Академический Документы

Профессиональный Документы

Культура Документы

(In Accordance With ANSI/FCI 70 2 and IEC 60534-4) : Control Valve Seat Leakage Classifications

Загружено:

milton19870 оценок0% нашли этот документ полезным (0 голосов)

334 просмотров1 страницаLeakage Classes

Оригинальное название

Leakage Classes

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документLeakage Classes

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

334 просмотров1 страница(In Accordance With ANSI/FCI 70 2 and IEC 60534-4) : Control Valve Seat Leakage Classifications

Загружено:

milton1987Leakage Classes

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

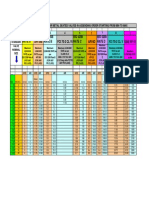

Control Valve Seat Leakage Classifications

(In accordance with ANSI/FCI 70−2 and IEC 60534-4)

Leakage Maximum Test Test Pressures Testing Procedures

Class Leakage Medium Required for

Designation Allowable Test Establishing Rating

---- ---- ---- No test required provided

I

user and supplier so agree.

0.5% of rated Air or water 3-4 bar (45−60 Pressure applied to valve

capacity at psig) or max. inlet, with outlet open to

II 10−52_C operating atmosphere or connected to

(50−125_F) differential, a low head loss measuring

whichever is device, full normal closing

lower. thrust provided by actuator

0.1% of rated As above As above As above

III

capacity

0.01% of rated As above As above As above

IV

capacity

0.0005ml /min of Water at Max. service

valve inlet after filling entire

water per inch of 10−52_C pressure drop

body cavity and connected

orifice diameter (50−125_F) across valve

piping with water and stroking

per psi diff. plug, not to

valve plug closed. Use net

V (5 X 10−12m3 exceed ANSI

specified max. actuator

per second of body rating,

thrust, but no more, even if

water per mm of or lesser available during test. Allow

orifice diameter pressure by

time for leakage flow to

per bar diff.l). agreement.stabilize

Not to exceed Air or 3.5 bar (50

Pressure applied to valve

amounts shown nitrogen at psig) or max.

inlet. Actuator should be

in following table 10−52_C rated differential

adjusted to operating

based on port (50−125_F) pressure across

conditions specified with full

VI diameter valve plug,

normal closing thrust applied

whichever is

to valve plug seat. Allow time

lower for leakage flow to stabilize

and use suitable measuring

device.

Class VI Maximum Seat Leakage Allowable

(In accordance with ANSI/FCI 70−2)

NOMINAL PORT DIAMETER BUBBLES PER MINUTE(1)

in mm ml per minute Bubbles per minute

1 25 0.15 1

1-1/2 38 0.30 2

2 51 0.45 3

2-1/2 64 0.60 4

3 76 0.90 6

4 102 1.70 11

6 152 4.00 27

8 203 6.75 45

1. Bubbles per minute as tabulated are a suggested alternative based on a suitably calibrated

measuring device, in this case a 1/4 inch (6.3 mm) O.D. x 0.032 inch (0.8 mm) wall tube

submerged in water to a depth of from 1/8 to 1/4 inch (3 to 6 mm). The tube end shall be cut

square and smooth with no chamfers or burrs, and the tube axis shall be perpendicular to the

surface of the water. Other apparatus may be constructed and the number of bubbles per minute

may differ from those shown as long as they correctly indicate the flow in ml per minute.

Вам также может понравиться

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОт EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОценок пока нет

- Vana Seçimi Control Valve Selection Practical GuideДокумент7 страницVana Seçimi Control Valve Selection Practical GuideÖmer EmelОценок пока нет

- Selecting Control and Balancing Valves in A Variable Flow System - ASHRAe Journal - Jun 1997Документ10 страницSelecting Control and Balancing Valves in A Variable Flow System - ASHRAe Journal - Jun 1997Vince DavidОценок пока нет

- Overview of Odorization SystemsДокумент5 страницOverview of Odorization Systems14071988Оценок пока нет

- Permanent Mooring System Wire Rope, Sockets, Pins and Connectors For Deepwater Floating Structures (Based On Dnv-Os-E304)Документ18 страницPermanent Mooring System Wire Rope, Sockets, Pins and Connectors For Deepwater Floating Structures (Based On Dnv-Os-E304)yvОценок пока нет

- GDN-115 Fire Fighting EquipmentsДокумент71 страницаGDN-115 Fire Fighting EquipmentsChanchal Kumar Tiwari100% (1)

- SKUM Over The Top Foam Generators OFG OFGR - FDS14334 0214 LRДокумент4 страницыSKUM Over The Top Foam Generators OFG OFGR - FDS14334 0214 LRValentin A.Оценок пока нет

- Refrigerant Monitoring Systems for Mechanical Equipment SafetyДокумент8 страницRefrigerant Monitoring Systems for Mechanical Equipment SafetyradusettОценок пока нет

- Cryo Piping SystemsДокумент19 страницCryo Piping SystemsaravindhcamОценок пока нет

- Valve Leakage Class CompДокумент1 страницаValve Leakage Class CompSantoshi PriyaОценок пока нет

- MILITARY SPECIFICATION A24179aДокумент24 страницыMILITARY SPECIFICATION A24179aCarlos Enrique Godoy Sifontes100% (1)

- Taco Expansion TankДокумент20 страницTaco Expansion TankDhirendra Singh RathoreОценок пока нет

- Project Planni NG - AS Appli ED I N Engi Neeri NG AND Constructi ON FOR Capi TAL ProjectsДокумент20 страницProject Planni NG - AS Appli ED I N Engi Neeri NG AND Constructi ON FOR Capi TAL ProjectsBrajan Esteban Nieto EspinozaОценок пока нет

- Install Aboveground Fuel TanksДокумент6 страницInstall Aboveground Fuel TanksGyanendra Narayan NayakОценок пока нет

- OPMP Candidate GuidebookДокумент27 страницOPMP Candidate Guidebookfawad ahmadОценок пока нет

- ASHRAE Journal - VAVR Vs ACB+DOAS PDFДокумент12 страницASHRAE Journal - VAVR Vs ACB+DOAS PDFmlamourОценок пока нет

- BS en 12502-3Документ18 страницBS en 12502-3laboratorium logamОценок пока нет

- EPE201008 - PT Badak NGL BlackOut Start Up SystemДокумент4 страницыEPE201008 - PT Badak NGL BlackOut Start Up SystemNasrulSyahruddinОценок пока нет

- Shell Brake Clutch Fluid DOT 4 ESL TDS PDFДокумент2 страницыShell Brake Clutch Fluid DOT 4 ESL TDS PDFwicka3Оценок пока нет

- Energy Efficient RatingДокумент28 страницEnergy Efficient RatingPoovanaan Sathiya SeelanОценок пока нет

- GPSS3Документ82 страницыGPSS3Charlie CB PortnerОценок пока нет

- E-1 Deluge ValveДокумент10 страницE-1 Deluge ValveTracy SankarОценок пока нет

- API Recommended Practice For The Design and Installation of Pressure Relieving Systems in RefineriesДокумент22 страницыAPI Recommended Practice For The Design and Installation of Pressure Relieving Systems in RefineriesWADEОценок пока нет

- Vapor Intrusion ASTM 2600Документ2 страницыVapor Intrusion ASTM 2600Tecnohidro Engenharia AmbientalОценок пока нет

- Sinorix 1230 - Quick, Safe and Environmentally FriendlyДокумент4 страницыSinorix 1230 - Quick, Safe and Environmentally Friendlyf.BОценок пока нет

- NFPA 45 (2004) Requirements That Apply NowДокумент8 страницNFPA 45 (2004) Requirements That Apply NowCarlos EduardoОценок пока нет

- COP 101 Version 9.1 Document (Text) Jan 2006Документ41 страницаCOP 101 Version 9.1 Document (Text) Jan 2006MarcusОценок пока нет

- Q99020 Oss PDFДокумент4 страницыQ99020 Oss PDFCarolineОценок пока нет

- Ma05m Centrifugal Pumps SpecificationДокумент21 страницаMa05m Centrifugal Pumps SpecificationandyОценок пока нет

- Plumb Ling VentingДокумент30 страницPlumb Ling VentingNatthasart MuangsuankwanОценок пока нет

- Gny Pantograph AssyДокумент10 страницGny Pantograph Assyprem nautiyalОценок пока нет

- Ni 1710 KДокумент19 страницNi 1710 KThiago MerloОценок пока нет

- TrueUnion - True Union Ball ValveДокумент4 страницыTrueUnion - True Union Ball ValveKarthick VenkateshОценок пока нет

- GAPS Guidelines: Water Mist SystemsДокумент4 страницыGAPS Guidelines: Water Mist SystemsGerardo D. AguilarОценок пока нет

- Cavitation in Restriction Orifices and Valves - NeutriumДокумент8 страницCavitation in Restriction Orifices and Valves - NeutriumAbbasОценок пока нет

- Control Valve - EN 1349Документ5 страницControl Valve - EN 1349Nemanja PapricaОценок пока нет

- Emerson - SAPAG Butterfly ValveДокумент14 страницEmerson - SAPAG Butterfly ValvekuraimundОценок пока нет

- Disinfect Water TanksДокумент4 страницыDisinfect Water Tanksamalart99Оценок пока нет

- SECTION 22 61 19 Compressed-Air Equipment For Laboratory and Healthcare FacilitiesДокумент7 страницSECTION 22 61 19 Compressed-Air Equipment For Laboratory and Healthcare FacilitiesKaruna KaranОценок пока нет

- IPS e El 110Документ105 страницIPS e El 110alinaghibОценок пока нет

- Ventilation For Commercial Cooking Operations: ANSI/ASHRAE Addendum C To ANSI/ASHRAE Standard 154-2016Документ5 страницVentilation For Commercial Cooking Operations: ANSI/ASHRAE Addendum C To ANSI/ASHRAE Standard 154-2016mahboobОценок пока нет

- Is.4544.2000 0Документ17 страницIs.4544.2000 0Davorin IvićОценок пока нет

- NEBB Duct Leakage Presentation 11Документ1 страницаNEBB Duct Leakage Presentation 11hemantОценок пока нет

- Development of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PДокумент20 страницDevelopment of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PSen HuОценок пока нет

- GAPS Guidelines: Electrostatic PrecipitatorsДокумент4 страницыGAPS Guidelines: Electrostatic PrecipitatorsAsad KhanОценок пока нет

- Heat Release Rate Concerns in Fire Engineering DesignДокумент9 страницHeat Release Rate Concerns in Fire Engineering Design1jess6Оценок пока нет

- VFD Booster Controls GuideДокумент13 страницVFD Booster Controls GuideCristianDumitruОценок пока нет

- Ringleman Chart FlareДокумент12 страницRingleman Chart FlareguhadebasisОценок пока нет

- Floating Roof Sinking Failure ReportДокумент17 страницFloating Roof Sinking Failure ReportPablo Vladimir Millanao FuentesОценок пока нет

- DBB CatalogueДокумент28 страницDBB CatalogueHeri SetyantoОценок пока нет

- Valves - App Guide PDFДокумент40 страницValves - App Guide PDFarnoldmoyaОценок пока нет

- VACUUM AND PRESSURE SYSTEMS HANDBOOK - Gastmfg PDFДокумент20 страницVACUUM AND PRESSURE SYSTEMS HANDBOOK - Gastmfg PDFDayo IdowuОценок пока нет

- 48 Safety Aspects of Industrial DryersДокумент29 страниц48 Safety Aspects of Industrial DryersVama DevОценок пока нет

- WikiLeaks - Sensitive Cables, GY Tag - PT 2Документ186 страницWikiLeaks - Sensitive Cables, GY Tag - PT 2Brigadier David GrangerОценок пока нет

- V001t02a007 Ipc2000 117Документ10 страницV001t02a007 Ipc2000 117zafarbadalОценок пока нет

- Highloader - ABДокумент3 страницыHighloader - ABRafiq DurraniОценок пока нет

- 60.32-069 - 1994 Pressure TransmittersДокумент5 страниц60.32-069 - 1994 Pressure TransmitterspradeepОценок пока нет

- Industrial Insulation Applications: Green Engineering-1 Insulation Spreadsheets - ContentДокумент55 страницIndustrial Insulation Applications: Green Engineering-1 Insulation Spreadsheets - ContentRashel HasanОценок пока нет

- Gas Cylinder Rules 2004Документ2 страницыGas Cylinder Rules 2004Sachin DarneОценок пока нет

- PA-AT-7776Документ2 страницыPA-AT-7776milton1987Оценок пока нет

- PA-DPI-7883Документ2 страницыPA-DPI-7883milton1987Оценок пока нет

- Pa LT 7508Документ3 страницыPa LT 7508milton1987Оценок пока нет

- Service Conditions Tubing: Instrument Specification Flow Transmitter - DPДокумент2 страницыService Conditions Tubing: Instrument Specification Flow Transmitter - DPmilton1987Оценок пока нет

- Group Head-Instruments Control Object Check ListДокумент5 страницGroup Head-Instruments Control Object Check Listmilton1987Оценок пока нет

- Checklist For CablesДокумент4 страницыChecklist For Cablesmilton1987Оценок пока нет

- G-INST-004.232-A Checklist For Capacitance Type Level InstrumentДокумент5 страницG-INST-004.232-A Checklist For Capacitance Type Level Instrumentmilton1987Оценок пока нет

- G-INST-004.231-A Checklist For Displacement Type Level InstrumentДокумент6 страницG-INST-004.231-A Checklist For Displacement Type Level Instrumentmilton1987Оценок пока нет

- G-INST-004.233-A Checklist For Ultrasonic Level TransmitterДокумент6 страницG-INST-004.233-A Checklist For Ultrasonic Level Transmittermilton1987Оценок пока нет

- G-INST-004.220-A Checklist For Orifice PlateДокумент5 страницG-INST-004.220-A Checklist For Orifice Platemilton1987Оценок пока нет

- Pa TT 7041Документ2 страницыPa TT 7041milton1987Оценок пока нет

- PB FSH 8658Документ2 страницыPB FSH 8658milton1987Оценок пока нет

- Check List Analyzer and Analyzer SystemДокумент6 страницCheck List Analyzer and Analyzer Systemmilton1987Оценок пока нет

- Actuator Types Advantages Disadvantages ApplicationsДокумент1 страницаActuator Types Advantages Disadvantages Applicationsmilton1987Оценок пока нет

- Group Head-Instruments Control Object Check ListДокумент5 страницGroup Head-Instruments Control Object Check Listmilton1987Оценок пока нет

- Checklist For Desuperheater StationДокумент7 страницChecklist For Desuperheater Stationmilton1987Оценок пока нет

- Hydrogen (H) AnalyserДокумент4 страницыHydrogen (H) Analysermilton1987Оценок пока нет

- Control Object Check List TitleДокумент5 страницControl Object Check List Titlemilton1987Оценок пока нет

- Training Module: AnalysersДокумент28 страницTraining Module: Analysersmilton1987Оценок пока нет

- Analyser Sample Handling System DesignДокумент28 страницAnalyser Sample Handling System Designmilton1987Оценок пока нет

- Butrfly VДокумент6 страницButrfly Vmilton1987Оценок пока нет

- Installation TenderДокумент5 страницInstallation Tendermilton1987Оценок пока нет

- CV2 FormatДокумент6 страницCV2 Formatmilton1987Оценок пока нет

- Training Manuals-Instruments: Preparation of Installation TenderДокумент9 страницTraining Manuals-Instruments: Preparation of Installation Tendermilton1987Оценок пока нет

- CV 3Документ6 страницCV 3milton1987Оценок пока нет

- Pressure Regulator Specification SheetДокумент6 страницPressure Regulator Specification Sheetmilton1987Оценок пока нет

- GeneralДокумент6 страницGeneralmilton1987Оценок пока нет

- CV 4Документ6 страницCV 4milton1987Оценок пока нет

- Temp RegДокумент6 страницTemp Regmilton1987Оценок пока нет

- GB VДокумент6 страницGB Vmilton1987Оценок пока нет

- Fits and Clearances - Contents: Propeller Maintenance Manual 132AДокумент8 страницFits and Clearances - Contents: Propeller Maintenance Manual 132AAlexis KidemaОценок пока нет

- DatacenterДокумент80 страницDatacenterHany FathyОценок пока нет

- Towers 140425022025 Phpapp02Документ72 страницыTowers 140425022025 Phpapp02GeorgeEdward100% (1)

- Hardlock Set Screw: AdvantagesДокумент4 страницыHardlock Set Screw: AdvantagesJayden BarnesОценок пока нет

- TLEEIM Grade9 QTR3 Module1 Part2 Lighting-Fixtures-and-Lamps-modular-2Документ20 страницTLEEIM Grade9 QTR3 Module1 Part2 Lighting-Fixtures-and-Lamps-modular-2Lorde Flores100% (1)

- Electronics Engineering Mastery Test 7 ECE Pre-Board PDFДокумент29 страницElectronics Engineering Mastery Test 7 ECE Pre-Board PDFXyОценок пока нет

- Switch Yard REVISEДокумент28 страницSwitch Yard REVISEPratheek ReddyОценок пока нет

- Fosmon 4-In-1 Charging Dock For Nintendo Switch Joy-Con Controller With LED IndicatorДокумент2 страницыFosmon 4-In-1 Charging Dock For Nintendo Switch Joy-Con Controller With LED Indicatorhenry sarmientoОценок пока нет

- 350X2 Manual de ServicioДокумент1 154 страницы350X2 Manual de ServicioJuan David Gomez Avella100% (1)

- Manual Asus P5GPL-XДокумент94 страницыManual Asus P5GPL-XJuan PerezОценок пока нет

- CMMP AS M3 HW - 2012 03 - 760322g1 PDFДокумент112 страницCMMP AS M3 HW - 2012 03 - 760322g1 PDFViick MartinezОценок пока нет

- Terminations: Underground Electric Distribution StandardsДокумент20 страницTerminations: Underground Electric Distribution StandardsHendrix LevaОценок пока нет

- CircuitiKz ManualДокумент62 страницыCircuitiKz ManualnospherathusОценок пока нет

- mpl-h11s ManualДокумент37 страницmpl-h11s Manualvũ trầnОценок пока нет

- Hg43au800aw SpecДокумент8 страницHg43au800aw SpecG & M Soft Technologies Pvt LtdОценок пока нет

- B-64603en - 01 - 0if Connection Manual (Hardware)Документ484 страницыB-64603en - 01 - 0if Connection Manual (Hardware)SergioОценок пока нет

- Expression of Interest (E.O.I.) Fire Fighting System BOQ (NSRДокумент3 страницыExpression of Interest (E.O.I.) Fire Fighting System BOQ (NSRKarthick MahadevanОценок пока нет

- Tecumseh Model Lav35 40327k Parts ListДокумент8 страницTecumseh Model Lav35 40327k Parts ListTorney BenedictОценок пока нет

- Maintenance Schedule FormatДокумент18 страницMaintenance Schedule FormatAntoni100% (1)

- Machine Design Trial QuestionsДокумент13 страницMachine Design Trial QuestionsJerdОценок пока нет

- MH 3621 U3 - 中英文Manual PDFДокумент22 страницыMH 3621 U3 - 中英文Manual PDFwghazaliОценок пока нет

- MSA M1 SCBA LeafletДокумент5 страницMSA M1 SCBA LeafletForum PompieriiОценок пока нет

- Etc Lmg-Ssc12a64Документ10 страницEtc Lmg-Ssc12a64Dubis EszterОценок пока нет

- Title: Model Ut50A/B/C: Operating ManualДокумент33 страницыTitle: Model Ut50A/B/C: Operating ManualEibar016Оценок пока нет

- KD 65 X 8000 CДокумент98 страницKD 65 X 8000 CkalleОценок пока нет

- 70 Series line monitoring relaysДокумент10 страниц70 Series line monitoring relaysovidiuОценок пока нет

- Index ChillДокумент95 страницIndex Chillreezqee100% (1)

- 2010 + Chevrolet Camaro - LightingДокумент203 страницы2010 + Chevrolet Camaro - Lightingsled novaОценок пока нет

- Shoe Dryer Fyp DKM 07Документ53 страницыShoe Dryer Fyp DKM 07Dasir Baluan AsiriОценок пока нет