydrous basis) x [100 – water content (% w/w)]

P = _____________

In case of Raw material from more than one A.R. No.

From first A.R number:

Available stock quantity (R) = Kg

% w/w assay % w/w Water content

Entered by/date (PR) Verified by / date (IPQA)

(on anhydrous basis) (B1) (C1)

From second A.R number:

% w/w assay % w/w Water content

Entered by/date (PR) Verified by / date (IPQA)

(on anhydrous basis) (B2) (C2)

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 7 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

Quantity to be added from second A.R number (S) =

436.500 – Rx B1 x (100-C1) X 100 x 100____ = ____________ kg

100 x 100 B2 x (100-C2)

Quantity of Ciprofloxacin hydrochloride Ph.Eur to be added from the second AR.No. (S) = _______kg

Total quantity of Ciprofloxacin Ph.Eur to be added for the batch (Q) = R+S = __________kg

3.2 Compensation of maize starch Ph.Eur:

Actual Quantity of maize starch Ph.Eur (T) = (Standard quantity of ciprofloxacin + Standard quantity of maize

starch) – (Quantity of ciprofloxacin to be dispensed) + 5%

T = ______________kg

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 8 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

4.0 Raw Material Storage Condition for batch manufacturing

Specifications and testing

S.No. Materials Storage Condition

requirements

Ciprofloxacin hydrochloride Store below 25º C in an airtight

1 container, protected from light. As per Ph.Eur

Ph.Eur

Protected from light and

2 Maize Starch BP/Ph.Eur As per BP/Ph.Eur

moisture.

Colloidal Anhydrous Silica

3 Store below 25º C As per BP/ Ph.Eur

BP/Ph.Eur

Cellulose microcrystalline Store in tightly

4 As per Ph.Eur

Ph.Eur (Avicel PH102) closed container

Sodium starch glycolate (Type Store in tightly

5 closed container at ambient As per Ph.Eur

A) Ph.Eur

temperature

Store in a tightly closed

6 Magnesium Stearate Ph.Eur As per Ph.Eur

container

7 Hydroxy propyl methyl cellulose Store in a tightly closed

As per Ph.Eur

15cps container, cool and dry place.

8 Store in a well closed container

Titanium dioxide Ph.Eur As per Ph.Eur

below 25°C

9 Store in a tightly closed

Purified talc BP / Ph.Eur As per Ph.Eur

container

10 Polyethylene glycol 4000

Store in tightly closed container As per Ph.Eur

(Macrogol PEG 4000) BP/Ph.Eur

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 9 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

5.0 Equipments/Utilities to be used:

List of equipments used in List of equipments recommended to be used

S.No.

Optimisation batch. in Production.

Electronic balance - 210 g, 220 g, 3.00kg, Electronic balance (210 g, 220 g, 3.00kg,

1 30.00kg, 150.00kg) 30.00kg, 150.00kg, 1500.00 kg)

2 Vibratory sifter (30”) Vibratory sifter (30”)

3 Sieves ( #16,#40, #100 ) Sieves ( #16,#40, #100 )

4 Vacuum cleaner Vacuum cleaner

5 Sifter(100#,40#,16#) Sifter(100#,40#,16#)

6 Cone mill (1.5mm) Cone mill (1.5mm)

7 Steam kettle Steam kettle

8 Rapid mixer granulator (150 L) Rapid mixer granulator (800 L)

9 Fluid bed equipment (125 L) Fluid bed equipment (800 L)

10 Bin blender (300L) Bin blender (1500L)

11 IPC Bin (150L) IPC Bin (1500L)

12 Manufacturing accessories Manufacturing accessories

13 Compression machine 51 station Compression machine 51 station

14 Auto coating machine (600mm) Auto coating machine (1500mm)

15 Inspection machine Inspection machine

16 IPQA Instruments IPQA Instruments

17 Moisture analyzer Moisture analyzer

18 Required Accessories

Scoops, SS vessels, SS spoons, HDPE containers and poly bags.

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 10 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

6.0 Material Safety Data

6.1 Ciprofloxacin Hydrochloride

Handling precautions Hazard identification First Aid measures

Avoid contact with eyes. Avoid Health Effects: Eye Contact: Flush eyes with

prolonged repeated skin contact Acute toxicity –category -4(oral/dermal) plenty of water for at least 15

and breathing dust /powders. Eye irritant –category 2B minutes ,occasionally lifting the

Handling: Wash thoroughly after Mutagenicity-No information found upper and lower eyelids. Get

handling. Use the adequate Carcinogenicity Effects: No information. medical aid.

ventilation. Minimize dust Found reproductive /Developmental – Skin Contact:

generation and accumulation. Category 2 Get medical aid Flush skin with

Avoid contact with eyes, skin, Target organ toxicity(repeated) –Category- plenty of soap solution and

and clothing. Keep container 3 water atleast 15 minutes after

tightly closed. Avoid ingestion Environmental: Chronic aquatic toxicity- removing contaminated

and inhalation. chronic category -4 clothing and shoes. Wash

Store in a tightly closed container . contaminated cloths before

reuse.

Ingestion: Never give anything

by mouth to an unconscious

person. Get medical aid. Do not

induce vomiting. If conscious

and alert, rinse mouth and drink

2-4 cupfuls of milk or water.

Inhalation: Remove the

inhaled person from exposure

to fresh air immediately. If not

breathing, give artificial

respiration. If breathing is

difficult, give oxygen. Get

medical aid.

7.0 Instructions

7.1 Carefully read and follow all manufacturing instructions.

7.2 Clean all equipment as per prescribed SOP and operate as per prescribed Work Instruction.

7.3 Check and confirm each area is cleaned as per relevant SOP.

7.4 Wear prescribed garments, hand gloves, mouth mask at every processing stage.

7.5 Conduct in-process check for parameters mentioned and take corrective steps as required.

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 11 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

8.0 PROCESS FLOW DIAGRAM

Dispense all the raw materials as

Stage 1: Dispensing

per the manufacturing formula

provided.

Sifting Stage 2: Sifting

Ciprofloxacin hydrochloride (Equipment: Vibro Sifter)

Ph.Eur # 16 mesh, Maize starch

Ph.Eur #100 mesh and Colloidal

Anhydrous silica Ph.Eur # 40 Stage 3: Granulation – Dry mixing

Extra granular addition (Equipment: RMG 800L)

Sodium starch glycolate Ph.Eur, Load the Sifted Ciprofloxacin hydrochloride

Cellulose microcrystalline Ph.Eur, Maize starch Ph.Eur and Colloidal

Ph.Eur, Colloidal Anhydrous Anhydrous silica Ph.Eur in RMG and mix for

silica Ph.Eur and Magnesium 20 minutes at slow speed /Chopper off

Stearate BP/Ph.Eur through # 40

mesh Stage 3.1: Granulation – wet mixing

(Equipment: RMG 800L)

Binder Addition: Split the purified water into

2 equal half. Add first half of purified water

is added slowly into dry mix through Granulation fluid:

sprinkler for 2 minutes at Impeller-Slow 27.770 Kg Purified water

BP/Ph.Eur (Previously boiled

and chopper fast, then open the lid rack

and cooled)

properly to get uniform mass. And add

second half of purified water in to RMG for

2 minute

Stage 4: Sizing (Co-mill) 10 mm Drying parameters

screen Inlet temperature: 60 - 70°C

Exhaust temperature: NMT

Stage 5: Drying (Equipment: FBE) 45°C

Product temperature: NMT

38°C

Dried granules sifted through 16# and Stage 6: Sizing & Milling Blower drive: NMT 100%

retentions milled through 1.5mm (Equipment: Vibro sifter and cone mill) LOD: NMT 4.0 % w/w

screen.

Stage 7: Blending (1500 L IPC Bin)

Load the sized and sifted granules into the IPC bin and blend for 5minutes at 5 RPM

Add the sifted Sodium starch glycolate Ph.Eur, Cellulose microcrystalline Ph.Eur, Colloidal

anhydrous to the above blend and mix for 10min at 5 RPM.

Stage 8: Lubrication

Add the sifted Magnesium stearate into the IPC bin and mix for 2 minutes at 5 RPM

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 12 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

Cont…

500mg tablets

Average weight - 760.00mg ± 5%

Thickness - 5.0 – 5.4 mm

Hardness - NLT 110N

Friability - NMT 1.0%

Stage 9: Compression Disintegration time- NMT 15min

(51 Station compression machine) Speed - 15-25RPM

Disintegration time – NMT

15min

Acceptance criteria Stage 10: Coating Coating Parameters**

Average weight : 775.2 ± 5% Preheating : NMT 45°C

Weight gain : 15.2 mg/tablet Inlet temp : 65± 10°C

Disintegration : NMT 30mins Exhaust air temp : 40 - 50°C

Bed temperature : 35 - 45°C

Pan motor : 3 - 8 rpm

Stage 11: Packing

Spray rate : 10 – 60 g/min/gun

No. of spray gun : 6

Atomization air : 1.5- 4.0 kg/cm2

Pressure

9.0 Manufacturing / Processing Area Environment Conditions

Area Temperature Relative Humidity

Dispensing Area NMT 25°C NMT 65% RH

Granulation area NMT 25°C NMT 65% RH

Blending area NMT 25°C NMT 65% RH

Compression NMT 25°C NMT 45% RH

Coating NMT 25°C NMT 65% RH

Inspection NMT 25°C NMT 65% RH

Packing NMT 25°C NMT 65% RH

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 13 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

10.0 Manufacturing procedure

Safety precautions: Wear 3M nose mask and goggles before entry to the area.

10.1 Dispensing

10.1.1 Dispense all the material as per the BOM using calibrated balances.

10.2 Sifting

Sift Ciprofloxacin Hydrochloride through #16 mesh and Maize starch through 100# and Colloidal

10.2.1

silicon dioxide through #40mesh collect in a double lined polyethylene container with separate label

Sift Microcrystalline cellulose Ph.Eur, Sodium starch glycolate, colloidal silicon dioxide and

10.2.2

Magnesium stearate Ph. Eur through #40 mesh and collect in a separate labeled container.

10.2.3 Check and record the sieve integrity before and after sifting.

10.3 Dry mixing

Load the sifted Ciprofloxacin Hydrochloride, Maize starch and Colloidal silicon dioxide into RMG.

10.3.1 Ensure the discharge valve is closed at the time of material charging. Mix the charged materials with

impeller in ‘Slow’ speed and chopper ‘off’ for 20 minutes.

10.3.2 Record the impeller speed and duration of dry mixing in batch processing record.

10.4 Granulation fluid

Take approximately 27.770 kg of Purified water (previously boiled and cooled) and split into 2 lots and

10.4.1

kept aside in cleaned vessel.

10.5 Wet granulation

Add first half Binder solution of step no.10.4.1 through Sprinkler to RMG containing dry mix materials

of pt.no.10.3.1 with impeller slow and chopper fast up to 2 minutes. Open the lid, rack properly for

10.5.1 uniform mixture, and continue addition of second half granulation fluid into RMG with impeller slow

and chopper fast up to 2 minutes. After complete addition of solution, knead for 1 minute at impeller

fast and chopper fast. Monitor and record the amperage value.

Continue mixing for further time with slow speed till granulation end point reached. If required use

10.5.2

previous boiled and cooled Purified water in increments of 0.500L

Determination of End point:

Precaution: Use hand gloves for this test

10.5.3 Procedure: Take one handful of wet mass and press to form a lump, open the palm and break the lump

by pressing the thump at the centre of the lump

Observation: The lump should break into small pieces

Record all the in-process parameters like impeller and chopper speeds, Granulation fluid addition time,

10.5.4 actual wet granulation time, additional quantity of purified water and the Ampere reading of impeller

obtained after completion of granulation in batch processing record.

Unload the wet granulated mass in FBE Bowl by opening the RMG discharge valve at impeller slow

10.5.5

with 10mm screen attached.

Repeat above process for another 2 lots of dry mix

10.6 Drying

Transfer the wet mass into the FBE bowl. Switch on FBE and dry the wet granules at following set

parameters

10.6.1

Inlet temperature: 60-70°C

Product temperature : NMT 38°C

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 14 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

Exhaust temperature: NMT45°C

Blower drive : NMT 100 %

Initially air dry the FBE bowl for 10 minutes and Carry out the drying as per the condition

10.6.2

mentioned above and rack the material every 15minutes to get uniform drying process.

LOD limit: NMT 4% w/w at 105°C in IR moisture analyzer.

10.7 Sifting and milling of dried granules

Sift the dried granules through #16 mesh and mill the retains (if any) using cone mill fitted with 1.5

10.7.1

mm screen at medium speed.

10.7.2 Sift the milled granules through #16 mesh and mill retains of #16 mesh through 1.5mm screen

Observe the milled granules visually. Check and record the LOD and description of the milled

10.7.3

granules and load the milled granules in IPC.

10.7.4 Verify and record all the integrity of screens and sieves before and after use.

10.7.5 Verify and record the yield of sized granules in Batch Processing Record.

10.8 Pre- Lubrication

10.8.1 Load the sifted and sized granules into the Blender and mix for 5minutes at 5 RPM

Load the sifted quantity of Microcrystalline cellulose Ph.Eur, Sodium starch glycolate, colloidal

10.8.2

silicon dioxide into the above step 10.8.3 and mix for 10 minutes at 5 RPM into IPC bin.

10.8.3 Lubrication: Transfer weighed and sifted quantity of magnesium stearate into blender.

10.8.4 Mix for 2 minutes at 5 RPM speed of blender.

10.8.5 Verify and record the yield of sized granules in Batch Processing Record.

10.8.6 Bulk density of granules : 0.66 g/ml Tapped density: 0.89 g/mL (For information only)

10.9 COMPRESSION

10.9.1 Set up and operate the compression machine & metal detector as per their respective SOP.

10.9.2 Check the upper Punch, Lower Punch and dies before starting the Machine for the correctness.

Compress the lubricated blend in 51 – Station compression machine.

10.9.3

Machine speed 15-25 rpm (optimum- 25rpm)

Punches:

Upper punch : 18.5 x 7.5 mm capsule shaped with breakline and “CPR & 500” embossing on either

10.9.4

side of breakline

Lower Punch: 18.5 x 7.5 mm, capsule shaped with “BL” embossing.

Die: 18.5 x 7.5 mm capsule shaped

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 15 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

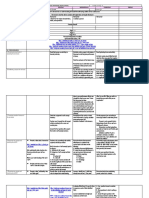

10.11 In-process specification and frequency of testing

Recommended No of Equipments to be

S.No. Parameters Specification Frequency tablets to used

PR/IPQA be checked

White to creamish white

capsule shaped, uncoated

Every 60 min / NA

1 Appearance tablets debossed “CPR500” 51

120 min

with breakline on one side and

“BL” on the reverse.

Weight of 20 15.200 g ± 3.0% (14.74 – Every 30 min / 220 g analytical

2 20

tablets 15.65 g) 120 min balance

760.00 mg ± 3.0% (737.20 – Every 60 min / 220 g analytical

3 Average weight 20

782.80mg) 120 min balance

Uniformity of NMT 2/20 to exceed ±5.0% Every 60 min / 220 g analytical

4 20

weight and none then exceed ±10% 120 min balance

Every 30 min / Vernier caliper

5 Thickness 5.0 - 5.4mm 5

120 min

NLT 110 N (Target 150N and Every 30 min/ 5 Hardness tester

6 Hardness

above) 120min

Every 30 min/ Vernier caliper

7 Dimension 18.5 x 7.5 mm ± 0.2mm 5

120min

Disintegration Every 4 hours / Disintegration Tester

8 NMT 15 minutes 6

time Once in shift apparatus

Every 60 min/

9 Friability Not more than 1.0 % w/w 10 Friability Tester

120min

11.0 Film coating

11.1 Preparation of coating solution

11.1.1 Operate the stirrer as per the SOP.

11.1.2 Transfer 114.630 kg of Purified water in SS container.

Disperse HPMC into it, then add purified talc, titanium dioxide and polyethylene glycol one by one to

11.1.3

above solution under stirring and stir for approx 5 minutes after each addition.

11.1.4 Then stir the above solution for approx. 10 minutes.

Homogenize for further approx. 30minutes before and continue stirring during film coating. Filter the

11.1.5

coating solution through #100 mesh.

11.2 Method of film coating

Transfer the approved tablets into pan of auto coater. Set the pan and spray parameters at optimum

11.2.1

level. Coat the tablets with coating solution with optimum parameters given below.

11.2.2 Charge the coating fluid into the solution-holding tank and close the tank.

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 16 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

11.3 Coating Process instructions

11.3.1 Connect the silicon tube between peristaltic pump, spray gun assembly and solution holding tank.

11.3.2 Check spray rate and spray pattern

11.3.3 Check and ensure the pressure differential between coating area and coating pan.

11.3.4 Adjust the distance between tablet bed to spray gun by 15 to 30cm

Before start the coating process, dry the core tablets at an inlet air temperature of 60°C while jogging

11.3.5

the pan with optimum RPM for 5 minutes.

Set the coating parameters as given below

PARAMETERS SET VALUE

Inlet air temperature 65±10°C

Exhaust air temperature 40 - 50°C

Bed temperature 35 - 45°C

Pan motor speed 3 - 8 RPM

11.3.6

Distance between spray gun to tablet bed 15 - 30 cm

Spray rate 10 - 60 g/min/gun

No. of Spray guns 6

Atomizing air pressure 0.5 – 3.0 Kg/cm2

Carry out the coating operation until the weight build up of 15.2 mg (2.00 %) per tablet for 500 mg and

11.3.7

maintain coating parameters as detailed above till the completion of coating operation.

11.3.8 Check and record the weight build up whenever required.

After completion of coating, dry the tablets to room temperature at an inlet air temperature of 40°C

11.3.9

while jogging the pan with 1-2 RPM for 15 – 20minutes.

Allow the tablets to cool at room temperature for 10 minutes by inching the pan continuously before

11.3.10

unloading the tablets.

12.0 Physical parameter of Film Coated Tablet

S.No. Parameters Specification

White to creamish white capsule shaped film coated tablets debossed

1 Description

“CPR 500” with a breakline one side and “BL” on the reverse.

Target weight of coated

2 775.2 ± 3% (751.94 – 798.45 mg)

tablet

3 Weight of 20 tablets 15.504 ± 3% (15.038 – 15.969g)

4 Weight build up 15.2 mg per tablet

5 Disintegration time NMT 30min

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 17 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

14.0 Inspection

14.1 Inspect the tablets for capping, chipping, picking, sticking and black spot on the tablets.

14.2 Any other predominant changes in the tablets.

15.0 Storage Instructions

Stage Container and labeling Area and Condition of storage

Store in granule hold area

Blended Store in IPC bins; label each container with B. No. details,

(Temperature: NMT 25°C and RH:

Granules weight and container Number.

NMT 65%)

Store in HDPE containers with double polythene bag lined Store in hold for coating area

Core

and tightly closed & label each container with B. No. details, (Temperature: NMT 25°C and

Tablets

weight and container Number. RH: NMT65%)

HDPE containers with double polythene bag lined, tightly Store in hold for inspection area

Coated

closed and label each container with B. No. details, weight (Temperature: NMT 25°C and

tablets

and container Number RH: NMT 65%)

Store in Tablet/capsule hold for

HDPE containers with double line polythene bag, tightly

Inspected packaging area

closed and label each container with batch number details,

tablets (Temperature: NMT 25°C and

weight and container number.

RH: NMT 65%)

16.0 MFR Attachments

S. No. Title Document No.

1 Bill of materials

2 Blend Specification

3 In process specification

4 Bulk product specification

5 Finished product specification

6 Blend standard test procedure

7 In process standard test procedure

8 Bulk product standard test procedure

9 Finished product standard test procedure

10 Cleaning validation standard test procedure

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

FOURRTS (INDIA) LABORATORIES PVT.LIMITED

PLANT II, Venkatamangalam, Chennai – 600127

MASTER FORMULA RECORD

Department Formulation Development Page 18 of 18

MFR No MFR-103/00 Supersedes no. NA

MFR for Ciprofloxacin 500 mg tablets Effective Date

Prepared by Reviewed by Approved by

FD Department FD Department FD Head QA Head

Sign/date Sign/date Sign/date Sign/date

Вам также может понравиться

- Azithromycin 250mg TabletДокумент12 страницAzithromycin 250mg TabletziadddОценок пока нет

- MFR Ciprofloxacin Tablets 500 MGДокумент10 страницMFR Ciprofloxacin Tablets 500 MGmaxtar biogenics100% (3)

- Process Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDДокумент16 страницProcess Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDsamia khanОценок пока нет

- FP Spec.Документ3 страницыFP Spec.ShagorShagorОценок пока нет

- BMR of Vericef 500capsuleДокумент17 страницBMR of Vericef 500capsuleShagorShagor100% (1)

- Vatakulantka Rasa TabletДокумент7 страницVatakulantka Rasa Tabletreflectprakash3610Оценок пока нет

- MFRДокумент9 страницMFRHarshal PawarОценок пока нет

- BMR Cephracap 500 Cap Checked 1Документ16 страницBMR Cephracap 500 Cap Checked 1jordan7half7don100% (1)

- Manufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Документ6 страницManufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Mohammed ZubairОценок пока нет

- Manufacturing Formula: Product: Ctzine SyrupДокумент6 страницManufacturing Formula: Product: Ctzine SyrupMohammed ZubairОценок пока нет

- Aphrin 500 MG Capsule BPR 2Документ16 страницAphrin 500 MG Capsule BPR 2ShagorShagor100% (2)

- Co Dabamal Tablet 9m606001Документ22 страницыCo Dabamal Tablet 9m606001joerichladОценок пока нет

- 01 BMR Placebo TabletsДокумент10 страниц01 BMR Placebo TabletsIris Patrisha Abigail BalutocОценок пока нет

- Quality Dossier of Asmatab TabletДокумент16 страницQuality Dossier of Asmatab TabletShagorShagor100% (1)

- BPR - FP025-1 V-1Azinil 35ml PFSДокумент17 страницBPR - FP025-1 V-1Azinil 35ml PFSShagorShagor100% (1)

- BMR - Elfexo 120 TabletДокумент13 страницBMR - Elfexo 120 TabletShagorShagor100% (1)

- Chlorpheniramine Maleate: Supriya Lifescience LTDДокумент17 страницChlorpheniramine Maleate: Supriya Lifescience LTDRaul JimenezОценок пока нет

- Acitral Syrup 1000litДокумент4 страницыAcitral Syrup 1000litAhmad HussainОценок пока нет

- Process Validation Protocol For Ketofast 10 TabletДокумент26 страницProcess Validation Protocol For Ketofast 10 TabletShagorShagor100% (6)

- Aphrin 500 MG Capsule BPR 1Документ12 страницAphrin 500 MG Capsule BPR 1ShagorShagor100% (1)

- Aphrin Pfs BPR p1 v-1Документ13 страницAphrin Pfs BPR p1 v-1ShagorShagorОценок пока нет

- Applicant's PartДокумент114 страницApplicant's PartCesar RodriguezОценок пока нет

- Metformin FormulationДокумент6 страницMetformin Formulationsujit50% (2)

- BMR SuspensionsДокумент16 страницBMR SuspensionsMohammed Zubair0% (1)

- SOP For Yield Range For TV Batches With CommentsДокумент5 страницSOP For Yield Range For TV Batches With CommentsPurushothaman SubramanianОценок пока нет

- A Product Which Has Completed All Stages of Manufacture, Including Final PackagingДокумент4 страницыA Product Which Has Completed All Stages of Manufacture, Including Final Packagingom shankar JhaОценок пока нет

- Manufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Документ5 страницManufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Mohammed ZubairОценок пока нет

- Emiset - BPRДокумент25 страницEmiset - BPRjordan7half7donОценок пока нет

- Prepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusДокумент17 страницPrepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusLegese HailuОценок пока нет

- 2 Leozinc B SyrupДокумент2 страницы2 Leozinc B SyrupShagorShagorОценок пока нет

- BMR - Reference - Moisturizing CreamДокумент6 страницBMR - Reference - Moisturizing CreamNIKHIL YEMUL100% (1)

- Batch Manufacturing Record: Wellborne Pharmachem & BiologicalsДокумент23 страницыBatch Manufacturing Record: Wellborne Pharmachem & BiologicalsMohammed Zubair100% (1)

- Xoxiban 10mg Tab VPДокумент13 страницXoxiban 10mg Tab VPziauddin bukhariОценок пока нет

- BMR - fp025-01 v-1 Azinil Pfs 35mlДокумент14 страницBMR - fp025-01 v-1 Azinil Pfs 35mlShagorShagorОценок пока нет

- Juvia Protocol 50-1000Документ16 страницJuvia Protocol 50-1000ziauddin bukhariОценок пока нет

- 17 04 2023Документ34 страницы17 04 2023BIONIAL HEALTHCAREОценок пока нет

- Aphrin PFS BMR V-01Документ13 страницAphrin PFS BMR V-01ShagorShagorОценок пока нет

- Ointment BMRДокумент22 страницыOintment BMRspp80% (5)

- Guide To Master Formulae Final 2012Документ119 страницGuide To Master Formulae Final 2012MohamedRefaatMohamedОценок пока нет

- Actpro Al Drysyrup 3b001Документ48 страницActpro Al Drysyrup 3b001joerichladОценок пока нет

- Analytical Report For Ketofast 10 TabletДокумент20 страницAnalytical Report For Ketofast 10 TabletShagorShagorОценок пока нет

- Temperature Mapping For FG StoreДокумент19 страницTemperature Mapping For FG Storemehrdarou.qaОценок пока нет

- Master Formula RecordДокумент39 страницMaster Formula RecordAbhijit kanavaje100% (1)

- OQ Protocol Capsulating MachineДокумент11 страницOQ Protocol Capsulating MachineNadine LilleОценок пока нет

- Master Formula CardДокумент7 страницMaster Formula CardTrilochan Ayurveda100% (1)

- Product Quality ReviewДокумент46 страницProduct Quality Reviewjibran khanОценок пока нет

- List of Raw Material ActiveДокумент11 страницList of Raw Material ActiveShagorShagor0% (1)

- Finished Product - Test ProcedureДокумент13 страницFinished Product - Test ProcedureShagorShagor100% (3)

- Micro ManualДокумент55 страницMicro ManualNiranjan PradhanОценок пока нет

- Manufacturing Formula: Product: Univit SyrupДокумент6 страницManufacturing Formula: Product: Univit SyrupMohammed ZubairОценок пока нет

- Sop-Qa-038-00-Stability StudiesДокумент22 страницыSop-Qa-038-00-Stability Studiesnareshph28Оценок пока нет

- 01 - Assay Procedure Development Protocol (APDP) of Celozin TabletДокумент5 страниц01 - Assay Procedure Development Protocol (APDP) of Celozin TabletShagorShagorОценок пока нет

- Ointment Process Validation-OriginalДокумент26 страницOintment Process Validation-Originalasit_m100% (1)

- Batch ManufacturingДокумент1 страницаBatch ManufacturingAishikpaul50% (2)

- Master Formula Brimolol SolutionДокумент3 страницыMaster Formula Brimolol SolutionSarfarazpk1Оценок пока нет

- Batch Manufacturing RecordДокумент7 страницBatch Manufacturing RecordAnu JoshiОценок пока нет

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersОт EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersОценок пока нет

- cGMP Current Good Manufacturing Practices for PharmaceuticalsОт EverandcGMP Current Good Manufacturing Practices for PharmaceuticalsРейтинг: 1 из 5 звезд1/5 (2)

- Regulatory Aspects of Pharmaceutical Quality System: Brief IntroductionОт EverandRegulatory Aspects of Pharmaceutical Quality System: Brief IntroductionОценок пока нет

- Test Glo-Qc-Tm-0729Документ5 страницTest Glo-Qc-Tm-0729Anonymous IVUj0uiОценок пока нет

- Test Glo-Qc-Tm-0699Документ3 страницыTest Glo-Qc-Tm-0699Anonymous IVUj0ui100% (1)

- MCC GradeДокумент14 страницMCC GradeAnonymous IVUj0uiОценок пока нет

- Noumed 2Документ7 страницNoumed 2Anonymous IVUj0uiОценок пока нет

- DIABETES MELLITUS BensonДокумент14 страницDIABETES MELLITUS BensonNixon KeyaОценок пока нет

- D435L09 Dental Trauma-2C Cracked Teeth - 26 Root FractureДокумент73 страницыD435L09 Dental Trauma-2C Cracked Teeth - 26 Root FractureD YasIr MussaОценок пока нет

- To Be or Not To Be Healthy 4144Документ3 страницыTo Be or Not To Be Healthy 4144Vesna Milosavljevic100% (1)

- Wound Dressing ChecklistДокумент3 страницыWound Dressing ChecklistBUAHIN JANNA100% (1)

- Fundamentals of Risk Based AuditingДокумент3 страницыFundamentals of Risk Based AuditingRobertus Wisnu WijayaОценок пока нет

- LUBRICANTCOOLANT Answer With ReflectionДокумент5 страницLUBRICANTCOOLANT Answer With ReflectionCharles Vincent PaniamoganОценок пока нет

- Define and State The Purpose of Therapeutic DietДокумент10 страницDefine and State The Purpose of Therapeutic DietKen GarciaОценок пока нет

- Reviewer Crim 3 FinalsДокумент6 страницReviewer Crim 3 FinalsMaria Rafaella P. DadoОценок пока нет

- Improving Communication Skills of Pharmacy StudentДокумент13 страницImproving Communication Skills of Pharmacy StudentAbdul QadirОценок пока нет

- High Prices Most Unique ProductsДокумент1 страницаHigh Prices Most Unique ProductsJusteen BalcortaОценок пока нет

- Cytomegalovirus Infection and Disease in The New Era of Immunosuppression Following Solid Organ TransplantationДокумент9 страницCytomegalovirus Infection and Disease in The New Era of Immunosuppression Following Solid Organ TransplantationReza Firmansyah IIОценок пока нет

- Bituminous MixesДокумент13 страницBituminous MixesRanjit SinghОценок пока нет

- Boost Listening 1 Teacher S Edition PDFДокумент96 страницBoost Listening 1 Teacher S Edition PDFHuy Lê QuangОценок пока нет

- Corrosion Short Courses - Environmental CrackingДокумент8 страницCorrosion Short Courses - Environmental CrackingMario SalayaОценок пока нет

- Amsoil Synthetic CVT Fluid (CVT)Документ2 страницыAmsoil Synthetic CVT Fluid (CVT)amsoildealerОценок пока нет

- Burns Plastic Reconstructive Surgery MSCДокумент4 страницыBurns Plastic Reconstructive Surgery MSCCareer VoyageОценок пока нет

- AJINOMOTO 2013 Ideal Amino Acid Profile For PigletsДокумент28 страницAJINOMOTO 2013 Ideal Amino Acid Profile For PigletsFreddy Alexander Horna Morillo100% (1)

- Doppler EffectДокумент47 страницDoppler EffectLouies UngriaОценок пока нет

- Daily Lesson Log Personal Dev TДокумент34 страницыDaily Lesson Log Personal Dev TRicky Canico ArotОценок пока нет

- Souvenir Mushrooms 1986Документ106 страницSouvenir Mushrooms 1986Ankit MishraОценок пока нет

- Antibacterial Effects of Essential OilsДокумент5 страницAntibacterial Effects of Essential Oilsnightshade.lorna100% (1)

- Affidavit Format FOR ART LEVEL 1 CLINIC RegistrationДокумент2 страницыAffidavit Format FOR ART LEVEL 1 CLINIC Registrationward fiveОценок пока нет

- Lending Policies of Indian BanksДокумент47 страницLending Policies of Indian BanksProf Dr Chowdari Prasad80% (5)

- Standard DetailsДокумент168 страницStandard DetailsMurathan Paksoy100% (1)

- Aswani Construction R 07102013Документ3 страницыAswani Construction R 07102013Balaji RathinavelОценок пока нет

- Manufacturer: Jaguar Model: S-Type 2,5 Engine Code: JB Output: 147 (200) 6800 - 6/9/2022 Tuned For: R-Cat Year: 2002-05 V9.200Документ2 страницыManufacturer: Jaguar Model: S-Type 2,5 Engine Code: JB Output: 147 (200) 6800 - 6/9/2022 Tuned For: R-Cat Year: 2002-05 V9.200Official Feby AfriwanОценок пока нет

- Cat 4401 UkДокумент198 страницCat 4401 UkJuan Ignacio Sanchez DiazОценок пока нет

- Di SilvioДокумент47 страницDi SilviomaryroseengОценок пока нет

- Me22 M1a1Документ2 страницыMe22 M1a1Jihoo JungОценок пока нет

- HD Management Brochure - Final PDFДокумент2 страницыHD Management Brochure - Final PDFVanzari RBMОценок пока нет