Академический Документы

Профессиональный Документы

Культура Документы

2019-2020 Defect Verification Sheet

Загружено:

ajayИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2019-2020 Defect Verification Sheet

Загружено:

ajayАвторское право:

Доступные форматы

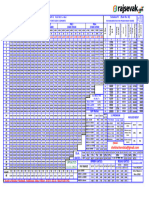

Counter measure Effectiveness Monitoring Sheet-2019-2020

EFFECTIVENESS MONITORING STATUS

(REMARKS- "M1" IS THE FIRST MONTH STATUS AFTER DEFECT HAS BEEN PUNCHED. REVIEW AND STATUS TO BE

Horizontal UPDATED TILL 7TH OF EVERY MONTH)

No of

Sr Repeat Reported C/m to prevent Reason for C/m to prevent Deployme

Date Part Name ModelSHOP Defect Photograph part Root cause

No no. from M/G recurrence Outflow Outflow nt

punched

(if any )

M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12 M13 M14 M15 M16 M17 M18 Remarks

Check point was

Part locating block /pin not 1. Check point has been

not available for

available in puncing tool Punching tool to be added in FINAL

punching out

1 4/9/2019 BKT ENG HARN INTK EECO BOP Punching out 1 NO G due to this part shifted in modified with proper INSPECTION SHEET N/A

issue in Final

punching operation and NG locating. 2. Training given to all

Inspection

part Made. cancern person .

Standard Sheet

The NG Parts have been

SWITCH STAY

made with out Fixing the 1- Slider Block has been

BKT FOUND NG Check point was 1. Check Point has been

Position of Sliding block fixed permannently.

2 6/14/2019 CLUTCH PEDAL ASSY Y9T ROBO RESULTING IN 8 NO G not avaialble on added in inprocess gauge

during the mig welding of 2- Location pin has

FREE PLAY NIL gauge. and Assy gauge too.

Bracket clutch cable on been tied with fixture.

CLUTCH PEDAL

Fixture

limit sample was

BURR clearence between puch limit sample has been

punch & bush has been not there to YBA /YAD

3 6/19/2019 MBR ROOF BACK INNER YJC PRESS OBSERVED IN 10 YES G and Bush was NG. Due to made at working area with

changed verification the /EECO

SLOT (12X20) PM missing quality alert .

burr level

PREPARED BY(QA SR. ER.):- VERIFIED BY (QUALITY HEAD):- APPROVED BY (PLANT HEAD):-

DEFECT REPEATED Y

Legends for Filling Effectiveness

Monitoring:

DEFECT NO REPEATED N

EFFECTIVE DATE:- 01/01/2019 REVISION NO.:- 01 FORMAT NO.:- F03/QA/01

Вам также может понравиться

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Документ4 страницыMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaОценок пока нет

- Kansal Industries - Tool Development Plan Model 'N': Assy T0 SampleДокумент2 страницыKansal Industries - Tool Development Plan Model 'N': Assy T0 SampleajayОценок пока нет

- Kansal Industries - Tool Development Plan Model 'N': Assy T0 SampleДокумент2 страницыKansal Industries - Tool Development Plan Model 'N': Assy T0 SampleajayОценок пока нет

- Design Fmea 1 ST Pipe Teflon HoseДокумент11 страницDesign Fmea 1 ST Pipe Teflon HoseSandeep PandeyОценок пока нет

- Apqp Timing Chart-Macro Plan: ActivityДокумент2 страницыApqp Timing Chart-Macro Plan: Activitysuchig8453750% (2)

- The Rebel Fleet: Star Wars: The Empire Strikes BackДокумент2 страницыThe Rebel Fleet: Star Wars: The Empire Strikes BackAndrewL91Оценок пока нет

- Flight From Terror - Otto StrasserДокумент247 страницFlight From Terror - Otto StrasserJeffrey Michael Wood100% (1)

- Meenakshi Molding Private Limited Process FMEA: O C C U RДокумент4 страницыMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- DVA Women in War Part3Документ26 страницDVA Women in War Part3Sorin OpreaОценок пока нет

- Tactical Control System TCS System Subsystem SpecificationДокумент148 страницTactical Control System TCS System Subsystem SpecificationHồ ThànhОценок пока нет

- Potential Failure Mode and Effects Analysis (Process FEMA)Документ1 страницаPotential Failure Mode and Effects Analysis (Process FEMA)Asif Iqbal100% (2)

- 25mm Ammunition: The Ammunition Choice For Ground, Sea and Air PlatformsДокумент2 страницы25mm Ammunition: The Ammunition Choice For Ground, Sea and Air PlatformsEnriquenf50% (2)

- Risk Assessment of Manual Excavation and TrenchingДокумент14 страницRisk Assessment of Manual Excavation and TrenchingJayson Escamillan100% (1)

- POST PRU 14 Revenue Report 13 May 2018Документ78 страницPOST PRU 14 Revenue Report 13 May 2018Mohd. Anis AbdullahОценок пока нет

- dFMEA 4th Edition BlankДокумент1 страницаdFMEA 4th Edition BlankTom@GGCОценок пока нет

- Risk Assessment For BorescopeДокумент14 страницRisk Assessment For BorescopeJayson Escamillan100% (1)

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationДокумент4 страницыL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILОценок пока нет

- Advanced Photoshop Issue 049Документ87 страницAdvanced Photoshop Issue 049Dipesh Bardolia100% (2)

- Welder Wise Repair PercentageДокумент135 страницWelder Wise Repair PercentageaakashОценок пока нет

- Large and Medium Scale Manufacturing Industries in EthiopiaДокумент47 страницLarge and Medium Scale Manufacturing Industries in EthiopiaAdmachew MohammedОценок пока нет

- The Most Secret List of Soe Agents: KДокумент54 страницыThe Most Secret List of Soe Agents: KeliahmeyerОценок пока нет

- Boq Smartfren Med0169 - Simpang EmpatДокумент2 страницыBoq Smartfren Med0169 - Simpang EmpatAlbert HamonanganОценок пока нет

- Design Fmea Sae j1739Документ1 страницаDesign Fmea Sae j1739Tarek SanОценок пока нет

- (Package 2 - Pec-Dcsm) NSRP Daily Progress Report - 201910 - 23Документ21 страница(Package 2 - Pec-Dcsm) NSRP Daily Progress Report - 201910 - 23duyanhОценок пока нет

- T-002 RoadMachine Manual2010 PDFДокумент8 страницT-002 RoadMachine Manual2010 PDFJone DoeОценок пока нет

- Quality Competencies Matrix: PrintДокумент1 страницаQuality Competencies Matrix: PrintAnonymous SQ5kprsQnОценок пока нет

- LPMC QTRLY FormДокумент1 страницаLPMC QTRLY FormDILG Benguet CDS CDSОценок пока нет

- Aspect Impact-PUP - Aug.2011Документ1 страницаAspect Impact-PUP - Aug.2011Surendran AОценок пока нет

- 20201401CIWIDEY 2019 Rainforest FarmerlistДокумент4 страницы20201401CIWIDEY 2019 Rainforest FarmerlistghianОценок пока нет

- .1st Batch of P&IDs Consolidated For MCPPДокумент26 страниц.1st Batch of P&IDs Consolidated For MCPPbaqerhassanОценок пока нет

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseДокумент1 страницаOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochОценок пока нет

- F 20 Template Rev2 E SheetДокумент1 страницаF 20 Template Rev2 E SheetalfredОценок пока нет

- Anpqp - Design Potential FmeaДокумент2 страницыAnpqp - Design Potential FmeaJoaquinОценок пока нет

- Aditya Engineering College - mBAJA - Pithampur - DFMEAДокумент1 страницаAditya Engineering College - mBAJA - Pithampur - DFMEAMani Shankar YadavОценок пока нет

- RENR88270001Документ4 страницыRENR88270001Guido Emanuel SteinbachОценок пока нет

- Macho RD - CondicionesДокумент1 страницаMacho RD - CondicionesferminОценок пока нет

- Preventive Maintenance Plan-2022Документ1 страницаPreventive Maintenance Plan-2022Mina MedhatОценок пока нет

- Annex E Pro-Forma Monthly Report March 9 2018Документ3 страницыAnnex E Pro-Forma Monthly Report March 9 2018OmsОценок пока нет

- Far Ra 10964 - ExendedДокумент33 страницыFar Ra 10964 - ExendedKenneth Cyrus OlivarОценок пока нет

- Appendix 13 3 PFEMA and DFEMAДокумент5 страницAppendix 13 3 PFEMA and DFEMADearRed FrankОценок пока нет

- FORMATO. Component Supply Chain Chart (CSCC)Документ1 страницаFORMATO. Component Supply Chain Chart (CSCC)karimeОценок пока нет

- Monitorig Cek List - BAST 1Документ5 страницMonitorig Cek List - BAST 1Achmad SukocoОценок пока нет

- Sais Short Air 3100-3300-5300-6300 EuДокумент4 страницыSais Short Air 3100-3300-5300-6300 EuAli DiabОценок пока нет

- JTB Lubricant List 20160210 A1Документ32 страницыJTB Lubricant List 20160210 A1Fandemen AdintaОценок пока нет

- Daily Report: Embasy Renovation ProjectДокумент3 страницыDaily Report: Embasy Renovation ProjectQuốc Hùng VũОценок пока нет

- 854K Wheel Dozer and Electrical System 992K Wheel LoaderДокумент6 страниц854K Wheel Dozer and Electrical System 992K Wheel LoaderSergio PizarroОценок пока нет

- Guide To Small Tools: Section OrganizationДокумент48 страницGuide To Small Tools: Section OrganizationKasia MazurОценок пока нет

- Guide To External Turning Tools: Section OrganizationДокумент46 страницGuide To External Turning Tools: Section OrganizationKasia MazurОценок пока нет

- Process Failure Modes and Effects Analysis Process Failure Modes and Effects AnalysisДокумент2 страницыProcess Failure Modes and Effects Analysis Process Failure Modes and Effects AnalysisEnzo AscañoОценок пока нет

- Tank Activity LogДокумент5 страницTank Activity Logdada khalandarОценок пока нет

- Engine Controls Powertrain Management ALLDATA Repair 10Документ4 страницыEngine Controls Powertrain Management ALLDATA Repair 10AUTOEPC LAAM (LUFACANA)Оценок пока нет

- 325D Elect - SchematicДокумент6 страниц325D Elect - SchematicNartoОценок пока нет

- Backgrounder: Transformative Urban Recovery From COVID-19Документ2 страницыBackgrounder: Transformative Urban Recovery From COVID-19Aliya RahmanОценок пока нет

- Temporary Support For West FenceДокумент1 страницаTemporary Support For West FenceMohamed ElsayedОценок пока нет

- Diagrama DinaelДокумент4 страницыDiagrama DinaelSuzy VieiraОценок пока нет

- Anpqp - Component Supply Chain Chart (CSCC)Документ1 страницаAnpqp - Component Supply Chain Chart (CSCC)r.vargasОценок пока нет

- Pay Chart NewДокумент1 страницаPay Chart Newveenushreya2012Оценок пока нет

- PERIODIC CERTIFICATION June13Документ1 страницаPERIODIC CERTIFICATION June13Pushpendra YadavОценок пока нет

- Anpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRДокумент1 страницаAnpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRjefry sitorusОценок пока нет

- Mech. Shop Drawings Construction ScheduleДокумент1 страницаMech. Shop Drawings Construction ScheduleAMMAR MAWОценок пока нет

- Disclosure Summary Page JAN 2 2 2002 DR-2Документ18 страницDisclosure Summary Page JAN 2 2 2002 DR-2Zach EdwardsОценок пока нет

- 65-1501 Victor Equipos OxicombustibleДокумент6 страниц65-1501 Victor Equipos OxicombustiblecarlosОценок пока нет

- Baseline Data For ISS AngulДокумент1 страницаBaseline Data For ISS Angulsuperintending engineerОценок пока нет

- Bom For Trolley-For IndentДокумент1 страницаBom For Trolley-For IndentajayОценок пока нет

- 49612-74l10 Gap Flush Ok FilledДокумент5 страниц49612-74l10 Gap Flush Ok FilledajayОценок пока нет

- Model-Rx Data Status Available at Agro As On 09-10-2014: Part Number Part NameДокумент2 страницыModel-Rx Data Status Available at Agro As On 09-10-2014: Part Number Part NameajayОценок пока нет

- BomДокумент33 страницыBomajayОценок пока нет

- Gap Flush (49631-79J00)Документ6 страницGap Flush (49631-79J00)ajayОценок пока нет

- Press Shop PPM Press Shop PPM February 2019 Total Production Total PPM Rework PPM Scrap PPM Total Occurance Rework Occurance Scrap OccuranceДокумент2 страницыPress Shop PPM Press Shop PPM February 2019 Total Production Total PPM Rework PPM Scrap PPM Total Occurance Rework Occurance Scrap OccuranceajayОценок пока нет

- Defect Total Occurance Rework Qty Scrap Qty: Press Shop PPM Total ProductionДокумент6 страницDefect Total Occurance Rework Qty Scrap Qty: Press Shop PPM Total ProductionajayОценок пока нет

- Month Wise PlanДокумент53 страницыMonth Wise PlanajayОценок пока нет

- Press Shop PPM Press Shop PPM March 2019 Total Production Total PPM Rework PPM Scrap PPM Total Occurance Rework Occurance Scrap OccuranceДокумент2 страницыPress Shop PPM Press Shop PPM March 2019 Total Production Total PPM Rework PPM Scrap PPM Total Occurance Rework Occurance Scrap OccuranceajayОценок пока нет

- QR CodeДокумент5 страницQR CodeajayОценок пока нет

- Gap Flush - Filled ReportДокумент7 страницGap Flush - Filled ReportajayОценок пока нет

- Press Shop PPM Press Shop PPM March 2019 Total Production Total PPM Rework PPM Scrap PPM Total Occurance Rework Occurance Scrap OccuranceДокумент2 страницыPress Shop PPM Press Shop PPM March 2019 Total Production Total PPM Rework PPM Scrap PPM Total Occurance Rework Occurance Scrap OccuranceajayОценок пока нет

- Defect Total Occurance Rework Occurance Scrap OccuranceДокумент4 страницыDefect Total Occurance Rework Occurance Scrap OccuranceajayОценок пока нет

- 21 June 2019 Manesar SCHEDULEДокумент3 страницы21 June 2019 Manesar SCHEDULEajayОценок пока нет

- 21 June 2019 ScheduleДокумент8 страниц21 June 2019 ScheduleajayОценок пока нет

- Final InspectionДокумент20 страницFinal InspectionP. Lakshmanakanth100% (2)

- Col. Thomas Brown's Reply To David Ramsay, 1786Документ4 страницыCol. Thomas Brown's Reply To David Ramsay, 1786Wm. Thomas ShermanОценок пока нет

- Oef Xi-Xii Deployment NewsletterДокумент60 страницOef Xi-Xii Deployment Newsletterblacknight03Оценок пока нет

- Basic Introduction To Breakthrough: 1 RulesДокумент6 страницBasic Introduction To Breakthrough: 1 RulesjakeОценок пока нет

- Lich ClassДокумент1 страницаLich ClassZhori DuberryОценок пока нет

- M&B Bannerlord Custom Troop Tree ModДокумент10 страницM&B Bannerlord Custom Troop Tree ModYo YoОценок пока нет

- Karl Bilt KnjigaДокумент3 страницыKarl Bilt KnjigaAna NovovicОценок пока нет

- The Myawady Daily (3-9-2012)Документ15 страницThe Myawady Daily (3-9-2012)TheMyawadyDailyОценок пока нет

- The Path To Glory RosterДокумент35 страницThe Path To Glory RosterNickОценок пока нет

- Athens & Spartans ChartДокумент5 страницAthens & Spartans Chartapi-277540088Оценок пока нет

- Deputation PolicyДокумент38 страницDeputation PolicyHumayoun Ahmad FarooqiОценок пока нет

- SHTF 50Документ6 страницSHTF 50Tonyf6188Оценок пока нет

- The Turkish Straits Vessel Traffic Service (TSVTSДокумент11 страницThe Turkish Straits Vessel Traffic Service (TSVTSNemo Westie Ogi IIОценок пока нет

- Working Methodology-Cement Concrete Pavement: Punj Lloyd LimitedДокумент14 страницWorking Methodology-Cement Concrete Pavement: Punj Lloyd LimitedDwijendra ChanumoluОценок пока нет

- Flying Colors GMT Ship of The Line ExpansionДокумент25 страницFlying Colors GMT Ship of The Line Expansionэдуард зайцевОценок пока нет

- Image Analysis: A VDV Operation at The Strugi Krasnye RangeДокумент5 страницImage Analysis: A VDV Operation at The Strugi Krasnye RangeUppotappОценок пока нет

- Delta PDFДокумент18 страницDelta PDFAgbeyegbe AmejumaОценок пока нет

- Aenya rpg1Документ61 страницаAenya rpg1AdamThePonyОценок пока нет

- Introduction To US Bomb FuzesДокумент19 страницIntroduction To US Bomb FuzesEOD987654321100% (5)

- SF6 Character Notes - CammyДокумент5 страницSF6 Character Notes - CammyDiego VianaОценок пока нет

- Informativo Segcidada21Документ41 страницаInformativo Segcidada21Carlos IsraelОценок пока нет

- Aceleramiento 28Документ2 страницыAceleramiento 28Ciro Pacho PerezОценок пока нет

- Pravartee Sales PVT LTDДокумент55 страницPravartee Sales PVT LTDJeeshan IdrisiОценок пока нет

- ملخص العلاقاتДокумент14 страницملخص العلاقاتRaghad BabОценок пока нет