Академический Документы

Профессиональный Документы

Культура Документы

QRG010202 1113 0514 en UK DryRiser LR

Загружено:

Syafiq KhalilОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

QRG010202 1113 0514 en UK DryRiser LR

Загружено:

Syafiq KhalilАвторское право:

Доступные форматы

Trusted above all.

Dry & Wet Riser Systems

Quick Reference Guide

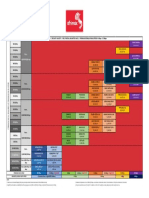

Typical Dry Riser Arrangement

About Dry & Wet Riser Systems

Air Dry & wet riser systems, what are they used for?

release

valve Dry risers are intended to be used by the Fire Service to

provide a readily available means of delivering large volumes

Landing

outlet of water to extinguish a fire or to prevent one spreading.

valve If a fire risk assessment concludes that the intervention of

the Fire Service might be necessary to fight a fire, building

Top owners have to ensure that their riser systems or hydrants are

floor working properly.

The Local Authority and Fire Officer must be consulted to

evaluate the exact requirements before the installation of dry

or wet rising mains.

Dry and wet riser; what is the difference between

Landing them?

outlet

valve A dry riser is made up of a system of valves and pipework

that enables the Fire Service to pump water up to upper

floors of a building.

First A wet riser is made up of a system of valves and pipework

floor that are kept permanently filled with water.

Dry and wet risers are often called “Rising Mains”.

Where are wet/dry riser found?

Dry risers will be found:

External

wall • in buildings over 18 metres above ground level

• in low level buildings where there are excessive distances

Steel cabinet Landing from entrances (60m)

with glazed outlet

door valve Wet risers are found in buildings over 60 metres above

2 Way inlet ground level.

breeching

25mm drain Dry/wet riser systems; what do they look like?

valve

Ground Typical dry/wet riser systems contain the following

floor

components:

• large vertical piping of 100 mm (4”) diameter that can

run internally or externally to the building

• twin inlet connection at street level housed in a steel

cabinet with a glazed door (for dry riser only)

• outlet valves at each landing

• an automatic air release valve at the highest point to

enable automatic bleeding of air from the system when

it is filled with water

• a pump (for wet riser only)

www.viking-emea.com May 2014

Dry & Wet Riser Valves

Dry & wet riser system valves

Dry riser landing valve with flange

Size: 65 mm

Max. pressure: 16.5 bar

Inlet: Flanged

Outlet: Female BS 336

Material: Gunmetal BS1400 LG2

Weight: 8.95 kg

Part number: LV-25GF

Gate valve with male screw inlet

Size: 65 mm (2½”)

Max. pressure: 16.5 bar

Inlet: Male threaded

Outlet: Female BS 336

Material: Gunmetal BS1400 LG2

Weight: 6.65 kg

Part number: GV-SM25

Gate valve with female screw inlet

Size: 65 mm (2½”)

Max. pressure: 16.5 bar

Inlet: Female threaded

Outlet: Female BS 336

Material: Gunmetal BS1400 LG2

Weight: 6.75 kg

Part number: GV-SF25

High pressure regulating landing valve (wet riser)

Size: 65 mm (2½”)

Max. pressure: 21.0 bar (a 30.0 bar version is also available on request)

Inlet: Flanged (BS 4504 (PN16&25)

Outlet: Female BS 336

Material: Gunmetal BS1400 LG2

Weight: 13.5 kg

Part number: DH6I

2-way inlet breeching valve

Max. pressure: 24.0 bar

Inlet: 65 mm Male coupling

Flange: PN16 (BS EN1092-2; 1997)

Material (body): Cast iron (HT200)

Weight: 16.2 kg

Part number: DR-095

4-way inlet breeching valve

Max. pressure: 24.0 bar

Inlet: 65 mm Male coupling

Flange: PN16 (BS EN1092-2; 1997)

Material (Body): Cast iron (HT200)

Weight: 39.0 kg

Part number: WR-115

May 2014 www.viking-emea.com

Automatic air release valve

Size: 25 mm (1”)

Max. pressure: 20.0 bar

Connection Inlet:

25 mm BSP male thread

Material: Brass

Weight: 0.3 kg

Part number: 03015600

Dry Riser Cabinets

Dry riser outlet cabinet (recessed)

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (excluding architrave) (H x W x D): 628.0 mm x 460.0 mm x 270.0

Weight: 18.75 kg

Part number: C-DR1

Dry riser vertical inlet cabinet (recessed)

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (excluding architrave) (H x W x D): 590.0 mm x 395.0 mm x 295.0

Weight: 17.0 kg

Part number: C-DR2

Dry riser horizontal inlet cabinet (recessed)

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (excluding architrave) (H x W x D): 395.0 mm x 595.0 mm x 295.0

Weight: 17.0 kg

Part number: C-DR3

Dry riser outlet frame (architrave) & door

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (excluding architrave) (H x W x D): 630.0 mm x 460.0 mm x 80.0

Weight: 10.1 kg

Part number: C-DR4

Dry riser inlet vertical frame (architrave) & door

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (excluding architrave) (H x W x D): 595.0 mm x 400.0 mm x 80.0

Weight: 9.8 kg

Part number: C-DR6

www.viking-emea.com May 2014

Dry riser inlet horizontal frame (architrave) & door

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (excluding architrave) (H x W x D): 400.0 mm x 595.0 mm x 80.0

Weight: 9.8 kg

Part number: C-DR7

Dry riser vertical outlet cabinet (surface mounted)

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (H x W x D): 668.0 mm x 500.0 mm x 270.0

Weight: 18.8 kg

Part number: C-DR8

Dry riser vertical inlet cabinet (surface mounted)

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (H x W x D): 630.0 mm x 435.0 mm x 270.0

Weight: 17.0 kg

Part number: C-DR9

Dry riser horizontal inlet cabinet (surface mounted)

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (H x W x D): 435.0 mm x 635.0 mm x 270.0

Weight: 17.0 kg

Part number: C-DR10

4-way inlet breeching valve cabinet (recessed)

Material: 1.5 mm EG Plate (Stainless steel version available on request)

Finish: Red epoxy powder coated

Dimensions (excluding architrave) (H x W x D): 595.0 mm x 595.0 mm x 295.0

Weight: 20.0 kg

Part number: C-4B10

Dry Riser System Accessories

Riser padlock

Part number: 03016900

Riser leather strap

Part number: 03016800

May 2014 www.viking-emea.com

Riser cabinet wall T-bracket (long)

Part number: 90801500

Riser cabinet wall T-bracket (short)

Part number: 90801501

Riser cabinet floor bracket

Part Number: 90801502

Grooved fittings

Selection of standard & high pressure grooved fittings:

Couplings | Flange adaptors | Tees | Pitcher tees | Elbows (standard & long

radius) | Blank ends | Lubricants

Model GD6765 grooved butterfly valve

Size: 4”/DN100

Working Pressure: 24 bar (350 psi)

Weight: 12.7 kg

Options: With and without

supervisory switch

Part Number: GD67658N04

Model KG900W grooved check valve

Size: 4”/DN100

Working pressure: 24 bar (350 psi)

Weight: 3.9 kg

Type: Double-door, silent

Part number: G900W350100

Pipe support materials

Filbows

Strut channel

U-Brackets for strut channels

Strut channel nuts

Threaded rod

U-Bolts (including nuts & washers)

Anchors

www.viking-emea.com May 2014

Europe, Middle East & Africa

BENELUX CENTRAL & EASTERN EUROPE

Hinmanweg 11d Industriestr. 10/12

NL-7575 BE Oldenzaal D-23843 Bad Oldesloe

The Netherlands Germany

Tel.: +31 541 573233 Tel.: +49 (0) 4531 803 8087

Fax: +31 541 573234 Fax: +49 (0) 4531 803 137

vikingnetherlands@vikingcorp.com contact@viking-emea.com

FRANCE IBÉRICA

Centre d’Affaires CESCOM Mar Cantábrico, 10

4, rue Marconi P. I. San Fernando I

BP 25180 San Fernando de Henares

F-57075 Metz Cedex 03 E-28830 Madrid

France Spain

Tel.: +33 800 10 29 23 Tel.: +34 91 677 8352

Fax: +33 800 88 70 46 Fax: +34 91 677 8498

vikingfrance@vikingcorp.com vikingspain@vikingcorp.com

ITALY MIDDLE EAST

Via Pogliano, 26/a LOB 19 Office #2506

I-20020 Lainate (MI) Post Box No. 17531

Italy Jebel Ali Free Zone, Dubai

Tel.: +39 02 932 851 1 United Arab Emirates

Fax: +39 02 932 851 30 Tel.: +971 4 8895 561

vikingitaly@vikingcorp.com Fax: +971 4 8895 562

vikingdubai@vikingcorp.com

NORDIC POLAND

Staffans Väg 5 ul. Płaskowickiej Filipiny 46/33

S-192 78 Sollentuna PL-02 778 Warsaw

Sweden Poland

Tel.: +46 (0)8 594 415 90 Tel.: +48 22 403 57 90

Fax: +46 (0)8 591 280 18 Fax: +48 22 403 57 69

vikingsweden@vikingcorp.com vikingpoland@vikingcorp.com

TURKEY UK & IRELAND

İnönü Cad. Sümer Sok. Zitaş İş Merkezi D2 Unit 2 - Byram House, Newborn Court

Blok K:5, D:12 Chapel Street

Kozyatağı, Kadıköy, İstanbul Epworth DN9 1HQ

Turkey United Kingdom

Tel.: +90 216 403 18 00 Tel.: +44 (0) 1427 871 000

Fax: +90 216 403 18 03 Fax: +44 (0) 1427 873 917

QRG 1.2.2/1113-0514/en_UK

vikingturkey@vikingcorp.com vikinguk@vikingcorp.com

For further information, please visit

www.viking-emea.com

In all cases the full product datasheet remains the reference document

Information, photos and drawings are not contractually binding

Subject to modifications without notice

Viking S.A. | Z.I. Haneboesch, L-4562 Differdange / Niederkorn, Luxembourg | Tel.: +352 58 37 37 - 1, Fax: +352 58 37 36, vikinglux@vikingcorp.com

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Ansi C37.72-1987 PDFДокумент25 страницAnsi C37.72-1987 PDFIvanОценок пока нет

- EOHSP 07 Communication Consultation Participation PDFДокумент5 страницEOHSP 07 Communication Consultation Participation PDFSyafiq KhalilОценок пока нет

- Plate and Frame Filter PressДокумент11 страницPlate and Frame Filter PressOmar Bassam0% (1)

- IIUM Emergency Response Team (ERT) PDFДокумент34 страницыIIUM Emergency Response Team (ERT) PDFSyafiq Khalil100% (2)

- Ir. Noorazman - Seminar 11 Nov 2014Документ41 страницаIr. Noorazman - Seminar 11 Nov 2014ezal2100% (1)

- Integrator Info Training Slide PO2Документ103 страницыIntegrator Info Training Slide PO2Syafiq KhalilОценок пока нет

- Safety Vest InformationДокумент2 страницыSafety Vest InformationSyafiq KhalilОценок пока нет

- Choosing The Right GlovesДокумент1 страницаChoosing The Right GlovesSyafiq KhalilОценок пока нет

- Mobile Master Card PayPass TSM Functional Requirements v1-0Документ40 страницMobile Master Card PayPass TSM Functional Requirements v1-0Wiraj GunasingheОценок пока нет

- Basic Ship Design PhasesДокумент1 страницаBasic Ship Design PhasesJhon GreigОценок пока нет

- Overheat Freeze Mechanisms of Solar CollectorsДокумент5 страницOverheat Freeze Mechanisms of Solar CollectorsJuli HasanajОценок пока нет

- ViewSonic Q19wb-3 VS11578 Pow. Delta EADP-45AF BFДокумент70 страницViewSonic Q19wb-3 VS11578 Pow. Delta EADP-45AF BFaladinthewizardОценок пока нет

- Mechanics of Composite Materials and Structures by Madhujit Mukhopadhyay 8173714770Документ5 страницMechanics of Composite Materials and Structures by Madhujit Mukhopadhyay 8173714770Jinsan JinsanОценок пока нет

- Boeing 757 Normal Checklist: Power Up & Preliminary PreflightДокумент4 страницыBoeing 757 Normal Checklist: Power Up & Preliminary PreflightАлексей ЯрлыковОценок пока нет

- Afrimax Pricing Table Feb23 Rel BДокумент1 страницаAfrimax Pricing Table Feb23 Rel BPhadia ShavaОценок пока нет

- Centrica, Scottish Gas Training AcademyДокумент1 страницаCentrica, Scottish Gas Training AcademyGary McAlpineОценок пока нет

- 8 PCO Training Invitation Letter December 2018Документ2 страницы8 PCO Training Invitation Letter December 2018sayo goraОценок пока нет

- Multilateral Drilling and Completions - Applications in Practice D. ThemigДокумент12 страницMultilateral Drilling and Completions - Applications in Practice D. ThemigFaiz TalpurОценок пока нет

- Amces 2020Документ1 страницаAmces 2020Karthik GootyОценок пока нет

- Temperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldДокумент8 страницTemperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldMirwansyah TanjungОценок пока нет

- Justeq07 Product BulletinДокумент1 страницаJusteq07 Product BulletinjusteqОценок пока нет

- NeuCardio E12Документ2 страницыNeuCardio E12Daniel ParОценок пока нет

- BRF90Документ10 страницBRF90Lukas Van VuurenОценок пока нет

- Testing A SCRДокумент2 страницыTesting A SCRtenisonОценок пока нет

- History Desktop PublishingДокумент16 страницHistory Desktop PublishingsanchezromanОценок пока нет

- 1 Salwico Fire Alarm SystemДокумент173 страницы1 Salwico Fire Alarm SystemAung SquОценок пока нет

- Reference Letter of DR Zaka EmadДокумент2 страницыReference Letter of DR Zaka EmadRMRE UETОценок пока нет

- Silent Sound Technology Seminar ReportДокумент42 страницыSilent Sound Technology Seminar ReportSrinivas B India79% (14)

- Introduction To Matlab - Simulink Control Systems: & Their Application inДокумент13 страницIntroduction To Matlab - Simulink Control Systems: & Their Application inTom ArmstrongОценок пока нет

- 3M Work Gloves BrochureДокумент4 страницы3M Work Gloves BrochureherminОценок пока нет

- AZ-Edit User ManualДокумент288 страницAZ-Edit User Manualdjjd40Оценок пока нет

- Vaas Head Office DetailsДокумент8 страницVaas Head Office DetailsDanielle JohnsonОценок пока нет

- Gold Kacha Flyer 2012Документ2 страницыGold Kacha Flyer 2012gustavus1Оценок пока нет

- MSupply BuilderДокумент21 страницаMSupply BuilderRohan BagadiyaОценок пока нет

- Cs - cp56 64 74 Specalog (Qehq1241)Документ20 страницCs - cp56 64 74 Specalog (Qehq1241)firman manaluОценок пока нет