Академический Документы

Профессиональный Документы

Культура Документы

Black Rubber Shims (Approved - CCC)

Загружено:

Fodor ZoltanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Black Rubber Shims (Approved - CCC)

Загружено:

Fodor ZoltanАвторское право:

Доступные форматы

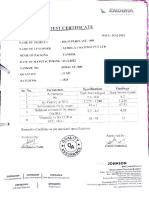

COmPOSITfS SOLUTIOn

RUBBER SHEETS

------

n PROPERTIES TEST

METHOD

VALUES

FPS UNITS

TEST METHOD VALUES

METRIC UNITS

-'

HARDNESS DIN 53505 65 ± 5 Sh A ASTM 02240 65 ± 5 Sh A

- --------------------------~ 7

_ _!ENSILE STRENGTH (min) DIN 53504 1800 PSI ASTM 0412 126 Kg/cm

~LONGATION AT BREAK (min) DIN 53504 700% ASTM D412 700%

- --

COMPRESSION SET (70.C/24 DIN 53517 48% ASTM D395 48%

h r~ 25% Compression) (m ax) METHOD B

TEAR RESI~TAN CE (Angul ar) min DIN 53515 120 Lbs/lnch ASTM D624 . ~3 kg/cm

-

CHANGE IN PROPERTIES AFTER , __

HEAT AGEING FOR (72 hrs AT ASTM 0573

70"C)

- ....

HARDNESS (Pt~) - - - - -- - -

TENSILE STRENGTH-'(_%"-)_

ELONGATION AT BREAK (%)

+5 (max)

+ 10 I -20

+ 10 /-20

- +-5 (m~x )__

+ 10 I -2o

+ 10 / ·20

....--

VOLUME SWE LL: AT 70•c FOR 72 ASTM D 471

HRS

---t---

_IN_ A IL _N_O..!__ _

_S_T_M _Q_ - +-_ +_ ___ ,__________ ~+ 27%

27_%

·-- +39%

-----·-- - - ------------ T39%

+75% t- 75%

() -- - ~

- - - ---- -·- - - - -- - - --

CHEMICAL RESISTANCE

-------------~--

OZONE GOOD ASTM D 1149 GOOD

DILUTE ACIDS AND BASES FAIR FAIR

- r

CONCENTRATED ACIDS AND NOT NOT

BAS ES RECOMMEN RECOMMEND

OILS

I

DED

NOT

RECOMMEN

--· NOT

. RECOMMEND

ED

DED ED

!-·

SOLVENTS NOT NOT

RECOMMEN RE COMMEND

DED ED

-29• TO

·--25·

-TO- -

+8o·c

TEMPERATURE RANGE

+so·c

- -- --

COLOUR BLACK BLACK

-· -- ~--

Admin Office : 310, Creative Industrial Estate, Sitaram Mill Compound, N. M. Joshi Marg, Mumbai- 400 011

E-mail : info@compositessolution .com Website : www.compos1tessolution.com

Tel./ Fax : +91 -22-4023 8805106107

73

Вам также может понравиться

- Calcul Des Structures Acier: EN 1993-1:2005/AC:2009, Eurocode 3: Design of Steel StructuresДокумент2 страницыCalcul Des Structures Acier: EN 1993-1:2005/AC:2009, Eurocode 3: Design of Steel StructuresMouhaОценок пока нет

- Neoprene - RubberДокумент1 страницаNeoprene - RubberAnandОценок пока нет

- "Only Valid For Quotation": Component List Description #Material Hardness Heat Treatment RemarksДокумент1 страница"Only Valid For Quotation": Component List Description #Material Hardness Heat Treatment RemarksMotiram SavargaveОценок пока нет

- Lc-Jiuli - :: Prindpal Lndust Al Tralnln1 InstitutДокумент1 страницаLc-Jiuli - :: Prindpal Lndust Al Tralnln1 InstitutVivek SinghОценок пока нет

- MF-10 Recommendable Lub. Oil ListДокумент22 страницыMF-10 Recommendable Lub. Oil ListpcatruongОценок пока нет

- General Motors: Motor EngineДокумент24 страницыGeneral Motors: Motor EngineRETIFICA ITATIBAОценок пока нет

- Din 1624Документ2 страницыDin 1624avinashchauhan2695Оценок пока нет

- Section 1-1: NotesДокумент1 страницаSection 1-1: Notestuyen nguyenОценок пока нет

- Motor Engine: Idem Piston # 424 With Compression Height - 0,5 MMДокумент2 страницыMotor Engine: Idem Piston # 424 With Compression Height - 0,5 MMRETIFICA ITATIBAОценок пока нет

- Maharashtra Seamless Limited: Location de Test SpecimensДокумент3 страницыMaharashtra Seamless Limited: Location de Test SpecimensRavi TyagiОценок пока нет

- CoA - MTC - LOT 4525 - 4408Документ1 страницаCoA - MTC - LOT 4525 - 4408dipen royОценок пока нет

- DZR BrassДокумент1 страницаDZR BrasssmrdojeОценок пока нет

- Indenor InfДокумент2 страницыIndenor InfRetíficaitatibaОценок пока нет

- Certificado de Calidad Esparrago b7Документ1 страницаCertificado de Calidad Esparrago b7HERSON FARID BUENO PIÑEROSОценок пока нет

- Prohper PdsДокумент2 страницыProhper PdsCao Đức TrungОценок пока нет

- Prohper PdsДокумент2 страницыProhper PdsCao Đức TrungОценок пока нет

- Equipment Process Data Sheet: 'GYPT "".SCДокумент3 страницыEquipment Process Data Sheet: 'GYPT "".SCMo ZeroОценок пока нет

- 0 SBAR-SBBR MergedДокумент8 страниц0 SBAR-SBBR MergedRaphael EduardoОценок пока нет

- Anup SS304L TC 1Документ2 страницыAnup SS304L TC 1B.M Industrial Works100% (1)

- Anti-Belier 4000L - 03-03-2019Документ1 страницаAnti-Belier 4000L - 03-03-2019Cherif GhalebОценок пока нет

- Sumaja MTC 40 RNDДокумент1 страницаSumaja MTC 40 RNDRINL GZB0% (1)

- Polyester Limited: Properties Average ThicknessДокумент1 страницаPolyester Limited: Properties Average ThicknessPuneet SingalОценок пока нет

- Surface Vehicle StandardДокумент11 страницSurface Vehicle StandardAngel HernándezОценок пока нет

- Datasheet For Steel Grades Carbon Steel SAE 1090Документ2 страницыDatasheet For Steel Grades Carbon Steel SAE 1090Todd FlowОценок пока нет

- RH HDC 23 24 021Документ1 страницаRH HDC 23 24 021Sawan GautamОценок пока нет

- MTC FormatДокумент1 страницаMTC FormatNirmit GandhiОценок пока нет

- Product Specifications: Specifications For Continuous Cast ProductsДокумент4 страницыProduct Specifications: Specifications For Continuous Cast ProductsvejanidbОценок пока нет

- Transcendia Datasheet NatureFlex NKA-F v1Документ2 страницыTranscendia Datasheet NatureFlex NKA-F v1Avichai MarcoviciОценок пока нет

- Pm-Clinic Service: PMEB100100Документ2 страницыPm-Clinic Service: PMEB100100Naughty VongОценок пока нет

- Material Product Data Sheet Cobalt Chromium (Nickel Tungsten Silicon) Carbon Alloy Powders (Similar To Stellite, Ultimet, Mar M 509)Документ6 страницMaterial Product Data Sheet Cobalt Chromium (Nickel Tungsten Silicon) Carbon Alloy Powders (Similar To Stellite, Ultimet, Mar M 509)imtiyazОценок пока нет

- F2 Lesson 5 03102020Документ28 страницF2 Lesson 5 03102020Sing En SingОценок пока нет

- Set-Up Approval Report-Separator MiddleДокумент2 страницыSet-Up Approval Report-Separator Middleswaran autoqaОценок пока нет

- Roots - Rxc. : MachineДокумент315 страницRoots - Rxc. : MachineAndres SantanaОценок пока нет

- Ncut Antiextrusion Ring For Metric Ing: MaterialДокумент4 страницыNcut Antiextrusion Ring For Metric Ing: MaterialArun JaisonОценок пока нет

- TABLACOMPARATIVAДокумент12 страницTABLACOMPARATIVADyno CrowlyОценок пока нет

- GPGNДокумент3 страницыGPGNMilosОценок пока нет

- Adobe ScanДокумент1 страницаAdobe ScanCardboard GamingОценок пока нет

- Sec 4C 6CC PDFДокумент26 страницSec 4C 6CC PDFThomas KrohОценок пока нет

- Adobe Scan 10 Aug 2020Документ12 страницAdobe Scan 10 Aug 2020Shobhith DevadigaОценок пока нет

- HOT Induction Bend MPS - CommentedДокумент11 страницHOT Induction Bend MPS - CommentedHASAN SHAHRIAR100% (1)

- Lab ResultsДокумент9 страницLab ResultsMaveric EnriquezОценок пока нет

- Testing For Agg - Base CourseДокумент1 страницаTesting For Agg - Base CourseasepОценок пока нет

- Ncut Antiextrusion Ring For Standard Ing: MaterialДокумент6 страницNcut Antiextrusion Ring For Standard Ing: MaterialArun JaisonОценок пока нет

- PT Fuchs Lubricants (Arrow Asia-Aldaco Citrajaya) - Nissan-Samp PDFДокумент1 страницаPT Fuchs Lubricants (Arrow Asia-Aldaco Citrajaya) - Nissan-Samp PDFpinot san92Оценок пока нет

- 01 25284124-8230-26-013-0001 REV.03 Piping List DHDTДокумент7 страниц01 25284124-8230-26-013-0001 REV.03 Piping List DHDTRajeev KumarОценок пока нет

- Pot 5K Bourns 3362P-1-502LFДокумент2 страницыPot 5K Bourns 3362P-1-502LFJoão Oliveira BentesОценок пока нет

- Ika InfДокумент1 страницаIka InfRetíficaitatibaОценок пока нет

- 09.2 Gyro Compass Annual MaintenanceДокумент1 страница09.2 Gyro Compass Annual MaintenanceTC Atilla KarakaşОценок пока нет

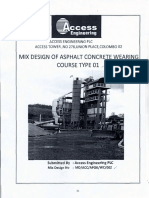

- Mix Design For Wearing CourseДокумент33 страницыMix Design For Wearing CourseSumith 2KОценок пока нет

- Pm-Clinic Service: PMEB100300Документ2 страницыPm-Clinic Service: PMEB100300Naughty VongОценок пока нет

- Wps 225Документ29 страницWps 225Muhammad firdaus rusliОценок пока нет

- Mechanical Test Properties (Minimum) : RemarksДокумент6 страницMechanical Test Properties (Minimum) : RemarksSandeepОценок пока нет

- Aanwtdo-Bztbonr-Unomowinftmnsfn - BG: umw1Fwehwqb8n@D.TДокумент1 страницаAanwtdo-Bztbonr-Unomowinftmnsfn - BG: umw1Fwehwqb8n@D.Tสิงห์Оценок пока нет

- Oil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil NaduДокумент11 страницOil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil Nadudevi JammanaОценок пока нет

- Inc 800 MTC - FlangeДокумент1 страницаInc 800 MTC - Flangeranjith_007100% (1)

- RK1 RK1PB - 42CrMo4 Nr.1.7225 42CrMoS4 Nr.1.7227 ENG PDFДокумент2 страницыRK1 RK1PB - 42CrMo4 Nr.1.7225 42CrMoS4 Nr.1.7227 ENG PDFAnonymous yshOO0tEjKОценок пока нет

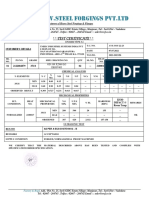

- A.V.Steel Forgings PVT - LTD: Test CertificateДокумент1 страницаA.V.Steel Forgings PVT - LTD: Test CertificateNirmit GandhiОценок пока нет

- 6468 Ab 5 C 1622 C Adobe Scan 20 May 20232 CompressedДокумент5 страниц6468 Ab 5 C 1622 C Adobe Scan 20 May 20232 CompressedAnkit Bhardwaj 17Оценок пока нет

- Mill Test Certificate: S0148/4180/DBX/ST2014Документ1 страницаMill Test Certificate: S0148/4180/DBX/ST2014Fodor Zoltan100% (2)

- Mill Test Certificate: Din 125 Washer Electro Zinc PlatedДокумент1 страницаMill Test Certificate: Din 125 Washer Electro Zinc PlatedFodor ZoltanОценок пока нет

- IPB K Staticki ProracunДокумент98 страницIPB K Staticki ProracunFodor ZoltanОценок пока нет

- BS5950 End Plate DesignДокумент4 страницыBS5950 End Plate DesignFodor ZoltanОценок пока нет

- Base Plate Design BS CodeДокумент3 страницыBase Plate Design BS CodeFodor ZoltanОценок пока нет

- Authoritarian DemocracyДокумент2 страницыAuthoritarian DemocracyFodor ZoltanОценок пока нет

- Against All OddsДокумент125 страницAgainst All OddsFodor ZoltanОценок пока нет

- A Strategy Based On FaithДокумент20 страницA Strategy Based On FaithFodor ZoltanОценок пока нет

- A Symbol Perfected in DeathДокумент16 страницA Symbol Perfected in DeathFodor ZoltanОценок пока нет

- Operational ArtДокумент12 страницOperational ArtFodor ZoltanОценок пока нет

- BAHASA INGGRIS 3 MA Ganjil 2016-2017Документ5 страницBAHASA INGGRIS 3 MA Ganjil 2016-2017Rofial Mubarok100% (1)

- A Computational Fluid Dynamics Model of Algal Growth Development and ValidationДокумент11 страницA Computational Fluid Dynamics Model of Algal Growth Development and ValidationsuyyinОценок пока нет

- Fundamentals of Digital Image Processing - A Practical Approach With Examples in Matlab Chris Solomon, Toby BreckonДокумент3 страницыFundamentals of Digital Image Processing - A Practical Approach With Examples in Matlab Chris Solomon, Toby Breckonశ్రీనివాస బాబ్జి జోస్యులОценок пока нет

- The Knelson Concentrator: Application and Operation at RoseberyДокумент9 страницThe Knelson Concentrator: Application and Operation at RoseberyVivek RanganathanОценок пока нет

- Slides OctaveДокумент24 страницыSlides Octaveamru_rzlОценок пока нет

- ASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1Документ5 страницASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1jothi vel muruganОценок пока нет

- Solid Dispersion PolymorphismДокумент37 страницSolid Dispersion PolymorphismAmey KamtheОценок пока нет

- Design of Sanitary Sewer SystemДокумент11 страницDesign of Sanitary Sewer SystemAhmad SanaОценок пока нет

- Chapter 4. Translational Equilibrium and Friction.: Free-Body DiagramsДокумент16 страницChapter 4. Translational Equilibrium and Friction.: Free-Body DiagramsAlma GalvànОценок пока нет

- Lekula2018 PDFДокумент60 страницLekula2018 PDFJulian DelgadoОценок пока нет

- Difference Between Pipe and TubeДокумент3 страницыDifference Between Pipe and TubeAnonymous fQAeGFОценок пока нет

- SOM 2-2 (Students Note)Документ15 страницSOM 2-2 (Students Note)HasmitthaОценок пока нет

- MAG8000 Manual PDFДокумент137 страницMAG8000 Manual PDFHanks EpphОценок пока нет

- ANSYS 10.0 Workbench Tutorial - Description of TutorialsДокумент7 страницANSYS 10.0 Workbench Tutorial - Description of TutorialssangeethsreeniОценок пока нет

- DMP4015SK3: P-Channel Enhancement Mode MosfetДокумент7 страницDMP4015SK3: P-Channel Enhancement Mode MosfetpaulpuscasuОценок пока нет

- Overhead Line Design NotesДокумент35 страницOverhead Line Design NotesiaessackjeeОценок пока нет

- Gree Change 18-24 Technical Manual EngДокумент101 страницаGree Change 18-24 Technical Manual Engstr.maintenance.reОценок пока нет

- MRG - D R.sirДокумент30 страницMRG - D R.sirPLASTIC LAB CBDОценок пока нет

- Honorscourselist Spring22 Nov 18Документ4 страницыHonorscourselist Spring22 Nov 18akОценок пока нет

- SHS LAS Gen - Physics1 MELC12 Q2 Week-1Документ14 страницSHS LAS Gen - Physics1 MELC12 Q2 Week-1ChricellFОценок пока нет

- Physcis Unit Test 3Документ5 страницPhyscis Unit Test 3Yuta NeyaОценок пока нет

- State EstimationДокумент13 страницState Estimationkubera uОценок пока нет

- ENSC3024 Ideal Gas Lab 1Документ12 страницENSC3024 Ideal Gas Lab 1Max ShervingtonОценок пока нет

- Astrology WebcourseДокумент310 страницAstrology Webcoursexlearner100% (18)

- Flux Cored Arc Welding I (Gas Shielded)Документ38 страницFlux Cored Arc Welding I (Gas Shielded)greatsteelОценок пока нет

- 2.2 GHZ Laser HHOДокумент32 страницы2.2 GHZ Laser HHOalkatrash100% (3)

- Kcet Chemistry 2015Документ11 страницKcet Chemistry 2015BURHAN0% (1)

- Runway DesignДокумент44 страницыRunway DesignAnonymous 0pzPb3q100% (1)

- Characterization and Analysis of The Efficiency of A Hermetic CompressorДокумент7 страницCharacterization and Analysis of The Efficiency of A Hermetic CompressorMohammed Naim UddinОценок пока нет

- Spatial Disorientation in AviationДокумент12 страницSpatial Disorientation in AviationT-CAS0% (1)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (242)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincОт EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincРейтинг: 3.5 из 5 звезд3.5/5 (137)

- It's Elemental: The Hidden Chemistry in EverythingОт EverandIt's Elemental: The Hidden Chemistry in EverythingРейтинг: 4 из 5 звезд4/5 (10)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyОт EverandSodium Bicarbonate: Nature's Unique First Aid RemedyРейтинг: 5 из 5 звезд5/5 (21)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyОт EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyРейтинг: 4 из 5 звезд4/5 (1)

- Taste: Surprising Stories and Science About Why Food Tastes GoodОт EverandTaste: Surprising Stories and Science About Why Food Tastes GoodРейтинг: 3 из 5 звезд3/5 (20)

- Building Construction Technology: A Useful Guide - Part 1От EverandBuilding Construction Technology: A Useful Guide - Part 1Рейтинг: 4 из 5 звезд4/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactОт EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactРейтинг: 5 из 5 звезд5/5 (5)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОт EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОценок пока нет

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Chemistry for Breakfast: The Amazing Science of Everyday LifeОт EverandChemistry for Breakfast: The Amazing Science of Everyday LifeРейтинг: 4.5 из 5 звезд4.5/5 (14)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionОт EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Guidelines for Defining Process Safety Competency RequirementsОт EverandGuidelines for Defining Process Safety Competency RequirementsРейтинг: 3 из 5 звезд3/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisОт EverandGuidelines for Chemical Process Quantitative Risk AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeОт EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeРейтинг: 5 из 5 звезд5/5 (1)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationОт EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettРейтинг: 4 из 5 звезд4/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeОт EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeРейтинг: 4 из 5 звезд4/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeОт EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeРейтинг: 5 из 5 звезд5/5 (4)

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeОт EverandChemistry for Breakfast: The Amazing Science of Everyday LifeРейтинг: 4.5 из 5 звезд4.5/5 (90)