Академический Документы

Профессиональный Документы

Культура Документы

D12 Volvo

Загружено:

maxim ivanovИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

D12 Volvo

Загружено:

maxim ivanovАвторское право:

Доступные форматы

Engine

Fact Sheet D12D500, EM-EC01

The D12D500 is a 500 hp, 12-litre, straight, six-cylinder

diesel engine with turbo, intercooler and turbo-compound.

The engine meets EU regulations regarding exhaust emissions

according to Euro 3

The D12D is a new generation of Volvo’s well-proven and sturdy

D12 engine. D12D is equipped with renewed fuel injection and

the Volvo EMS engine control system for optimal combustion.

The turbo-compound is an extra turbine placed behind the turbo

and recovers energy from the exhaust gases. The D12D500 is

fitted with a common cylinder head, four valves per cylinder,

overhead camshaft, two-part articulated piston and electronically

controlled unit injectors. Modified cooling of cylinder liners and

cylinder head provides improved heat dissipation. Engine

performance and exhaust emissions have been optimised through

extensive combustion development. The introduction of the

second-generation unit injectors with improved injection

characterise, combined with extensive improvement of the

combustion system, makes the D12D in the Euro 3 version still

highly competitive with regard to efficiency and with regard to

service intervals, now extended

.

The D12D500 is a very fuel-efficient engine with good drivability

developed for heavy, demanding driving for long-haul and

construction transport. The D12D500 in the Euro 3 version also

has long service intervals. The engine is equipped with VCB

(Volvo Compression Brake) with very good brake efficiency. The

following product features characterise the D12D500:

• The turbo-compound provides high engine power, low

fuel consumption and high efficiency, especially with regard

to heavy driving.

• Quick response and very good low-rpm characteristics

capability result in good starting and reversing capabilities.

• Electronic engine management, EMS, with precise fuel

injection results in efficient combustion with low emis-

sion values.

• Vertical centrally located unit injectors result in Power, kW

symmetrical distribution of the fuel.

• By means of a electronic sensor, the oil level can be read 360

on the driver’s graphic display. Net output

according to:

• Various power take-offs are available for a directly dri- 340

¥ ISO 1585

¥ Dir. 89/491/EEC

ven hydraulic pump (option). 368 kW 1600-1800 r/min

¥ ECE Reg 85

(500 hp metric)

320

Torque, Nm

2400 Nm

1000-1300 r/min

300 2400

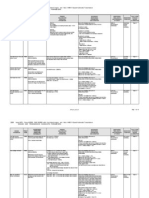

Specifications 280 2200

Designation .................................. D12D500, EM-EC01 260 2000

Max output at 1600-1800 r/min ........ 368 kW (500 HP)

Max rpm ..................................................... 1900 r/min 240 1800

Max torque at 1000-1300 r/min ..................... 2400 Nm

1600

No. of cylinders .......................................................... 6 220

Bore ................................................................. 131 mm 200

Economy 1400

Stroke .............................................................. 150 mm

1000-1700 r/min

Displacement ..................................................12.1 dm3 180

Compression ratio ...............................................18.1:1 Spec. Fuel

consumption

g/kWh

Engine brake output (VCB) at 2300 r/min ....... 225 kW 160

Economy engine speeds ...................... 1000-1700 r/min 210

Engine oil capacity, including filter .................... 33-38 l

200

190

No. of oil filters ........................... 2 full-flow, 1 by-pass 186 g/kWh EC01 180

Cooling system, total volume ................................. 44 l

Weight .........................................................1170 kg 800 1000 1200 1400 1600 1800 2000 r/min

2004-11-05 ENG Version 02

Engine

Fact Sheet D12D500, EM-EC01

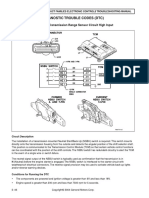

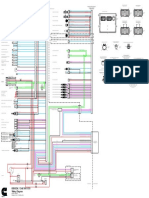

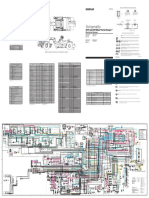

Electronic engine management Turbo-compound Unit injectors with quick

integrated into the vehicle’s provides extra power at heavy injection provide efficient

electrical system load combustion

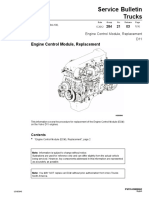

The D12D engine is fitted with Volvo The turbo-compound is an extra turbine The D12D500 is equipped with unit

EMS (Engine Management System), located behind the ordinary one and injectors with a 17-mm pump stroke,

which means that the engine’s functions recovers energy from the exhaust gases. which results in high injection pressure.

are completely electronically The extra power is transmitted through The high pressure is created

controlled. EMS provides efficient a hydrodynamic coupling and a mechanically through a rocker arm,

engine management and advanced gearwheel to the crankshaft. The turbo- which is driven by the overhead

capability for diagnostics and fault- compound provides very good low- camshaft.

tracing. The engine’s control module rpm characteristics and quick response The centrally placed injector has been

is connected to the vehicle’s electrical combined with low fuel consumption renewed and provides quick and well-

system’s data links, and information is at heavy load. controlled injection with symmetrical

presented in an easy-to-read display distribution of the fuel in the

on the instrument panel. combustion chamber.

The engine control module is located The cylinder head has only one common

in an aluminium housing on the left fuel channel to the injectors and large-

side of the engine, where the electronic diameter inlet channels and valves for

components are cooled by the fuel via low pressure drop.

a built-in cooling coil. The engine’s

wiring has been gathered in one place

and is well-protected in a wiring ter-

minal located under the inlet manifold.

Well-dimensioned

cooling system with high

efficiency

The thermostat is integrated in the

cylinder head, providing a compact

construction.

The engine has wet cylinder liners for

efficient heat dissipation.

The graphical display inform the driver about They are exchangeable and are made

for example engine oil temperature without a flame edge. D12D has

improved internal cooling for the cy-

linder head and for the oil system.

Inside the engine, all the calibrated

cooling channels co-operate in order

Electronically controlled fuel to bring about a balanced cooling pro-

injection gives low emission cess. The cooling flow is distributed Designed for high reliability and

values. between the lower and upper cooling long

casing and the cylinder head. service life

In order to allow operating data to be

registered, the engine is fitted with The engine is equipped with piston The D12D engine is built for a long

several sensor functions. cooling. The upper section of the pis- and reliable service life. It is provided

The engine control module compares ton and the piston ring zone are cooled with a common cylinder head with a

current readings with stored data, and efficiently as oil is sprayed underneath steel gasket and with induction-

regulates the amount of fuel and the the piston. Cooling is ensured even at hardened camshaft and crankshaft

injection timing. low idle. induction. The camshaft is equipped

The entire combustion process is pre- with a vibration damper to reduce

cision-controlled in all operating sound output.

situations, resulting in low fuel The heavy-duty cylinder block is also

consumption and a minimum of noise fitted with reinforcement ribs of

and exhaust emissions. nodular iron, a design feature that also

The D12D500 meets EU regulations offers lower noise levels and less vi-

regarding exhaust emissions according bration. An engine-mounted fuel fil-

to the requirements and additional ter with water separator is available as

requirements for Euro 3. option.

Вам также может понравиться

- DDDL706 ReadmeДокумент3 страницыDDDL706 ReadmeTuấn NeoОценок пока нет

- 16s151 PDFДокумент28 страниц16s151 PDFYazid KarimОценок пока нет

- 1300 Edi Series 220 SplitДокумент10 страниц1300 Edi Series 220 Split何青Оценок пока нет

- Service Bulletin Trucks: Special Tools, Group 7Документ8 страницService Bulletin Trucks: Special Tools, Group 7mattkidoОценок пока нет

- Torque Specifications: Engine Mechanical (4Hk1, 6Hk1) 1A-113Документ1 страницаTorque Specifications: Engine Mechanical (4Hk1, 6Hk1) 1A-113Владимир ШведОценок пока нет

- Service Bulletin Trucks: Immobilizer FeatureДокумент7 страницService Bulletin Trucks: Immobilizer FeatureRegistr RegistrОценок пока нет

- Alternators To Suit MitsubishiДокумент7 страницAlternators To Suit MitsubishiDave BowenОценок пока нет

- 34 TWSM0814R 4M5 enДокумент81 страница34 TWSM0814R 4M5 enclaudiosilvahОценок пока нет

- Fuel Injection Pump - Install - With Electronic GovernorДокумент5 страницFuel Injection Pump - Install - With Electronic Governoreshopmanual limaОценок пока нет

- DD100 5 PI Installation ManualДокумент8 страницDD100 5 PI Installation Manualprala_marian5780Оценок пока нет

- Feul Feed Pressure CheckingДокумент20 страницFeul Feed Pressure Checkingzoe zetОценок пока нет

- BWTS 2014 Performance Turbo Catalog PDFДокумент68 страницBWTS 2014 Performance Turbo Catalog PDFАндрей СтрилецОценок пока нет

- Standard Equipment: SK350LC-10 SK350NLC-10Документ20 страницStandard Equipment: SK350LC-10 SK350NLC-10miguel anabalonОценок пока нет

- Cylinder Head Removal D13A 211 76 1-8-06Документ12 страницCylinder Head Removal D13A 211 76 1-8-06Minn Thet NaingОценок пока нет

- Final OSB PRIMA - 4038 - 4738 - 3APRIL14Документ232 страницыFinal OSB PRIMA - 4038 - 4738 - 3APRIL14sengottaiyanОценок пока нет

- (-) (-) (-) (-) (Honda New Items)Документ5 страниц(-) (-) (-) (-) (Honda New Items)Fredy HernanОценок пока нет

- Lubrification 3412Документ37 страницLubrification 3412Mirabeau Tchio DasseОценок пока нет

- 6917 - Ext - 13 - 0 4hk1Документ66 страниц6917 - Ext - 13 - 0 4hk1Abdul KhaliqОценок пока нет

- Diagnostic Trouble Codes (DTC) : DTC P0708 Transmission Range Sensor Circuit High InputДокумент4 страницыDiagnostic Trouble Codes (DTC) : DTC P0708 Transmission Range Sensor Circuit High Inputluis eduardo corzo enriquezОценок пока нет

- Service Bulletin Trucks: Engine Control Unit, ReplacementДокумент8 страницService Bulletin Trucks: Engine Control Unit, ReplacementLucho Volvo TronicОценок пока нет

- D275a 5RДокумент8 страницD275a 5RBalraj Bawa100% (1)

- Prueba de Presion de Combustible COPLДокумент20 страницPrueba de Presion de Combustible COPLtonomart79Оценок пока нет

- Motor Vehicle Air Conditioning System Operation and Refrigerant Cycle of Motor Vehicles PDFДокумент49 страницMotor Vehicle Air Conditioning System Operation and Refrigerant Cycle of Motor Vehicles PDFmariA ANNAОценок пока нет

- Ford 2011 ObdДокумент251 страницаFord 2011 ObdschraeubleОценок пока нет

- Basic Informations-Clg856 Dcec IiДокумент49 страницBasic Informations-Clg856 Dcec IiNezar AminОценок пока нет

- Model FA (Vacuum Servo)Документ54 страницыModel FA (Vacuum Servo)Komatsu Perkins Hitachi100% (1)

- PV776 20002691 PDFДокумент96 страницPV776 20002691 PDFShane LinОценок пока нет

- SI 1201 - Troubleshooting CAN System - Rev 1Документ15 страницSI 1201 - Troubleshooting CAN System - Rev 1rharihar265970% (1)

- 2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XДокумент12 страниц2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XJorge RaulОценок пока нет

- Clutch PDFДокумент12 страницClutch PDFIzz BaharОценок пока нет

- Outlet Temperature HighДокумент5 страницOutlet Temperature HighOzan Gürcan100% (3)

- Service Manual Hino Dutro 1999 DemoДокумент15 страницService Manual Hino Dutro 1999 DemoMe YouОценок пока нет

- 2006 Trans Eng12Документ19 страниц2006 Trans Eng12eurospeed2Оценок пока нет

- ZF85A Marine Propulsion SystemДокумент9 страницZF85A Marine Propulsion SystemJun AballeОценок пока нет

- Scaneo Ecu d13Документ3 страницыScaneo Ecu d13Roni Socompi100% (1)

- mm37 PDFДокумент32 страницыmm37 PDFSaša OljačaОценок пока нет

- 600 - 001 Wabco Abs BlinkcodesДокумент5 страниц600 - 001 Wabco Abs BlinkcodesPatrick ByronОценок пока нет

- Service Bulletin Trucks: Special Tools, Group 2Документ46 страницService Bulletin Trucks: Special Tools, Group 2mattkidoОценок пока нет

- 966H, 972H Service Tools ListДокумент76 страниц966H, 972H Service Tools ListevanОценок пока нет

- Engine Control Module, ReplacementДокумент9 страницEngine Control Module, ReplacementIzz BaharОценок пока нет

- EDIS Introduction Manual-Rev BДокумент77 страницEDIS Introduction Manual-Rev BDavid JarafОценок пока нет

- Sect. 1 Technical DataДокумент20 страницSect. 1 Technical Datamanuel12515Оценок пока нет

- ISB/ISD6.7 CM2150 B120 Wiring Diagram: Engine Harness Connector Engine Control Module Engine Control ModuleДокумент1 страницаISB/ISD6.7 CM2150 B120 Wiring Diagram: Engine Harness Connector Engine Control Module Engine Control ModuleOmar Hernández100% (1)

- Engine Display GEMДокумент20 страницEngine Display GEMAlvaro PradaОценок пока нет

- tp99124 PDFДокумент20 страницtp99124 PDFDieselkОценок пока нет

- Diagrama C-15 PDFДокумент2 страницыDiagrama C-15 PDFjose100% (1)

- EC210 - Track Motor, DisassemblyДокумент14 страницEC210 - Track Motor, DisassemblyPreett Rajin MenabungОценок пока нет

- 966h 972h Sn-bj6 WXZ Bs6 NpeДокумент75 страниц966h 972h Sn-bj6 WXZ Bs6 NpeevanОценок пока нет

- Service Bulletin Trucks: Timing Gears, Replacement (All)Документ7 страницService Bulletin Trucks: Timing Gears, Replacement (All)Miller Andres ArocaОценок пока нет

- Fault Code: 2215 - SPN: 94 - FMI: 18: ISX CM871Документ14 страницFault Code: 2215 - SPN: 94 - FMI: 18: ISX CM871Engr Ramez KaawachОценок пока нет

- Boletin Enfriamiento de Mack EgrДокумент25 страницBoletin Enfriamiento de Mack Egrcristian picado100% (1)

- D10T Valve LAsh AdjustДокумент3 страницыD10T Valve LAsh AdjustSyahdiОценок пока нет

- 621F and 623F Wheel Tractor-Scraper Electrical System: Machine Harness Connector and Component LocationsДокумент2 страницы621F and 623F Wheel Tractor-Scraper Electrical System: Machine Harness Connector and Component LocationsSanОценок пока нет

- Unit Injector DescriptionДокумент2 страницыUnit Injector Descriptionwidanto0apriawanОценок пока нет

- Throttle Controls For Diesel EnginesДокумент42 страницыThrottle Controls For Diesel Enginesjonatan arangoОценок пока нет

- 6E AutoTrns 61 PDFДокумент30 страниц6E AutoTrns 61 PDFbelchiorОценок пока нет

- Fact Sheet: Engine D12C420, EM-EC01Документ2 страницыFact Sheet: Engine D12C420, EM-EC01AnbarasanОценок пока нет

- D12D380, Em-Ec96 - Esa - 02 - 586088Документ2 страницыD12D380, Em-Ec96 - Esa - 02 - 586088asif basha100% (2)

- Fact Sheet: Engine D12D460, EM-ECPT4Документ2 страницыFact Sheet: Engine D12D460, EM-ECPT4AnbarasanОценок пока нет

- Volvo Bus and Volvo Chassis With Volvo Compact Retarder VR 3250Документ2 страницыVolvo Bus and Volvo Chassis With Volvo Compact Retarder VR 3250maxim ivanovОценок пока нет

- 25 Powerful Little Known Anti Aging TipsДокумент36 страниц25 Powerful Little Known Anti Aging Tipsmaxim ivanov100% (1)

- Mercedes PRO Connect.: Real-Time Vehicle Monitoring That Improves Efficiency, Security and SafetyДокумент15 страницMercedes PRO Connect.: Real-Time Vehicle Monitoring That Improves Efficiency, Security and Safetymaxim ivanovОценок пока нет

- PaymentReceipt PDFДокумент1 страницаPaymentReceipt PDFmaxim ivanovОценок пока нет

- Favorite Foods: 5 To Fight DiabetesДокумент1 страницаFavorite Foods: 5 To Fight Diabetesmaxim ivanovОценок пока нет

- Juice ManДокумент1 страницаJuice Manmaxim ivanovОценок пока нет

- The Toxic BrainДокумент30 страницThe Toxic Brainmaxim ivanov67% (3)

- Book 1Документ6 страницBook 1Team UnitedОценок пока нет

- Calculation and Adjustment of Silica (Sio) Scaling For Reverse OsmosisДокумент3 страницыCalculation and Adjustment of Silica (Sio) Scaling For Reverse OsmosismerksssОценок пока нет

- Ama WB NX PDFДокумент36 страницAma WB NX PDFirinaОценок пока нет

- Angelia Septiane Beandda, M.D. Katherine Mae A. Doctor, M.D. Jacqueline Doctor Bernabe, MD, DPPSДокумент14 страницAngelia Septiane Beandda, M.D. Katherine Mae A. Doctor, M.D. Jacqueline Doctor Bernabe, MD, DPPSangelia beanddaОценок пока нет

- Foundation Design RequirementsДокумент18 страницFoundation Design RequirementsDanyal AhmedОценок пока нет

- U2 Lec4 SizeAdjustmentДокумент69 страницU2 Lec4 SizeAdjustmentVy NguyenОценок пока нет

- Advances in FerroelectricsДокумент542 страницыAdvances in FerroelectricsPhelippe Mendonça de PaivaОценок пока нет

- EngView Folding CartonДокумент89 страницEngView Folding CartonMarilyn AriasОценок пока нет

- Strion Led HL - SupДокумент2 страницыStrion Led HL - SupPatrickОценок пока нет

- Alpha New Trader GuideДокумент9 страницAlpha New Trader GuideChaitanya ShethОценок пока нет

- TomatoДокумент19 страницTomatoaravind kishanОценок пока нет

- Service Brake: Model FB (Air Over Hydraulic Brake)Документ97 страницService Brake: Model FB (Air Over Hydraulic Brake)Komatsu Perkins HitachiОценок пока нет

- 1.0 Intro To Aircon (Properties of Moist Air) With Sample ProblemДокумент10 страниц1.0 Intro To Aircon (Properties of Moist Air) With Sample ProblemRenneil De PabloОценок пока нет

- General Systems Theory A Mathematical ApproachДокумент385 страницGeneral Systems Theory A Mathematical Approachselotejp7100% (4)

- Data Model and ER Diagram QuestionsДокумент2 страницыData Model and ER Diagram QuestionsMoses MushinkaОценок пока нет

- GeaДокумент17 страницGeaEasy WriteОценок пока нет

- Micr Code Meaning of ChequeДокумент3 страницыMicr Code Meaning of Chequeमन्नू लाइसेंसीОценок пока нет

- 634904411345780000Документ24 страницы634904411345780000chintan kapadiaОценок пока нет

- Predictors of Failure of Endoscopic Retrograde Cholangiography in Clearance of Bile Duct Stones On Initial Procedure: A Moroccan Retrospective StudyДокумент4 страницыPredictors of Failure of Endoscopic Retrograde Cholangiography in Clearance of Bile Duct Stones On Initial Procedure: A Moroccan Retrospective StudyIJAR JOURNALОценок пока нет

- 526 - 20-80-20-103 (Emenda 3 Fios) 02 - ThiagoДокумент16 страниц526 - 20-80-20-103 (Emenda 3 Fios) 02 - ThiagoThiago Cesar MachadoОценок пока нет

- Air Vent Heads DNV 2003 PDFДокумент7 страницAir Vent Heads DNV 2003 PDFBhargav PatelОценок пока нет

- Blockchain Spec PDFДокумент18 страницBlockchain Spec PDFblueОценок пока нет

- Optimization of AirfoilsДокумент9 страницOptimization of AirfoilsMD SHAHRIARMAHMUDОценок пока нет

- Thanh Huyen - Week 5 - Final Test AnswerДокумент3 страницыThanh Huyen - Week 5 - Final Test AnswerNguyễn Sapphire Thanh HuyềnОценок пока нет

- Enterprise Security Script: Splunk Security Solutions Marketing October 2019Документ26 страницEnterprise Security Script: Splunk Security Solutions Marketing October 2019RainyОценок пока нет

- SAP Batch Determination - SAPs'WORD - We SAP For Your CauseДокумент15 страницSAP Batch Determination - SAPs'WORD - We SAP For Your CauseNikhil RaviОценок пока нет

- Pile CapДокумент19 страницPile Caprsdoost1345Оценок пока нет

- Omniclass: Description and Illustration: Rajan F CДокумент22 страницыOmniclass: Description and Illustration: Rajan F CTomas SirusasОценок пока нет

- Lab 3Документ8 страницLab 3Muhd Nur RidzwanОценок пока нет

- Electric Motor Control: DC, AC, and BLDC MotorsОт EverandElectric Motor Control: DC, AC, and BLDC MotorsРейтинг: 4.5 из 5 звезд4.5/5 (19)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestОт EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestРейтинг: 4 из 5 звезд4/5 (28)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemОт EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemОценок пока нет

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyОт EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyРейтинг: 5 из 5 звезд5/5 (1)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentОт EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsОт EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsОценок пока нет

- Electric Motors and Drives: Fundamentals, Types and ApplicationsОт EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsРейтинг: 4.5 из 5 звезд4.5/5 (12)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsОт EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsРейтинг: 5 из 5 звезд5/5 (4)

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionОт EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionРейтинг: 5 из 5 звезд5/5 (2)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingОт EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingОт EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingОценок пока нет

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsОт EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsРейтинг: 4.5 из 5 звезд4.5/5 (17)

- Automotive Master Technician: Advanced Light Vehicle TechnologyОт EverandAutomotive Master Technician: Advanced Light Vehicle TechnologyРейтинг: 5 из 5 звезд5/5 (1)