Академический Документы

Профессиональный Документы

Культура Документы

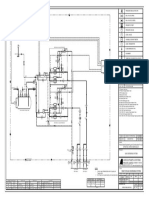

Steam Tracer Header and Branch Connection Details

Загружено:

Sathiyaseelan Sakthi ShanmugamИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Steam Tracer Header and Branch Connection Details

Загружено:

Sathiyaseelan Sakthi ShanmugamАвторское право:

Доступные форматы

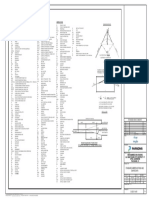

PA

SS NOTES

BY N

ON D O STEEL BANDS OR 1.5 SOFT GALV. WIRE LOOPS

C ER ATE STEAM SUPPLY ON 1000 CENTER. TO BE DETERMINED AT SITE 1- ALL THICKNESS VALUES AND DIMENSIONSARE IN mm.

A

TR INDICAM

NO SS GR

FASTENING WIRE CLOSE

TO BONNET AND BODY LE DIA 2- STEAM TRACING DETAILS ON THIS DWG. TO BE USED IN

POSITION OPTIONAL UN OW SEE DETAIL "E1" CONJUNCTION WITH IPS-E-PR-420.

FL STEAM HEADER

GUIDE CLIPS SEE USE TUBING FOR BOTH TRACER

AND COND. RETURN INSULATE NT 3- LOW POINTS IN THE TRACER LINES SHALL HAVE VALVE

DETAIL "K"

WITH PROCESS LINE ME

UIP DRAINS IF THE TRACER IS USED INTERMITTENTLY.

UNION OR EQ

FLANGE

TRACER 4- STEAM TRACING OF INSTRUMENTS TO BE AS SHOWN ON

CONDENSATE HEADER

THE FOLLOWING:

UNION OR

a) FLOW INSTRUMENTS DWG. IPS-D-IN-1007

FLANGE

b) LEVEL INSTRUMENTS DWG. IPS-D-IN-1007

TO TRACER

C) PRESSURE INSTRUMENT DWG. IPS-D-IN-1007

STEAM HEADER

INSULATION FROM TRACER

JUMPER, DO NOT INSULATE

GUIDE CLIPS SEE

CONDENSATE HEADER 5- ATTACH METAL TAG TO IDENTIFY VALVE AND TRAPS.

JUMPER, DONOT INSULATE EXCEPT EXCEPT WHERE REQUIRED T

DETAIL "K" WHERE REQ'D. FOR SAFETY FOR SAFETY PROCESS LINE

6- FOR STEAM TRAP DETAIL SEE DWG. IPS-D-PI-125.

NOTE: USE DETAIL. "A" IF FLOW UNION OR SEE NOTE T

DIAGRAM CALLS FOR VALVES FLANGE 5 & 6

TO BE TRACED. POSITION 7- FOR PIPE TRACERS FOLLOW IPS-E-PR-420.

TRACER CONNECTOR

OPTIONAL SEE NOTE 5 & 6

SHOW CONNECTOR OUTSIDE INSUL.

8- SIZE AND NUMBER OF TRACERS BASED ON STEAM CONDITION

SHALL BE SPECIFIED BY PROCESS.

DETAIL "A" DETAIL "B" DETAIL "C" DETAIL "E1" DETAIL "E" DETAIL "F" 9- USE UNION IN LOW PRESSURE STEAM CONNECTIONS AND

VALVE AND BONNET TRACER TO BE USED FLANGE JUMPER TRACING FOR TYPICAL CONTROL VALVE HOOKUP

ONLY WHEN SPECIFICALLY REQUIRED AND WHERE VALVES ARE NOT STEAM TRACED

FLANGED CONNECTION FOR MEDIUM AND HIGH PRESSURE

CALLED FOR ON THE FLOW DIAGRAM STEAM.

STEAM TRACING @ FLANGES & VALVES STEAM TRACING IN COMMON INSULATOR

10- SPACER BLOCK SHALL BE USED TO PREVENT GENERAL

OR LOCALIZED OVERHEATING FOR SPECIAL SERVICES OR

MTERIAL.(e.g.LOW BUBLE POINT, PLASTIC LINED PIPE

RESPECTIVELY).

PIPE WITH TOW TRACER

11- SPACER BLOCK MATERIAL IS CALCIUM SILICATE WITH 15

CLEARANCE +

_ 2 22.5

° MINIMUM THICKNESS.

30

UNION OR 12- UNION OR FLANGE SHALL BE USED WHEN FREQUENT

GUIDE HEIGHT FLANGE BREAKING OF LINE FOR MAINTENANCE IS REQUIRED.

1.5x50 LG. CHANNEL SEE CHART "1"

TRIM AS REQUIRED THIS PORTION OF TRACER TO BE

STEEL BANDS OR 1.5 SOFT GALV. REMOVABLE SO THAT PUMP MAY BE

WIRE ON 1000 CENTERS. STEEL BANDS EASILY DISMANTLED

TO BE USED WHERE PIPE CHANGES

DIRECTION ONLY

GUIDE CHANNEL DETAIL

1.5 CHANNEL GUIDE

SEE CHART "1" & DETAIL

UNION OR

0

12

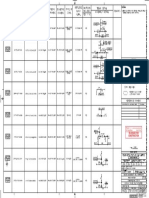

CHART 1

FLANGE

GUIDE HEIGHT FOR TRACER

PIPE SIZE

SIZE OF:

IF MORE THAN TOW TRACER IS UNION OR

NPS DN NPS DN NPS DN

REQUIRED LOCATE TRACER NPS DN FLANGE

EQUALLY SPACED. 1/2" 15 3/4" 20 1" 25 INSULATION T

UP TO 2"UP TO 50 19(TUBE) - -

2"~4" 50~100 27 - - 13x1 304 STAINLESS

6"~12" 150~300 27 33 - STEEL BAND

(THK. , LENGTH & WIDTH AT FIELD) T

INSULATING SPACER BLOCK SHALL BE 14"& OVER 350& OVER - 33 39

INSTALLED FOR EACH TRACER FASTENING

POINT.

DETAIL "K" UNION OR

DETAIL "Q"

TYPICAL TRACING GUIDE FLANGE

SEE NOTES 10 & 11

SEE NOTE 5 & 6 TYPICAL VENT & DRAIN TRACERS

SLOT BLOCK TO

DETAIL "G"

RECEIVE TIE WIRE

13x1 304 STAINLESS TYPICAL PUMP STEAM TRACING END SUCTION PUMP

STEEL BAND 3 BANDS ON 50 SHOWN. TRACING IS SIMILAR FOR OTHER TYPES OF PUMPS

DETAIL "I" CENTERS FOR

ANCHOR

TYPICAL TRACER CROSS SECTION

NOTE: CUT AWAY INSULATION FOR LINES WITHOUT

DETAIL "J"

EQUIPMENT STEAM TRACING DETAILS

SHOES: SEE DRAWING IPS-D-PI-133

TYPICAL TRACER ANCHOR

STEAM TRACING ALONG PIPE

MAIN HEADER BRANCH THIS VALVE NOT REQ'D

MAIN HEADER BRANCH IF BRANCH ORIGINATES

OR TRACER HEADER BRANCH

THIS VALVE NOT REQ'D IF BRANCH AT TRACER HEADER

ORIGINATES AT TRACER HEADER M

EA

ST TRACER HEADER BRANCH MAIN STEAM HEADER

IN R TUBING TRACER SAME SIZE AS TRACER

MAIN STEAM HEADER MA ADE FOR WINTERIZING

OR TRACER HEADER

OR TRACER HEADER HE

FROM TRAPS

TRACER HEADER BRANCH

ED INSULATE TO GETHER IF

AC

ER

ER

AC LE

TR SIB

INSULATION

POSSIBLE SEE DET. "E" THIS DWG. SUPERSEDES DWG. No. D-O-5001

TR D AR S

EA NE PO

H D IF

OL ES LOCATE CONNECTOR HERE SEE PIPING DWG. AND

NIF LIN

SEE PIPING DWG. AND MAIN HEADER BRANCH OR MA OR IF CLOSE COUPLED. SPOOL FOR LOCATION

E

SPOOLS FOR LOCATION OF TRACER HEADER BRANCH C AT ENT OF BRANCH CONN.

LO IPM TRACER 3

BRANCH CONNS. U M CO

EQ CONNECTOR TR AIN ND 2

UNION OR AC S .

ER TEA HE 1

BRANCH CONN. SEE FLANGE HE M O AD

LOCATE MANIFOLD NEAR TRACED TRACING STEAM WHICH MUST BE LEFT ON ER REV. DESCRIPTION DATE

DETAIL "N" CONTINUOUSLY (FOR HEAT CONSERVATION) AD R

EQUIPMENT OR LINES IF POSSIBLE ER

SHALL NOT TIE-INTO TRACER HEADER FOR

IRANIAN PETROLEUM STANDARDS

WINTERIZING BUT SHOULD TIE-INTO MAIN

STEAM HEADER

NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION

DETAIL "L" DETAIL "M" DETAIL "N" DETAIL "O" DETAIL "R"

HEADER CONN. FOR 2 OR MORE TRACERS TO BE USED WHEN SEPARATE TYPICAL BRANCH CONN. BRANCH TO 2 TRACERS VERTICAL HEADER CONNS. STEAM TRACING DETAILS

PIPING 4"(DN 100) & SMALLER

TRACER HEADER IS NECESSARY TO 1 TRACER FOR 2 OR MORE TRACERS.

SEE NOTE 5 & 8

SEE NOTE 8

STEAM TRACING HEADER AND BRANCH CONNECTION DETAILS DATE DRAWING No. SHEET REV.

IPS-D-PI-126

1

1

Вам также может понравиться

- Steam Separator and Steam Trap Are Almost Same in FunctionДокумент7 страницSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERОценок пока нет

- List of Valve StandardsДокумент8 страницList of Valve StandardsMuthu BalamuruganОценок пока нет

- Liquid Monopropellant CombustionДокумент4 страницыLiquid Monopropellant Combustionherdi sutanto adigunaОценок пока нет

- IR HL Heatless DryerДокумент1 страницаIR HL Heatless DryerYing Kei ChanОценок пока нет

- Previews-2024301 Pre PDFДокумент5 страницPreviews-2024301 Pre PDFKalai ArasiОценок пока нет

- API 6D Errata 10 UpdateДокумент1 страницаAPI 6D Errata 10 UpdateANANDОценок пока нет

- 608 - VLB Steam Conditioning ValveДокумент4 страницы608 - VLB Steam Conditioning Valvebk1202 skОценок пока нет

- Vent Tip Info Sheet SДокумент1 страницаVent Tip Info Sheet SabsahkahОценок пока нет

- Assembly Instructions For Taper JointsДокумент12 страницAssembly Instructions For Taper JointsmohdОценок пока нет

- PP Lined Pipe PDFДокумент27 страницPP Lined Pipe PDFNILADRI BHATTACHARYYAОценок пока нет

- Gasket Paking ListДокумент1 страницаGasket Paking ListIrwansyah MuchtarОценок пока нет

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityДокумент7 страницMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHIОценок пока нет

- Boiler Performance & Technical Data JT-K13467-E01-0Документ15 страницBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Varicon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemДокумент1 страницаVaricon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDeva NaiduОценок пока нет

- SBC (Safety Break-Away Couplings) v140630Документ16 страницSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Easyheat s27 - 02 SarcoДокумент8 страницEasyheat s27 - 02 SarcoMarcelo ResckОценок пока нет

- Integrity Testing of Water Filtration Membrane Systems: Standard Practice ForДокумент14 страницIntegrity Testing of Water Filtration Membrane Systems: Standard Practice ForOh No PotatoОценок пока нет

- Flame ArresterДокумент16 страницFlame Arresteriran1362Оценок пока нет

- Api 522 2022Документ22 страницыApi 522 2022Mittapelly praveenОценок пока нет

- HTTP - WWW Red-Bag Com Engineering-Guides HTMLДокумент4 страницыHTTP - WWW Red-Bag Com Engineering-Guides HTMLmashudi_fikriОценок пока нет

- Tantaline's Superior Corrosion Resistance in Sulfuric AcidДокумент4 страницыTantaline's Superior Corrosion Resistance in Sulfuric AcidManojkumar ThilagamОценок пока нет

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsДокумент3 страницыSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- A106-B Pipe Temperature CalculatorДокумент8 страницA106-B Pipe Temperature CalculatorAksheyОценок пока нет

- Process and utilities production area notesДокумент1 страницаProcess and utilities production area notesAndri SaputraОценок пока нет

- Pig ValvesДокумент3 страницыPig ValvesteacgОценок пока нет

- OISD Standard on Process Design and Operating Philosophy for Fired Process FurnacesДокумент25 страницOISD Standard on Process Design and Operating Philosophy for Fired Process FurnacesSanjay Patel0% (1)

- Pages From 05-01269 Regeneration API-617-datasheet-rev11 PDFДокумент1 страницаPages From 05-01269 Regeneration API-617-datasheet-rev11 PDFalikajbafОценок пока нет

- SEO-Optimized Title for API 685 Centrifugal Pump Data SheetДокумент5 страницSEO-Optimized Title for API 685 Centrifugal Pump Data SheetaltipatlarОценок пока нет

- API BB1 vs BB2: Radially split pumps better for H2S, high pressureДокумент1 страницаAPI BB1 vs BB2: Radially split pumps better for H2S, high pressurebomthanhphuОценок пока нет

- GoyalДокумент3 страницыGoyalVan LeОценок пока нет

- Design Guidelines FOR Hydrogen Piping and Pipelines: STP-PT-006Документ6 страницDesign Guidelines FOR Hydrogen Piping and Pipelines: STP-PT-006Andri Doemeri0% (1)

- Heat Exchangers Explained: KSI/... Series OverviewДокумент4 страницыHeat Exchangers Explained: KSI/... Series OverviewJohn F Diaz HОценок пока нет

- Product Handbook Complete Product Line 1st Edition PDFДокумент919 страницProduct Handbook Complete Product Line 1st Edition PDFHADIОценок пока нет

- 6206 Guide For Selection Installation andДокумент32 страницы6206 Guide For Selection Installation andakbavra80% (5)

- Thermowell Calculation Guide V1.3Документ19 страницThermowell Calculation Guide V1.3AymanelorbanyОценок пока нет

- Comparing ASME Code Fatigue Evaluation Methods for Nuclear PipingДокумент65 страницComparing ASME Code Fatigue Evaluation Methods for Nuclear PipingOtso Cronvall100% (1)

- DBB CatalogueДокумент28 страницDBB CatalogueHeri SetyantoОценок пока нет

- E-1 Deluge ValveДокумент10 страницE-1 Deluge ValveTracy SankarОценок пока нет

- PE-O-ME-TRE-001-00 Technical Specification For Piping According To EN 13480 PDFДокумент53 страницыPE-O-ME-TRE-001-00 Technical Specification For Piping According To EN 13480 PDFmarin cristian100% (1)

- Controlling Flow Accelerated Corrosion PDFДокумент36 страницControlling Flow Accelerated Corrosion PDFzerocool86Оценок пока нет

- WRC, PV Elite, NozzlePro Sign ConventionsДокумент13 страницWRC, PV Elite, NozzlePro Sign ConventionsADHIRAJ KOLIОценок пока нет

- Data Sheet For Spray NozzleДокумент3 страницыData Sheet For Spray Nozzlebecpavan100% (1)

- As 3814-2009 Industrial and Commercial Gas-Fired AppliancesДокумент9 страницAs 3814-2009 Industrial and Commercial Gas-Fired AppliancesSAI Global - APACОценок пока нет

- Standard Connection Specification DimensionsДокумент1 страницаStandard Connection Specification DimensionsPedro Montes MarinОценок пока нет

- Seal CoolerДокумент2 страницыSeal CoolerJulio Adolfo López Portocarrero100% (1)

- Calculating Relief Valves Under The New ASHRAEДокумент2 страницыCalculating Relief Valves Under The New ASHRAEchandrashekharsОценок пока нет

- EGE15B5Документ56 страницEGE15B5Jhonny Rafael Blanco CauraОценок пока нет

- TCE Air and Flue Gas Ducts Data SheetДокумент1 страницаTCE Air and Flue Gas Ducts Data Sheetjkhan_724384Оценок пока нет

- Appendix E1 Ages SP 09 002Документ13 страницAppendix E1 Ages SP 09 002SandeepNBabuОценок пока нет

- FEA On ThermowellДокумент4 страницыFEA On Thermowellvaisakp777Оценок пока нет

- Double Wall Ammonia Storage Tank Design and Engineering DocumentsДокумент33 страницыDouble Wall Ammonia Storage Tank Design and Engineering DocumentsErol DAĞ100% (1)

- Burst PR Calculation PDFДокумент1 страницаBurst PR Calculation PDFAranga KeerthiОценок пока нет

- Pipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationДокумент4 страницыPipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationsaerinОценок пока нет

- Steam Tracing AppendixДокумент13 страницSteam Tracing AppendixAmin BagheriОценок пока нет

- Hydrogen Spacing RationaleДокумент35 страницHydrogen Spacing RationaleshailendraОценок пока нет

- 1100.004.01 B31.3 STOPPLE FitДокумент6 страниц1100.004.01 B31.3 STOPPLE FitRaymundo Maldonado AlvarezОценок пока нет

- E 106Документ1 страницаE 106Bith SMGОценок пока нет

- Ci Ge 07 14 001Документ1 страницаCi Ge 07 14 001naveenОценок пока нет

- TB135483 008 00F1Документ1 страницаTB135483 008 00F1Rene HebaОценок пока нет

- LT380 NetworkSetupGuide ItalianДокумент40 страницLT380 NetworkSetupGuide ItalianSebastian FisherОценок пока нет

- B.GAS QuestionsДокумент54 страницыB.GAS QuestionsSathiyaseelan Sakthi Shanmugam100% (1)

- Piping Material SpecificationДокумент29 страницPiping Material SpecificationSathiyaseelan Sakthi Shanmugam100% (2)

- ABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesДокумент69 страницABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesBhaiJan59100% (4)

- Forgotten SiddhaДокумент87 страницForgotten SiddhaShanmuga Sundaram100% (3)

- Piping Coordination SystemsДокумент38 страницPiping Coordination SystemsSathiyaseelan Sakthi ShanmugamОценок пока нет

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Документ2 страницыWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- API 571 Exam InfoДокумент1 страницаAPI 571 Exam InfoSathiyaseelan Sakthi ShanmugamОценок пока нет

- Advance NDTДокумент28 страницAdvance NDTAhmed Gomaa100% (1)

- Fabrication of Piping SystemsДокумент17 страницFabrication of Piping SystemsSathiyaseelan Sakthi ShanmugamОценок пока нет

- Corrosion Revision QuestionsДокумент32 страницыCorrosion Revision QuestionsSathiyaseelan Sakthi Shanmugam100% (1)

- Fundamental of Welding-1Документ163 страницыFundamental of Welding-1Sathiyaseelan Sakthi ShanmugamОценок пока нет

- Sections: I Rules For Construction of Power BoilersДокумент68 страницSections: I Rules For Construction of Power BoilersAnonymous VohpMtUSN100% (1)

- PipingДокумент7 страницPipingSyed Muhammad Shamuel SheesОценок пока нет

- Sidha SothanaiДокумент42 страницыSidha SothanaiSathiyaseelan Sakthi ShanmugamОценок пока нет

- Thamilar Valvil TamilДокумент39 страницThamilar Valvil TamilSathiyaseelan Sakthi ShanmugamОценок пока нет

- Software Testing FrameworkДокумент25 страницSoftware Testing FrameworkRam_p100% (2)

- Weld Defects TWIДокумент96 страницWeld Defects TWISabir Shabbir100% (7)

- RT ImageДокумент41 страницаRT ImageSathiyaseelan Sakthi ShanmugamОценок пока нет

- Comparison BOO BOT IndiaДокумент26 страницComparison BOO BOT IndiaDhanes PratitaОценок пока нет

- Official Secrets ActДокумент3 страницыOfficial Secrets ActPrashant RohitОценок пока нет

- Election Laws (Nachura, de Leon, Bernas, Valencia) (2022)Документ101 страницаElection Laws (Nachura, de Leon, Bernas, Valencia) (2022)Aimee VenterosoОценок пока нет

- Uniform Statutory Rule Against Perpetuities (1986)Документ79 страницUniform Statutory Rule Against Perpetuities (1986)Brandon MarkОценок пока нет

- International Tax Transfer Pricing MethodsДокумент17 страницInternational Tax Transfer Pricing MethodsAshish pariharОценок пока нет

- Jurnal Harga Vskepuasan Pelanggan Vs Loyalitas PelangganДокумент13 страницJurnal Harga Vskepuasan Pelanggan Vs Loyalitas PelangganSyahrin AsmanОценок пока нет

- Standard Treatment GuidelinesДокумент5 страницStandard Treatment Guidelinesbournvilleeater100% (1)

- En PLC InterfaceДокумент2 страницыEn PLC InterfaceBsd FareedОценок пока нет

- Get That JobДокумент12 страницGet That JobNguyen PhamОценок пока нет

- Class Notes LUCT-updatedДокумент56 страницClass Notes LUCT-updatedYousef AzhariОценок пока нет

- Profile of FAOAДокумент5 страницProfile of FAOAqubrex1Оценок пока нет

- Scope and Nature of HotelДокумент2 страницыScope and Nature of HotelJan Hidalgo LaroyaОценок пока нет

- Risk Management Under Covid 19 CPA KimeuДокумент32 страницыRisk Management Under Covid 19 CPA KimeuREJAY89Оценок пока нет

- PLSQL - 5 - 6 - Brayan Ferney Perez Moreno PDFДокумент5 страницPLSQL - 5 - 6 - Brayan Ferney Perez Moreno PDFBryan PerezОценок пока нет

- Rig 2017Документ34 страницыRig 2017ralphОценок пока нет

- STM Turbine Overspeed Failure Investigation-1Документ11 страницSTM Turbine Overspeed Failure Investigation-1Abdulrahman AlkhowaiterОценок пока нет

- Behringer Europower-P0569 Hca2400 Sps1000 DPX Pmp-1280s 5000 SCHДокумент15 страницBehringer Europower-P0569 Hca2400 Sps1000 DPX Pmp-1280s 5000 SCHNorel Andrei100% (2)

- COMLAWREV Catindig 2009 ReviewerДокумент196 страницCOMLAWREV Catindig 2009 ReviewerShara LynОценок пока нет

- DFSK Glory 580 Pro User Manual (Indonesia)Документ210 страницDFSK Glory 580 Pro User Manual (Indonesia)Jake Sullivan100% (3)

- Operand Storage in The CPUДокумент3 страницыOperand Storage in The CPUisaac setabiОценок пока нет

- Verification of Hook Element in Midas GenДокумент3 страницыVerification of Hook Element in Midas GenSASHIN ServiSoftОценок пока нет

- NetSDK Programming Manual (Camera)Документ93 страницыNetSDK Programming Manual (Camera)Bat-Erdene NasanbatОценок пока нет

- Romualdez-Marcos v. ComelecДокумент2 страницыRomualdez-Marcos v. ComelecSecret Student100% (1)

- Session 3 - Leadership Documents PDFДокумент17 страницSession 3 - Leadership Documents PDFAde TenyomОценок пока нет

- Tools and Techniques of Cost ReductionДокумент27 страницTools and Techniques of Cost Reductionপ্রিয়াঙ্কুর ধর100% (2)

- Catalogo Medesy 2011Документ133 страницыCatalogo Medesy 2011DentaDentОценок пока нет

- FINANCIAL RATIOS AND CALCULATIONSДокумент13 страницFINANCIAL RATIOS AND CALCULATIONS1 KohОценок пока нет

- Scrum Developer AssessmentДокумент11 страницScrum Developer Assessmentmohannad44% (9)

- CF - UM21MB641B Unit 1 Class 6-Stockholders, Bondholders and ManagersДокумент11 страницCF - UM21MB641B Unit 1 Class 6-Stockholders, Bondholders and ManagersPrajwalОценок пока нет

- Bell Type Packoff: B & T Oilfield Products Wireline Product CatalogДокумент5 страницBell Type Packoff: B & T Oilfield Products Wireline Product CatalogaminoОценок пока нет