Академический Документы

Профессиональный Документы

Культура Документы

Consignment Inventory Process Flow (Rev 5)

Загружено:

rowentanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Consignment Inventory Process Flow (Rev 5)

Загружено:

rowentanАвторское право:

Доступные форматы

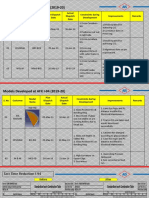

Consignment Details Steps

Consignment Inventory Process Responsibility Description

1. Operation Level need inform IT on the setup

Position Hierarchy:

a) MT Blanket Position Hierarchy

- Sourcing need to inform IT for the setup if have new user who need to create

the Blanket Purchase Agreement.

Subinventory

b) SM PR Hierarchy

Setup

- Buyer need to inform IT for the setup if have new user who need to create the

manual PR.

2. Setup for compulsary Consign Transaction and Operation Level need to

inform IT if have additional consign transaction needed

IT (refer next work sheet)

Setup the subinventory for eg : CONSIGNNEP ( refer next work sheet )

Organization item setup for Operation Level need to inform Finance on the setup to Pay on at Supplier Site.

Consign Finance ( refer next work sheet )

Admin Tick the Consign in Organization Item

ConsignmentSetup/Blanket PO Agreement Sourcing Create Blanket Purchase Agreement (PO type)

Tie up the Blanket Purchase Agreement (BPA) into the ASL

And tick the Consigned from supplier

Send Blanket PO agreement for Send the BPA for approval

SCM

Run MRP SCM Issue Consignment PO

a) Auto Create b) Create

manual PR for the consigment with quantity

Auto Create SCM Consignment PO Type must be set as standard PO

Consigned

PO with PO type =

Standard

Change Ship- to and PO Type to Consign, Consignment PO Ship To related Organization & must fill in the subinventory as

Set Subinventory SCM well. For eg : CONSIGNNEP

SCM Send Consignment PO for approval

Submit Consigned

PO for Approval

receeive of Consigned PO shipment

Perform Receiving Transaction & stick the orange sticker on the Consignment

a) Perform receiving. b)

Store part.

Label Must indicate Consign PO.

c) Stick the orange sticker with wording " CONSIGN "on the receiving part.

QA QA perform inspection per quality plan/quality inspection required.

Incoming QA perform quality

inspection

If inspection failed for Purchase Item Inspection -> QA need to perform reject in

QA system then deliver to Consign incoming MRB.

If inspection failed for non-inspection part -> QA only perform deliver to Consign

incoming MRB.

Inspection passed? Reject User Item Type = If passed QA need to perform accept in system (for Inspection part only)

Purchase Item

Inspection

No

Accept

Yes

System Transaction = Reject

User Item Type =

Purchase Item Inspection ?

Deliver to CONSINCMRB QA QA perform transaction to deliver to CONSINCMRB

Yes

NO

System Transaction = Accept SCM SCM to follow up disposition with supplier and collection

Consignee Disposition

For accepted part, perform delivery in system and move the stock to vendor

Store warehouse /consigned locator

For Rejected Part:

SCRAP SCM will request CN from vendor Or request DN from Finance.

QA need to transact from CONSINCMRB to CONSIGNMRB. Store

RTV need to perform Scrap if there is no replacement from vendor .

Store/SCM/QA

Request CN /DN from

Move to stock

Tag Material Ownership as For replacement or rework needed, QA need to perforn RTV to re-open the PO.

Supplier/Customer (Consignment If the rework perform by third party, buyer to follow up on rework return and

Deliver to CONSIGNMRB co-ordinate with IQA & store for MDR transaction.

System Re -Open PO

System & Physical SCRAP

transaction

NO

Require DJ ?

Yes

Order Fulfillment Release DJ in system for module order.

Release DJ for module

Production/

Manufacturing

Engineer Issue MIS for piece part order.

Piece Part order

- ME issue MIS.

System will auto generate

the move order.

Store perform

transaction to WIP Print out move order and transact materials issuance in system.

Print Out the move order and

Once the part is transacted out from consigned locator, the ownership turn to

issue materials to production.

Store SAM

Perform transaction after ME

verified.

IT have created daily auto schedule run for consumption advice to forward

Finance to specific AP personel.

Finance will send out the consumption report that generated

Auto Schedule

Change Ownership from suplier to Reference PO unit by system to Program (if consigned by customer) or to vendor directly.

Consumption

Organization price to Blanket PO a) Daily Schedule for running Consumption Advice

Advice

- Consignment Consumption Advice Schedule <Org Code> (Report Set)

- Example: Consignment Consumption Advice Schedule 037 (Report Set)

Reject at production

Production/

Manufacturing For part found rejecetd due to quality or form fit test at production,

Engineer Production/Manufacturing Engineer will raise the MDR.

With PRODMRB subinventory :-Production/Manufacturing Engineer will do the

ME/Production raise Send the Consumption Advice system transaction to move the stock from WIP to Production ConsignMRB for

the MDR to supplier the oracle sub-inventory from Production ConsignMRB )

Without PRODMRB subinventory :- Not required to do the system transaction

Production with " for disposition in oracle.

PRODMRB "

subinvemtory in oracle

UAI

Production/

Return to WIP Manufacturing

Engineer If UAI, Production/ME move it to WIP locator.

Disposition ?

AP match invoice with

UAI

Consumption Advice (issue CN

to Ter)

Reject

Reject

IQA

CONSIGNMRB

QA Will perform transaction from Production CONSIGNMRB to CONSIGNMRB

Pay

Vendor collect Request vendor If no replacement, SCM will request vendor CN/issue DN to vendor. Store will

CN/issue DN to vendor Invoice

Virtual C QA/SCM/STORE perform scrap.

If need for replacement, QA will transact to VIRTUALC

Once replacement part returned by vendor, QA will transact to CONSIGNMRB

as MRBC. The lot will be pending for IQA inspection.

Once the part Inspected and confirmed accept, Store will deliver to RM location.

Replacement Scrap internally

End

CONSIGNMRB (MRBC)

Move to

RM

Вам также может понравиться

- The Lean CFO PDFДокумент156 страницThe Lean CFO PDFPedroPimenta100% (2)

- Ici Supply Chain Management Report by Ali RazaДокумент38 страницIci Supply Chain Management Report by Ali RazaFaizan Sheikh100% (3)

- Corrective and Preventive Action (Capa) Procedure: Rev. No. Page No. Revision History Originator DateДокумент5 страницCorrective and Preventive Action (Capa) Procedure: Rev. No. Page No. Revision History Originator DateAlmario SagunОценок пока нет

- Humidity Indicator Card How To ReadДокумент10 страницHumidity Indicator Card How To ReadSneha PatelОценок пока нет

- KornFerry and Peoplescout JobsДокумент994 страницыKornFerry and Peoplescout JobsDeepak PasupuletiОценок пока нет

- Difference Between Product and ServicesДокумент21 страницаDifference Between Product and ServicesSania Asif100% (1)

- MIS Presentation On US SteelДокумент22 страницыMIS Presentation On US SteelVikram ChandoliaОценок пока нет

- E1 9.2 Forecast Management Implementation Guide E63914-05Документ128 страницE1 9.2 Forecast Management Implementation Guide E63914-05khsimoОценок пока нет

- A Control of Nonconforming Material: Document Number Revision Title Rev DateДокумент3 страницыA Control of Nonconforming Material: Document Number Revision Title Rev DateImam MansyurОценок пока нет

- QP 83001 Rev 09 Non-Conforming Material Control ProcedureДокумент6 страницQP 83001 Rev 09 Non-Conforming Material Control ProcedureImam MansyurОценок пока нет

- RQMS - IRIS - Stake Holder Analysis SheetДокумент6 страницRQMS - IRIS - Stake Holder Analysis Sheetabhisheksen.asindОценок пока нет

- DPR-04 Control of Non Conforming Product-06Документ14 страницDPR-04 Control of Non Conforming Product-06Ali KayaОценок пока нет

- Sop 7.4.4 Counterfeit Parts PreventionДокумент6 страницSop 7.4.4 Counterfeit Parts PreventionEDGAR GONZALEZОценок пока нет

- NCRДокумент6 страницNCRSaad NaeemОценок пока нет

- MM User ManualДокумент312 страницMM User ManualdbedadaОценок пока нет

- Environmental Assessment ReportДокумент6 страницEnvironmental Assessment ReportTichaona KwazvichasvikaОценок пока нет

- Procedure - Configuration Management - Rev 0Документ4 страницыProcedure - Configuration Management - Rev 0Venkat BhagavatiОценок пока нет

- CounterfeitДокумент5 страницCounterfeitVivek GoudОценок пока нет

- ECSS Q ST 60 13C (21october2013)Документ100 страницECSS Q ST 60 13C (21october2013)jsadachiОценок пока нет

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionДокумент1 страницаMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaОценок пока нет

- 8d-Report (Ishikawa)Документ12 страниц8d-Report (Ishikawa)Miro Vincek100% (1)

- ISO 9001 - 2015 - 2020 - October - Management Review - Last DayДокумент59 страницISO 9001 - 2015 - 2020 - October - Management Review - Last DayMatt Andrew Baquiano100% (1)

- QMP 8.2.4Документ3 страницыQMP 8.2.4vernier11Оценок пока нет

- Example of Using Pear FormДокумент2 страницыExample of Using Pear Formjohnoo7Оценок пока нет

- PPAP Process Checklist / Sign Off Sheet InstructionsДокумент7 страницPPAP Process Checklist / Sign Off Sheet InstructionsSharmad TamhaneОценок пока нет

- Jakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeДокумент24 страницыJakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeLeonardoViannaОценок пока нет

- Quality Plan Dyeing FinishingДокумент3 страницыQuality Plan Dyeing FinishingITOPS TeamОценок пока нет

- MD 010 Design Validation Sop 1 0 110905125013 Phpapp02Документ1 страницаMD 010 Design Validation Sop 1 0 110905125013 Phpapp02Omer ZiaОценок пока нет

- FM - MKT - 02 Quality Control Process ChartДокумент4 страницыFM - MKT - 02 Quality Control Process Chartbarja subarjaОценок пока нет

- 5 APQP 1 of 3Документ3 страницы5 APQP 1 of 3P G SumanОценок пока нет

- LSAI SQA Manual FileДокумент39 страницLSAI SQA Manual FileSivakumar L100% (1)

- Induction Training Text Format - StaffДокумент5 страницInduction Training Text Format - StaffJohnОценок пока нет

- First Article Inspection FAI AS9102 PresentationДокумент28 страницFirst Article Inspection FAI AS9102 PresentationaldiОценок пока нет

- Bs 6143 1 Guide To The Economics of Quality Part 1 Process Cost ModelДокумент23 страницыBs 6143 1 Guide To The Economics of Quality Part 1 Process Cost ModelFaber Camilo LlantenОценок пока нет

- FirstДокумент6 страницFirstvg_vvgОценок пока нет

- 04 Control of Calibrated Equipment SOPДокумент8 страниц04 Control of Calibrated Equipment SOPKamalakar KaramchetiОценок пока нет

- Supplier Deviation Request FormДокумент2 страницыSupplier Deviation Request Formjainik shahОценок пока нет

- COPQ Training - EPC (Repaired)Документ15 страницCOPQ Training - EPC (Repaired)syedfahadraza627Оценок пока нет

- Vendor Rejection and Debit PolicyДокумент6 страницVendor Rejection and Debit PolicysharanОценок пока нет

- Flow Chart For Person Entry at SiteДокумент2 страницыFlow Chart For Person Entry at Siteshamshad ahamedОценок пока нет

- CF 601 1 Purchasing Quality Assurance RequirementsДокумент3 страницыCF 601 1 Purchasing Quality Assurance RequirementsTrent CockerhamОценок пока нет

- Models Developed at AFX I-95 (2019-20)Документ4 страницыModels Developed at AFX I-95 (2019-20)sunil kumarОценок пока нет

- Stanzen Links: Procedure For Control of DocumentsДокумент5 страницStanzen Links: Procedure For Control of DocumentsasderbvaОценок пока нет

- Rms Quality CounterfeitДокумент24 страницыRms Quality CounterfeitFrancis LewahОценок пока нет

- Procedure For Qualification of Vendors For Raw Material and Packaging Materials - Pharmaceutical GuidelinesДокумент2 страницыProcedure For Qualification of Vendors For Raw Material and Packaging Materials - Pharmaceutical Guidelineskavya nainitaОценок пока нет

- Form - Supplier Quality Survey - Rev 0Документ3 страницыForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonОценок пока нет

- Sampling PlanДокумент6 страницSampling PlanGaurang DaveОценок пока нет

- Procedure For Emergency PreparenessДокумент4 страницыProcedure For Emergency PreparenessNaizil KareemОценок пока нет

- Procedure For Iden & TraceДокумент3 страницыProcedure For Iden & TraceMohammed ZubairОценок пока нет

- SOP-FES-10 Robbery Theft Vandalism Fire Violent CustomersДокумент5 страницSOP-FES-10 Robbery Theft Vandalism Fire Violent CustomersvikramОценок пока нет

- Rework & Rejection Flow ChartДокумент2 страницыRework & Rejection Flow ChartkishpchakraОценок пока нет

- Procedure Recall ProductДокумент3 страницыProcedure Recall ProductLinda Setya WatiОценок пока нет

- QSV 2 Product Release Procedure EN 01 PDFДокумент6 страницQSV 2 Product Release Procedure EN 01 PDFprashanthОценок пока нет

- Product Identification and TraceabilityДокумент5 страницProduct Identification and TraceabilityAbegale MonaresОценок пока нет

- SOP - Vendor Induction & Approval Procedure 062Документ1 страницаSOP - Vendor Induction & Approval Procedure 062ASIMОценок пока нет

- Cis-Sp-18-Customer Complaints HandlingДокумент5 страницCis-Sp-18-Customer Complaints HandlingVaibhav Gadhawe100% (1)

- Supplier Deviataion Request Form RevBДокумент2 страницыSupplier Deviataion Request Form RevBwdavid81100% (1)

- SOP-RD-7.1-001 Advanced Product Quality PlanningДокумент13 страницSOP-RD-7.1-001 Advanced Product Quality PlanningXionОценок пока нет

- Turtle Diagrams - Stores + ShippingДокумент1 страницаTurtle Diagrams - Stores + Shippingcem electromechОценок пока нет

- Equipment Installation, Servicing, On-Site Support SOPДокумент3 страницыEquipment Installation, Servicing, On-Site Support SOPBPG ServiceОценок пока нет

- IQ Check List (Inkjet Printer)Документ2 страницыIQ Check List (Inkjet Printer)JR CrusisОценок пока нет

- SOP For Receiving of Raw MaterialsДокумент3 страницыSOP For Receiving of Raw MaterialsAnnyka Dela CruzОценок пока нет

- Design of A Process Qualification and Continued Process Verification Program Within An Enhanced Development FrameworkДокумент20 страницDesign of A Process Qualification and Continued Process Verification Program Within An Enhanced Development Frameworkschumon100% (1)

- Stock Material Scenario OverviewДокумент4 страницыStock Material Scenario Overviewguru_3112Оценок пока нет

- BP-Make-to-Order Production Wo Variant ConfigurationДокумент9 страницBP-Make-to-Order Production Wo Variant ConfigurationMaxkОценок пока нет

- Oracle Fusion Example of Consigned Inventory AccountingДокумент5 страницOracle Fusion Example of Consigned Inventory AccountingrowentanОценок пока нет

- Oracle E-Business Tax Implementation Guide R12Документ206 страницOracle E-Business Tax Implementation Guide R12Vinoth NagarajanОценок пока нет

- Oracle 12 White PaperДокумент36 страницOracle 12 White Paperraaaj_99Оценок пока нет

- DEH 1850 ManualДокумент56 страницDEH 1850 ManualrowentanОценок пока нет

- Purchase Order & TypesДокумент11 страницPurchase Order & TypesChandan KumarОценок пока нет

- Infor LN Warehousing User Guide For WarehousesДокумент44 страницыInfor LN Warehousing User Guide For WarehousesVenkata Ramana100% (1)

- Dutiable Freight & InsuranceДокумент31 страницаDutiable Freight & InsuranceRosette RocoОценок пока нет

- Shipping IndustryДокумент35 страницShipping IndustryNureni SusilowatiОценок пока нет

- Laboratory Activity 7 Office SupplyДокумент6 страницLaboratory Activity 7 Office Supplyana lopezОценок пока нет

- Integrating Cloud Computing in Supply Chain Processes: A Comprehensive Literature ReviewДокумент33 страницыIntegrating Cloud Computing in Supply Chain Processes: A Comprehensive Literature ReviewAmit VishwakarmaОценок пока нет

- National Freight and Logistic PolicyДокумент70 страницNational Freight and Logistic PolicyMUHAMMAD KASHIF SiddiqiОценок пока нет

- Delivering Service Through Intermediaries and Electronic ChannelsДокумент9 страницDelivering Service Through Intermediaries and Electronic ChannelsAmit BhardwajОценок пока нет

- CH 04 Inventory Management & Control 22-09-2013 EДокумент42 страницыCH 04 Inventory Management & Control 22-09-2013 Ekemelew AregaОценок пока нет

- Kerala Dist StrategyДокумент2 страницыKerala Dist StrategymanugeorgeОценок пока нет

- Single Sourcing Vs Sole Sourcing 5m PROF - NEWДокумент6 страницSingle Sourcing Vs Sole Sourcing 5m PROF - NEWZakarya Al AzriОценок пока нет

- Dgex Form20180521Документ1 страницаDgex Form20180521Arif Tawil PrionoОценок пока нет

- 4-Case Study-Procter - and - Gamble and WallmartДокумент7 страниц4-Case Study-Procter - and - Gamble and WallmartHimanshu Dhawan0% (1)

- Study Guide RMKTG PDFДокумент29 страницStudy Guide RMKTG PDFarin123Оценок пока нет

- Describe The Classes of Manufacturing Costs and The Differences Between Product and Period CostsДокумент28 страницDescribe The Classes of Manufacturing Costs and The Differences Between Product and Period CostsLheia Micah De CastroОценок пока нет

- Om NCP 1Документ205 страницOm NCP 1Aruj MisraОценок пока нет

- Assignment For Lecture 9: Supply Chain Management: I MultichoiceДокумент8 страницAssignment For Lecture 9: Supply Chain Management: I MultichoiceThi Khanh Linh PhamОценок пока нет

- Kei Apics CSCP References 2013 130701Документ25 страницKei Apics CSCP References 2013 130701balu29oct0% (1)

- Supply Chain Management Case StudyДокумент13 страницSupply Chain Management Case StudyYouwan LeeОценок пока нет

- Sinotruk Zimbabwe: Ref: Sinotruk Part Sales Customer VisitsДокумент2 страницыSinotruk Zimbabwe: Ref: Sinotruk Part Sales Customer Visitselfigio gwekwerereОценок пока нет

- Assignment On E-Commerce: Hailey College of Commerce University of The Punjab LahoreДокумент7 страницAssignment On E-Commerce: Hailey College of Commerce University of The Punjab LahoreSabir RazaОценок пока нет

- Cargo Arrival Notice: Consignee NotifyДокумент2 страницыCargo Arrival Notice: Consignee NotifySRIKANTH VENKAMAMIDIОценок пока нет

- 2 Evolution of Supply Chain ManagementДокумент11 страниц2 Evolution of Supply Chain Managementanuragnirmal100% (1)

- LMIS AbstractДокумент2 страницыLMIS AbstractAdnanRifqyGhiffarinОценок пока нет