Академический Документы

Профессиональный Документы

Культура Документы

Manual de Servicio y Operacion (2800 ASV)

Загружено:

Luis Emilio Santana DiazАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Manual de Servicio y Operacion (2800 ASV)

Загружено:

Luis Emilio Santana DiazАвторское право:

Доступные форматы

POSI-TRACK

MODEL 2800

MODEL 2810

OPERATOR AND SERVICE

MANUAL

ALL SEASON VEHICLES, INC.

PO BOX 5160

840 LILY LANE

PART #0308-382 GRAND RAPIDS, MN 55744

POSI-TRACK 2800 & 2810

WELCOME

CONGRATULATIONS !! You have chosen the world’s

most versatile crawler/tractor. You will soon discover

that no other machine can match the POSI-TRACK’s

performance, versatility, and productivity. As an owner

or operator, it is your responsibility to learn the capabili-

ties of the POSI-TRACK to maximize both performance

and safety. Before operating the POSI-TRACK make

sure you read and understand this owners manual. If

you have any questions, don’t hesitate to contact your

dealer for answers.

ASV, INC. PAGE 1

POSI-TRACK 2800 & 2810

WARRANTY

1 YEAR, UNLIMITED HOUR WARRANTY

T

he WARRANTY herein set forth applies solely to the POSI-TRACK 2800,

POSI-TRACK 2810, and POSI-TRACK 4810 manufactured by ASV, INC. and

is in lieu of all other warranties, expressed or implied. No person, agent, or dealer

is authorized or empowered to give any other warranty or to assume any other li-

ability on behalf of ASV, INC. The WARRANTY is limited to the original purchaser only.

No warranty is transferable to any subsequent owner.

ASV, INC. warrants the POSI-TRACK 2800, POSI-TRACK 2810, and the

POSI-TRACK 4810 against defects in material and workmanship under normal use and ser-

vice for a period of ONE YEAR with unlimited hours, from the date of delivery, and will

repair or replace at ASV, INC.’s option, free of charge to the original purchaser, any part

that our examination reveals to be defective in material or workmanship.

(A) Only Original Equipment Manufacture parts are covered by this WARRANTY.

(B) Wear Items are not warranted against normal use.

(C) The CATERPILLAR Engine is separate from ASV, INC.'S WARRANTY, and is

described in the CATERPILLAR Warranty Information.

(D) The ISUZU engine warranty is separate from ASV, INC.’s WARRANTY. The

ISUZU engine warranty is described in the ISUZU Warranty Information.

ASV, INC. reserves the right to inspect the equipment prior to any decision involving a war-

ranty claim. In no case shall ASV, INC. grant a remedy that exceeds the purchase price of

the component or part, and the time to remove and replace the component.

ASV, INC. reserves the right to make design changes without incurring any obligation to

make such changes to previously manufactured equipment. This WARRANTY does not ap-

ply to damage caused by misuse, abuse, neglect, or improper adjustment, accident, or im-

proper application. Any repairs or alterations made to the equipment without authorization

from ASV, INC. will void this WARRANTY.

NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY ASV, INC. EXPRESSED OR

IMPLIED, STATUTORY, BY OPERATION OR LAW, OR OTHERWISE, INCLUDING MERCHANT-

ABILITY AND FITNESS FOR A PARTICULAR PURPOSE. ASV, INC. DISCLAIMS LIABILITY FOR

INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND.

ASV, INC. PAGE 2

POSI-TRACK 2800 & 2810

WARRANTY LIMITATIONS

GROSS VEHICLE WEIGHT

The GVW (Gross Vehicle Weight) of the POSI-TRACK 2800 or 2810 should not exceed

10,500 lbs. This weight includes any accessories, attachments, or material being carried. Ex-

ceeding the 10,500 lb. GVW will void the WARRANTY.

MODIFICATIONS

The limited WARRANTY covers the POSI-TRACK and its accessories as built by ASV, INC.

Any modifications made to the vehicle can affect the WARRANTY. Before any modifications

are made, have your dealer contact ASV, INC. for written approval. Modifications include, but

are not limited to: additional hydraulic plumbing, alternative attachment mounting, welding to

the frame or roll cage, welding to the undercarriage, track modification, etc.

ATTACHMENTS

Attachment use can also affect the WARRANTY. The attachment should be sized correctly

for the vehicle’s operating capacity and hydraulic system. An attachment that cannot accept

the machines hydraulic flow and pressure can create extreme heat and cause failures to the ve-

hicle’s hydraulic system. An attachment which is oversized for the vehicle’s carrying capac-

ity, can cause premature failure to the vehicle’s mounting system, frame, undercarriage, axles,

bearings, etc. When determining the weight of the attachment the following items must be

considered: the distance the mounted attachment is extended from the vehicle and the weight

of the attachment’s load. (refer to page 22 for operating capacity limits)

ASV, INC. PAGE 3

POSI-TRACK 2800 & 2810

TABLE OF CONTENTS

WARRANTY ......................................................................................................................................................................................2

WARRANTY LIMITATIONS ............................................................................................................................................................3

FOREWORD.......................................................................................................................................................................................5

SECTION 1 - SPECIFICATIONS

GENERAL ..........................................................................................................................................................................................6

ENGINE ..............................................................................................................................................................................................6

TRACKS .............................................................................................................................................................................................6

FINAL DRIVE ....................................................................................................................................................................................7

CAPACITIES ......................................................................................................................................................................................7

LOADER ASSEMBLY .......................................................................................................................................................................8

ELECTRICAL .....................................................................................................................................................................................8

SECTION 2 – GENERAL SAFETY .................................................................................................................................9,10

SECTION 3 – GENERAL OPERATION

DRIVE CONTROL CONSOLE DEFINITIONS .................................................................................................................................11

HYDRAULIC CONTROL CONSOLE DEFINITIONS......................................................................................................................12,13

OPERATING INSTRUCTIONS .........................................................................................................................................................14,15

HYDROSTATIC DRIVE ....................................................................................................................................................................16

LOADER VALVE CONTROL ...........................................................................................................................................................17

LOADER LOCK OUTS ......................................................................................................................................................................18

QUICK ATTACH MOUNT ................................................................................................................................................................19

FRAME MOUNT ................................................................................................................................................................................20,21

OPERATING CAPACITY ..................................................................................................................................................................22

MOVING DIRT ..................................................................................................................................................................................23

BI-DIRECTIONAL OPERATION ......................................................................................................................................................24

SIDE HILLING ...................................................................................................................................................................................25

PRE START CHECK LIST ................................................................................................................................................................26

STARTING INSTRUCTIONS ............................................................................................................................................................26

SECTION 4 – GENERAL MAINTENANCE

BREAK IN PROCEDURES................................................................................................................................................................27,28

MAINTENANCE SCHEDULE ..........................................................................................................................................................29

GREASE POINTS ...............................................................................................................................................................................30,31

ENGINE OIL AND FILTER CHANGE .............................................................................................................................................32

HYDRAULIC OIL AND FILTER CHANGE .....................................................................................................................................33

BLEEDING THE FUEL SYSTEM .....................................................................................................................................................34

TRACK TENSION..............................................................................................................................................................................35

PLANETARY OIL CHANGE ............................................................................................................................................................36,37

RADIATOR AND OIL COOLER .......................................................................................................................................................38

AIR CLEANER & BATTERY ............................................................................................................................................................39

CHANGING FUEL FILTER ...............................................................................................................................................................40

SECTION 5 – SERVICE

TRACK REMOVAL ...........................................................................................................................................................................41,42

TRACK INSTALLATION ..................................................................................................................................................................43,44

BOGIE CARRIAGE REMOVAL .......................................................................................................................................................45

WHEEL TUBE REMOVAL ...............................................................................................................................................................45

WHEEL REPLACEMENT .................................................................................................................................................................46

END TUBE REMOVAL .....................................................................................................................................................................46

SPROCKET REMOVAL ....................................................................................................................................................................47

HYDRAULIC FLOWS .......................................................................................................................................................................48

SECTION 6 - TROUBLE SHOOTING

GENERAL ..........................................................................................................................................................................................49-52

ELECTRICAL .....................................................................................................................................................................................53-58

SERVICE LOG...........................................................................................................................................................................59-60

NOTES ............................................................................................................................................................................................61-63

ASV, INC. PAGE 4

POSI-TRACK 2800 & 2810

FOREWORD

This manual contains operation, maintenance, service and trouble shooting information for

the POSI-TRACK 2800 and the 2810. It is designed to aid and instruct operators and ser-

vice personnel in the safe operation and normal maintenance of the vehicle.

This manual is divided into six sections. The sections cover specifications, general safety,

general operation, general maintenance, service and trouble shooting.

By studying this manual, operators and service personnel will become more familiar with

the construction, operation and normal maintenance of the vehicle. As operators and service

personnel become more efficient in operation and maintenance, they will save time and be-

come more productive.

Throughout this manual the words WARNING, CAUTION, and NOTE are used to empha-

size certain information. The word WARNING is used to identify personal safety informa-

tion. The information should be read carefully and understood. Failure to heed warnings

could result in bodily injury. The word CAUTION is used to identify possible damage to

the vehicle or components. Failure to follow the suggested procedures will probably result

in damage to the vehicle. The word NOTE identifies supplementary information worthy of

particular attention.

At the time of publication of this manual, all information, photographs, and illustrations are

technically correct. Since ASV, INC. is constantly improving and refining its products, no

retroactive obligation is incurred.

VEHICLE IDENTIFICATION NUMBERS (VIN)

The POSI-TRACK VIN is located on the side of the control console.

Always provide the VIN when contacting the dealer

about parts, service, warranty, or accessories. No warranty claims will be processed if the

VIN number is not given.

ASV, INC. PAGE 5

POSI-TRACK 2800 & 2810 SECTION

SPECIFICATIONS 1

GENERAL

82.5"

Height 69"

Width 113"

Length 16"

Ground Clearance 6,800 lbs.

Weight (Without Loader) 7,450 lbs.

Weight (With Loader) 7 mph

Top Speed 2.4 psi (Without Loader)

Ground Pressure w/Zero Track Penetration 2826 sq. in.

Square Inches of Track on the Ground

P

ENGINE

Isuzu 4JB1

Model Diesel, liquid Cooled, In-Line 4 Cylinder

Type 2.8 liter ( cid)

Displacement 70 hp at 3,000 rpm

Horsepower , 2800 75 hp at 3,000 rpm

Horsepower , 2810 128 ft.-lb.

Peak Torque, 2800 152 ft.-lb. (Continuous)

Peak Torque, 2810

P

TRACK SPECIFICATIONS

18"

Width 220"

Length 265 lbs.

Weight 2

P

TRACK CONSTRUCTION

Molded Rubber with Kevlar™ reinforcement, no steel in track, 2 rows of internal drive lugs.

ASV, INC. PAGE 6

POSI-TRACK 2800 & 2810

SPECIFICATIONS

POSITIVE DRIVE

Self-Cleaning Internal Drive Sprocket drives the track via two rows of molded rubber drive lugs

on interior of track. 24 roller pins per sprocket, 110 molded drive lugs per track.

UNDERCARRIAGE

Articulating roller carriages with rubber tor-

Type sion axles

48

Number of wheels supporting the track Sealed, oil bath bearings

Lubrication

P

TRANSMISSION & FINAL DRIVE

Sundstrand, tandem variable displacement

Drive Pumps Eaton Model , 2.48 cu. In.

Drive Motors Planetary gear box

Final Drive

P

AUXILIARY PUMPS

19 gallons per minute max.

Low Flow at full engine rpm 25 gallons per minute max.

High Flow at full engine rpm 2,750 psi

Pressure at full flow

P

CAPACITIES

13 gal.

Fuel Tank 28 gal.

Hydraulic Reservoir 2.3 gal.

Coolant 6.8 qt.

Engine Oil w/filter

ASV, INC. PAGE 7

POSI-TRACK 2800 & 2810

SPECIFICATIONS

LOADER ASSEMBLY

2,350 lbs.

Operating Capacity (SAE, Skid-Steer loader) 1,645 lbs.

Operating Capacity (SAE, Tracked loader) 5,000 lbs.

Breakout force 109"

Lift height to hinge pin 2 pin, universal skid steer type

Quick-Attach

P

OPERATOR’S COMPARTMENT

ROPS/FOPS approved

Protection system Reversible, operator presence switch

Seat Hand controls for drive and loader/bucket

Controls

P

INSTRUMENTATION

Fuel, engine RPM, water temp., hour meter,

Standard instruments include: engine oil pressure, amp meter, hot hydraulic,

oil light, replace filter lights

P

ELECTRICAL SYSTEM

2 front, 2 rear

Lights 12 volt, 950 CCA

Battery 35 amp

Alternator

P

ADDITIONAL FEATURES

Side by side radiator and oil cooler

Cooling package Pumps mounted inside reservoir to minimize

Environmental potential oil leaks from reaching the ground

Dozer blade, 3-point hitch, and backhoe can be

Attachment receptacle mounted to the frame of the POSI-TRACK.

P

ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTIFICATION.

ASV, INC. PAGE 8

POSI-TRACK 2800 & 2810 SECTION

GENERAL SAFETY 2

NEVER start vehicle without sitting in the seat

with the seat belt fastened.

ALWAYS wear your seat belt when operating

the POSI-TRACK.

ALWAYS drive with the loader in the lowest

possible position. Traveling with the loader

raised causes the center of gravity (CG) to be

raised, which increases the possibility of roll

over in any direction.

USE EXTREME CAUTION and common

sense when traveling on inclines. Avoid sudden

stops, excessive speed, and avoid obstacles.

Sudden shifts in CG could cause roll over.

NEVER use the POSI-TRACK to transport per-

sonnel. Never let anyone ride on the vehicle or

in the bucket.

ALWAYS shut the engine off when adding

fuel, oil, or water to the engine. Always shut

the engine off when cleaning the radiator and

oil cooler or when doing any maintenance or

adjustments.

NEVER get out of the vehicle when an attach-

ment is in motion.

ASV, INC. PAGE 9

POSI-TRACK 2800 & 2810

GENERAL SAFETY

NEVER get in or out of the operator’s seat with

the loader in the raised position, unless the

loader lock out pins are engaged. Lower the

loader all the way down before getting out of

the vehicle. Always step over the attachment

when getting in or out of the vehicle – NEVER

UNDER IT.

THE SIDE SCREENS MUST be installed

when the loader is attached to the vehicle. Fail-

ure to install side screens could result in serious

injury or death to the operator.

ALWAYS use caution when carrying a load.

Sudden stops can cause roll over.

ALWAYS make sure all levers are in neutral

before starting the engine.

BECOME FAMILIAR with all controls and

WARNING decals before operating the vehi-

cle.

NEVER allow an unqualified person to operate

the POSI-TRACK. Anyone operating the vehi-

cle must read and understand the operator’s

manual.

NEVER operate the POSI-TRACK on any fro-

zen body of water. Ice can be very dangerous

and unpredictable.

THINK SAFETY FIRST

ASV, INC. PAGE 10

POSI-TRACK 2800 & 2810 SECTION

GENERAL OPERATION 3

CONSOLE DEFINITIONS

E F

MAIN DRIVE CONTROL (Fig. 1 and Fig. 2)

A

A) Coolant Temperature Gauge C

This gauge indicates the temperature of the en-

gine coolant. Normal coolant temperature B

should be between 180° and 205°F.

D

B) Engine Oil Pressure Gauge Fig. 1

This gauge is used to monitor the engines oil

pressure. If the gauge shows low oil pressure,

turn off the engine and determine the cause.

(Refer to troubleshooting section)

H

C) Tachometer GG

The tachometer displays the RPM of the engine.

Normal operating RPM should be between

2,000 and 3,000 RPM. Maximum RPM is

3,000. Fig. 2

D) Hour Meter

The hour meter should be used to schedule

maintenance intervals. (See maintenance chart)

E) Throttle

Controls engine RPM.

F) Drive Levers

Each lever controls one track.

G) High Flow Lever

Controls the direction of the high flow hydraulic

oil.

H) Seat Switch Receptacle

Allows seat switch to be plugged in when seat is

reversed.

ASV, INC. PAGE 11

POSI-TRACK 2800 & 2810

GENERAL OPERATION

HYDRAULIC CONTROL CONSOLE L M

(Fig. 3 and Fig. 4) LM JJ

J) Main Valve Joystick

Controls the loader, dozer or 3-point hitch.

K) Auxiliary Low Flow Lever

Controls the direction of the low flow hydraulic

oil. K

L) Parking Brake Switch Fig. 3

Used to activate the brake activating solenoid. Fig. 3

This switch locks in position to prevent acci-

dental engagement. There is a small switch

within the main switch, that must be pressed

before the main switch will unlock.

NOTE

It is important that the low flow Aux. lever is

in neutral if nothing is hooked up to the low-

flow circuit. If it is not in neutral, sluggish

operation of the machine, loader and engine

will occur. The machine will also start hard if

this lever is not in the center (neutral) posi-

tion.

M) Glow Plug Switch

When pressed, activates the engine glow plugs.

NOTE

The parking brake is automatically engaged

when the engine is turned off. The brake so-

lenoid will allow you to engage the brake

while the engine is running.

ASV, INC. PAGE 12

POSI-TRACK 2800 & 2810

GENERAL OPERATION

N) Light Switch N OP Q

This switch turns on/off both the front and rear N OP Q R

work lights.

S

O) Front Windshield Wiper Switch T

Controls the optional front windshield wipers. R

W US

P) Fan Switch V

Controls the optional heater fan. X T

W Fig.

U 4

Fig. 4

Q) Rear Windshield Wiper Switch

Controls the optional rear windshield wiper.

R) Ignition

Key operated switch starts engine and powers

electrical accessories.

S) Glow Plug Indicator Element

T) Change 5" Filter

This light will come on if the 5" filter needs to

be changed.

U) Change 3" Filter

This light will come on if the 3" filter needs to

be changed.

V) Hot Hydraulic Oil Indicator

This light will come on if the hydraulic oil rises

above 200°F.

W) Amp Gauge

Used to monitor the battery charging system

while the engine is running.

X) Fuel Gauge

ASV, INC. PAGE 13

POSI-TRACK 2800 & 2810

GENERAL OPERATION

OPERATING INSTRUCTIONS

Enter the vehicle when the loader is all the way

down. Never enter the vehicle by going under a

raised loader. (Fig. 5)

!WARNING!

Entering or exiting the vehicle under a raised

loader could cause serious injury or death.

Never put yourself underneath a raised, unse- Fig. 5

cured, loader. (Fig. 6)

Adjust the seat forward or back so both feet

reach the footrest and both hands reach the con-

trols.

Check to make sure all auxiliary levers are in

NOTE

It is recommended that your elbows reach the

arm rests on the seat. This will allow for

steadier control over rough terrain and will Fig. 6

also lessen fatigue.

the neutral position and that the throttle is in the

idle position.

Fasten seat belt, and adjust so it fits snugly

around your waist. (Fig. 7)

Fig. 7

!WARNING!

Failure to wear the seat belt could lead to seri-

ous injury or death.

ASV, INC. PAGE 14

POSI-TRACK 2800 & 2810

GENERAL OPERATION

Start the vehicle and allow engine to warm up

for two minutes before increasing throttle to de-

sired RPM. First time operators will want to

learn at a lower RPM (2,000 or less) until they

feel comfortable with the controls. It is also rec-

ommended that the first time operator concen-

trate on learning the drive controls before mov-

ing on to the loader or other attachment controls.

Place one hand over both drive control levers.

Fig. 8

NOTE

The engine will not start if the drive controls

are not in neutral. Loader valve will not func-

tion unless the operator is seated.

Push both levers forward in unison to move for-

ward, and pull both levers back in unison to

move in reverse. The further the levers are

moved, the faster the vehicle travels in either di-

rection.

To turn to the right, push the left lever farther Fig. 9

than the right lever (this makes the left track turn

faster than the right track). To turn to the left,

push the right lever further than the left lever.

To turn the vehicle in its own axis (counter-

rotate) push one lever forward and pull the other

in reverse.

NOTE

For best performance, always put power to

both tracks when making a turn. When both

tracks are turning, the vehicle will turn easier,

which also results in less damage to the

ground.

ASV, INC. PAGE 15

POSI-TRACK 2800 & 2810

GENERAL OPERATION

HYDROSTATIC DRIVE ARE THERE GEARS?

POWER & SPEED CONTROL No, not in the traditional sense. Hydro-

static drive offers an infinite amount of

The POSI-TRACK transmits the power from gears from 0 to full speed. The closer the

the engine to the tracks using a hydrostatic levers are to the neutral position the lower

transmission. The hydrostatic transmission the gear the vehicle is in.

sends oil under pressure to two individual hy-

draulic motors, one for each track. The hydro- ADVANTAGES

static transmission consists of two individual

hydrostatic pumps. One pump for each motor. With hydrostatic drive there aren't any

Track speed is increased by sending more oil to clutches, brakes, or shift sticks to mess

the hydraulic motors, and power is increased by with. Hydrostatic drive enables the opera-

sending less oil to the hydraulic motors. With a tor to always find the right speed, and also

mechanical transmission the operator must shift turn, counter-rotate and stop with ease and

down to increase power. With hydrostatic drive precision.

the operator can simply pull back on the drive

controls, reducing speed and increasing power

at the same time.

DRIVE CONTROLS

1 = MOST POWER and least speed

2 = LESS POWER and more speed

3 = MORE SPEED and less power

4 = MOST SPEED and least power

ASV, INC. PAGE 16

POSI-TRACK 2800 & 2810

GENERAL OPERATION

LOADER VALVE CONTROL (Fig. 10 and

Fig. 11)

To raise the loader, pull back on the joystick at

a controlled rate.

To lower the loader, push forward on the joy-

stick at a controlled rate.

To put the loader in “float” position, push the

lever all the way forward with a quick motion. Fig. 10

To curl the attachment, such as a bucket, move

the joystick to the left at a controlled rate.

To tilt the attachment forward, move the joy-

stick to the right at a controlled rate.

LOADER LOCK OUT PINS

The roll cage comes equipped with two retract-

able pins that slide outward to secure the

loader in the “up” position. It is critical to use

these pins when there is service to be done on

the vehicle, when the loader is up, hooking up

a frame mount attachment, or when someone

has to get in or out of the vehicle when the Fig. 11

loader is up.

!WARNING!

The loader lock out pins must be used to pre-

vent serious injury or death. Never leave the

loader in the “up” position without using the

lock out pins.

ASV, INC. PAGE 17

POSI-TRACK 2800 & 2810

GENERAL OPERATION

ENGAGING THE LOCK OUT PINS

(Fig. 12)

1. Raise the loader past the top of the roll cage

and turn off the engine.

2. Loosen the two knobs and undo the red

latch.

3. Slide the knobs outward until they stop and

tighten. Fig. 12

4. Turn the key to the “on” position, to unlock

the loader valve (DO NOT START ENGINE).

Lower the loader onto the pins.

A

FUSE PANEL

The fuse panel is located to the left of the opera-

tors seat when the operators seat is facing the B

loader end of the vehicle.

1. Loosen the fiberglass cover (A) by removing Fig. 13

the three thumb screws (B).

2. Remove the cover by lifting straight up on

the fiberglass cover. This will expose the fuse

panel (C)

3. For extensive work on the fuse panel, remov-

ing the seat will allow better access to the fuse C

panel and wiring.

!WARNING!

Before working on the fuse panel or any wir- Fig. 14

ing, always disconnect the battery before be-

ginning.

ASV, INC. PAGE 18

POSI-TRACK 2800 & 2810

GENERAL OPERATION

QUICK-ATTACH MOUNT

Quick-attach attachments are designed to be

quick and easy to install or remove. The follow-

ing instructions use the backhoe as an example.

The backhoe uses additional stabilizers that

other quick-attach attachments do not.

1. With the quick-attach levers up, drive into Fig. 15

the backhoe’s quick-attach plate and curl the

backhoe towards the vehicle with the quick-

attach tilt cylinders. (Fig. 15)

2. Lock the levers in place by pulling the levers

inward and down. (Fig. 16)

3. Replace the loaders lift cylinder pins, with

the pins that are supplied with the backhoe.

These pins will allow a place for the stabilizers Fig. 16

to attach to the loader for extra stability. (A)

A

4. Secure the stabilizers to the loaders lift cylin-

der pins using the supplied lynch pins. (Fig. 17)

5. Hook up the hydraulic quick-couplers.

6. Move the low flow auxiliary lever to the

“down” position. This will send hydraulic oil to

the backhoe valve and it is ready to use. Fig. 17

(Fig. 18)

Fig. 18

ASV, INC. PAGE 19

POSI-TRACK 2800 & 2810

GENERAL OPERATION

FRAME MOUNT B

C

Frame mount attachments include the six-way D A

dozer blade, three-point hitch, and the frame

mount backhoe. The frame mount receptacle

allows the attachment to be rigidly mounted to

the frame for added strength and stability. The E

following instructions are for the six-way dozer

blade. Fig. 19

1. If the vehicle has a loader assembly installed,

use the loader lockout pins to secure the loader

in the “up” position. (See page 18)

2. Turn the engine off and then turn the key to

the “on” position to unlock the loader valve.

(DO NOT RESTART THE ENGINE) Move

the loader control and the auxiliary valve in all

directions to relieve any pressure in the lines.

3. Disconnect all loader hoses at the quick-

couplers.

4. Using a floor jack, raise the dozer mount so

it is high enough to line up with the vehicle

frame mount receptacle. (Fig. 19)

5. Remove the loader stop (A) by removing the

two pins (B).

6. Drive the vehicle so the dozer mount (C) and

the axle arms (D) slide into the receptacle (E)

and around the front axle.

ASV, INC. PAGE 20

POSI-TRACK 2800 & 2810

GENERAL OPERATION

7. Route the hoses between the roll cage and the

loader towers and hook up the hoses to the quick-

B

couplers. The hoses and the quick-couplers are D

all color coded for easy hook up; however, if the

color codes have been removed, refer to figures,

20, 21, 22 for proper hose configuration. (Match F

the letters on the dozer blade with the letters on C

the quick-couplers for proper hose configura- E

tion). F A

A

8. Line up the holes in the receptacle and in the

dozer blade and insert the pins through the recep- B

tacle. Secure the pins with the small lynch pins.

If the pins do not line up, use the blade hydrau-

lics to fine tune the hole alignment.

Fig. 21

B

E

D

A C

Fig. 20 F

Fig. 22

ASV, INC. PAGE 21

POSI-TRACK 2800 & 2810

GENERAL OPERATION

The operating capacity refers to how much addi-

tional weight can be put into the POSI-TRACK’s

loader bucket. This operating capacity is meas-

ured at the mid point of the low profile bucket.

The operating capacity is 2,350 lbs. when the low

profile bucket is quick attached to the machines

loader assembly, and is at the farthest point from

the vehicle (half way up). The heavier the

attachment, such as a 4-in-1 bucket, the less the

operating capacity will be. Moving the load

farther from the vehicle, such as a tree spade, will

significantly reduce the operating capacity.

THE MOST SIGNIFICANT FACTOR IN OPERATING CAPACITY IS THE

DISTANCE BETWEEN THE FRONT PIVOT POINT OF THE VEHICLE

AND THE CENTER OF GRAVITY OF THE MATERIAL BEING CARRIED.

2,350 LB. OPERATING

CAPACITY RATED AT

BUCKET’S CENTER OF

GRAVITY

INCREASING THE DISTANCE FROM

THE FRONT PIVOT POINT TO THE

FRONT PIVOT POINT

PAYLOAD WILL DECREASE THE

OPERATING CAPACITY

ASV, INC. PAGE 22

POSI-TRACK 2800 & 2810

GENERAL OPERATION

MOVING DIRT WITH THE BUCKET

Certain techniques can be used to become more

efficient in moving dirt with the bucket. The

following are simple guidelines for those who

do not have much experience moving dirt.

The POSI-TRACK’S loader is designed to push

against the frame while leveling or digging dirt. Fig. 23

Lower the loader all the way down until it stops

against the loader-stop.

Tilt the bucket forward until the bucket engages

the ground. This is the proper position for dig-

ging with the POSI-TRACK. (Fig. 23)

In uneven terrain, it may be necessary to dig

with the loader raised off the loader-stop, how-

ever, digging in this manner should be kept to a

minimum to reduce damage to the loader arms.

Always move dirt with the bucket level with the

ground. Never tilt the bucket all the way for-

ward and use as a dozer blade. (Fig. 24) This

puts tremendous stress on the bucket, the quick-

attach, and the bucket cylinders. Damage to

any of the previously mentioned can occur if

the bucket is used in this manner.

When filling the bucket with dirt, the slower

you travel the more power the vehicle will have.

The POSI-TRACK has incredible traction and

the bucket can easily be filled by slowly driving

into the pile of dirt.

ASV, INC. PAGE 23

POSI-TRACK 2800 & 2810

GENERAL OPERATION

BI-DIRECTIONAL OPERATION

A unique feature of the POSI-TRACK is the

ability to reverse the seat and the footrest in or-

der to face the engine.

1. Remove the footrest by pulling up from both

ends with even pressure. (Fig. 25)

Fig. 25

2. To remove the seat, remove the two lynch

pins, which secure the seat to the pegs, and un-

plug the seat cord from the console. Pull up on

the seat from both sides. (Fig. 26)

3. Once removed, take the seat out of the cab.

Place the footrest over the pegs where the seat

used to be. Place the seat on the pegs where the

footrest used to be. (Fig. 27)

Fig. 26

4. The seat cord must be plugged into the recep-

tacle on the console in order for the vehicle to

operate. There is a receptacle on both consoles

so the seat can be plugged in no matter which di-

rection it is facing. (Fig. 28)

NOTE

When operating the POSI-TRACK as a tractor,

with the loader removed and with the seat fac- Fig. 27

ing the engine, the side screens should be re-

moved to allow better access to the operator's

seat.

NOTE

When the seat is facing the engine, the en-

closed cab is not functional. The door will not

close and there is poor access to the operator’s

compartment. Fig. 28

ASV, INC. PAGE 24

POSI-TRACK 2800 & 2810

GENERAL OPERATION

SIDE HILLING

Although the POSI-TRACK works well on side

hills, extreme caution must always be used.

Never exceed a 3 to 1 slope. This means 3 feet

of run to every 1 foot of rise. (Fig. 29)

When turning to go up hill while side hilling,

the following technique should always be used:

Fig. 30

1. Stop the vehicle and back the vehicle down

the hill until the front of the vehicle is pointed

in the direction you want to go. Then drive for-

ward. (Fig. 30, 31, 32)

2. This turning technique will reduce the

chance of track derailment and will also put

less stress on the track system.

Fig. 31

CAUTION

While operating on a side hill, the more weight

there is on the vehicle, the greater the chance

of track derailment. Gravity is trying to pull

the vehicle downhill, while the tracks are keep-

ing the vehicle on the hill. The less weight that

is on the vehicle, the less chance there will be

for track derailment

Fig. 32

1 1:1 = 100% = 45°

1

1 2:1 = 50% = 26.6°

2

1

3:1 = 33.3% = 18.4°

3

Fig. 29

ASV, INC. PAGE 25

POSI-TRACK 2800 & 2810

GENERAL OPERATION

PRESTART CHECKLIST ITEM REMARKS

Tracks Check tension

Prior to operating the POSI-TRACK, several Engine coolant Check level

items need to be checked to ensure safe, trou- Hydraulic fluid Check level

ble-free operation. It is also important that pe- Engine oil Check level

riodic maintenance be done correctly and Fan belt Check tension

safety. Follow a regular maintenance schedule Hoses Check for wear

that includes replacement and / or adjustment Fittings Check for leaks

of any component found to be excessively Radiator Clean thoroughly

worn, out of adjustment, or damaged. Before Nuts & bolts Tighten if needed

starting the engine and operating the POSI- Battery Check cables

TRACK, check the items on figure 33. Aux. levers Check for neutral

Drive controls Check for neutral

STARTING INSTRUCTIONS

1. Perform all Pre-Start checks outlined Fig. 33

(Fig. 33) before starting engine.

2. Adjust seat, fasten seat belt, make sure all

levers are in neutral.

CAUTION

3. From the slow idle position, push the throt- Do not operate the starter for more than

tle 1/3 of the way open. 30 seconds at a time. If the engine does

not start, wait 2 minutes before trying

4. Pre-heating: In temperatures below 32° F it again. If engine still does not start, refer

may be necessary to use the glow plugs. The to the trouble shooting section in this

glow plug indicator will glow red while the manual.

glow plugs are activated.

5. Activate the glow plugs for at least 30 sec- CAUTION

onds or for as long as 3 minutes depending on The engine should be brought back to

the outside temperature. an idle and run for at least 2 minutes be-

fore shutting off. This will allow hot

6. After the glow plugs have been activated engine parts to cool.

immediately turn the key to the "start" posi-

tion. Any delay will allow the glow plugs to

cool making them much less affective.

ASV, INC. PAGE 26

SECTION

POSI-TRACK 2800 & 2810

4

GENERAL MAINTENANCE

BREAK-IN PROCEDURES CAUTION

Failure to perform the proper break-in

Although all systems on the POSI-TRACK are procedures will cause premature compo-

tested at the factory to ensure proper operation, nent failure.

there are a few items that require a break-in

period. Certain components need readjustment

and others require special care within the first

100 hours of operation. PROPER BREAK-IN

PROCEDURES ARE CRITICAL TO THE

LONG TERM RELIABILITY OF THE POSI-

TRACK. Extra care during this period will

pay-off down the road.

TRACKS Track will loosen during break-in

Proper track tension plays an important part in

the over-all performance of the POSI-TRACK.

A track run too loose can cause premature

track failure and cause the track to derail. Al-

though track tension is set properly at the fac-

tory, the tracks will need an adjustment after

break-in. Once the KevlarTM and other special Track needs to be tightened after break-in

materials in the track are pulled straight, mini-

mal adjustment will be required. The break-in

period of a track can range from just a few

hours to over 10 hours, depending on the track

and how the vehicle is operated.

The tracks on the POSI-TRACK are easy to

tighten. It takes only a few minutes and will

be well worth the time (See page 35 for track

tensioning procedure.) After the initial track

break-in, the tracks may not need to be tight-

ened for several hundred hours, however, the

tracks should be inspected daily and tight-

ened as necessary.

ASV, INC. PAGE 27

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

ENGINE

The engine is ready for normal use; however,

extra care during the first 100 hours will result

in longer engine performance and life. During

the break-in period set the engine at 2400 rpm.

Brief periods of full throttle operation and

variations in engine load also contribute to

good engine break-in. Lug nuts

Fig. 34

PLANETARY DRIVES

CAUTION

Each track’s final drive consists of a hydraulic Failure to change the planetary oil at the

drive motor, a planetary gearbox and an inter- 50 hour break-in interval, will drastically

nal drive sprocket. The planetary gearbox re- shorten the life of the planetary gear

quires a break-in period for the lug nuts and box. Failure to follow this procedure

for the planetary oil. The 9 lug nuts, which will also void the warranty of the plane-

attach the sprocket to the planetary gearbox, tary gear box.

are torqued to 115 ft.-lbs. at the factory, and

should be re-torqued to 115 ft.-lbs. after 10

hours of operation. (Fig. 34)

The planetary gearbox requires an oil change

at 50 hours. The break-in time allows the

gears in the planetary to properly mesh. This

is a crucial oil change since the oil will have a

high metal content. After this initial oil

change, the planetary oil should be changed

every 1,000 hours or annually. (Refer to page

36 for proper planetary oil changing proce-

dure.)

ASV, INC. PAGE 28

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

MAINTENANCE SCHEDULE

ITEM FREQUENCY LUBRICANT

Hydraulic fluid 500 hours Amoco Rykon MV

Hydraulic filters 250 hours or as needed

Engine oil and filter 100 hours Refer to page 31

Engine fuel filter As needed

Engine air filter As needed

Planetary oil 1,000 hours or annually

(After 50 hr. break-in) SAE 80w-90 gear lube

Drive shaft 250 hours Low temp grease

Loader grease fittings 25 hours, or as needed Low temp grease

Wheel tubes Check level at 1,000 hours SAE 80w-90 gear lube

Track tension As needed

SERVICE ITEMS

FLUID CAPACITY TYPE

Fuel 13 gallons Diesel

Hydraulic oil 28 gallons Amoco Rykon MV

Planetary oil 1 quart SAE 80w-90 gear lube

Wheel tube oil 1 pint SAE 80w-90 gear lube

Engine coolant 2.3 gallons Isuzu approved

Engine oil 6.8 quarts See chart below

Engine oil viscosity

chart.

ASV, INC. PAGE 29

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

GREASE POINTS

LOADER ASSEMBLY

There are 12 grease fittings on the POSI-

TRACK’S loader assembly, which should be

greased every 25 hours, or as needed. The

grease fittings are located in the following

spots on both sides of the loader: Fig. 37

1. The main loader hinge points. (Fig. 35)

2. Both ends of the lift cylinders. (Fig. 36, 37)

3. Both ends of the quick-attach cylinders.

(Fig. 38, 39)

4. Hinge points for the quick-attach. (Fig. 40)

Fig. 38

Fig. 39

Fig. 35

Fig. 36 Fig. 40

ASV, INC. PAGE 30

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

DRIVE SHAFT

The drive shaft must be greased every 250

hours. Lack of grease will cause a failure of

the drive shaft, which could cause damage to

other components.

The time it takes to grease the drive shaft can

be kept to a minimum if the following instruc-

tions are used. Fig. 41

1. Remove seat.

2. Remove drive shaft / hose guard panel.

3. Using a grease gun with a hose extension,

grease both u-joints of the drive shaft. There

is also a grease fitting in the middle of the

drive shaft that needs to be greased. (Fig. 41)

ASV, INC. PAGE 31

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

ENGINE OIL & FILTER CHANGE

Engine oil and filter should be changed every A

250 hours after the initial 100 hour break-in.

This service interval should be shortened if the

vehicle is used in extremely dusty conditions.

1. Run engine approximately 5 minutes to warm

up oil. Shut off engine.

Fig. 42

2. Remove oil drain plug (A) beneath the en-

gine compartment and allow to drain.

B

3. Using a filter wrench, remove oil filter ele-

ment (B) and dispose of properly.

4. Replace with new filter element, and tighten

¾ to 1¼ turn after the filter contacts the housing.

DO NOT over tighten.

5. Install oil pan drain plug, ensure plug seal is Fig. 43

still in good condition.

6. Fill engine crankcase to specified level.

(6.8 quarts)

7. Run engine to check for possible leaks.

8. Stop engine for 10 minutes and recheck oil

level. Oil level should be within the crosshatch

of the dipstick.

ASV, INC. PAGE 32

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

HYDRAULIC OIL & FILTER CHANGE

One of the most critical systems on the POSI-

A

TRACK is the hydrostatic drive. The hydraulic

oil should be changed every 500 hours and the

hydraulic filters should be changed every 250

hours. These precision components require ex-

tremely clean oil in order to have a long service Fig. 44

life. Changing the hydraulic oil and filters at the

proper intervals can prevent expensive repairs

later down the road.

Before beginning the procedure extreme care

should be taken to ensure the vehicle is in a clean

working environment. Precautions should be

taken to prevent any debris from entering the hy-

drostatic system.

1. Remove hydraulic oil drain plug (A) from bot-

tom of reservoir. Drain into suitable container. Fig. 45

2. The three hydraulic filters are housed on a

manifold under the engine hood. (Fig. 45)

3. The three inch and the five inch filters are both

disposable spin on type filters. These filters can

be removed by hand or by using a filter wrench.

Always dispose of filters properly.

4. The third filter is a canister type. The canister

has an interior filter element which must be re-

placed. DO NOT REPLACE THE CANISTER

ITSELF.

ASV, INC. PAGE 33

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

BLEEDING THE FUEL SYSTEM

If the engine has run out of fuel, or the fuel sys-

tem has been opened for service, it will be nec-

essary to bleed the fuel system.

1. Loosen the air bleed vent screw two full

turns. (A) (2810, Fig. 46) (2800, Fig. 47)

A

2. Unscrew primer on the 2800 until the primer

pops up. It is not necessary to unscrew the

primer on the 2810. Pump the primer until fuel

flowing out the vent is free of air bubbles. (B)

(2810, Fig. 46) (2800, Fig. 48)

3. Tighten bleed screw securely, screw the

primer on the 2800 back in until it is secure.

Fig. 47

4. Start engine and check for leaks.

Fig. 46 A Fig. 48

ASV, INC. PAGE 34

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

TRACK TENSION

The tracks should be adjusted so there is no sag

between the drive sprocket and the top carrier

wheels. DO NOT OVER TIGHTEN. Only

tighten the amount it takes to eliminate the sag.

Over tightening the tracks can lead to power

loss, bearing failure, and track damage.

Fig. 49

Located in the side filter box is a screw jack and

a wrench that will allow the tracks to be tight-

ened in the field.

1. Insert the screw jack between the undercar-

riage frame and the sliding mount, which houses

the drive sprocket. (Fig. 49)

2. Loosen (DO NOT REMOVE) the bolts in the

slots which allow the sprocket mount to slide. Fig. 50

(Fig. 50)

3. Rotate the screw jack with the wrench to take

some pressure off the tension adjustment bolts.

4. Remove the tension adjustment bolts (one on

each side). (Fig. 51)

5. Rotate the screw jack with the wrench until

the track has zero sag between the drive sprocket Fig. 51

and the top carrier wheels. (Fig. 52)

6. Line up the next available holes in the sliding

mount with a hole in the undercarriage frame

and reinsert the tension adjustment bolts and

tighten. (both sides). Tighten bolts in slots.

Tension adjustment bolts must be placed in

the same adjustment hole, or the sprocket will

be out of alignment causing track derailment.

Fig. 52

ASV, INC. PAGE 35

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

PLANETARY OIL CHANGE

After the initial 50-hour break-in change, the

planetary oil should be changed every 1,000

hours or annually, which ever comes first.

Before starting the procedure, the planetary case

must be cleaned thoroughly. It is crucial that no

dirt falls into the case when removing the plugs. Fig. 53

In the filter service compartment of the POSI-

TRACK, there is a kit which will make chang-

ing the planetary oil easier. This kit includes a

fitting and a hose.

There are two plugs, which are 180° from each

other. One is for draining the oil, the other is for

filling the oil. It doesn’t matter which plug is

used for which part of the job. Fig. 54

NOTE

Drive the POSI-TRACK for 10 to 15 minutes

Before changing the planetary oil. This will

warm up the oil and allow it to drain more thor-

oughly.

1. Rotate the sprocket until one of the plugs is

lined up with the u-shaped notch at the top of

the bearing plate. This will also line up the

other plug with the hole in the bottom of the

bearing plate. (Fig. 53)

2. Attach the hose to the fitting and be prepared

to insert the fitting into the drain hole. Remove

the drain plug through the bottom hole and

quickly insert the fitting with the hose. (Fig. 54)

ASV, INC. PAGE 36

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

3. Remove the top plug to vent the case and al-

low the oil to drain. (Fig. 55)

4. Remove the fitting with the hose from the

bottom plug and reinsert the plug.

5. Insert the fitting and hose into the top hole.

Use a 32 oz. Bottle of 80W-90 gear lube or simi-

lar container, which can be filled with gear lube.

Attach the other end of the hose to the bottle.

Squeezing the bottle slightly will help push the Fig. 55

oil into the case. (Fig. 56)

Fig. 56

ASV, INC. PAGE 37

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

RADIATOR AND OIL COOLER

The 2800 and 2810 use a "pusher" fan which

pull air in through the sides of the engine hood

and pushes it through the coolers and the lou-

vered grill (Fig. 57). This system allows the air

to be "filtered" through the hood's screening be-

fore it reaches the coolers. This also keeps hot

air and dust off the operator. Depending on the

conditions the coolers will most likely need to Fig. 57

be cleaned at some point. Since any debris will

collect on the engine side of the coolers the de-

bris must be cleaned by forcing the debris off

from the other side of the coolers. Air or water

under pressure works best for thorough clean-

ing. A

1. Open the hood by undoing the 2 rubber

!WARNING!

Always shut the vehicle off before cleaning the

radiator and oil cooler.

Fig. 58

bungie cords, which secure the hood to the

frame.

2. Undo the two clasps (A) that holds the lou-

vered grill shut. (Fig. 58)

3. Swing the grill away from the engine.

(Fig. 59)

4. The coolers are now totally accessible for Fig. 59

cleaning.

ASV, INC. PAGE 38

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

CHANGING THE AIR FILTER

The air cleaner is one of the most important

maintenance items on the vehicle. A poorly

maintained air cleaner can seriously shorten the

life of the engine. A

1. After the hood is opened, loosen the clamp

(A) on the end of the air cleaner until the cover Fig. 60

can be removed. (Fig. 60)

2. Loosen the wing nut (B), holding the filter in B

and remove the element. (Fig. 61 & 62)

NOTE

When working in dusty conditions the air

cleaner should be checked frequently.

Fig. 61

BATTERY

The Battery is located behind a removable fiber-

glass fire wall between the engine and the op-

erators compartment. (Fig. 63) The battery re-

quires minimal maintenance to operate at its

peak performance. Fig. 62

1. Ensure the cables and posts are free from

corrosion at all times.

2. Make sure the cables are tight on the posts

and that the battery is secured properly.

3. Always maintain the battery at full charge.

Fig. 63

ASV, INC. PAGE 39

POSI-TRACK 2800 & 2810

GENERAL MAINTENANCE

CHANGING THE FUEL FILTER

The fuel filter should be changed every 500

hours or as needed. Both the 2800 (A) and the

2810 (B) have spin on fuel filters, however they A

do not have the same filter.

1. Clean filter area thoroughly before removing Fig. 64

the filter. B

2.. Using a filter wrench remove the filter B

slowly and catch any spilled fuel with a rag.

3. Install new filter element onto base, and

A

bleed the fuel system.

NOTE Fig. 65

A plugged or partially plugged fuel filter

can cause loss of engine power, erratic

engine rpm, and poor starting.

FILTER PRE-SCREEN (2800 only)

Another main cause of poor engine perform-

C

ance is a plugged pre-screen. This small item is Fig. 66

often overlooked and is often the culprit.

1. Remove the banjo nut underneath the fuel D

primer with 17mm wrench (C). There are two

rubber washers on the banjo nut, one on top and

one below the banjo nut. Be extra careful not to

lose these rubber washers, the engine will not

run without them.

2. Remove the white plastic screen (D) and Fig. 67

clean thoroughly. Reinstall making sure both

rubber washers are in place.

ASV, INC. PAGE 40

SECTION

POSI-TRACK 2800 & 2810

5

SERVICE

TRACK REMOVAL

In some cases removing the track is necessary to

work on some undercarriage components.

Using a floor jack or a forklift, jack the POSI-

TRACK off the ground (Fig. 68) until there is

approximately 4 inches between the bottom of

the track and the floor. Jack stands specially de-

signed for the POSI-TRACK can be purchased

Fig. 68

through your POSI-TRACK dealer (PN # 454-

876)

For occasional track tensioning, the screw jack

that comes with the machine is fine, however, a

remote hydraulic jack is best for track removal A

and installation. A remote hydraulic jack with

all the necessary extensions can be purchased

from your POSI-TRACK dealer ( PN # 455-

3445)

1. On the inside and the outside of the under- Fig. 69

carriage, there are two long slots. Loosen the

bolts (A) that are in these slots (DO NOT RE-

MOVE). (Fig. 69)

2. Place the jack between the sliding planetary

mount and the undercarriage frame (Fig. 70).

Jack the planetary mount back just enough so

the track adjustment bolts can be removed. Af-

ter the bolts have been removed, release the jack

and remove it from the undercarriage.

3. On the inside of the undercarriage there is a Fig. 70

steel tab (B) welded to the sliding planetary

mount. This tab will allow the planetary mount

to be jacked forward. (Fig. 71)

ASV, INC. PAGE 41

POSI-TRACK 2800 & 2810

SERVICE

4. Insert the jack between the rear axle mount

and the steel tab (Fig. 71). Jack the planetary

mount forward until the jack is full stroke. Re-

move the jack and add an extension to the ram B

of the jack. Continue jacking the planetary

mount forward until it comes in contact with the

undercarriage frame.

5. There are 4 bolts, which mount the carrier Fig. 71

wheels to the undercarriage frame. The 2 bolts

closest to the drive sprocket (C) need to be loos-

ened enough so the assembly can hinge on

them. (DO NOT REMOVE ).

6. Remove the other 2 bolts and hinge the as-

sembly back until it hits the undercarriage

frame. (Fig. 72)

Fig. 72 C

7. Position yourself behind the drive sprocket

and grab the bottom inside portion of the track.

Pull the track down, getting the drive lugs to

clear the 10" idler wheels and then pull the track

to the outside. Do not attempt to get the whole

track off yet, just get one row of drive lugs past

the outside 10" idler wheel.

8. Pull the track up and off the drive sprocket.

The track can now be pulled off the 10" idler Fig. 73

wheels. Continue pulling the track off the top

of the undercarriage and slide it out from be-

neath the undercarriage. Pull the track forward

and out to remove the track from the 14" idler

wheels. The track is now off. (Fig. 74)

Fig. 74

ASV, INC. PAGE 42

POSI-TRACK 2800 & 2810

SERVICE

TRACK INSTALLATION

1. Place the track parallel to the undercarriage

so the end of the track is even with the end of

the undercarriage.

2. Pull the track up and onto the 14" idler

wheels. Slide as much track as possible under Fig. 75

the undercarriage. Pull the track up and on to

the hinged carrier wheels. (Fig. 75)

3. Pull the track up and onto the drive sprocket.

Get one row of drive lugs into the drive

sprocket. Move one row of drive lugs past the

10" idler wheels. (Fig. 76)

4. Pull the rest of the track up and onto the

drive sprocket, and then under the 10" idler Fig. 76

wheels.

5. Hinge the carrier wheels back in place, and

retighten all bolts. The track is now on. It only

needs to be tightened.

6. To tighten the track, the jack can either be

placed on the inside of the undercarriage be-

tween the two steel tabs or on the outside be-

tween the carrier wheel assembly and the sliding Fig. 77

planetary mount (Shown). If the planetary

mount starts to bind, place the jack on the other

side. (Fig. 77)

7. Once the planetary mount is back far enough,

place the jack between the sliding planetary

mount and the rear axle mount. (Fig. 78)

Fig. 78

ASV, INC. PAGE 43

POSI-TRACK 2800 & 2810

SERVICE

8. Jack the planetary mount back until the track

is straight (Fig. 79) between the drive sprocket

and the carrier wheels. (DO NOT OVER

TIGHTEN).

9. Line up the set of holes in the sliding motor

mount and the undercarriage frame. Insert track

adjustment bolts and tighten. (bolts should be in

same hole location.) (Fig. 80)

Fig. 79

10. Tighten bolts in slots on both sides of the

undercarriage.

CAUTION

It is critical that the drive sprocket is aligned

with the undercarriage frame. The tension ad-

justment bolts must be in the same hole location

or track derailment will occur.

Fig. 80

ASV, INC. PAGE 44

POSI-TRACK 2800 & 2810

SERVICE

BOGIE CARRIAGE REMOVAL

1. Once the track is removed, slide a floor jack

under the bogie carriage that is being removed

and raise until there is some pressure on the bo-

gie carriage. (Fig. 81)

2. Remove the 4 bolts that secure the bogie car-

riage to the undercarriage frame. Fig. 81

3. Lower the floor jack and slide the jack out A

from the bogie carriage.

4. Using the floor jack, raise the suspension

frame (A) just enough so the bogie carriage can

be slid out from under the suspension frame.

(Fig. 82)

Fig. 82

WHEEL TUBE REMOVAL

1. Place the bogie carriage on the floor so all

wheels are facing up. (Fig. 83)

B

2. Remove the 4 bolts (B), which secure the

wheel tube to the bogie carriage.

3. Lift wheel tube straight up out of the slots in

the bogie carriage. Fig. 83

4. Once the wheel tube is removed, the two

brackets that secure the tube to the carriage will

be visible. These two brackets keep the shaft

from turning and allow the tube and the wheels

to rotate.

ASV, INC. PAGE 45

POSI-TRACK 2800 & 2810

SERVICE

WHEEL REPLACEMENT

A

1. The center wheel is split (A) for easy removal

and the two outside wheels are whole wheels.

2. Remove wheels by unbolting the wheel hub

that secures the wheels to the tube. The outside

wheel hubs are slid off the shaft and the wheel Fig. 84

can then be removed easily.

END TUBE REMOVAL

The end wheel tubes are extremely easy to re-

move. There are 4 bolts that fasten the shaft to

the undercarriage frame. Remove 4 bolts and the

tube will slide off the end of the frame. (Fig. 85)

Fig. 85

ASV, INC. PAGE 46

POSI-TRACK 2800 & 2810

SERVICE

SPROCKET REMOVAL

There are 3 bolts that fasten the planetary bear-

ing plate to the undercarriage frame, and 4 bolts

that fasten it to the bearing flange. The track

needs to be removed before beginning this pro-

cedure.

1. Remove the 4 bolts that fasten the bearing Fig. 86

plate to the flange. (Fig. 86)

2. Remove the 3 bolts that fasten the bearing

plate to the undercarriage frame. (Fig. 87)

3. Tapping the bearing plate with a rubber ham-

mer will help dislodge it from the flange. Pull

the bearing plate straight out. (Fig. 88)

Fig. 87

4. Remove the 9 lug nuts that fasten the drive

sprocket to the planetary gearbox. Pull the

sprocket straight out from the planetary gearbox.

(Fig. 89)

Fig. 88

Fig. 89

ASV, INC. PAGE 47

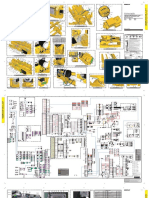

POSI-TRACK 2800 & 2810

APPENDIX 1

HIGH & LOW FLOW AUXILIARY

HYDRAULIC CIRCUIT

ASV, INC. PAGE 48

SECTION

POSI-TRACK 2800 & 2810

6

TROUBLE SHOOTING (GENERAL)

PROBLEM CAUSE REMEDY

Vehicle won’t 1. Battery cables loose 1. Tighten or clean cables

turn over or corroded.

2. Drive levers 2. Put levers in neutral

are not in neutral

Vehicle turns over 1. Out of fuel or 1. Add more fuel

but will not start fuel pick-up may not and bleed fuel system

be in fuel if parked on a hill

2. Pinched fuel line 2. Find and correct

3. Load on engine from 3. Put lever in neutral

High or Low flow auxiliary lever

being engaged

4. Fuel solenoid is not opening 4. Refer to electrical

trouble shooting guide

5. Plugged fuel filter 5. Change filter

6. Cold weather – need 6. Refer to

starting aid. Engine manual

Vehicle starts but 1. Low-flow auxiliary 1. Put lever in neutral

engine runs rough hydraulic lever is engaged

2. High-flow auxiliary 2. Put lever in neutral

hydraulic lever is engaged

Vehicle starts but 1. Operator not seated in seat 1. Sit down & fasten

tracks won’t go seat belt.

2. Defective seat switch 2. Refer to electrical

trouble shooting guide

3. Defective solenoid 3. Refer to electrical

trouble shooting guide

4. Low charge pressure 4. Contact dealer

Under heavy load 1. Tracks have broken traction 1. Reduce load or put more

or in loose material power to the inside track

vehicle won’t turn 2. Oil going to drive motor 2. Reduce load. Increase

is going over the relief valve power to inside track

ASV, INC. PAGE 49

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (GENERAL)

PROBLEM CAUSE REMEDY

Attachment won’t 1. Quick-coupler not plugged 1. Find and plug in

operate in all the way quick coupler

2. Faulty quick-coupler 2. Replace

3. The other auxiliary lever 3. Put lever in neutral

is engaged

4. Hoses hooked up wrong 4. Refer to hydraulic flow

diagram on page 48

5. Faulty attachment 5. Contact dealer or refer to

an attachment owners

manual

Hot oil light comes on 1. Hydraulic oil cooler is 1. Clean with compressed

plugged with debris air or pressure washer

2. Hydraulic attachment is 2. Get the right sized

undersized for the flow attachment or reduce the

and/ or pressure engine rpm until the flow

is in the correct range

(Refer to decal on vehicle)

3. One of the auxiliary hydraulic 3. Put lever in neutral

levers is engaged without an

attachment being hooked up.

4. Defective sender or light 4. Replace as needed

5. Wires to light are grounding out 5. Repair

Attachment doesn’t 1. Attachment is incorrect size 1. Get the appropriate

work properly for the flow and pressure. attachment

2. Auxiliary hydraulic pressure 2. Contact dealer

is set too low.

Loader doesn’t 1. Auxiliary hydraulic pressure 1. Contact dealer

lift proper weight is set too low

2. Weight is too far out from 2. Bring load in closer

vehicle or reduce load

3. Auxiliary lever is engaged 3. Put lever in neutral

ASV, INC. PAGE 50

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (GENERAL)

PROBLEM CAUSE REMEDY

Attachments, tracks 1. One or both auxiliary hydraulic 1. Put lever in neutral

weak on power levers are engaged

2. Hydraulic oil is still cold 2. Let oil warm up for a

few minutes

Tracks respond 1. Hydraulic oil is still cold 1. Let oil warm up for

sluggishly a few minutes

2. Low charge pressure 2. Contact Dealer

3. Low hydraulic oil 3. Add hydraulic oil

4. Hydraulic filters plugged 4. Change filters

One track won’t go 1. Brake is engaged 1. Rotate track in both

directions to take bind

off brake ram

2. Cable is disconnected on 2. Reconnect cable

lever

3. Cable is disconnected on 3. Contact dealer

pump

Track will only 1. Loosen or disconnected drive

go in one direction tube or fitting 1. Contact dealer

2. Broken drive tube inside 2. Contact dealer

hydraulic reservoir

3. Cable linkage in tank 3. Contact dealer

is broken

Track derails 1. Track is too loose 1. Tighten to proper

adjustment.

2. Bearing failure in one of 2. Replace bearing

the end tubes or out board

bearing on drive sprocket

3. Drive Sprocket miss aligned 3. Make sure tension

undercarriage frame. Adjustment bolts are in

the same adjustment holes

4. Bent idler wheel 4. Replace wheel

5. Terrain too steep or improper

driving techniques

ASV, INC. PAGE 51

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (GENERAL)

PROBLEM CAUSE REMEDY

Engine coolant 1. Radiator is plugged with 1. Clean with compressed

overheats debris air or pressure washer

2. Low engine coolant 2. Add approved coolant

3. Fan belt is slipping 3. Check tension pulley

4. Fan is on backward 4. Replace correctly

5. Faulty sender, gauge or 5. Replace

wiring

After running out of 1. Fuel system has not been bled 1. Refer to page 34

fuel and refueling,

engine will not start

ASV, INC. PAGE 52

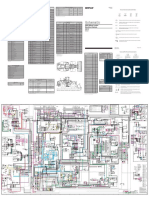

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (ELECTRICAL)

ASV, INC. PAGE 53

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (ELECTRICAL)

ASV, INC. PAGE 54

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (ELECTRICAL)

ASV, INC. PAGE 55

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (ELECTRICAL)

ASV, INC. PAGE 56

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (ELECTRICAL)

ASV, INC. PAGE 57

POSI-TRACK 2800 & 2810

TROUBLE SHOOTING (ELECTRICAL)

ASV, INC. PAGE 58

POSI-TRACK 2800 & 2810

MAINTENANCE & SERVICE

DATE DATE DATE DATE DATE

ITEM

HOURS HOURS HOURS HOURS HOURS

ASV, INC. PAGE 59

POSI-TRACK 2800 & 2810

MAINTENANCE & SERVICE

DATE DATE DATE DATE DATE

ITEM

HOURS HOURS HOURS HOURS HOURS

ASV, INC. PAGE 60

POSI-TRACK 2800 & 2810

NOTES

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

ASV, INC. PAGE 61

POSI-TRACK 2800 & 2810

NOTES

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

ASV, INC. PAGE 62

POSI-TRACK 2800 & 2810

NOTES

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________