Академический Документы

Профессиональный Документы

Культура Документы

Sludge Management Master Plan For A Highly Urbanized Metro

Загружено:

MARIANОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sludge Management Master Plan For A Highly Urbanized Metro

Загружено:

MARIANАвторское право:

Доступные форматы

SLUDGE MANAGEMENT MASTER PLAN

FOR A HIGHLY URBANIZED METRO

D. Perez*, S. Cerbito**

*Used Water Operations Department, Manila Water Company, Inc., Quezon City, Philippines (email: donna.cabalona@manilawater.com)

**Used Water Operations Department, Manila Water Company, Inc., Quezon City, Philippines (email: sharon.cerbito@manilawater.com)

INTRODUCTION METHODOLOGY

Manila Water is the private company providing water and sewerage A Sludge Management Master Plan was crafted to mitigate the adverse

service in the East Zone of Metro Manila through a Concession effects in operating costs brought about by the increasing sludge

Agreement via a Public-Private Partnership with the Metropolitan production of all used water facilities.

Waterworks and Sewerage System (MWSS).

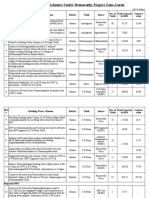

PRELIMINARY PILOT TRIAL OF WASTE-TO-ENERGY

EVALUATION WASTE-TO-ENERGY PROJECT

BIOCHEMICAL FACILITY TRIAL FULL SCALE

METHANE IMPLEMENTATION

POTENTIAL STUDY

Figure 1: Dewatered sludge sample

Figure 2: The Sludge Management Master Plan

With the expansion of its sewerage service and coverage, new and The strategy is anchored on anaerobic digestion technology.

centralized used water treatment facilities are expected to be built Anaerobic digestion is a process that breaks down biodegradable

within the next 22 years. Hence, a need to mitigate the increasing total matter in the absence of oxygen and converts it to biogas–-which in

operating costs specially for power and sludge management. turn can be converted to energy.

RESULTS AND DISCUSSIONS

The last stage of the Sludge Management Master Plan then involves the

full scale implementation of the Waste-To-Energy (WTE) facilities in which

there are 3 proposed sites. Amongst the 40 existing sewage treatment

facilities, a cost benefit analysis was conducted to ascertain the optimum

number of waste-to-energy facilities and the corresponding treatment

process to be used per site. It was then determined that a minimum of 3

sites will be installed with a waste-to-energy facility and all 3 will cater to

the sludge production of all the 40 existing treatment facilities. The

combined benefits of the 3 WTE facilities is a net power generation of

20,000 KWH/day with a total sludge volume reduction of 52% and a total

annual operational cost savings of Php 66M.

Figure 3: Methane Volume Measurement Set-Up (Diagram)

The Sludge Management Master Plan has three main stages:

1) Preliminary evaluation

2) Pilot Trial

3) implementation of waste-to-energy project

In the preliminary evaluation stage, the various substrates from used

water treatment facilities (septage, primary sludge and waste activated

sludge) were assayed in a lab scale experiment to quantity and

characterize their degradability and corresponding biogas production. In

this experiment, the results showed that all the 3 substrates are biogas

producing – with septage sludge performing similar to secondary sludge.

In the second stage, a pilot trial facility was constructed in FTI Septage Figure 4: BMP Values of Various Substrates

treatment plant. The pilot facility was completed last Dec. 2016 and is

operational using septage sludge as substrate. Septage sludge was used

amongst all the other different substrates due to limited studies on Notes:

Primary sludge – settled solids from primary clarifier

anaerobic digestion using septage sludge. The results of the facility Secondary sludge – waste activated sludge; removed sludge from aeration tanks to maintain bacteria count

proved to be successful and was able to reach a methane yield of 90-100 Septage – septage from FTI SpTP

Dewatered sludge blend – blended biosolids from 7 STPs composed of primary and secondary sludge

mL CH4 / kg volatile solids with an SRT of 15 days. The pilot facility is Dewatered sludge blend – blended biosolids from 7 STPs composed of secondary sludge alone

currently being optimized using various types of substrates and

differentiating substrate feed into the system.

CONCLUSIONS

In view of the expansion for the progressive execution of the service obligations and the current uneconomical current disposal method, a

comprehensive sludge management strategy to decrease volume and minimize hauling cost should be undertaken by Manila Water. This tactic will not

only mitigate the increasing OPEX but will also pave for non-core business opportunities.

Вам также может понравиться

- HM Transport's Engineer's Report on Operations and Wastewater ManagementДокумент2 страницыHM Transport's Engineer's Report on Operations and Wastewater ManagementMark Louie DyОценок пока нет

- PROJECT ENVIRONMENTAL MONITORING AND AUDIT PRIORITIZATION QUESTIONNAIREДокумент10 страницPROJECT ENVIRONMENTAL MONITORING AND AUDIT PRIORITIZATION QUESTIONNAIREAlverastine AnОценок пока нет

- SCC EPRMP Draft Aug2017 PDFДокумент314 страницSCC EPRMP Draft Aug2017 PDFGerald Ortiz100% (1)

- Engineer's Report Wastewater Discharge Permit RequirementsДокумент7 страницEngineer's Report Wastewater Discharge Permit Requirementscyril tasicОценок пока нет

- SMR FormДокумент18 страницSMR Formrenato d. de la cruzОценок пока нет

- 2.principle and Design of Waste MinimizationДокумент27 страниц2.principle and Design of Waste MinimizationFx NiubieОценок пока нет

- Arabis Water Refilling Station Engineer's ReportДокумент2 страницыArabis Water Refilling Station Engineer's ReportPaw LabadiaОценок пока нет

- SMR 2st Quarter 2010 For ZPI Plastic Corp.Документ3 страницыSMR 2st Quarter 2010 For ZPI Plastic Corp.Robert UlatanОценок пока нет

- Abandonement - Decomissioning Plan PDFДокумент1 страницаAbandonement - Decomissioning Plan PDFjuan dela cruzОценок пока нет

- Proposed Vitali Water System (Source Development) Project: Sitio Kamalik, Vitali, Zamboanga CityДокумент3 страницыProposed Vitali Water System (Source Development) Project: Sitio Kamalik, Vitali, Zamboanga CityAlathea Donne100% (1)

- Generic Initial Environmental Examination (Iee) Checklist ReportДокумент16 страницGeneric Initial Environmental Examination (Iee) Checklist Reportchandler roldanОценок пока нет

- Project Environmental Monitoring and Audit Prioritization Scheme (Pemaps) QuestionnaireДокумент6 страницProject Environmental Monitoring and Audit Prioritization Scheme (Pemaps) QuestionnaireLorelie BinoyaОценок пока нет

- Engineers Report - Leading Success - Factory 1Документ7 страницEngineers Report - Leading Success - Factory 1Jayvee ArimbuyutanОценок пока нет

- DOH Septage OpManual 8-21-08Документ52 страницыDOH Septage OpManual 8-21-08Alathea Donne100% (1)

- CMR Workshop - PPT NewДокумент13 страницCMR Workshop - PPT NewKing Balmilero50% (2)

- EIA Cheat Sheet PDFДокумент6 страницEIA Cheat Sheet PDFRenan RoqueОценок пока нет

- 3 57 Boracay Engineers Report PDFДокумент12 страниц3 57 Boracay Engineers Report PDFAngela Emanuelle V. Estil100% (1)

- EIS Compostela SteelДокумент14 страницEIS Compostela SteelChelsea MartinezОценок пока нет

- Permit To Operate PDFДокумент13 страницPermit To Operate PDFRorieОценок пока нет

- PEMAPSДокумент4 страницыPEMAPSPaulo MarañaОценок пока нет

- Engineer's ReportДокумент2 страницыEngineer's ReportValerie F. LeonardОценок пока нет

- Application Form For Clearance For AccreditatiДокумент2 страницыApplication Form For Clearance For AccreditatiJohn Reneil Antonio0% (1)

- Annual IEC ProgramДокумент5 страницAnnual IEC ProgramJANICE MANGINSAYОценок пока нет

- DENR Administrative Order No 2016-08Документ51 страницаDENR Administrative Order No 2016-08YursОценок пока нет

- Requirements For New Application of Permit To Operate (Duly Notarized, Triplicate Copies)Документ2 страницыRequirements For New Application of Permit To Operate (Duly Notarized, Triplicate Copies)norlyn esguerraОценок пока нет

- DAO 2013-25 Revised Regulation On CCOДокумент33 страницыDAO 2013-25 Revised Regulation On CCOЙонас РуэлОценок пока нет

- Kiambu County Sanitary Landfill DesignДокумент10 страницKiambu County Sanitary Landfill DesignEdwin KaranjqОценок пока нет

- Comprehensive Contingency Plan-Used Oil PDFДокумент6 страницComprehensive Contingency Plan-Used Oil PDFNeil John Lequigan100% (2)

- Ecc Online AttachmentsДокумент1 страницаEcc Online AttachmentsMai UgayОценок пока нет

- ANNEX 2-7d Project Environmental Monitoring and Audit Prioritization Scheme (Pemaps) QuestionnaireДокумент9 страницANNEX 2-7d Project Environmental Monitoring and Audit Prioritization Scheme (Pemaps) QuestionnaireMarinel AbriamОценок пока нет

- RA 6969 CHEMICAL MANAGEMENTДокумент68 страницRA 6969 CHEMICAL MANAGEMENTVinz SelabeОценок пока нет

- NSWMC Reso 669 Final WTE Guidelines1Документ6 страницNSWMC Reso 669 Final WTE Guidelines1Carl VonОценок пока нет

- Laguna Lake Development Authority Quarterly Self-Monitoring ReportДокумент9 страницLaguna Lake Development Authority Quarterly Self-Monitoring ReportNina Arra RiveraОценок пока нет

- Environmental Monitoring Plan FinalДокумент6 страницEnvironmental Monitoring Plan FinalErnald Janssen ManalastasОценок пока нет

- Wastewater Discharge Form, Emb, DenrДокумент3 страницыWastewater Discharge Form, Emb, Denrgabinuang64% (11)

- Fianal Project Components of SJAFFAДокумент5 страницFianal Project Components of SJAFFADon MaximoОценок пока нет

- PICCS and PMPIN UpdatesДокумент86 страницPICCS and PMPIN UpdatesMylen TrinidadОценок пока нет

- Application Permit To Operate Southpick ResortДокумент3 страницыApplication Permit To Operate Southpick ResortRoselier MercadoОценок пока нет

- Constraint Factors of Domestic Solid Waste Management (Case Study: Agona Swedru)Документ28 страницConstraint Factors of Domestic Solid Waste Management (Case Study: Agona Swedru)Nhyiraba Okodie Adams100% (1)

- Dao 2014 02 Revised Guidelines For Pco'sДокумент15 страницDao 2014 02 Revised Guidelines For Pco'shendrexОценок пока нет

- RA 9275 Written Report - Discharge FeeДокумент5 страницRA 9275 Written Report - Discharge FeekayelaurenteОценок пока нет

- Online Permitting and Monitoring System (Opms) Online Application For Permit To Operate (Pto) Requirements I. NEWДокумент2 страницыOnline Permitting and Monitoring System (Opms) Online Application For Permit To Operate (Pto) Requirements I. NEWphilsat reviewerОценок пока нет

- PD 1152 (Phil. Envi. Code)Документ11 страницPD 1152 (Phil. Envi. Code)Hannah Tolentino-Domantay50% (2)

- OPMS - Process ApplicationДокумент6 страницOPMS - Process ApplicationSean Carl100% (1)

- CMR Form TemplateДокумент4 страницыCMR Form TemplateJosh F. YuОценок пока нет

- ANNEX 2-7d Project Environmental Monitoring and Audit Prioritization Scheme (Pemaps) QuestionnaireДокумент9 страницANNEX 2-7d Project Environmental Monitoring and Audit Prioritization Scheme (Pemaps) QuestionnaireGerald OrtizОценок пока нет

- IEEC - Batching-Crushing Plant ChecklistДокумент16 страницIEEC - Batching-Crushing Plant ChecklistgabinuangОценок пока нет

- Chapter 6-Dynamics-Kinematics-KineticsДокумент36 страницChapter 6-Dynamics-Kinematics-Kineticsعمر صرانОценок пока нет

- Hazardous Waste Management PlanДокумент2 страницыHazardous Waste Management PlanNeil John LequiganОценок пока нет

- EPRMP San JoseДокумент18 страницEPRMP San JoseMoriel PradoОценок пока нет

- Summary DENR LawsДокумент8 страницSummary DENR LawsRapha RachoОценок пока нет

- SBDP Guidelines and Project Minimum StandardsДокумент85 страницSBDP Guidelines and Project Minimum StandardsMarc Arjo MontelibanoОценок пока нет

- ENGINEER'S REPORTДокумент15 страницENGINEER'S REPORTNaldre PhamhinthuanОценок пока нет

- EPRMP Screening ReportДокумент3 страницыEPRMP Screening Reportgabinuang0% (1)

- Non-Food Manufacturing Plants ProjectsДокумент19 страницNon-Food Manufacturing Plants ProjectsQA JasonОценок пока нет

- LLDA Citizens - CharterДокумент346 страницLLDA Citizens - CharterAdoniz TabucalОценок пока нет

- DENR Quarterly Self-Monitoring Report ComplianceДокумент2 страницыDENR Quarterly Self-Monitoring Report CompliancesaguliteОценок пока нет

- Wastewater Treatment Plant Synthesis and DesignДокумент16 страницWastewater Treatment Plant Synthesis and Designewertonemmanuel2Оценок пока нет

- Environmental GroupeДокумент15 страницEnvironmental GroupeSalan XierzatiОценок пока нет

- CDM Shruti DДокумент9 страницCDM Shruti DShruti DeogiriОценок пока нет

- ACFrOgDYhQg3JsE9Dkcyt2 SK9N7lFKD02x2iDk7aRv32CuR981my5DDVE c91mC npfDskBMqu8WwAB2RQrn9Jx760ozzSLjGA844jH7pVqsx4N8uNMNxLkbNBCuGsДокумент2 страницыACFrOgDYhQg3JsE9Dkcyt2 SK9N7lFKD02x2iDk7aRv32CuR981my5DDVE c91mC npfDskBMqu8WwAB2RQrn9Jx760ozzSLjGA844jH7pVqsx4N8uNMNxLkbNBCuGsAhsan JamilОценок пока нет

- HPC Proceedings 26.06.2020 PDFДокумент46 страницHPC Proceedings 26.06.2020 PDFSPD OdishaОценок пока нет

- Table 1 Minimum Separation DistancesДокумент123 страницыTable 1 Minimum Separation DistancesjhonОценок пока нет

- Projects PipelineДокумент8 страницProjects PipelineDinesh Lakmal SilvaОценок пока нет

- Dma 904Документ7 страницDma 904ShoaibIbnHasanОценок пока нет

- Water Desalination Processes and TechnologiesДокумент34 страницыWater Desalination Processes and TechnologiesDina BorhanОценок пока нет

- SLII Task 1Документ7 страницSLII Task 1Naimish AgarwalОценок пока нет

- Water Supply Design Manual v.v1.1 PDFДокумент374 страницыWater Supply Design Manual v.v1.1 PDFbhathiya01Оценок пока нет

- Turbidity Measurement ExperimentДокумент6 страницTurbidity Measurement Experimentbakhtawar soniaОценок пока нет

- Drinking Water Schemes District Taluk Source SL.N o Nos. of Tanks Tank Capacity in Mcft. Contract ValueДокумент3 страницыDrinking Water Schemes District Taluk Source SL.N o Nos. of Tanks Tank Capacity in Mcft. Contract Valuehoney honeyОценок пока нет

- PWTLecture8 (SedimentationII)Документ55 страницPWTLecture8 (SedimentationII)JojoОценок пока нет

- Wastewater and Solid Waste Management NoteДокумент403 страницыWastewater and Solid Waste Management NoteAbebawОценок пока нет

- MAPUA HYDROLOGY LECTUREДокумент12 страницMAPUA HYDROLOGY LECTUREKristine CervanciaОценок пока нет

- UK Rainwater Harvesting Literature Review - Bradford UniversityДокумент59 страницUK Rainwater Harvesting Literature Review - Bradford UniversityFree Rain Garden Manuals92% (13)

- 250+ TOP MCQs On Water Conservation, Rainwater Harvesting, Watershed Management and AnswersДокумент5 страниц250+ TOP MCQs On Water Conservation, Rainwater Harvesting, Watershed Management and AnswersIrfan Awan100% (1)

- Synthetic Unit Hydrographs 25Документ6 страницSynthetic Unit Hydrographs 25GОценок пока нет

- CE309 Water Resources Engineering PDFДокумент3 страницыCE309 Water Resources Engineering PDFAshker DxОценок пока нет

- Submersible Water SystemДокумент2 страницыSubmersible Water SystemAnonymous kSdoX7100% (2)

- 100 KLD STP New-1Документ13 страниц100 KLD STP New-1Anjita KumariОценок пока нет

- The Wetland Machine of SidwellДокумент5 страницThe Wetland Machine of SidwellnabihmezherОценок пока нет

- Website Tech Note 1 v5Документ6 страницWebsite Tech Note 1 v5a350Оценок пока нет

- CPWASH Project Improves Rural SanitationДокумент4 страницыCPWASH Project Improves Rural SanitationmeepadsОценок пока нет

- Diagramas de Instalacion Splash PadДокумент6 страницDiagramas de Instalacion Splash PadJosse RuizОценок пока нет

- Construction Process: Reported By: Arnell John DuhaylungsodДокумент14 страницConstruction Process: Reported By: Arnell John DuhaylungsodJan DaveОценок пока нет

- Proposal For Extracting A Drip Irrigation System and ImplementingДокумент36 страницProposal For Extracting A Drip Irrigation System and ImplementingEngr Muhammad Asif Javaid0% (1)

- Group 4 Bsce 1-3 Position Paper Purcom FinalsДокумент5 страницGroup 4 Bsce 1-3 Position Paper Purcom FinalsAndrea CastilloОценок пока нет

- Water Resources Best Notes 2023Документ4 страницыWater Resources Best Notes 2023Prachi MatelaОценок пока нет

- Aquatabs BrochureДокумент8 страницAquatabs Brochureedo dwi guntoroОценок пока нет

- Interview MRF SindalanДокумент2 страницыInterview MRF SindalanMaemi Alessia ManalotoОценок пока нет

- Little Cypress Creek Frontier ProgramДокумент1 страницаLittle Cypress Creek Frontier ProgramHouston ChronicleОценок пока нет