Академический Документы

Профессиональный Документы

Культура Документы

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3 Competition Code: 1809 - FS - MMM - ISCF - FARADAY - R3

Загружено:

Jack PadiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3 Competition Code: 1809 - FS - MMM - ISCF - FARADAY - R3

Загружено:

Jack PadiАвторское право:

Доступные форматы

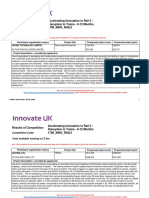

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

CDO2 LIMITED Printed sensors for EV battery current £108,579 £76,005

density imaging

ACELERON LIMITED £48,024 £33,617

BRILL POWER LIMITED £86,523 £60,566

CENTRE FOR PROCESS INNOVATION LIMITED £99,167 £99,167

PEACOCK TECHNOLOGY LIMITED £112,176 £78,523

University of Strathclyde £19,731 £19,731

University of Sussex £25,406 £25,406

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 1

Project description - provided by applicants

The growth in the electrification of transport, including electric vehicles (EVs), has been driven by lithium-ion batteries. However, to make the next-generation

of vehicles cheaper and more efficient, we need to be able to monitor, diagnose and respond to batteries in real-time. This project aims to combine new

types of sensors to feed data into a battery management system (BMS) that will be able to react to the changing state of battery health and charge and

improve operational safety. This could lead to an increase in battery life of up to 60%.

Crucially, we will look at producing sensors that are robust, sensitive and significantly cheaper than those commercially available. Our goal is that the

sensors will be deployed into battery modules at low cost and adopted by industry. Eventually, they may become a requirement for new car certification and

help to improve consumer safety, confidence and uptake of EVs.

To verify the feasibility of our approach, our consortium covers a range of commercial and academic expertise that will build sensors into a prototype battery

pack.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 2

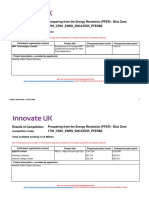

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

WARDELL ARMSTRONG INTERNATIONAL Securing Domestic Lithium Supply Chain £231,852 £162,296

LIMITED for UK

CORNISH LITHIUM LTD £159,164 £111,415

The Natural History Museum £106,439 £106,439

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 3

Project description - provided by applicants

The transition to electric vehicles (EVs), and consequent changes to the supply chain, manifests some significant challenges given that manufacturing of

cars, trucks and other vehicles is a vital part of the UK 's industrial base. If the country is to maintain its current market share of car production of over 1.5

million units p.a., it is estimated that this will require at least 75,000 tpa of LCE (Lithium Carbonate Equivalent): roughly a third of current global annual

supply. Whilst global supply of LCE is expected to rise rapidly much of this additional supply has already been secured by China for its burgeoning battery

manufacturing industry and it is therefore increasingly important that the UK investigates possible domestic production of raw materials required for battery

manufacture. This project will utilise existing expertise within the consortium to assess the feasibility of extracting and converting a supply of lithium from

indigenous sources in order to provide a secure supply of a vital battery material, enabling the UK to become a world-leader in batteries for EVs.

Developing such a supply chain is of paramount importance given competition from Asia. Potential sources of lithium and other battery raw materials have

been identified in the UK and Europe, and offer potential for the UK to secure a domestic supply of a significant proportion of the lithium a thriving EV

industry requires. A fully-integrated domestic supply chain will offset the risks of the UK vehicle industry being destroyed by competition from Asia. This

project will leverage existing knowledge to create innovative solutions for the current raw materials gap that exists in the supply chain.

The project consortium will assess various processing methods for lithium sources, and the feasibility of locating such a plant within the UK. The project will

build on recent work by consortium members during the European-funded FAME project and will assess the viability of taking feedstock from Cornwall, and

potentially Europe, and producing a central concentrate for conversion to battery grade lithium chemicals.

The FAME project, which focussed on the processing of European lithium ores, was led by Wardell Armstrong International with feedstock characterisation

by the Natural History Museum, two of the consortium members for this feasibility study. The third member, Cornish Lithium, is the only company actively

exploring the potential for lithium production from novel sources in Cornwall. They bring a highly experienced commercial team with extensive industry and

investment banking experience.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 4

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

GRANTA DESIGN LIMITED Intelligent enterprise Data Management £242,606 £145,564

platform for BATtery manufacturing -

IDMBAT (or HESTIA)

INTELLEGENS LIMITED £107,656 £75,359

University of Birmingham £148,325 £148,325

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 5

Project description - provided by applicants

Responding to the growing battery manufacturing market and significant technical challenges, IDMBAT will address a substantial gap in the market by

developing software solutions for battery manufacturers to reduce fabrication and development costs while improving key batteries metrics. This will be

achieved by combining the proven benefits of a systematic, enterprise approach to materials information, with new artificial intelligence (AI) capabilities for

predicting optimum process parameters from complex interdependencies.

The consortium is led by Granta Design (Granta) , the world largest company and R&D organisation operating in the materials information technology

market. University of Birmingham (UB, Prof. Emma Kendrick) brings in battery technical leadership and will host a small-scale manufacturing facility to

generate data. Intellegens (INT), a fast-growing micro SME, will develop cutting edge artificial intelligence algorithms for process parameter prediction.

The proposed feasibility study endeavours to:

-De-risk scaling up innovative technologies across the battery value chain (including cell materials and components, cells, modules and packs,

manufacturing processes) by means of intelligent, systematic information management approach which reduces future costs of reproducibility by ensuring

full traceability and enables predictions and comparisons;

-Remove technical and commercial barriers to cell manufacture in the UK (advancement in battery metrics, reduced costs of trials and experimentation,

reduce use of materials resources);

-Support the overall goal of the Faraday Battery Challenge to make the UK the go-to place for the research, development, scale up and industrialisation of

cutting-edge battery technology by building upon existing UK industrial and academic leadership.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 6

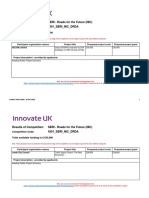

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

AMTE POWER LTD. UK - Gigawatt Hour Cell Manufacturing £249,711 £174,798

Facility Feasibility (Giga Factory)

HSSMI LIMITED £101,388 £101,388

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 7

Project description - provided by applicants

This collaborative innovation project is focused on assessing the commercial feasibility of establishing a scalable Battery Cell Manufacturing Facility in the

UK, with the capability to ramp up to a Gigawatt hour worth of cell production (35m units) of mixed pouch and cylindrical cells by the year 2024\. This is

driven by the strategic need to establish the UK as a global leader in the development and manufacture of battery cells for electric vehicles. This project will

result in the delivery of a business case and manufacturing blueprint for the proposed GigaFactory that will enable AMTE Power to advance their production

and supply chain readiness of their battery cells towards the level of capability, scale and cost per Kwh required by the UK's burgeoning EV sector and it's

global demand.

The project is being led by AMTE Power and delivered in partnership with HSSMI. The project will take place over 12 months and deliver the following as

part of the study:

* A market assessment that provides an analysis into the size of the market, projected growth, target demographics, partnership and collaboration

opportunities and competitor analysis

* A building and site specification for the Gigawatt facility, addressing: building requirements, required machinery and equipment for fit out, labour

requirements in the build and operation of the facility, supply chain requirements and an assessment of the potential impact such a facility would have on

land, zoning laws and the surrounding environment and local habitats.

* An Economic assessment of where to locate the facility, taking into consideration the cost benefits in relation to: access to suppliers, knowledge partners,

customers, a local skills base, and the availability of regional economic incentives. It will also take into consideration the resultant environmental and socio-

economic impacts the facility will have on local habitats, town and communities, the supply chain and the surrounding environment.

* The definition of a manufacturing strategy that addresses: factory layout, manufacturing specification, production management, logistics (internal and

external), Bill of Processes, warehousing, automation, ICT systems, development of smart factory concept, reject strategy and end of life management of the

manufactured battery cells.

* A factory design concept, illustrated in 3D and accessible through Virtual Reality, that demonstrates the size, fit and flow of the facility.

Total Project costs are £350,895

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 8

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

ANAPHITE LIMITED Scaling-up the Production of Graphene- £349,846 £244,892

Metal Oxide Composites as Li-ion Battery

Materials (GRAMOX)

University of Warwick £149,622 £149,622

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 9

Project description - provided by applicants

This project is led by Anaphite Limited (UK), a start-up materials science company developing graphene-based nanocomposites for applications in energy

storage, photocatalysis and thermal management. Warwick Manufacturing group (WMG) at Warwick University is an academic department with world-

leading expertise in research and application of smart, connected, autonomous and electrified transport. This project also exploits state-of-the-art materials

characterisation facilities at the National Physical Laboratory (NPL).

This project aims to create graphene-metal-oxide nanocomposite materials for applications as electrodes in next-generation lithium ion batteries.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 10

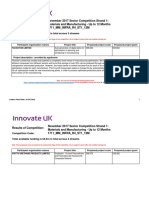

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

HOMEODYNAMIC AUTONOMY LIMITED Technical Feasibility Study (TFS) of £158,043 £110,630

Battery Remanufacturing for Electric

Vehicles (BATREV)

ASPIRE ENGINEERING LIMITED £114,498 £68,699

J D WHITEHOUSE ENTERPRISES LTD £75,260 £52,682

RECO TURBO LIMITED £86,094 £60,266

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 11

Project description - provided by applicants

The main motivation for the BATREV Technology Feasibility Study (TFS) is addressing the business need for remanufacturing warranty-return &

damaged/worn/EoL Electric Vehicle Batteries, (EVBs), the variety & quantities of which are increasing exponentially as vehicle manufacturers compete

fiercely in the EV market.

The main states-of-the art address high-volume/low-variety EVB-remanufacturing markets, i.e. (i) high-cost fixed-automation, and/or (ii) robots with limited

intelligence which is insufficient for technical fitness-for-purpose for small-batch production & frequent change-overs. This provides an immediate and

growing BATREV business opportunity as current technologies cannot cope with EVB-disassembly's adverse health & safety conditions, varying levels of

wear, corrosion and damage, and part identification/location uncertainty created through in-service maintenance/up-grading/component degradation.

BATREV-outputs will be at virtual-demonstrator-level, i.e.: (1) TFSPLAN & TFSSIM database tools of RRE simulation assets enabling (i) creation &

visualisation of RRE-scenarios, (ii) RRE mechanical-characteristics, (iii) end-effector motions, (iv) scalability and manufacturability data-collection & output to

TFS. (2) TFSOPT AI-enabled tool for optimised RRE Planning & QCDE characteristics.

The UK economy benefits from BATREV by providing routes to high levels of import substitution by originally-imported engines being remanufactured in the

UK and being substituted by UK OEMs for new imported engines.

The Technical Feasibility Study of Battery Remanufacturing for Electric Vehicles (BATREV) project will undertake a feasibility study to identify the scalability,

manufacturability and capability of using autonomous robots and autonomous operations planning systems to undertake the remanufacturing of EVBs, i.e.

battery-to-component disassembly, operations planning of component repair & reconditioning processes and component-to-battery reassembly.

Providing a clear understanding of the processes needed to scale-up will be a primary aim of the BATREV project particularly in terms of: (1) De-risking

scaling-up of the innovative autonomous Robot Remanufacturing Engineer (RRE) technology and autonomous operations planning methods. (2) making

scaling-up faster and less costly, and (3) providing a clear route to scale-up of RRE technology.

BATREV TFS will examine RRE scale-up and its effects on UK competitiveness, and numbers and size of EVB remanufacturers.

Social benefits arise through improved job security and employment opportunities from increased organisational growth rates through greater robot enabled

productivity. Quality of life impacts inside/outside the consortium are derived from competitive advantage improvements. Environmental and economic

benefits arise from (1) reuse of battery components where materials are ~65% of costs, (2) reduced waste, landfill, pollution, CO2 emissions, and (3)

reduced lead times hence less factory light & heat energy/EVB-unit, and (4) less energy costs through less factory space requirements.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 12

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

JOHNSON MATTHEY PLC Cathodes, Anodes, and Solid-state £248,019 £124,010

Electrolytes for Lithium Ion Batteries

(CASE LIBs)

TALGA TECHNOLOGIES LIMITED £116,860 £81,802

University of Sheffield £133,824 £133,824

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 13

Project description - provided by applicants

Solid state batteries have the potential to realise significant improvements in energy density (dense material layers) and cycle life (no solvent decomposition)

while enabling faster charging and offer improved safety (no flammable solvents). Whilst numerous automotive manufacturers are known to be researching

solid state batteries, thus far the technology remains at low technology readiness level and is considered to be several years from commercialisation. This is

in part due to handling, processing, and scaled production of the electrolyte materials, as well as ensuring suitable interaction at the electrolyte/active

material interface to mitigate persistent issues such as high impedance and mechanical fatigue.

This project aims to address these industrial and fundamental challenges by bringing together three leading organisations that are at the forefront of battery

materials and ceramic processing innovation. Johnson Matthey (one of UKs largest battery companies and a leading global cathode material manufacturer)

Talga Technologies (a SME with extensive experience in graphene production and R&D), University of Sheffield (ceramics group with advanced ceramics

processing capability).

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 14

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

INTERCAL(UK) LIMITED Assessment and development of the novel £98,004 £68,603

Intercal-Indra Battery Management System

“i-BMS”

INDRA RENEWABLE TECHNOLOGIES LIMITED £149,945 £104,962

University of Warwick £71,897 £71,897

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 15

Project description - provided by applicants

WMG (University of Warwick) are collaborating with battery management experts Intercal (UK) Ltd and EV integrators Indra Renewable Technologies Ltd in

the third phase of evaluation and development of a novel battery management system (the "i-BMS").

This patented technology has been developed through proof of concept and initial field trials with the aid of two previous Innovate grants. The technology

signals a radical departure from prior art by eliminating the need for routine balancing of the cells.

This important feature offers scope for a greatly simplified battery pack design and thereby opens up opportunities for cost savings, greatly improved pack

maintainability and end-of-life re-use.

A major potential benefit identified in completed trials is the potential for very early fault detection, which has major safety and reliability benefits. Tests have

shown that, by eliminating all cell balancing currents, the i-BMS can be configured to provide sensitive detection of the first signs of anomalous behaviour by

any cell in the pack, thereby allowing timely intervention before any risk of failure or fire develops.

The current study will combine advanced modelling and simulations by WMG to evaluate the i-BMS performance, coupled with a supplementary programme

of laboratory tests and field trials led by Intercal and Indra respectively. Taken together, these will, if successful, validate the functionality of the i-BMS,

including comparison of the pack's usable energy capacity, degradation rate and diagnostic capability alongside conventional BMS solutions.

The project will also explore the opportunities provided by the elimination of complex cell balancing circuits, to simplify modular assembly, maintenance and

end-of-life repurposing of battery packs.

The partners' objective is to develop the technology to a state where it will be available for licensing to third parties for application in automotive, grid storage,

aviation and marine battery applications, a growing global market currently in excess of $1Bn annually.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 16

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

UNIPART GROUP LIMITED Project DETAIN: Designing an intelligent £89,073 £44,536

EV battery storage facility capable of the

DETection and contiAINment of thermal

runaway

ASPIRE ENGINEERING LIMITED £95,009 £66,506

HORIBA MIRA LIMITED £187,956 £93,978

INSTRUMENTEL LIMITED £84,750 £42,375

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 17

Project description - provided by applicants

Project DETAIN brings together the expertise of Unipart Logistics, Aspire Engineering, HORIBA MIRA, and Instrumentel, to develop an 'intelligent' high

voltage battery storage solution to mitigate the risks associated with thermal runaway. The consortium have an ambition to use intelligent systems to DETect

and contAIN thermal runaway: DETAIN.

Project DETAIN draws on the varying expertise, responsibilities and growth ambitions of the consortium to review industry-wide requirements and develop an

intelligent storage facility to provide the end-to-end Electric Vehicle supply chain with a sustainable alternative to sacrificial storage and the 'let it burn'

approach.

The Faraday Challenge has set a target to eliminate thermal runaway at pack level by 2035\. Until that is achieved, the batteries that are designed and built

will still be susceptible to thermal runaway, particularly when damaged or faulty, and will need to be safely stored. Project DETAIN aligns with the supply

chain need to better manage the batteries currently in production and enable the imminent growth predicted. The project also supports the Faraday

challenge for recyclability, as safe and effective storage solutions will be key to development of efficient remanufacturing, reuse for End-of-Life and recycling.

To detect thermal runaway there will be three areas of focus: 1) BMS thermal runaway detection algorithms for next generation hardware, 2) externally

mounted (on battery) thermal runaway detection systems, and 3) distributed sensor networks for battery storage facilities.

To contain thermal runaway, Project DETAIN will investigate automation, fire suppression materials, and combinations of the two, to deliver an effective

unmanned containment response when thermal runaway has been detected.

The project has additional focus on the safety, legislative and regulatory requirements to ensure solutions being developed are approved by relevant

Insurance bodies, and the testing requirements to approve the solution.

The feasibility study allows the consortium to fully investigate the potential of an intelligent battery storage facility and understand the requirements to deliver

a proof of concept. Project DETAIN's objectives are to:

* Complete a holistic analysis of the state-of-the-art processes, products and technology to detect and contain thermal runaway,

* Predict how an connected, intelligent storage solution could function in line with safety and insurance requirements,

* Produce a gap analysis to identify further developments required,

* A design and plan for the proof of concept facility,

* Specify the testing facilities required to measure the efficacy of the proof of concept.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 18

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

ZAPGO LTD 'Carbon Copy' - Driving New Standards for £340,852 £238,596

Carbon-Ion Battery Systems

University of Warwick £146,076 £146,076

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 19

Project description - provided by applicants

This project meets the need set out in the Faraday Battery Challenge to undertake research that will underpin the formation of a new supply chain able to

scale-up a novel energy storage technology and accelerate its adoption. The project will tackle the challenge of translating the component technology into a

complete battery system, primarily focussed on the road transport sector but with spill-over benefits to the aerospace, rail and marine sectors.

Oxford R&D companyZap&Go has developed a new generation of capacitive energy storage devices. The technology goes under the name of Carbon-Ion

(C-Ion), in contrast to Lithium-ion (Li-ion). It exploits the properties of novel nano-carbons and electrolytes to give increased energy density in an ultra-fast

charging package. Work to date has demonstrated the potential to double or even triple the energy density of today's supercapacitors.

When presenting the benefits of this new UK-generated technology to technically literate customers there are significant challenges. While these customers

are familiar with the testing and combining of different conventional battery types, the performance characteristics of C-Ion are significantly different. The

adoption of C-Ion technology would be boosted if it could be characterised in a standardised way, enabling the design of novel packs, modules and BMS's

using either C-Ion alone or as a hybrid with other energy storage. This adds an important, high power density capability for the automotive industry to

incorporate into electrification systems.

If Zap&Go is to engage with OEM or Tier 1 automotive customers, it is essential for it to produce independently verifiable, system-based evidence to

demonstrate that their cells perform as claimed. The project will generate data that will allow them to satisfy these expectations. It will also encourage and

support a new supply chain through defining proper test and validations methods.

Zap&Go's bid partner WMG is an academic department of Warwick University, where it runs the Energy Innovation Centre with unique experimental facilities

that enable development, characterisation and testing of individual battery cells through to complete energy storage systems.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 20

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

DEREGALLERA LTD Advanced metamaterials for sodium-ion £308,190 £215,733

battery anodes – a scalability and

economic feasibility study

University of Southampton £128,954 £128,954

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 21

Project description - provided by applicants

The cost of lithium-ion batteries is set to rise substantially in the near future, due to limited availability of lithium and the growing furore over "African blood

Cobalt", a key material of automotive LIB. Sodium-ion batteries are a viable alternative but suffer from larger size and weight. This high risk feasibility study

seeks to address this by investigating the potential of novel _metamaterial-carbon composites_ as high energy density, highly cyclable sodium-ion battery

anodes to manufacture sodium-ion batteries with no significant energy density loss compared to lithium-ion batteries. We will theoretically screen 100,000+

metamaterials for suitability, and synthesise the most promising ones in nanostructured carbon-composite particles.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 22

Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies Round 3

Competition Code: 1809_FS_MMM_ISCF_FARADAY_R3

Total available funding is £2 million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

HEAT TRACE LIMITED Novel self-regulating CHIP (Cooling and £175,384 £105,230

Heating Integrated Pipe) thermal

management systems for EV batteries

NOBEL AUTOPARTS U.K. LIMITED £174,576 £87,288

University of Warwick £149,904 £149,904

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 23

Project description - provided by applicants

This is a 12-month feasibility project with 3 partners, Heat Trace Ltd (Lead Partner and SME), Nobel Autoparts UK Ltd (Tier 1 supplier and a Large company)

and Warwick Manufacturing Group (RTO)

Our vision is the transfer Heat Trace's aluminium-based polymeric smart self-regulating technology into Battery Thermal Management systems. Self-

regulating heaters cannot burn out which eliminates thermal runaways.

The key objectives are the

1) Development of heating prototypes

2) Incorporation of cooling modules

3) Development of a combined heating/cooling module

4) Development of electrical and fluid connectors

5) Thermal modelling

6) Evaluation of scale up

Our approach has 2 steps. In step 1 we replace a state-of-the art EV battery heater with a self-regulating polymer heater. We have estimated that the

benefits include better safety, reduced costs and reduced weight of the battery.

Step 2 is to replace the state-of-the-art EV cooling module with a CHIP (Cooling and Heating Integrated Pipe). A CHIP module can be either operated as a

cooling module or a heating module. We have estimated the benefits and compared them to the 8 Faraday targets. Our analysis shows that the CHIP

technology will have significant benefits in 7 of the 8 Faraday targets and in addition will show significant weight reduction of the EV battery.

The innovate features include

1) The CHIP module can be operated either as a heating module or a cooling module

2) The self-regulating polymer will minimise variation of surface temperature

3) The aluminium conductors enable flexible geometry, so heater can be customised to any shape, any cell type or module/pack configuration.

Note: you can see all Innovate UK-funded projects here: https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 18/02/2019 24

Вам также может понравиться

- Cyberforce Overview PresentationДокумент21 страницаCyberforce Overview Presentationandreko11Оценок пока нет

- LNC-T510i Operator's Manual-V04.00.000 (4408110053) ENGДокумент94 страницыLNC-T510i Operator's Manual-V04.00.000 (4408110053) ENGEduardo Gonzalez OleaОценок пока нет

- Results of Competition: Newton - UK-China Agri Tech Challenge 2017 Competition Code: 1706 - CRD1 - NEWTON - CHNBBSRCДокумент19 страницResults of Competition: Newton - UK-China Agri Tech Challenge 2017 Competition Code: 1706 - CRD1 - NEWTON - CHNBBSRCJack PadiОценок пока нет

- Energy Storage: Legal and Regulatory Challenges and OpportunitiesОт EverandEnergy Storage: Legal and Regulatory Challenges and OpportunitiesОценок пока нет

- Results of Competition: Newton - UK-China Agri Tech Challenge 2017 Competition Code: 1706 - CRD1 - NEWTON - CHNBBSRCДокумент19 страницResults of Competition: Newton - UK-China Agri Tech Challenge 2017 Competition Code: 1706 - CRD1 - NEWTON - CHNBBSRCJack PadiОценок пока нет

- Global Pharma and Healthcare Social Media Market Research Report, 2020-2026 PDFДокумент95 страницGlobal Pharma and Healthcare Social Media Market Research Report, 2020-2026 PDFSomya SrivastavaОценок пока нет

- Enrollment System Complete Capstone DocumentationДокумент16 страницEnrollment System Complete Capstone DocumentationRaymund Zuela100% (1)

- Sea Tel Tac 92Документ75 страницSea Tel Tac 92Liviu Anghel100% (2)

- Results of Competition: APC 11: Advancing The UK's Low Carbon Automotive Capability Competition Code: 1808 - CRD1 - TRANS - APC11Документ6 страницResults of Competition: APC 11: Advancing The UK's Low Carbon Automotive Capability Competition Code: 1808 - CRD1 - TRANS - APC11Jack PadiОценок пока нет

- Results of Competition: Faraday Battery Challenge: Innovation R&D Studies Round 3 Competition Code: 1809 - CRD - MMM - ISCF - FARADAY - R3Документ26 страницResults of Competition: Faraday Battery Challenge: Innovation R&D Studies Round 3 Competition Code: 1809 - CRD - MMM - ISCF - FARADAY - R3Jack PadiОценок пока нет

- Competition Results - Transforming Accountancy With AI Data Large Consortia PDFДокумент8 страницCompetition Results - Transforming Accountancy With AI Data Large Consortia PDFJack PadiОценок пока нет

- Wireless Electric Vehicle Charging For Commercial Users - FS - Competition Results PDFДокумент19 страницWireless Electric Vehicle Charging For Commercial Users - FS - Competition Results PDFJack PadiОценок пока нет

- Results of Competition: APC 10: Advancing The UK's Low Carbon Automotive Capability Competition Code: 1804 - CRD1 - TRANS - APC10Документ6 страницResults of Competition: APC 10: Advancing The UK's Low Carbon Automotive Capability Competition Code: 1804 - CRD1 - TRANS - APC10Jack PadiОценок пока нет

- Results of Competition: Robotics and AI: Inspect, Maintain and Repair in Extreme Environments Competition Code: 1805 - ROBOTICSДокумент11 страницResults of Competition: Robotics and AI: Inspect, Maintain and Repair in Extreme Environments Competition Code: 1805 - ROBOTICSJack PadiОценок пока нет

- Competition Results - Energy Catalyst R6 Transforming Energy Access PDFДокумент36 страницCompetition Results - Energy Catalyst R6 Transforming Energy Access PDFJack PadiОценок пока нет

- Results of Competition: Smart Local Energy Systems: Concepts and Designs Competition Code: 1804 - ISCF - SMART - ENERGY - DESIGNДокумент26 страницResults of Competition: Smart Local Energy Systems: Concepts and Designs Competition Code: 1804 - ISCF - SMART - ENERGY - DESIGNJack PadiОценок пока нет

- Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies - Round 2 1801 - FS - TRANS - BATTERY - R2Документ14 страницResults of Competition: Faraday Battery Challenge: Innovation Feasibility Studies - Round 2 1801 - FS - TRANS - BATTERY - R2Jack PadiОценок пока нет

- Results of Competition: Commercialising Quantum Devices: Innovation R&D Competition Code: 1804 - CRD - CO - ISCF - QUANTUMДокумент12 страницResults of Competition: Commercialising Quantum Devices: Innovation R&D Competition Code: 1804 - CRD - CO - ISCF - QUANTUMJack PadiОценок пока нет

- Results of Competition: Aerospace Technology Institute Batch 26 Competition Code: 1309 - SPEC - TRA - ATI - Batch26Документ16 страницResults of Competition: Aerospace Technology Institute Batch 26 Competition Code: 1309 - SPEC - TRA - ATI - Batch26Jack PadiОценок пока нет

- Results of Competition: UKART: Fast-Track Collaborative R&D Round 1 Full Stage Competition Code: 1809 - CRD - FT - UKART - R1Документ14 страницResults of Competition: UKART: Fast-Track Collaborative R&D Round 1 Full Stage Competition Code: 1809 - CRD - FT - UKART - R1Jack PadiОценок пока нет

- Results of Competition: UKART: Collaborative R&D Round 1 Full Stage Competition Code: 1809 - CRD - UKART - R1Документ8 страницResults of Competition: UKART: Collaborative R&D Round 1 Full Stage Competition Code: 1809 - CRD - UKART - R1Jack PadiОценок пока нет

- Results of Competition: Electric Vehicle Charging For Public Spaces: Feasibility Studies Competition Code: 1807 - FS - OLEV - ELEC - ST1Документ45 страницResults of Competition: Electric Vehicle Charging For Public Spaces: Feasibility Studies Competition Code: 1807 - FS - OLEV - ELEC - ST1Jack PadiОценок пока нет

- Results of Competition: Productive and Sustainable Crop and Ruminant Agricultural Systems Competition Code: 1808 - CRD - HLS - AFTFPДокумент51 страницаResults of Competition: Productive and Sustainable Crop and Ruminant Agricultural Systems Competition Code: 1808 - CRD - HLS - AFTFPJack PadiОценок пока нет

- Results of Competition: Newton - UK-India Industrial Biotechnology (BBSRC) 1706 - Crd1 - Newton - IndbbsrcДокумент8 страницResults of Competition: Newton - UK-India Industrial Biotechnology (BBSRC) 1706 - Crd1 - Newton - IndbbsrcJack PadiОценок пока нет

- Demonstrator For Robotics and AI in Extreme and Challenging Environments Phase 2 - Competition Results PDFДокумент18 страницDemonstrator For Robotics and AI in Extreme and Challenging Environments Phase 2 - Competition Results PDFJack PadiОценок пока нет

- Competition Results - Open Grant Funding Competition R3 PDFДокумент102 страницыCompetition Results - Open Grant Funding Competition R3 PDFJack PadiОценок пока нет

- Competition Results - Analysis For Innovators Round 3 - Mini Projects Phase 2 PDFДокумент118 страницCompetition Results - Analysis For Innovators Round 3 - Mini Projects Phase 2 PDFJack PadiОценок пока нет

- Results of Competition: Agri-Tech Catalyst Colombia Competition Code: 1804 - AGRITECH - COLOMBIAДокумент14 страницResults of Competition: Agri-Tech Catalyst Colombia Competition Code: 1804 - AGRITECH - COLOMBIAJack PadiОценок пока нет

- Results of Competition: Accelerating Innovation in Rail 5 - Disruption To Trains - 0-12 Months 1709 - INNV - RAIL5Документ22 страницыResults of Competition: Accelerating Innovation in Rail 5 - Disruption To Trains - 0-12 Months 1709 - INNV - RAIL5Jack PadiОценок пока нет

- Results of Competition: Increase Productivity, Performance and Quality in UK Construction Competition Code: 1807 - ISCF - IPPQUKCДокумент52 страницыResults of Competition: Increase Productivity, Performance and Quality in UK Construction Competition Code: 1807 - ISCF - IPPQUKCJack PadiОценок пока нет

- Results of Competition: Sustainable Urbanisation Global Initiative (SUGI) 1612 - EU - ERANET - URBANДокумент7 страницResults of Competition: Sustainable Urbanisation Global Initiative (SUGI) 1612 - EU - ERANET - URBANJack PadiОценок пока нет

- Competition Results - January 2018 Sector Competition - Strand 2 Emerging and Enabling PDFДокумент83 страницыCompetition Results - January 2018 Sector Competition - Strand 2 Emerging and Enabling PDFJack PadiОценок пока нет

- Competition Results - ICURe Follow On Funding PDFДокумент12 страницCompetition Results - ICURe Follow On Funding PDFJack PadiОценок пока нет

- Results of Competition: Icure: Open Competition For Spin-Out Companies Competition Code: 1804 - Icure - OpenДокумент12 страницResults of Competition: Icure: Open Competition For Spin-Out Companies Competition Code: 1804 - Icure - OpenJack PadiОценок пока нет

- Results of Competition: November 2017 Sector Competition Strand 2: Infrastructure Systems - 3 To 12 Months 1711 - MM - INFRA - R4 - ST2 - 12MДокумент32 страницыResults of Competition: November 2017 Sector Competition Strand 2: Infrastructure Systems - 3 To 12 Months 1711 - MM - INFRA - R4 - ST2 - 12MJack PadiОценок пока нет

- Results of Competition: Biomedical Catalyst 2018 Round 1 Feasibility Studies Competition Code: 1803 - BMC - R1 - FSДокумент31 страницаResults of Competition: Biomedical Catalyst 2018 Round 1 Feasibility Studies Competition Code: 1803 - BMC - R1 - FSJack PadiОценок пока нет

- Competition Results - SBRI First of A Kind 2 - Demonstrating Tomorrow S PDFДокумент20 страницCompetition Results - SBRI First of A Kind 2 - Demonstrating Tomorrow S PDFJack PadiОценок пока нет

- Results of Competition: UK-Sweden EUREKA Proposals For Aerospace Research and Development Competition Code: 1807 - EURNET - SWEDENДокумент10 страницResults of Competition: UK-Sweden EUREKA Proposals For Aerospace Research and Development Competition Code: 1807 - EURNET - SWEDENJack PadiОценок пока нет

- Results of Competition: Medicines Manufacturing Round 2: Challenge Fund Competition Code: 1803 - ISCF - ASHN - MEDMANR2Документ22 страницыResults of Competition: Medicines Manufacturing Round 2: Challenge Fund Competition Code: 1803 - ISCF - ASHN - MEDMANR2Jack PadiОценок пока нет

- Results of Competition: Establishing A Core Innovation Hub To Transform UK Construction Competition Code: 1803 - ISCF - TCCIHДокумент2 страницыResults of Competition: Establishing A Core Innovation Hub To Transform UK Construction Competition Code: 1803 - ISCF - TCCIHJack PadiОценок пока нет

- Results of Competition: Icure Follow On Funding Round 4 Competition Code: 1901 - Fs - CRD - Co - Icure - R4Документ6 страницResults of Competition: Icure Follow On Funding Round 4 Competition Code: 1901 - Fs - CRD - Co - Icure - R4Jack PadiОценок пока нет

- Results of Competition: Newton Fund - China - Guangdong Province 1707 - CRD1 - NEWTON - CHNGDSTДокумент10 страницResults of Competition: Newton Fund - China - Guangdong Province 1707 - CRD1 - NEWTON - CHNGDSTJack PadiОценок пока нет

- Results of Competition: Audience of The Future Demonstrators Competition Code: 1805 - ISCF - AUDIENCE - DEMOДокумент9 страницResults of Competition: Audience of The Future Demonstrators Competition Code: 1805 - ISCF - AUDIENCE - DEMOJack Padi100% (1)

- Results of Competition: Digital Health Technology Catalyst Round 3: Collaborative R&D Competition Code: 1809 - CRD - HEAL - DHTC - R3Документ29 страницResults of Competition: Digital Health Technology Catalyst Round 3: Collaborative R&D Competition Code: 1809 - CRD - HEAL - DHTC - R3Jack PadiОценок пока нет

- Results of Competition: Robotics and AI in Extreme Environments 1806 - ROB - AIДокумент1 страницаResults of Competition: Robotics and AI in Extreme Environments 1806 - ROB - AIJack PadiОценок пока нет

- Results of Competition: Prospering From The Energy Revolution (PFER) - Blue Zone 1703 - CRD1 - ENRG - ENCATES5 - PFERBZДокумент22 страницыResults of Competition: Prospering From The Energy Revolution (PFER) - Blue Zone 1703 - CRD1 - ENRG - ENCATES5 - PFERBZJack PadiОценок пока нет

- Results of Competition: UKRI and Sky Ocean Ventures Plastics Innovation and Investment Fund Competition Code: 1901 - IA - MMM - SKY - SOVPДокумент2 страницыResults of Competition: UKRI and Sky Ocean Ventures Plastics Innovation and Investment Fund Competition Code: 1901 - IA - MMM - SKY - SOVPJack PadiОценок пока нет

- Results of Competition: UK-China Collaboration To Tackle Antimicrobial Resistance Competition Code: 1802 - CRD - DH - CHN - AMRДокумент28 страницResults of Competition: UK-China Collaboration To Tackle Antimicrobial Resistance Competition Code: 1802 - CRD - DH - CHN - AMRJack PadiОценок пока нет

- Results of Competition: VIA Project Energy Catalyst R5 Late Stage Competition Code: 1810 - CRD - CGI - ECSPECPROДокумент2 страницыResults of Competition: VIA Project Energy Catalyst R5 Late Stage Competition Code: 1810 - CRD - CGI - ECSPECPROJack PadiОценок пока нет

- Results of Competition: SBRI - Roads For The Future (NIC) 1801 - SBRI - NIC - DRDAДокумент5 страницResults of Competition: SBRI - Roads For The Future (NIC) 1801 - SBRI - NIC - DRDAJack PadiОценок пока нет

- Results of Competition: SBRI: Protecting Nuclear Decommissioning Operators Competition Code: 1804 - SBRI - SELLAFIELDДокумент26 страницResults of Competition: SBRI: Protecting Nuclear Decommissioning Operators Competition Code: 1804 - SBRI - SELLAFIELDJack PadiОценок пока нет

- Results of Competition: Regulators Pioneer Fund Competition Code: 1807 - REG - PFДокумент30 страницResults of Competition: Regulators Pioneer Fund Competition Code: 1807 - REG - PFJack PadiОценок пока нет

- Results of Competition: Advanced Therapy Treatment Centres: Network Projects Competition Code: 1806 - ATTC - NETWORKДокумент5 страницResults of Competition: Advanced Therapy Treatment Centres: Network Projects Competition Code: 1806 - ATTC - NETWORKJack PadiОценок пока нет

- Results of Competition: Women in Innovation 2018 Competition Code: 1806 - WOMEN - IN - INNOVATIONДокумент18 страницResults of Competition: Women in Innovation 2018 Competition Code: 1806 - WOMEN - IN - INNOVATIONJack PadiОценок пока нет

- Results of Competition: Innovation in Health and Life Sciences Round 3 - Up To 12 Months 1710 - HLS - R3 - 12MДокумент56 страницResults of Competition: Innovation in Health and Life Sciences Round 3 - Up To 12 Months 1710 - HLS - R3 - 12MJack PadiОценок пока нет

- Results of Competition: SBRI: Protecting Nuclear Decommissioning Operators - Phase 2 Competition Code: 1901 - SBRI - SELLAFIELD - PH2Документ6 страницResults of Competition: SBRI: Protecting Nuclear Decommissioning Operators - Phase 2 Competition Code: 1901 - SBRI - SELLAFIELD - PH2Jack PadiОценок пока нет

- Results of Competition: Planning Rail Capacity Through Automated Infrastructure Design Competition Code: 1810 - CRD - NETWORKRAILДокумент8 страницResults of Competition: Planning Rail Capacity Through Automated Infrastructure Design Competition Code: 1810 - CRD - NETWORKRAILJack PadiОценок пока нет

- Results of Competition: UKI2S Accelerator Programme For Technology Development Projects: Round 3 Competition Code: 1809 - UKI2S - R3Документ6 страницResults of Competition: UKI2S Accelerator Programme For Technology Development Projects: Round 3 Competition Code: 1809 - UKI2S - R3Jack PadiОценок пока нет

- Results of Competition: Innovation Loans: Infrastructure Systems 1711 - LOAN - INFRA - FOAKДокумент13 страницResults of Competition: Innovation Loans: Infrastructure Systems 1711 - LOAN - INFRA - FOAKJack PadiОценок пока нет

- Results of Competition: DCMS Cyber Security Academic Startup Programme Phase 2 1804 - FS - DCMS - CSASP2Документ18 страницResults of Competition: DCMS Cyber Security Academic Startup Programme Phase 2 1804 - FS - DCMS - CSASP2Jack PadiОценок пока нет

- Results of Competition: Biomedical Catalyst 2018 Round 1: Early Stage Award Competition Code: 1803 - BMC - R1 - EARLYДокумент18 страницResults of Competition: Biomedical Catalyst 2018 Round 1: Early Stage Award Competition Code: 1803 - BMC - R1 - EARLYJack PadiОценок пока нет

- Results of Competition: Icure Follow On Funding Round 3 Competition Code: 1812 - Fs - CRD - Co - Icure - R3Документ18 страницResults of Competition: Icure Follow On Funding Round 3 Competition Code: 1812 - Fs - CRD - Co - Icure - R3Jack PadiОценок пока нет

- Results of Competition: Biomedical Catalyst 2018 Round 2 Late Stage Competition Code: 1808 - BMC - R2 - LSДокумент18 страницResults of Competition: Biomedical Catalyst 2018 Round 2 Late Stage Competition Code: 1808 - BMC - R2 - LSJack PadiОценок пока нет

- Results of Competition: November 2017 Sector Competition Strand 1: Materials and Manufacturing - Up To 12 Months 1711 - MM - INFRA - R4 - ST1 - 12MДокумент44 страницыResults of Competition: November 2017 Sector Competition Strand 1: Materials and Manufacturing - Up To 12 Months 1711 - MM - INFRA - R4 - ST1 - 12MJack PadiОценок пока нет

- Results of Competition: Innovation Loans: Manufacturing and Materials Readiness Competition Code: 1802 - LOAN - MMДокумент16 страницResults of Competition: Innovation Loans: Manufacturing and Materials Readiness Competition Code: 1802 - LOAN - MMJack PadiОценок пока нет

- Results of Competition: Biomedical Catalyst 2018 Round 2 Primer Award Competition Code: 1808 - BMC - R2Документ28 страницResults of Competition: Biomedical Catalyst 2018 Round 2 Primer Award Competition Code: 1808 - BMC - R2Jack PadiОценок пока нет

- Results of Competition: November 2017 Sector Competition Strand 1: Materials and Manufacturing - Up To 12 Months 1711 - MM - INFRA - R4 - ST1 - 12MДокумент44 страницыResults of Competition: November 2017 Sector Competition Strand 1: Materials and Manufacturing - Up To 12 Months 1711 - MM - INFRA - R4 - ST1 - 12MJack PadiОценок пока нет

- Results of Competition: SBRI: Protecting Nuclear Decommissioning Operators Competition Code: 1804 - SBRI - SELLAFIELDДокумент26 страницResults of Competition: SBRI: Protecting Nuclear Decommissioning Operators Competition Code: 1804 - SBRI - SELLAFIELDJack PadiОценок пока нет

- Results of Competition: Innovation in Health and Life Sciences Round 3 - Up To 12 Months 1710 - HLS - R3 - 12MДокумент56 страницResults of Competition: Innovation in Health and Life Sciences Round 3 - Up To 12 Months 1710 - HLS - R3 - 12MJack PadiОценок пока нет

- Results of Competition: Increase Productivity, Performance and Quality in UK Construction Competition Code: 1807 - ISCF - IPPQUKCДокумент52 страницыResults of Competition: Increase Productivity, Performance and Quality in UK Construction Competition Code: 1807 - ISCF - IPPQUKCJack PadiОценок пока нет

- Results of Competition: November 2017 Sector Competition Strand 2: Infrastructure Systems - 3 To 12 Months 1711 - MM - INFRA - R4 - ST2 - 12MДокумент32 страницыResults of Competition: November 2017 Sector Competition Strand 2: Infrastructure Systems - 3 To 12 Months 1711 - MM - INFRA - R4 - ST2 - 12MJack PadiОценок пока нет

- Competition Results - SBRI First of A Kind 2 - Demonstrating Tomorrow S PDFДокумент20 страницCompetition Results - SBRI First of A Kind 2 - Demonstrating Tomorrow S PDFJack PadiОценок пока нет

- Results of Competition: Robotics and AI in Extreme Environments 1806 - ROB - AIДокумент1 страницаResults of Competition: Robotics and AI in Extreme Environments 1806 - ROB - AIJack PadiОценок пока нет

- Results of Competition: First of A Kind: Demonstrating Tomorrow's Trains Today 1710 - SBRI - FOAK - RAILДокумент17 страницResults of Competition: First of A Kind: Demonstrating Tomorrow's Trains Today 1710 - SBRI - FOAK - RAILJack PadiОценок пока нет

- Results of Competition: Electric Vehicle Charging For Public Spaces: Feasibility Studies Competition Code: 1807 - FS - OLEV - ELEC - ST1Документ45 страницResults of Competition: Electric Vehicle Charging For Public Spaces: Feasibility Studies Competition Code: 1807 - FS - OLEV - ELEC - ST1Jack PadiОценок пока нет

- Results of Competition: Support For Smes To Evaluate Innovative Medical Technologies 1801 - CRD - Ols - SmeimtДокумент15 страницResults of Competition: Support For Smes To Evaluate Innovative Medical Technologies 1801 - CRD - Ols - SmeimtJack PadiОценок пока нет

- Results of Competition: Newton Fund - China - Guangdong Province 1707 - CRD1 - NEWTON - CHNGDSTДокумент10 страницResults of Competition: Newton Fund - China - Guangdong Province 1707 - CRD1 - NEWTON - CHNGDSTJack PadiОценок пока нет

- Results of Competition: Sustainable Urbanisation Global Initiative (SUGI) 1612 - EU - ERANET - URBANДокумент7 страницResults of Competition: Sustainable Urbanisation Global Initiative (SUGI) 1612 - EU - ERANET - URBANJack PadiОценок пока нет

- Results of Competition: Prospering From The Energy Revolution (PFER) - Blue Zone 1703 - CRD1 - ENRG - ENCATES5 - PFERBZДокумент22 страницыResults of Competition: Prospering From The Energy Revolution (PFER) - Blue Zone 1703 - CRD1 - ENRG - ENCATES5 - PFERBZJack PadiОценок пока нет

- Results of Competition: SBRI: Antimicrobial Resistance (AMR) in Humans Competition Code: 1807 - SBRI - ANTIMICROBIALДокумент26 страницResults of Competition: SBRI: Antimicrobial Resistance (AMR) in Humans Competition Code: 1807 - SBRI - ANTIMICROBIALJack PadiОценок пока нет

- Results of Competition: Young Innovators' Awards Batch 1 1802 - CRD - YOUNG - INNOV - 1Документ24 страницыResults of Competition: Young Innovators' Awards Batch 1 1802 - CRD - YOUNG - INNOV - 1Jack PadiОценок пока нет

- Design Foundations Round 1 2018 - Competition Results PDFДокумент74 страницыDesign Foundations Round 1 2018 - Competition Results PDFJack PadiОценок пока нет

- Results of Competition: Newton - UK-India Industrial Biotechnology (BBSRC) 1706 - Crd1 - Newton - IndbbsrcДокумент8 страницResults of Competition: Newton - UK-India Industrial Biotechnology (BBSRC) 1706 - Crd1 - Newton - IndbbsrcJack PadiОценок пока нет

- Results of Competition: SBRI - Roads For The Future (NIC) 1801 - SBRI - NIC - DRDAДокумент5 страницResults of Competition: SBRI - Roads For The Future (NIC) 1801 - SBRI - NIC - DRDAJack PadiОценок пока нет

- Results of Competition: Precision Medicine Technologies: Shaping The Future Competition Code: 1805 - CRD - ASHN - PREC - MEDДокумент39 страницResults of Competition: Precision Medicine Technologies: Shaping The Future Competition Code: 1805 - CRD - ASHN - PREC - MEDJack PadiОценок пока нет

- January 2018 Sector Competition - Strand 1 Health and Life Sciences - Competition Results PDFДокумент63 страницыJanuary 2018 Sector Competition - Strand 1 Health and Life Sciences - Competition Results PDFJack PadiОценок пока нет

- Results of Competition: Faraday Battery Challenge: Innovation Feasibility Studies - Round 2 1801 - FS - TRANS - BATTERY - R2Документ14 страницResults of Competition: Faraday Battery Challenge: Innovation Feasibility Studies - Round 2 1801 - FS - TRANS - BATTERY - R2Jack PadiОценок пока нет

- Results of Competition: Medicines Manufacturing Round 2: Challenge Fund Competition Code: 1803 - ISCF - ASHN - MEDMANR2Документ22 страницыResults of Competition: Medicines Manufacturing Round 2: Challenge Fund Competition Code: 1803 - ISCF - ASHN - MEDMANR2Jack PadiОценок пока нет

- December 2017 Sector Competition - Open - Competition Results Up - To - 12 - Months PDFДокумент22 страницыDecember 2017 Sector Competition - Open - Competition Results Up - To - 12 - Months PDFJack PadiОценок пока нет

- Results of Competition: Innovation Loans: Infrastructure Systems 1711 - LOAN - INFRA - FOAKДокумент13 страницResults of Competition: Innovation Loans: Infrastructure Systems 1711 - LOAN - INFRA - FOAKJack PadiОценок пока нет

- Results of Competition: UK-China Collaboration To Tackle Antimicrobial Resistance Competition Code: 1802 - CRD - DH - CHN - AMRДокумент28 страницResults of Competition: UK-China Collaboration To Tackle Antimicrobial Resistance Competition Code: 1802 - CRD - DH - CHN - AMRJack PadiОценок пока нет

- Results of Competition: Innovation Loans: Manufacturing and Materials Readiness Competition Code: 1802 - LOAN - MMДокумент16 страницResults of Competition: Innovation Loans: Manufacturing and Materials Readiness Competition Code: 1802 - LOAN - MMJack PadiОценок пока нет

- Results of Competition: DCMS Cyber Security Academic Startup Programme Phase 2 1804 - FS - DCMS - CSASP2Документ18 страницResults of Competition: DCMS Cyber Security Academic Startup Programme Phase 2 1804 - FS - DCMS - CSASP2Jack PadiОценок пока нет

- Results of Competition: Women in Innovation 2018 Competition Code: 1806 - WOMEN - IN - INNOVATIONДокумент18 страницResults of Competition: Women in Innovation 2018 Competition Code: 1806 - WOMEN - IN - INNOVATIONJack PadiОценок пока нет

- 900169-001-Ovation 1 Quick Start Guide-Rev00 PDFДокумент12 страниц900169-001-Ovation 1 Quick Start Guide-Rev00 PDFNorlan JoinerОценок пока нет

- TDD and Hexagonal Architecture in Microservices CraftHubДокумент24 страницыTDD and Hexagonal Architecture in Microservices CraftHubMarcelo LimaОценок пока нет

- UPS - Netpro Operation Manual 0k6 1k5 VaДокумент13 страницUPS - Netpro Operation Manual 0k6 1k5 VagoroonОценок пока нет

- 3 - Practical Benefit of Risk Assessment-Zone Determination by Layout Analysis PDFДокумент29 страниц3 - Practical Benefit of Risk Assessment-Zone Determination by Layout Analysis PDFrafecar100% (1)

- 2p6a 0822Документ3 страницы2p6a 0822Wasim IqbalОценок пока нет

- ONAP PNF Plug and PlayДокумент43 страницыONAP PNF Plug and PlayCapri CaviedesОценок пока нет

- US DOE Energy Tips On CDAДокумент2 страницыUS DOE Energy Tips On CDADarrenkjcОценок пока нет

- Manual VRRP MikrotikДокумент29 страницManual VRRP Mikrotikusopen0Оценок пока нет

- Design of JFET Bias Circuits: ExperimentДокумент11 страницDesign of JFET Bias Circuits: ExperimentShang Divina EbradaОценок пока нет

- Packet Life in LinuxДокумент19 страницPacket Life in LinuxshanbhagdhirajОценок пока нет

- Campus Recruitment System - PHP P012Документ10 страницCampus Recruitment System - PHP P012KBN MCAОценок пока нет

- Transportation SystemДокумент6 страницTransportation SystemMawi CrovempireОценок пока нет

- Sales EngineerДокумент2 страницыSales EngineerDeborah RyanОценок пока нет

- Niigata Power Systems Co., LTD.: After-Sales Service ProductДокумент2 страницыNiigata Power Systems Co., LTD.: After-Sales Service Productluis eduardoОценок пока нет

- SessionДокумент13 страницSessionVarun BhandariОценок пока нет

- NV Item 0-73821 20170425Документ1 356 страницNV Item 0-73821 20170425namelastin0% (1)

- Ripemd 160Документ17 страницRipemd 160Florist ScaОценок пока нет

- Introduction To Reactor Technology - BWR: Nuclear Regulatory CommissionДокумент10 страницIntroduction To Reactor Technology - BWR: Nuclear Regulatory CommissionJose DenizОценок пока нет

- Step by Step Guide For EFRIS Device and Thumbprint RegistrationДокумент10 страницStep by Step Guide For EFRIS Device and Thumbprint RegistrationlovicbrancoОценок пока нет

- Sap PM Function ModulesДокумент2 страницыSap PM Function ModulesMerugu JalendharОценок пока нет

- Retiming CamshaftДокумент1 страницаRetiming CamshaftArun SОценок пока нет

- Online Car Rental Management System PresentationДокумент14 страницOnline Car Rental Management System PresentationRaja Bilal JanjuaОценок пока нет

- Writing Vos ScriptДокумент11 страницWriting Vos Scriptvish_07Оценок пока нет

- Program Evaluation Documents (Table 1 To 16)Документ14 страницProgram Evaluation Documents (Table 1 To 16)Cristina CarpioОценок пока нет

- Engineering ProfessionДокумент26 страницEngineering ProfessionTyn MaturanОценок пока нет