Академический Документы

Профессиональный Документы

Культура Документы

BEMS Point Diagram UC PG 6

Загружено:

psn_kylmОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BEMS Point Diagram UC PG 6

Загружено:

psn_kylmАвторское право:

Доступные форматы

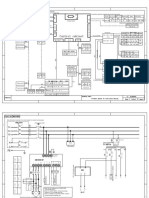

BEMS POINT SCHEDULE & MCC LOAD DIAGRAM

Utilities Compound, Boiler House

Starting Gear Type A

Load Item Power kW

Starting Gear Rating

Control Cable Cores

Analouge or Digital

Compartment #

Cable Cores

Nr of Points

Cable Type

Cable Size

Load Item

Location

Device

[X-G-P-B (01,02)]

P-B01 inverter enable / alarm / status MCC 4 D 5 X-G-P-B01

P-B01 inverter speed control / feedback MCC 2 A 4 1 INV 40 3 4 10 22kW Main LTHW Pump

P-B02 inverter enable / alarm / status MCC 4 D 5

X-1-MCC-03

P-B02 inverter speed control / feedback MCC 2 A 4

P-B01 Pressure Switch 1 Pipe 1 D 2 X-G-P-B02

P-B01 Pressure Switch 2 Pipe 1 D 2 2 INV 40 3 4 10 22kW Main LTHW Pump

P-B02 Pressure Switch 1 Pipe 1 D 2

P-B02 Pressure Switch 2 Pipe 1 D 2

P-B01 isolator Field 1 D 2

P-B02 isolator Field 1 D 2

Diff pressure detector - Index 1 Field 1 A 2

Diff pressure detector - index 2 Field 1 A 2

Diff pressure detector - local Pipe 1 A 2

[X-G-PSLS-01]

[X-G-PSLS-01]

LTHW Pump Enable MCC 1 D 2

DOL 16 3 4 4 2.2kW Shunt LTHW Pump

Pump Starter Status MCC 2 D 3

3

Pump Pressure Switch 1 Pipe 1 D 2

DOL 16 3 4 4 0.75kW Pump trap

Pump Pressure Switch 2 Pipe 1 D 2

Steam Control Valve Pipe 1 A 2

Steam High limit Valve Pipe 2 D 3

[X-G-PSLS-02]

[X-G-PSLS-02]

LTHW Pump Enable MCC 1 D 2

DOL 16 3 4 4 2.2kW Shunt LTHW Pump

Pump Starter Status MCC 2 D 3

4

Pump Pressure Switch 1 Pipe 1 D 2

DOL 16 3 4 4 0.75kW Pump trap

Pump Pressure Switch 2 Pipe 1 D 2

Steam Control Valve Pipe 1 A 2

Steam High limit Valve Pipe 2 D 3

[X-G-PSLS-03]

[X-G-PSLS-03]

LTHW Pump Enable MCC 1 D 2

DOL 16 3 4 4 2.2kW Shunt LTHW Pump

Pump Starter Status MCC 2 D 3

5

Pump Pressure Switch 1 Pipe 1 D 2

DOL 16 3 4 4 0.75kW Pump trap

Pump Pressure Switch 2 Pipe 1 D 2

Steam Control Valve Pipe 1 A 2

Steam High limit Valve Pipe 2 D 3

Common Flow Temperature Detector Pipe 1 A 2

Common Return Temperature Detector Pipe 1 A 2

[X-G-PSHS-01]

[X-G-PSHS-01]

HWS Pump Enable MCC 1 D 2

DOL 16 3 4 4 1.1kW Shunt HWS Pump

Pump Starter Status MCC 2 D 3

6

Pump Pressure Switch 1 Pipe 1 D 2

DOL 16 3 4 4 0.75kW Pump trap

Pump Pressure Switch 2 Pipe 1 D 2

Steam Control Valve Pipe 1 A 2

Steam High limit Valve Pipe 2 D 3

[X-G-PSHS-02]

[X-G-PSHS-02]

HWS Pump Enable MCC 1 D 2

DOL 16 3 4 4 1.1kW Shunt LTHW Pump

Pump Starter Status MCC 2 D 3

7

Pump Pressure Switch 1 Pipe 1 D 2

DOL 16 3 4 4 0.75kW Pump trap

Pump Pressure Switch 2 Pipe 1 D 2

Steam Control Valve Pipe 1 A 2

Steam High limit Valve Pipe 2 D 3

Common Flow Temperature Detector Pipe 1 A 2

[X-G-PU-02]

PU enable PU 1 D 2 [X-G-PU-02]

PU alarm 1 PU 1 D 2 DOL 20 3 4 6 3.5kW LTHW Pressurisation Unit

PU alarm 2 PU 1 D 2

8

Enable boilers BCP 1 D 2

Boiler Pressure set point reset BCP 1 A 2 [X-G-BFS-01]

B1 Alarm BCP 1 D 2 9 DOL 16 3 4 4 1.0 kW Boiler Feed System

B2 Alarm BCP 1 D 2

Steam Pressure Pipe 1 A 2

Feed water temperature Pipe 1 A 2 [X-G-FHR-01]

10 DOL 16 3 4 4 1.0 kW Flash heat recovery system

[X-G-P-01] X-G-P-01

Pump Starter MCC 3 D 5 DOL 16 2 4 4 1.1kW HWS pump

Pump isolator Field 1 D 2 11

[Fire Alarm]

Fire Alarm Interface Unit, zone 1 MCC 1 D 2

78

1. A = Analogue; D = Digital; C = Communication

2. Starters: DOL = Direct On Line; SD = Star/Delta; AT = Auto Transformer; Inv = Inverter

3 Cable Type :1 = Xlpe/Swa/LSF,2 = pvc/pvc. 3 = LSOH conductors

4. Numbers of Points and control cable cores are given for guidance. Tenderer to review against written specified requirements and make due allowance for what is required

Separate Electrical supplies for

Each boiler control panel (15kW)

Boiler Sequence control panel (0.5kW)

RE6309/D1361 Rev 0/2003 15910/1 BEMS Point Schedule

Вам также может понравиться

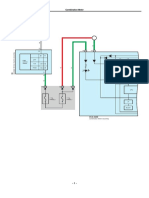

- Wire Diagram Complete Elevator - SL ELEVATOR 20190805Документ23 страницыWire Diagram Complete Elevator - SL ELEVATOR 20190805Eka Rama100% (2)

- Bedini's Free Energy Generator PDFДокумент7 страницBedini's Free Energy Generator PDFturangga ranayaОценок пока нет

- 322B L Excavator Electrical System: Electrical Schematic Symbols and DefinitionsДокумент2 страницы322B L Excavator Electrical System: Electrical Schematic Symbols and Definitionsgabriel palacios100% (3)

- 902, 906, & 908 Compact Wheel Loader Electrical System: Machine Harness Connector and Component LocationsДокумент2 страницы902, 906, & 908 Compact Wheel Loader Electrical System: Machine Harness Connector and Component Locationsait mimouneОценок пока нет

- Starting Guide For G11S-UDP Synchronous Motor Software: Date - Revision 14/12/05 - 4Документ12 страницStarting Guide For G11S-UDP Synchronous Motor Software: Date - Revision 14/12/05 - 4freddy garciaОценок пока нет

- Plumbing CalculationДокумент2 страницыPlumbing CalculationAnonymous qOBFvIОценок пока нет

- Surge Tank Size and CostДокумент1 страницаSurge Tank Size and CosthuangjlОценок пока нет

- Surge Calculation 1 - 373505Документ7 страницSurge Calculation 1 - 373505J A S JASОценок пока нет

- Chilled Water Pump Head CalculationДокумент6 страницChilled Water Pump Head CalculationMohammed Hassan Mohiuddin Khan67% (3)

- Introduction To Operations Management: Final ProjectДокумент10 страницIntroduction To Operations Management: Final ProjectHoney mirzaОценок пока нет

- BEMS Point Diagram UC PG 4Документ1 страницаBEMS Point Diagram UC PG 4psn_kylmОценок пока нет

- BEMS Point Diagram UC PG 5Документ1 страницаBEMS Point Diagram UC PG 5psn_kylmОценок пока нет

- BEMS Point Diagram THДокумент25 страницBEMS Point Diagram THpsn_kylmОценок пока нет

- BEMS Point Diagram UC PG 3Документ2 страницыBEMS Point Diagram UC PG 3psn_kylmОценок пока нет

- D7G2 SN 7MB05536Документ2 страницыD7G2 SN 7MB05536nurdinzaiОценок пока нет

- Neutral SwitchingДокумент2 страницыNeutral SwitchingCayanan ArmanОценок пока нет

- Gol 2010Документ16 страницGol 2010Fabian SandezОценок пока нет

- UNITROL Control Upgrade - Flyer - ENДокумент2 страницыUNITROL Control Upgrade - Flyer - ENfabyanoОценок пока нет

- Neutral of GeneratorДокумент2 страницыNeutral of GeneratorF. PratomoОценок пока нет

- T-485 Electrical Diagram R0 PDFДокумент35 страницT-485 Electrical Diagram R0 PDFRohitОценок пока нет

- RENR6719RENR6719-02 - SIS Diagrama ElectricoДокумент2 страницыRENR6719RENR6719-02 - SIS Diagrama ElectricoCEVegaOОценок пока нет

- LV Relay SettingДокумент12 страницLV Relay SettingRatheesh KumarОценок пока нет

- GHC PX-31 Adjustable AC-CDI CDI Specs English VersionДокумент2 страницыGHC PX-31 Adjustable AC-CDI CDI Specs English VersionlihgoyvroyrvouyrvouyrovuyriouОценок пока нет

- APFC Troubleshooting ManualДокумент28 страницAPFC Troubleshooting ManualMaintenance Circle100% (1)

- Pda Mechatro - Handbook 070226Документ40 страницPda Mechatro - Handbook 070226Paul Galvez100% (6)

- Machine Harness Connector and Component Locations: 320C Excavator Electrical SystemДокумент2 страницыMachine Harness Connector and Component Locations: 320C Excavator Electrical Systemjose luisОценок пока нет

- Cat - Dcs.sis - Controller Cs-663e AefДокумент2 страницыCat - Dcs.sis - Controller Cs-663e AefLhsan Rajawi0% (1)

- FR5050 1.1H CompleteДокумент38 страницFR5050 1.1H CompleteReid AllawayОценок пока нет

- Cat 320b Electrical. EschematichДокумент2 страницыCat 320b Electrical. EschematichNavarro NayraОценок пока нет

- Optocouplers For Variable Speed Motor ControlДокумент22 страницыOptocouplers For Variable Speed Motor Controln_navaneethОценок пока нет

- Jambaran Tiung Biru Project: Electrical Power and Control Cable Schedule - Substation No. 1Документ2 страницыJambaran Tiung Biru Project: Electrical Power and Control Cable Schedule - Substation No. 1Alif AnsharОценок пока нет

- Engineering Controlled Manufacturer:: Change DetailДокумент1 страницаEngineering Controlled Manufacturer:: Change DetailnobamoОценок пока нет

- Combination Meter: D1 (A), D2 (B)Документ10 страницCombination Meter: D1 (A), D2 (B)PeterОценок пока нет

- 3827-E10-067 - High Performance Butterfly Valve - BДокумент2 страницы3827-E10-067 - High Performance Butterfly Valve - BMohamed Elsaid El ShallОценок пока нет

- Application Configuration REC670Документ26 страницApplication Configuration REC670Baskaran GangatharanОценок пока нет

- Tabela Coordenação Tipo 1 Soft Start SMC50Документ1 страницаTabela Coordenação Tipo 1 Soft Start SMC50elclopesОценок пока нет

- Machine Harness Connector and Component Locations: Electrical System 320C ExcavatorДокумент2 страницыMachine Harness Connector and Component Locations: Electrical System 320C ExcavatorYudi setiawanОценок пока нет

- Example of Connection To Machine Controller MP2¡¡¡Документ8 страницExample of Connection To Machine Controller MP2¡¡¡Đạt Trương TuấnОценок пока нет

- RENR4343Документ2 страницыRENR4343Cecilia Gomez.contrerasОценок пока нет

- Ge - Zip 70 D Ae 3F: Generating Set DieselДокумент1 страницаGe - Zip 70 D Ae 3F: Generating Set DieselCallany AnycallОценок пока нет

- 330BL Serie 6DR ElectricoДокумент2 страницы330BL Serie 6DR ElectricojulianmataОценок пока нет

- Omron F7 SeriesДокумент18 страницOmron F7 SeriesfilipaclementeОценок пока нет

- Default Switch/Jumper SettingsДокумент16 страницDefault Switch/Jumper SettingsRafael Avella100% (1)

- Enphase Field Wiring Diagram M215 208vДокумент1 страницаEnphase Field Wiring Diagram M215 208vGareth PriceОценок пока нет

- Cat Dcs Sis Controller PDFДокумент4 страницыCat Dcs Sis Controller PDFsemahОценок пока нет

- Diagrama Minicargador 262CДокумент4 страницыDiagrama Minicargador 262CFabian Lopez100% (1)

- 272C PDFДокумент4 страницы272C PDFWilsonОценок пока нет

- Constant Current Regulator MicroprocessoДокумент8 страницConstant Current Regulator MicroprocessoEng-Waleed MohamadОценок пока нет

- Ge - Zip 120 D Ae 3F: Generating Set DieselДокумент1 страницаGe - Zip 120 D Ae 3F: Generating Set DieselCallany AnycallОценок пока нет

- HPS100 - 120 - 150-US DatasheetДокумент2 страницыHPS100 - 120 - 150-US DatasheetKCB TechnologiesОценок пока нет

- B11 Data Sheet - Regulador de PresiónДокумент2 страницыB11 Data Sheet - Regulador de PresiónBayronPalacioОценок пока нет

- 04 2 40 - UsДокумент4 страницы04 2 40 - UsAbdul MajidОценок пока нет

- Electrical Design AnalysisДокумент12 страницElectrical Design AnalysisJerome Virgo Catipay100% (2)

- Servo Transmission D10 T SuiteДокумент1 страницаServo Transmission D10 T SuiteMed EkahОценок пока нет

- Ge - Zip 60 D Ae-EnДокумент1 страницаGe - Zip 60 D Ae-EnCallany AnycallОценок пока нет

- Charging PDFДокумент16 страницCharging PDFred eagle winsОценок пока нет

- Type KD-3 and KD-5 Compensator Distance Relay: This Is The Lower Cylinder Unit. This Is The Upper Cylinder UnitДокумент4 страницыType KD-3 and KD-5 Compensator Distance Relay: This Is The Lower Cylinder Unit. This Is The Upper Cylinder UnitAna Laura Garcia CervantesОценок пока нет

- Microgrid SystemДокумент1 страницаMicrogrid SystemEkanit ChuaykoedОценок пока нет

- Report To CB Ph1Документ22 страницыReport To CB Ph1ramesh cuppuОценок пока нет

- Electrical Schematic Symbols and Definitions: Machine Harness Connector and Component LocationsДокумент2 страницыElectrical Schematic Symbols and Definitions: Machine Harness Connector and Component Locationsjicrgz7998Оценок пока нет

- Tabela Coordenação Tipo 2 Power Flex 753Документ1 страницаTabela Coordenação Tipo 2 Power Flex 753elclopesОценок пока нет

- Input Surge AnalysisДокумент1 страницаInput Surge AnalysisLeon PeterОценок пока нет

- Storm Sewer Pipe Sizing SpreadsheetДокумент6 страницStorm Sewer Pipe Sizing SpreadsheetMauricio DelgadoОценок пока нет

- Cold Hard FactsДокумент85 страницCold Hard Factspsn_kylmОценок пока нет

- Pipe Flow Friction Factor CalculationsДокумент10 страницPipe Flow Friction Factor CalculationspanchitasiОценок пока нет

- Cooling LoadДокумент91 страницаCooling LoadPiyush PandeyОценок пока нет

- BCA Energy Performance Points CalculatorДокумент95 страницBCA Energy Performance Points CalculatorCik BedahОценок пока нет

- Water Hammer Pressure/ Surge Pressure CalculationДокумент2 страницыWater Hammer Pressure/ Surge Pressure Calculationpsn_kylmОценок пока нет

- Design CalculationsДокумент50 страницDesign CalculationsMohammed AltafОценок пока нет

- Pressure Drop AND HEADДокумент2 страницыPressure Drop AND HEADpsn_kylmОценок пока нет

- LAUNDRY - Mechanical BOQ (Revised)Документ2 страницыLAUNDRY - Mechanical BOQ (Revised)psn_kylmОценок пока нет

- Mechanical CommentsДокумент6 страницMechanical Commentspsn_kylmОценок пока нет

- SI-XXXX - Pending MAS For Mechanical ServicesДокумент1 страницаSI-XXXX - Pending MAS For Mechanical Servicespsn_kylmОценок пока нет

- Heat Transfer Excel Calculations 1Документ39 страницHeat Transfer Excel Calculations 1Sharon LambertОценок пока нет

- Storm Water Calculation (20.01.21)Документ3 страницыStorm Water Calculation (20.01.21)psn_kylmОценок пока нет

- Bank Interest CalculationsДокумент1 страницаBank Interest Calculationspsn_kylmОценок пока нет

- Priced Boq - Beach RestaurantДокумент64 страницыPriced Boq - Beach Restaurantpsn_kylmОценок пока нет

- G E & C Saog: Alfar Ngineering OntractingДокумент1 страницаG E & C Saog: Alfar Ngineering Ontractingpsn_kylmОценок пока нет

- ASHRAE 15 - Reducing Toxic Leaks in HVAC Mechanical Equipment RoomsДокумент4 страницыASHRAE 15 - Reducing Toxic Leaks in HVAC Mechanical Equipment Roomspsn_kylmОценок пока нет

- Samples and Tips To Write An Apology LetterДокумент5 страницSamples and Tips To Write An Apology Letterpsn_kylmОценок пока нет

- Ac Unit Power CalculationДокумент1 страницаAc Unit Power Calculationpsn_kylmОценок пока нет

- Calculation of Water Flow Rates For Different Pipe Sizes - US UnitsДокумент4 страницыCalculation of Water Flow Rates For Different Pipe Sizes - US UnitsRyan KaneОценок пока нет

- Air Conditioning System: Pan Humidifier Load Calculation Building Room1Документ1 страницаAir Conditioning System: Pan Humidifier Load Calculation Building Room1psn_kylmОценок пока нет

- Cop & Eer CalculationДокумент1 страницаCop & Eer Calculationpsn_kylmОценок пока нет

- Chiller System Cop & EerДокумент2 страницыChiller System Cop & Eerpsn_kylmОценок пока нет

- Air Conditioning System: Pan Humidifier Load Calculation Building Room1Документ1 страницаAir Conditioning System: Pan Humidifier Load Calculation Building Room1psn_kylmОценок пока нет

- Understanding NPLV & Iplv by YorkДокумент4 страницыUnderstanding NPLV & Iplv by Yorkpsn_kylmОценок пока нет

- Royal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale QuotationДокумент3 страницыRoyal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale Quotationmuhammad aliОценок пока нет

- Bike Flasher - Amazing! by Colin MitchellДокумент1 страницаBike Flasher - Amazing! by Colin Mitchellledled711Оценок пока нет

- Lec13 Problem SolutionДокумент30 страницLec13 Problem Solutionbadviolenceisbad100% (1)

- Me (3) - 2Документ16 страницMe (3) - 2aviralОценок пока нет

- CRDIДокумент31 страницаCRDIJawahar Raj100% (3)

- Honda Regulator Rectifier - Replacement - For Cb-750, Cbr-1000, Cbr-1000f, St-1100. (Shindingen - Sh261-12)Документ23 страницыHonda Regulator Rectifier - Replacement - For Cb-750, Cbr-1000, Cbr-1000f, St-1100. (Shindingen - Sh261-12)PatPatОценок пока нет

- GelibridgeVCS Project Description Final CleanДокумент36 страницGelibridgeVCS Project Description Final CleanKrishna SrinivasanОценок пока нет

- STF Gas&TurbineДокумент20 страницSTF Gas&TurbinepedroanОценок пока нет

- Power Station OverviewДокумент11 страницPower Station OverviewjamilОценок пока нет

- 3VL 1706-1dd36-0aa0Документ4 страницы3VL 1706-1dd36-0aa0Omkar ThakurОценок пока нет

- Online Ups With Iso Ld1000 2000t-070917Документ2 страницыOnline Ups With Iso Ld1000 2000t-070917NaviОценок пока нет

- Gridtech 2013Документ6 страницGridtech 2013Kornepati SureshОценок пока нет

- TEA1755T DatasheetДокумент35 страницTEA1755T DatasheetDext JafremОценок пока нет

- The Advantages and Disadvantages of PetrolДокумент6 страницThe Advantages and Disadvantages of PetrolsuhanizamОценок пока нет

- Operation Manual For WP4CD Series Marine Diesel Gen-SetДокумент50 страницOperation Manual For WP4CD Series Marine Diesel Gen-SetHenrique100% (1)

- Lubricant Market Statistics 2023 Q1 ED1Документ22 страницыLubricant Market Statistics 2023 Q1 ED1Dharshan MylvaganamОценок пока нет

- Strategic Analysis: Ideas For Today and TomorrowДокумент29 страницStrategic Analysis: Ideas For Today and TomorrowLuke Haldun Unal100% (1)

- Flywheel Energy Storage For Regional Rail Vehicles: Matthew Read, Roderick A Smith, Keith PullenДокумент1 страницаFlywheel Energy Storage For Regional Rail Vehicles: Matthew Read, Roderick A Smith, Keith PullenJohn John IscoОценок пока нет

- Ignition SystemДокумент11 страницIgnition SystemSatyajitSahooОценок пока нет

- Engine Design and Operating ParametersДокумент66 страницEngine Design and Operating ParametersArsalan AhmadОценок пока нет

- Exam 3 SolutionsДокумент11 страницExam 3 SolutionsJohn LewisОценок пока нет

- Power Supplies TutorialДокумент9 страницPower Supplies TutorialBarry Bj ShaideОценок пока нет

- Reference Book 2014-05-19Документ84 страницыReference Book 2014-05-19Popa AndreiОценок пока нет

- Dual B Series Inverter 1500vdcДокумент4 страницыDual B Series Inverter 1500vdcrockydarkОценок пока нет

- Portable Inverter Generator: 2000 Max Watts / 1700 Rated WattsДокумент30 страницPortable Inverter Generator: 2000 Max Watts / 1700 Rated WattsWilmer SuarezОценок пока нет

- Why We Can't Store AC in Batteries Instead of DC - or Can We Store AC in Batteries Instead of DC?Документ5 страницWhy We Can't Store AC in Batteries Instead of DC - or Can We Store AC in Batteries Instead of DC?Debabrata DasОценок пока нет

- 491occ MinuteДокумент99 страниц491occ MinuteTarun HingoraniОценок пока нет

- Analysis of Corona Discharge and Earth Fault 0N 33Kv OverheadlineДокумент3 страницыAnalysis of Corona Discharge and Earth Fault 0N 33Kv Overheadlinem.a.hadiОценок пока нет