Академический Документы

Профессиональный Документы

Культура Документы

Deep Sea Electronics PLC 704 Automatic Mains Failure Module Instructions

Загружено:

Eduardo DavidОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Deep Sea Electronics PLC 704 Automatic Mains Failure Module Instructions

Загружено:

Eduardo DavidАвторское право:

Доступные форматы

DEEP SEA ELECTRONICS PLC

704 AUTOMATIC MAINS FAILURE MODULE

OPERATING INSTRUCTIONS

Author:- John Ruddock

Deep Sea Electronics Plc

Highfield House

Hunmanby

North Yorkshire

YO14 0PH

England

Tel: +44 (0) 1723 890099

Fax: +44 (0) 1723 893303

email: Sales@Deepseaplc.com

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -1-

<< This page is intentionally blank >>

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -2-

TABLE OF CONTENTS

1 DESCRIPTION OF OPERATION .......................................................... 4

1.1MANUAL MODE OPERATION.........................................................................4

1.2AUTOMATIC MODE OF OPERATION.............................................................5

1.3WARNINGS.......................................................................................................6

1.4SHUTDOWNS ...................................................................................................6

2 CONFIGURATION INSTRUCTIONS..................................................... 7

3 CONFIGURATION TABLES ................................................................. 8

4 TERMINAL DESCRIPTION................................................................. 12

5 SPECIFICATION ................................................................................. 13

6 SOLID STATE OUTPUTS................................................................... 14

7 DIMENSIONS ...................................................................................... 15

8 TYPICAL CONNECTIONS.................................................................. 15

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -3-

1 DESCRIPTION OF OPERATION

1.1 MANUAL MODE OPERATION

To initiate a start sequence in MANUAL, press the pushbutton, and the start sequence is

initiated.

NOTE:- There is no Start Delay in this mode of operation.

If the pre-heat output option is selected this timer is then initiated, and the auxiliary output selected

is energised.

After the above delay the Fuel Solenoid is energised, then the Starter Motor is engaged.

The engine is cranked for a 10 second period. If the engine fails to fire during this cranking attempt

then the starter motor is disengaged for a 10 second period. Should this sequence continue

beyond the 3 starting attempts, the start sequence will be terminated and Fail to Start fault

will be illuminated.

When the engine fires, the starter motor is disengaged and locked out at 20 Hz measured from the

Alternator output. Rising oil pressure can also be used to disconnect the starter motor, however it

cannot be used for underspeed or overspeed detection.

After the starter motor has disengaged, the Safety On timer is activated (which is fixed at 12

seconds), allowing Oil Pressure, High Engine Temperature, Under-speed, Charge Fail and any

delayed Auxiliary fault inputs to stabilise without triggering the fault.

Once the engine is running, the Warm Up timer, if selected, is initiated, allowing the engine to

stabilise before it can be loaded.

The generator will run off load, unless the mains supply fails or a Remote Start on load signal is

applied, at which point the load will be transferred to the generator.

The generator will continue to run On load regardless of the state of the mains supply or remote

start input until the Auto mode is selected.

If Auto mode is selected, and the mains supply is healthy with the remote start on load signal not

active, then the Remote Stop Delay Timer begins, after which, the load is disconnected. The

generator will then run off load allowing the engine a cooling down period.

Selecting STOP de-energises the FUEL SOLENOID, bringing the generator to a stop.

NOTE:- The safety on time (used for delayed alarms) is pre set to 12 seconds and can

not be changed.

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -4-

1.2 AUTOMATIC MODE OF OPERATION

This mode is activated by pressing the pushbutton. An LED indicator beside the button

confirms this action.

Whether the start sequence is initiated by mains (utility) failure or by remote start input, the

following sequence is followed:

To allow for short term mains supply transient conditions or false remote start signals, the Start

Delay timer is initiated. After this delay, if the pre-heat output option is selected then the pre-heat

timer is initiated, and the corresponding auxiliary output (if configured) will energise.

NOTE:- If the mains supply returns within limits, (or the Remote Start signal is

removed if the start sequence was initiated by remote start) during the Start Delay timer,

the unit will return to a stand-by state.

After the above delays the Fuel Solenoid is energised, then one second later, the Starter Motor is

engaged.

The engine is cranked for a 10 second period. If the engine fails to fire during this cranking attempt

then the starter motor is disengaged for a 10 second rest period. Should this sequence continue

beyond the 3 starting attempts, the start sequence will be terminated and

Fail to Start fault will be illuminated.

When the engine fires, the starter motor is disengaged and locked out at 20 Hz measured from the

Alternator output. Rising oil pressure can also be used to disconnect the starter motor, however it

cannot be used for underspeed or overspeed detection.

After the starter motor has disengaged, the Safety On timer is activated, allowing Oil Pressure,

High Engine Temperature, Under-speed, Charge Fail and any delayed Auxiliary fault inputs to

stabilise without triggering the fault.

Once the engine is running, the Warm Up timer, if selected is initiated, allowing the engine to

stabilise before accepting the load.

If the remote start is being used and has been configured to Remote start is on load, or the mains

has failed, the load will be transferred to the generator.

On the return of the mains supply, (or removal of the Remote Start signal if the set was started by

remote signal), the Stop delay timer is initiated. Once it has timed out, the load is transferred back

to the mains (utility). The Cooling timer is then initiated, allowing the engine a cooling down period

off load before shutting down. Once the Cooling timer expires the Fuel Solenoid is de-energised,

bringing the generator to a stop.

If the mains should fail (or a Remote Start signal is re-activated) whilst the generator is Cooling

down, the load will be immediately transferred to the generator.

Should the mains supply fall outside limits again (or the Remote Start signal be re-activated)

during the cooling down period, the set will return on load.

NOTE:- The safety on time (used for delayed alarms) is pre set to 12 seconds and can

not be changed.

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -5-

1.3 WARNINGS

Warnings are used to warn the operator of an impending fault

BATTERY CHARGE FAILURE, if the module does not detect a voltage from the warning light

terminal on the auxiliary charge alternator, the icon will illuminate. (Either 8 Volts or 16 Volts

depending on the configuration of Nominal DC Voltage).

Inputs 1 and 2 can be configured as warnings or shutdowns. The relevant icon will be illuminated

when the input is active

1.4 SHUTDOWNS

Shutdowns are latching and stop the Generator. The alarm must be cleared, and the fault removed

to reset the module. In the event of a shutdown the appropriate icon will be illuminated

NOTE:- The alarm condition must be rectified before a reset will take place. If the

alarm condition remains it will not be possible to reset the unit (The exception to this is the

Low Oil Pressure alarm and similar ‘delayed alarms’, as the oil pressure will be low with

the engine at rest). Any subsequent warnings or shutdowns that occur will be displayed

steady, therefore only the first-up shutdown will appear flashing.

NOTE:- The safety on time (used for delayed alarms) is pre set to 12 seconds and can

not be changed.

FAIL TO START, if the engine does not fire after the pre-set 3 attempts at starting, a shutdown will

be initiated.

The icon will illuminate.

LOW OIL PRESSURE, if the module detects that the engine oil pressure has fallen below the low

oil pressure switch after the Safety On timer has expired, a shutdown will occur.

The icon will illuminate.

HIGH ENGINE TEMPERATURE if the module detects that the engine coolant temperature has

exceeded the high engine temperature switch after the Safety On timer has expired, a shutdown

will occur.

The icon will illuminate.

OVERSPEED, if the engine speed exceeds the pre-set trip (14% above the nominal frequency) a

shutdown is initiated. Overspeed is not delayed, it is an immediate shutdown.

The icon will illuminate.

NOTE:- During the start-up sequence the overspeed trip level is extended to 24%

above the normal frequency for the duration of the saftey timer to allow an extra trip level

margin. This is used to prevent nuisance tripping on start-up.

UNDERSPEED, if the engine speed falls below the pre-set trip (20% of the nominal frequency)

after the Safety On timer has expired, a shutdown is initiated.

The icon will illuminate.

Inputs 1 and 2 can be configured as warnings or shutdowns. The relevant icon will be illuminated

when the input is active

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -6-

2 CONFIGURATION INSTRUCTIONS

♦ With the unit in Stop mode, Configuration Mode is selected by operation of a small

switch on the rear, left-hand edge of the PCB. This is partially hidden to prevent accidental

operation.

Normal

Configuration

♦ Once Configuration Mode is selected, the ‘Auto’ LED will commence rapid flashing, and all

normal operation is suspended.

♦ The Stop pushbutton can be used to select the LED ‘code’ that corresponds to the

required function. The 5 left-hand LED’s will form the code. See configuration table over leaf.

♦ The Manual pushbutton will allow the user to change the associated value. The 3 right-

hand LED’s inform the user of the current setting for the chosen function. See configuration

table over leaf.

♦ When the required parameters are displayed, pressing the Auto button will save

the new setting, and the process is repeated for each function change.

♦ When configuration is complete, the Configuration Mode Selector Switch should be returned

to the ‘Normal’ position.

Parameter Value

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -7-

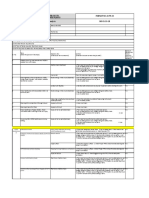

3 CONFIGURATION TABLES

FUNCTIONS AND CONFIGURATION TABLE

Function ! 1 ! 2 Value (Default in Bold)

Pre-heat Timer { { { { O { { { 0 Seconds

{ { O 5 Seconds

{ O { 10 Seconds

{ O O 15 Seconds

O { { 20 Seconds

O { O 30 Seconds

O O { 60 Seconds

O O O 180 Seconds

Used to pre-heat the engine prior to cranking. The output is active for the duration of the setting, prior to cranking.

Start Delay { { { O { { { { 0 Seconds

{ { O 5 Seconds

{ O { 10 Seconds

{ O O 15 Seconds

O { { 20 Seconds

O { O 30 Seconds

O O { 60 Seconds

O O O 180 Seconds

Used to give a delay between activating the remote start input, or a mains failure, and actually starting the engine.

Stop Delay { { { O O { { { 0 Seconds

Mains Return Delay { { O 5 Seconds

{ O { 10 Seconds

{ O O 15 Seconds

O { { 20 Seconds

O { O 30 Seconds

O O { 60 Seconds

O O O 180 Seconds

Used to give a delay between the mains returning and the system switching the load back to the mains. Used to ensure

that the mains is steady before this action is executed.

Energise to Stop { { O { { { { { 0 Seconds

Hold Timer { { O 5 Seconds

{ O { 10 Seconds

{ O O 15 Seconds

O { { 20 Seconds

O { O 30 Seconds

O O { 60 Seconds

O O O 180 Seconds

Used for the control of the engine stop solenoid. When the engine is to be stopped, the Energise To Stop output

becomes active, closing the stop solenoid (fuel valve). When the engine comes to rest, the stop solenoid will remain

energised for the period of the Energise To Stop Timer, to ensure the engine has come to a complete stop.

Warm-up Timer { { O { O { { { 0 Seconds

{ { O 5 Seconds

{ O { 10 Seconds

{ O O 15 Seconds

O { { 20 Seconds

O { O 30 Seconds

O O { 60 Seconds

O O O 180 Seconds

Delay between the engine being available for use, and the closure of the generator load-switching device to allow time

for the engine to warm before being loaded. This occurs after the 12 second safety on timer.

Cooling Timer { { O O { { { { 0 Seconds

{ { O 5 Seconds

{ O { 10 Seconds

{ O O 15 Seconds

O { { 20 Seconds

O { O 30 Seconds

O O { 60 Seconds

O O O 180 Seconds

Delay between opening the generator load-switching device and stopping the engine to allow time for the engine to

cool down before being stopped. This is particularly useful when used in conjunction with turbo-charged engines.

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -8-

FUNCTIONS AND CONFIGURATION TABLE

Function ! 1 ! 2 Value (Default in Bold)

Nominal Frequency { O { { { 50 Hz (O/S +14% /

{ { {

Overshoot +24%)

60 Hz (O/S +14% /

{ { O

Overshoot +24%)

The systems nominal frequency. Either 50 Hz or 60 Hz

Nominal DC Voltage { O { { O { { { 12V DC (CF 8V)

{ { O 24V DC (CF 16V)

The generator battery voltage. Either 12 Volts or 24 Volts. It is used for the charge alternator failure level.

LOP Switch Contact { O { O { { { { Close on Fault

{ { O Open on Fault

Configuration for the oil pressure switch. Either to close to battery negative on a fault, or open on a fault.

HET Switch Contact { O { O O { { { Close on Fault

{ { O Open on Fault

Configuration for the coolant temperature switch. Either to close to battery negative on a fault, or open on a fault.

Crank disconnect on { O O { { { { { Disabled

Oil Pressure Enabled (2 Second

{ { O

Delay)

If this is enabled, the starter motor will disconnect 2 seconds after the oil pressure switch detects oil pressure.

NOTE:- Not suitable for all generators, due to the different monitoring points on lubrication systems.

Underspeed { O O { O { { { Disabled

Detection { { O Enabled (U/S –20%)

If this is enabled, the unit will shut down the generator if the frequency falls below 20% of the nominal frequency.

Remote start { O O O { { { { Remote start

function { { O Simulated mains

Programmable input can be configured to one of the following.

♦ Remote start – If the input is active the generator will be started, and stopped if the input is deactive. Mains fail is

allways active.

♦ Simulated mains – If the input is active the generator will not start in the event of a mains failure. E.G. if the

generator is supporting a non 24 hour operation, a 24 hour timer can be used to prevent a mains failure from

starting the generator and taking load.

Remote start on load { O O O O Remote start is off

{ { {

(ignore if simulated load

mains) { { O Remote start is on load

The remote start input can be configured to one of the following.

♦ Remote start is off load – The generator will start and run off load when the remote start input is active.

♦ Remote start is on load – The generator will start, and the load transferred to the generator when the remote start

is active.

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR -9-

FUNCTIONS AND CONFIGURATION TABLE

Function ! 1 ! 2 Value (Default in Bold)

Auxiliary Input 1 O { { { { Immediate Warning

{ { {

Function Close on Fault

{ { O

Immediate Warning

Open on Fault

{ O {

Immediate Shutdown

Close on Fault

{ O O

Immediate Shutdown

Open on Fault

O { {

Delayed Warning

Close on Fault

O { O

Delayed Warning

Open on Fault

O O {

Delayed Shutdown

Close on Fault

O O O

Delayed Shutdown

Open on Fault

Programmable input, can be configured to on of the following

♦ Immediate warning close on fault – If the input is activated at any time the unit will alarm and energise the

common warning and common alarm output.

♦ Immediate warning open on fault – If the input is deactivated at any time the unit will alarm and energise the

common warning and common alarm output.

♦ Immediate shutdown close on fault – If the input is activated at any time the generator will be shutdown and

energise the common warning and common shutdown output. The generator can not be started.

♦ Immediate shutdown open on fault – If the input is deactivated at any time the generator will be shutdown and

energise the common warning and common shutdown output. The generator can not be started.

♦ Delayed warning close on fault – If the input is activated and the saftey time has elapsed the unit will alarm and

energise the common warning and common alarm output.

♦ Delayed warning open on fault – If the input is deactivated and the saftey time has elapsed the unit will alarm and

energise the common warning and common alarm output.

♦ Delayed shutdown close on fault – If the input is activated and the saftey time has elapsed the generator will be

shutdown and energise the common warning and common shutdown output.

♦ Delayed shutdown open on fault – If the input is deactivated and the saftey time has elapsed the generator will be

shutdown and energise the common warning and common shutdown output.

Auxiliary Input 2 O { { { O Immediate Warning

{ { {

Function Close on Fault

{ { O

Immediate Warning

Open on Fault

{ O {

Immediate Shutdown

Close on Fault

{ O O

Immediate Shutdown

Open on Fault

O { {

Delayed Warning

Close on Fault

O { O

Delayed Warning

Open on Fault

O O {

Delayed Shutdown

Close on Fault

O O O

Delayed Shutdown

Open on Fault

Programmable input, can be configured to on of the following

♦ Immediate warning close on fault – If the input is activated at any time the unit will alarm and energise the

common warning and common alarm output.

♦ Immediate warning open on fault – If the input is deactivated at any time the unit will alarm and energise the

common warning and common alarm output.

♦ Immediate shutdown close on fault – If the input is activated at any time the generator will be shutdown and

energise the common warning and common shutdown output. The generator can not be started.

♦ Immediate shutdown open on fault – If the input is deactivated at any time the generator will be shutdown and

energise the common warning and common shutdown output. The generator can not be started.

♦ Delayed warning close on fault – If the input is activated and the saftey time has elapsed the unit will alarm and

energise the common warning and common alarm output.

♦ Delayed warning open on fault – If the input is deactivated and the saftey time has elapsed the unit will alarm and

energise the common warning and common alarm output.

♦ Delayed shutdown close on fault – If the input is activated and the saftey time has elapsed the generator will be

shutdown and energise the common warning and common shutdown output.

♦ Delayed shutdown open on fault – If the input is deactivated and the saftey time has elapsed the generator will be

shutdown and energise the common warning and common shutdown output.

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR - 10 -

FUNCTIONS AND CONFIGURATION TABLE

Function ! 1 ! 2 Value (Default in Bold)

Auxiliary Output 1 O { { O { { { { Not used

Function { { O Pre-heat

{ O { Engine Running

{ O O Common Warning

O { { Common Shutdown

O { O System in Auto

O O { Common Alarm

O O O Energise to Stop

Programmable output can be configured to one of the following.

♦ Pre-heat. - The output is energised for the period of pre-heat time prior to cranking, and between the cranking

attempts.

♦ Engine Running. - The output is active after the saftey timer has elapsed.

♦ Common warning. - The output is active if there are any warning alarm active.

♦ Common shutdown - The output is active if there are any shutdown alarms active.

♦ System in auto. - The output is active when the system is in automatic mode.

♦ Common Alarm. - The output is active if there is any alarm condition.

♦ Energise to stop. - The output is energised when the engine is required to stop (normal or fault conditions), and

will remain energised for the period of the Energise To Stop Timer, to ensure the engine has come to a complete

stop.

Auxiliary Output 2 O { { O O { { { Not used

Function { { O Pre-heat

{ O { Engine Running

{ O O Common Warning

O { { Common Shutdown

O { O System in Auto

O O { Common Alarm

O O O Energise to Stop

Programmable output can be configured to one of the following.

♦ Pre-heat. - The output is energised for the period of pre-heat time prior to cranking, and between the cranking

attempts.

♦ Engine Running. - The output is active after the saftey timer has elapsed.

♦ Common warning. - The output is active if there are any warning alarm active.

♦ Common shutdown - The output is active if there are any shutdown alarms active.

♦ System in auto. - The output is active when the system is in automatic mode.

♦ Common Alarm. - The output is active if there is any alarm condition.

♦ Energise to stop. - The output is energised when the engine is required to stop (normal or fault conditions), and

will remain energised for the period of the Energise To Stop Timer, to ensure the engine has come to a complete

stop.

Mains Under O { O { { { { { 60V / 70V

Voltage { { O 70V / 80V

(Trip / Return) { O { 80V / 90V

{ O O 90V / 100V

O { { 120V / 140V

O { O 140V / 160V

O O { 160V / 180V

O O O 180V /200V

If for example 180/200 is selected the generator will be started and the load transferred if any phase falls below 180V

with respect to the neutral for the duration of the delay start timer. The load will be transferred back to mains when the

mains voltage returns to 200V or higher for the duration of the mains return timer. (The system must be in Auto)

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR - 11 -

4 TERMINAL DESCRIPTION

PIN DESCRIPTION CABLE NOTES

No SIZE

1 DC Plant Supply Input 1.0mm Connected to plant battery negative

(-ve)

2 DC Plant Supply Input 1.0mm Connected to plant battery positive

(+ve) (Recommended Fuse 2A)

3 Fuel relay Output 1.0mm Used to operate the fuel relay.

4 Start relay Output 1.0mm Used to operate the cranking relay.

5 Auxiliary Output relay 1 1.0mm Configurable output.

6 Auxiliary Output relay 2 1.0mm Configurable output.

7 Charge Fail Input/ Excitation 1.0mm Must NOT be connected to plant supply

Output negative if not used.

8 Low Oil Pressure Input 0.5mm Switch to negative.

9 High Engine Temp Input 0.5mm Switch to negative.

10 Auxiliary Input 1 0.5mm Switch to negative.

11 Auxiliary Input 2 0.5mm Switch to negative.

12 Remote Start Input 0.5mm Switch to negative.

13 Mains loading Relay 1.0mm Used to close the mains

Normally Open contact contactor / breaker

14 Generator loading Relay 1.0mm Used to close the generator

Normally Open contact contactor / breaker

15 Functional Earth 1.0mm Connect to a good clean earth point

16 Mains L1 1.0mm Connect to Mains L1 supply (AC)

Voltage Monitoring Input (Recommend 2A Fuse Max.)

17 Mains L2 1.0mm Connect to Mains L1 supply (AC)

Voltage Monitoring Input (Recommend 2A Fuse Max.)

18 Mains L3 1.0mm Connect to Mains L1 supply (AC)

Voltage Monitoring Input (Recommend 2A Fuse Max.)

19 Mains N 1.0mm Connect to Mains N supply (AC)

Voltage Monitoring Input

20 Alternator Input L1 1.0mm Do not connect if not used. (2A Fuse)

21 Alternator Input N 1.0mm Do not connect if not used.

NOTE:- For single phase mains monitoring the neutral should be connected to terminal

19, L1 should be connected to terminals 16,17 and 18.

NOTE:- For two phase mains monitoring the L2 should be connected to terminal 19, L1

should be connected to terminals 16,17 and 18. The voltage between the two phases must

not exceed 305 Volts.

NOTE:- All the outputs are solid state, rated at 1.2 Amps 8 Volts to 35 Volts DC, and

switch to battery negative when active.

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR - 12 -

5 SPECIFICATION

DC Supply: 8 Volts to 35 Volts DC Continuous.

Cranking Dropouts: Able to survive 0 Volts for 50 mS, providing supply was at

least 10 V before dropout and supply recovers to 5 Volts.

This is achieved without the need for internal batteries.

Max. Current: Operating 50mA

Standby 10mA

Alternator Input Range: 75 Volts (ph-N) to 277 Volts (ph-N) AC (+20%)

Mains Input Voltage 15 – 277 Volts (ph-N) AC (+20%)

Alternator Input Frequency: 50 - 60 Hz at rated engine speed

(Minimum: 75V AC Ph-N)

(Crank Disconnect from 15V Ph-N @ 20Hz)

Overspeed +14% (+24% overshoot)

Underspeed –20%

Mains Frequency 50 – 60 Hz

Start Output: 1.2 Amp DC at supply voltage.

Fuel Output: 1.2 Amp DC at supply voltage.

Auxiliary Outputs: 1.2 Amp DC at supply voltage.

Dimensions: 125mm x 165mm x 28 mm

Charge Fail: 12 Volts = 8 Volts CF 24 Volts = 16 Volts CF

Operating Temperature Range: -30°C to + 700C

Applicable Standards Compliant with BS EN 60950 Low Voltage Directive

Compliant with BS EN 50081-2: 1992 EMC Directive

Compliant with BS EN 61000-6-4: 2000 EMC Directive

Compliance to European Legislation

Registered Component for USA & Canada

Deep Sea Electronics plc reserve the right to change specification without notice.

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR - 13 -

6 SOLID STATE OUTPUTS

DSE’s utilisation of Solid State Outputs gives many advantages, the main points being:

♦ No Moving Parts

♦ Fully Overload / Short Circuit Protected.

♦ Smaller dimensions hence lighter, thinner and cheaper than conventional relays.

♦ Less power required making them far more reliable.

The main difference from conventional outputs is that solid state outputs switch to negative (–ve)

when active. This type of output is normally used with an automotive or plug in relay.

TYPICAL CONNECTIONS

Solid state output from DSE module

Fuel Solenoid (+ terminal)

eg. Terminal 3 of 703/4 - FUEL

* Observe polarity when using

relays fitted with integral diodes! A D

B C

Battery positive (+)

Solid State Output Automotive 8 Pin Plugin relay Function

from DSE Module Pin relay Pin

A 3 86 7 Fuel Output

B 85 2 To Positive supply via fuse

C 30 1 To Positive supply via fuse

D 87 3 To Fuel Solenoid

Example of relay pins connected to DSE solid state output to drive a fuel solenoid.

See overleaf for overall typical wiring diagram

NOTE:- The Close Mains Relay should be NORMALLY CLOSED when de-energised for fail

safe reasons. Should the DC supply fail the mains will always be available. The output from the

DSE solid state output when energised will OPEN the relay therefore isolating the mains supply.

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR - 14 -

7 DIMENSIONS

Dimensions:

165mm x 125mm x 29mm

(6.5” x 4.9” x 1.2”)

Panel cutout:

149mm x 109mm

(5.9” x 4.3”)

Mounting Method:

4 x 4.2mm diameter holes suitable for M4

screws.

8 TYPICAL CONNECTIONS

Mechanical Interlock

Load

Alternator Output Mains / Utility supply

L3 L3

L2 L2

L1 L1

N N

Electrical Interlock SSO = Solid state outputs

G M

F 2A

FUSES 2A = External 'Automotive' or 'Plug-in' type relays

Normally open

NOTE * Normally closed

* Close mains relay must be normally closed

to ensure fail safe operation

+ Close gen relay Close mains relay +

21 20 14 13 16 17 18 19

SSO

SSO

Close Gen output Close mains output

15

Fuel output Start output Auxiliary Outputs

SSO SSO SSO SSO Auxiliary Alarm

Inputs

1 2 3 4 5 6 7 8 9 10 11 12

Engine temperature

Remote Start

Oil Pressure

+ + + +

F2A F

+ Crank

Fuel Starter Charge

Battery motor alt

Terminals suitable for 22-16 awg (0.6mm2-1.3mm2 )field wiring

Tightening Torque = 0.8N-m (7lb-in)

704 Operating Instructions Issue Issue 2 07/05/2003 3:50 PM JR - 15 -

Вам также может понравиться

- Automotive Actuators and EVAP System TestingОт EverandAutomotive Actuators and EVAP System TestingРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Diesel Engine Care and Repair: A Captain's Quick GuideОт EverandDiesel Engine Care and Repair: A Captain's Quick GuideРейтинг: 5 из 5 звезд5/5 (1)

- Inyector Common Rail 1 PDFДокумент5 страницInyector Common Rail 1 PDFEduardo DavidОценок пока нет

- 509 ManualДокумент54 страницы509 ManualBruno Mariano33% (9)

- PDM1 Engine Protection Board Reference ManualДокумент8 страницPDM1 Engine Protection Board Reference ManualMuhammad Shoaib Hussain100% (2)

- Fujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsОт EverandFujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsОценок пока нет

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- PowerWizard 1.0Документ2 страницыPowerWizard 1.0Nelson Graça78% (9)

- CMD 2 ManualДокумент30 страницCMD 2 ManualAbdul Manan60% (5)

- SC1000 and Smart Tow ManualДокумент37 страницSC1000 and Smart Tow ManualJerry WoodsОценок пока нет

- Marine Electrics Made Simple or How to Keep the Batteries ChargedОт EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedОценок пока нет

- Markon Generator ManualДокумент52 страницыMarkon Generator ManualMd Rodi Bidin67% (3)

- Manual de Operación Deepsea DSE702Документ21 страницаManual de Operación Deepsea DSE702Carlos Andrés Marín ArcosОценок пока нет

- Learn to Drive: Everything New Drivers Need to KnowОт EverandLearn to Drive: Everything New Drivers Need to KnowРейтинг: 4 из 5 звезд4/5 (1)

- M6 Control Unit: Professional Manual Version 1.0Документ22 страницыM6 Control Unit: Professional Manual Version 1.0Jhezy Andron Andron100% (2)

- 3 Phase Auto Change Over SwitchДокумент23 страницы3 Phase Auto Change Over Switchajaykeshav100% (3)

- PCC 0300Документ8 страницPCC 0300Ammar BaigОценок пока нет

- The Hubbard Energy Transformer by Gaston BurridgeДокумент6 страницThe Hubbard Energy Transformer by Gaston BurridgepboserupОценок пока нет

- Gaseous Fuels - Application & Installation Guide - Lebw4977Документ48 страницGaseous Fuels - Application & Installation Guide - Lebw4977Yosmar Guzman100% (1)

- Dse720 ManualДокумент25 страницDse720 ManualJesus Manuel Aguirre AguirreОценок пока нет

- F 171Документ115 страницF 171Michael Parohinog Gregas100% (1)

- A-1.JSA-Service Panel & U.P.SДокумент1 страницаA-1.JSA-Service Panel & U.P.SVivek SinghОценок пока нет

- Deep Sea Electronics PLC: 702 Automatic Start Module Operating InstructionsДокумент10 страницDeep Sea Electronics PLC: 702 Automatic Start Module Operating InstructionsAmborsius SitorusОценок пока нет

- Harsen GU611A-EN0724 PDFДокумент34 страницыHarsen GU611A-EN0724 PDFSteven J Baynes100% (2)

- MANUAL SMARTGEN HGM6100 - v2.0 - enДокумент24 страницыMANUAL SMARTGEN HGM6100 - v2.0 - enManuel Otero100% (2)

- Dse720 ManualДокумент25 страницDse720 ManualSandeep Saikia100% (7)

- Auto Start / Instrumentation Generator Control Module - Pvs1Документ12 страницAuto Start / Instrumentation Generator Control Module - Pvs1FAOUZIОценок пока нет

- Deep Sea 704 ManualДокумент15 страницDeep Sea 704 ManualTri Mulyono Jr.Оценок пока нет

- Manual Deep Sea 520Документ19 страницManual Deep Sea 520MH..202380% (5)

- GCU-10 Automatic Engine Control Operators ManualДокумент11 страницGCU-10 Automatic Engine Control Operators ManualChhoan Nhun100% (1)

- Automatic Transfer Switch Panel Operation GuideДокумент23 страницыAutomatic Transfer Switch Panel Operation Guideyorgo7002100% (2)

- Methods For Coordinating System Protective EquipmentДокумент17 страницMethods For Coordinating System Protective EquipmentMichael Parohinog GregasОценок пока нет

- Science Course Outline: Grade 2: Be Friend With NatureДокумент30 страницScience Course Outline: Grade 2: Be Friend With NaturePuput Maharani100% (1)

- Dse704 Manual PDFДокумент15 страницDse704 Manual PDFJulio Hinostroza AlarconОценок пока нет

- Deep Sea ModuleДокумент15 страницDeep Sea ModuleMudasar BukhariОценок пока нет

- Dse703 ManualДокумент15 страницDse703 Manualroozbehxox100% (1)

- Deep Sea Electronics PLC: 705 Automatic Transfer Switch Operating InstructionsДокумент13 страницDeep Sea Electronics PLC: 705 Automatic Transfer Switch Operating InstructionsdennyОценок пока нет

- Automatic Engine Control Unit Operators ManualДокумент11 страницAutomatic Engine Control Unit Operators ManualAhmad ArpaniОценок пока нет

- Automatic Engine Control Unit Operators Manual: Kutai Electronics Industry Co., LTDДокумент11 страницAutomatic Engine Control Unit Operators Manual: Kutai Electronics Industry Co., LTDalexanderОценок пока нет

- DSE710Документ26 страницDSE710Muhammad Umer Adnan33% (3)

- Manual Modulo DSE520Документ20 страницManual Modulo DSE520jordaz30Оценок пока нет

- Cascade CD101 Auto-Start Controller: Installation and Operations ManualДокумент26 страницCascade CD101 Auto-Start Controller: Installation and Operations ManualJonathan Julián Cantillana DonosoОценок пока нет

- Gcu 10 Manual enДокумент11 страницGcu 10 Manual enGhassan ABO ALIОценок пока нет

- MANUAL CENTRAL M6 - Rev1-FДокумент24 страницыMANUAL CENTRAL M6 - Rev1-FRuddy Fabrizio Galvez JustinianoОценок пока нет

- Ems 94132NДокумент14 страницEms 94132NShahid HussainОценок пока нет

- TE804Документ38 страницTE804byronsmart100% (2)

- Ecu 02 Manual enДокумент22 страницыEcu 02 Manual enMohd Ali Mohd Yunus100% (1)

- Gu601a En0507 PDFДокумент30 страницGu601a En0507 PDFChhoan Nhun100% (2)

- Genset Control Module-Level 0: Rear ViewДокумент7 страницGenset Control Module-Level 0: Rear ViewEdward R GrosvenorОценок пока нет

- Startc2003-Tw InstДокумент20 страницStartc2003-Tw InstMauricio Utrilla CadenasОценок пока нет

- Ecu 750 Instruction ManualДокумент8 страницEcu 750 Instruction ManualAu GroupsОценок пока нет

- Locomotive Safety DevicesДокумент5 страницLocomotive Safety DevicesmajjisatОценок пока нет

- ASTAT Plus Manual PDFДокумент35 страницASTAT Plus Manual PDFJesús Martin V MinayaОценок пока нет

- ASM720A-002: Data & Application NotesДокумент4 страницыASM720A-002: Data & Application Notesdargom salamanОценок пока нет

- User Manual: HGM180/180HC Automatic Control ModuleДокумент9 страницUser Manual: HGM180/180HC Automatic Control ModuleOdien SalehОценок пока нет

- Cascade CD101 - Auto-Start Controller - Installation and Operations Manual - 00-02.0594 - Sept 2011 - FW MURPHY PDFДокумент26 страницCascade CD101 - Auto-Start Controller - Installation and Operations Manual - 00-02.0594 - Sept 2011 - FW MURPHY PDFpevareОценок пока нет

- Am116a ManualДокумент11 страницAm116a Manualyusufemirsamuk74ysОценок пока нет

- Pump Manuals - Op-MV600Документ6 страницPump Manuals - Op-MV600kuladeepkatragaddaОценок пока нет

- MINCO F2 engine controller manualДокумент10 страницMINCO F2 engine controller manualAnas BasarahОценок пока нет

- Eaom-36r Eng v05Документ8 страницEaom-36r Eng v05Khaled KamelОценок пока нет

- HGM1770Документ16 страницHGM1770Thao Nguyen XuanОценок пока нет

- GTL Controller setting-TL182-021-00Документ20 страницGTL Controller setting-TL182-021-00uploader1514Оценок пока нет

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationОт EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationОценок пока нет

- A Through Zs of Learning to Drive, Accident Free!: Drivers HandbookОт EverandA Through Zs of Learning to Drive, Accident Free!: Drivers HandbookОценок пока нет

- Measure ground resistance easily with the EARTH HiTESTER 3143Документ4 страницыMeasure ground resistance easily with the EARTH HiTESTER 3143Eduardo DavidОценок пока нет

- Measure ground resistance easily with the EARTH HiTESTER 3143Документ4 страницыMeasure ground resistance easily with the EARTH HiTESTER 3143Eduardo DavidОценок пока нет

- Controls: Powerwizard 2.0 - Digital Control PanelДокумент2 страницыControls: Powerwizard 2.0 - Digital Control PanelEduardo DavidОценок пока нет

- 3InTouch Connectivity GuideДокумент19 страниц3InTouch Connectivity GuideFercho HuancaОценок пока нет

- TCs El TimeДокумент2 страницыTCs El TimeEduardo DavidОценок пока нет

- Power Wizart TreinningДокумент13 страницPower Wizart TreinningbagusОценок пока нет

- Connector Selector PDFДокумент64 страницыConnector Selector PDFEduardo David100% (1)

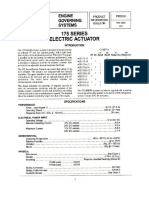

- Actuator Bosch 175 SeriesДокумент4 страницыActuator Bosch 175 SeriesEduardo DavidОценок пока нет

- DSE333 Operators ManualДокумент41 страницаDSE333 Operators ManualVictorRodriguezОценок пока нет

- Efectividad Bbva 21 03 11Документ1 страницаEfectividad Bbva 21 03 11Eduardo DavidОценок пока нет

- Presentation Sf6 Circuit BreakerДокумент19 страницPresentation Sf6 Circuit BreakerPalanisamy RОценок пока нет

- TWT8051WKДокумент7 страницTWT8051WKMOHAMMEDОценок пока нет

- PARTS CATALOGДокумент238 страницPARTS CATALOGmichael ourdanОценок пока нет

- Problems: 0-7/hr - The Shield Used Ihr. If A Given CompanyДокумент32 страницыProblems: 0-7/hr - The Shield Used Ihr. If A Given CompanyNikhil KumarОценок пока нет

- Panasonic Tc-p55vt50 Chassis Gpf15duДокумент108 страницPanasonic Tc-p55vt50 Chassis Gpf15duOK100% (1)

- Pspice TutorialДокумент25 страницPspice Tutorialamar7716dumОценок пока нет

- Zurc-Cat Analogicos GBДокумент20 страницZurc-Cat Analogicos GBAhmad DanishОценок пока нет

- Mindman MVSC-300 Solenoid ValveДокумент3 страницыMindman MVSC-300 Solenoid ValvecoronaqcОценок пока нет

- LEDs Student HandoutДокумент32 страницыLEDs Student HandoutercanОценок пока нет

- 28V, Low Iq, High Current, Fixed 3.3V-8A Synchronous Buck Converter With 100 Ma LDOДокумент18 страниц28V, Low Iq, High Current, Fixed 3.3V-8A Synchronous Buck Converter With 100 Ma LDORonytec SuporteОценок пока нет

- Motorola Semiconductor Data - MC14510BДокумент10 страницMotorola Semiconductor Data - MC14510BmamamammamammmmОценок пока нет

- Imanes PDFДокумент70 страницImanes PDFPablo TorresiОценок пока нет

- What Is Electrical Wiring.: Joint Box System or Tree System Loop or Ring SystemДокумент3 страницыWhat Is Electrical Wiring.: Joint Box System or Tree System Loop or Ring SystemCharles Ghati100% (1)

- W005F.... W10F: 1.5 A 50 V To 1000 VДокумент4 страницыW005F.... W10F: 1.5 A 50 V To 1000 VBraulio Manuel Trejo PerezОценок пока нет

- Justification Proposed RecloserДокумент3 страницыJustification Proposed Recloserjominique ferrerОценок пока нет

- Training ReportДокумент114 страницTraining ReportMuhammad JahenzebОценок пока нет

- Optical Power Debugging in The DWDM SystemДокумент31 страницаOptical Power Debugging in The DWDM SystemWubie NegaОценок пока нет

- Mathcad - 110 V Charger Diode DeterminationДокумент3 страницыMathcad - 110 V Charger Diode DeterminationAILEENОценок пока нет

- WindingsДокумент2 страницыWindingsCarlo Jay VizcarraОценок пока нет

- Zelio Plug-In Relays RXM2AB1JDДокумент6 страницZelio Plug-In Relays RXM2AB1JDAhmedОценок пока нет

- iSTAR Ultra LT QSG 8200 1335 01 D0 enДокумент27 страницiSTAR Ultra LT QSG 8200 1335 01 D0 enJan Andre RøeОценок пока нет

- Differential Pressure Switches For Gas, Air, Flue and Exhaust Gases GGW A4 GGW A4-U GGW A4/2 GGW A4-U/2Документ6 страницDifferential Pressure Switches For Gas, Air, Flue and Exhaust Gases GGW A4 GGW A4-U GGW A4/2 GGW A4-U/2chao wangОценок пока нет

- Sub 1Документ4 страницыSub 1AH TaiОценок пока нет

- Bandgap ReferencesДокумент15 страницBandgap ReferencesAyaz Masud SezanОценок пока нет

- Lab Activity No. 5 - Frequency Modulation GenerationДокумент9 страницLab Activity No. 5 - Frequency Modulation GenerationDavy JonesОценок пока нет