Академический Документы

Профессиональный Документы

Культура Документы

Troubleshooting guide for fire detection system

Загружено:

Rogerio SOUZAОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Troubleshooting guide for fire detection system

Загружено:

Rogerio SOUZAАвторское право:

Доступные форматы

The part no.

of this guide is 39214–099/Issue 3

Troubleshooting

Before investigating individual units for faults, it is important to check that the system wiring is fault free.

Earth faults on data loops or interface zone wiring may cause communication errors.

Many fault conditions are the result of simple wiring errors. Check all connections to the unit.

Fault finding

Problem Possible Cause

No response or missing Incorrect address setting

FIRE DETECTORS LIMITED

Incorrect loop wiring

Alarm condition Glass incorrectly fitted or broken

Test key not removed

XP95 Manual Call Point

Installation Guide

Transparent hinged cover (flip lid). General

To provide additional protection against accidental operation, a transparent hinged cover with locking tag, The XP95 Manual Call Point is available in four versions:

part no. 43785-165 is available, which can be fitted to the manual call points included in this guide. Please – part no. 55000-900, call point assembly

note that once a manual call point is fitted with such a lid it no longer complies with BS5839: Part 2. For non- – part no. 55000-905, incorporating the call point assembly and a backbox for surface mounting

UK installations, check compliance with the appropriate authority. – part no. 55000-906, incorporating the call point assembly and a terminal tray for flush mounting

– part no. 55000-907, incorporating the call point assembly and a pattress for surface mounting

using surface wiring

For further information on XP95 products, see Product Guide PP1039. Replacement XP95 glasses are also available, part no. 39117-217. For flush mounting an outlet box with a

minimum depth of 25mm is also needed. Manual call points are available in colours other than red. The part

numbers of these will be different from those shown above, but the mode of installation is identical. The

address of the unit is set using the DIL switch - see table overleaf. The installation must conform to BS5839:

Part 1 (or applicable local codes). This manual call point is suitable for indoor use only.

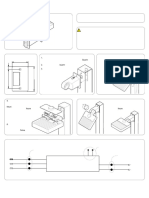

Installation of 55000-905– surface mounting using backbox

1. Fit the backbox to the wall.

2. Run the cables from the XP95 loop into the box and connect them as shown in Fig 1. Ensure that earth

continuity is maintained.

3. If a loop continuity test is to be done, it should be carried out before fitting the call point as described in

step 5.

4. Set the unit address on the DIL switch in accordance with the address table opposite. Peel the backing

from the label and stick it down.

5. Undo the small front cover retaining screw and remove the call point front cover. Remove the ‘NOT IN

USE’ insert. Connect all cables as shown in Fig. 1, secure the call point to the backbox and fit either the

‘NOT IN USE’ insert or the glass as required. Finally, replace the front cover.

Installation of 55000-906 – flush mounting

1. Chase out the wall and fit the outlet box.

2. Run the cables from the XP95 loop into the box and connect to the terminal tray as shown in Fig 2. Ensure

that earth continuity is maintained.

3. Use the screws provided to secure the terminal tray to the outlet box.

4. If a loop continuity test is to be done, it should be carried out before fitting the call point as described in

step 6.

5. Set the unit address on the DIL switch in accordance with the address table overleaf. Peel the backing

from the label and stick it down.

Apollo Fire Detectors Limited, 36 Brookside Road, Havant, Hants, PO9 1JR, UK 6. Undo the small front cover retaining screw and remove the call point front cover. Remove the ‘NOT IN

Tel +44 (0)23 9249 2412 Fax +44 (0)23 9249 2754 USE’ insert. Connect all cables as shown in Fig. 2, secure the call point to the terminal tray and fit either

Email: techsales@apollo-fire.co.uk Website: www.apollo-fire.co.uk the ‘NOT IN USE’ insert or the glass as required. Finally, replace the front cover.

4 1

Installation of 55000-907 – surface mounting using pattress for surface wiring Maximum Loop Current Consumption at 24V

1. Cut away the thinned section of the pattress wall to accept the intended cable(s). The packing card should

be fitted to the front face of the pattress when cutting cable ways to protect the small moulded features on typical switch-on surge, 2s typical 750µA

the front face. quiescent and alarm 400µA

2. Fit the pattress to the wall using the screw holes “A”, bring the cable(s) into the pattresss and connect as LED illuminated 3mA

shown. Ensure that earth continuity is maintained.

3. If a loop continuity test is to be done, it should be carried out before fitting the call point as described in Address Setting

step 5. The address of the Manual Call Point is set using the DIL switch. All segments of the switch are set to 0 or 1,

4. Set the unit address on the DIL switch in accordance with the address table opposite. Peel the backing using a small screwdriver or similar tool.

from the label and stick it down.

5. Undo the small front cover retaining screw and remove the call point front cover. Remove the ‘NOT IN A complete list of address settings is shown in the following table.

USE’ insert. Connect all cables as shown in Fig. 3, secure the call point to the pattress and fit either the

‘NOT IN USE’ insert or the glass as required. Finally, replace the front cover. DIL switch DIL switch DIL switch DIL switch DIL switch

setting setting setting setting setting

addr 1234567 addr 1234567 addr 1234567 addr 1234567 addr 1234567

Wiring Details

All wiring terminals accept solid or stranded cables up to 2.5mm². 1 1000000 11 1101000 21 1010100 31 1111100 41 1001010

2 0100000 12 0011000 22 0110100 32 0000010 42 0101010

L1 (-ve) The centre terminal 3 1100000 13 1011000 23 1110100 33 1000010 43 1101010

L2 (+ve) 4 0010000 14 0111000 24 0001100 34 0100010 44 0011010

may be used for an 5 1010000 15 1111000 25 1001100 35 1100010 45 1011010

earth connection 6 0110000 16 0000100 26 0101100 36 0010010 46 0111010

The top RED 7 1110000 17 1000100 27 1101100 37 1010010 47 1111010

terminal may To MCP 8 0001000 18 0100100 28 0011100 38 0110010 48 0000110

9 1001000 19 1100100 29 1011100 39 1110010 49 1000110

be used for BLACK 10 0101000 20 0010100 30 0111100 40 0001010 50 0100110

an earth

connection 51 1100110 61 1011110 71 1110001 81 1000101 91 1101101

52 0010110 62 0111110 72 0001001 82 0100101 92 0011101

53 1010110 63 1111110 73 1001001 83 1100101 93 1011101

54 0110110 64 0000001 74 0101001 84 0010101 94 0111101

55 1110110 65 1000001 75 1101001 85 1010101 95 1111101

56 0001110 66 0100001 76 0011001 86 0110101 96 0000011

To MCP 57 1001110 67 1100001 77 1011001 87 1110101 97 1000011

58 0101110 68 0010001 78 0111001 88 0001101 98 0100011

59 1101110 69 1010001 79 1111001 89 1001101 99 1100011

60 0011110 70 0110001 80 0000101 90 0101101 100 0010011

101 1010011 106 0101011 111 1111011 116 0010111 121 1001111

RED BLACK 102 0110011 107 1101011 112 0000111 117 1010111 122 0101111

L1 (-ve) 103 1110011 108 0011011 113 1000111 118 0110111 123 1101111

L2 (+ve) 104 0001011 109 1011011 114 0100111 119 1110111 124 0011111

105 1001011 110 0111011 115 1100111 120 0001111 125 1011111

Fig 1. Backbox Connection Diagram Fig 2. Terminal tray Connection Diagram 126 0111111

Commissioning

L1 (-ve) Ensure that a glass is fitted to each call point before testing. Use the test key provided to check the operation of

L2 (+ve) each device. An XP95 Test Set, part no. 55000-870, may be used to carry out functional testing of individual units.

The test set can also perform data integrity tests of an entire system.

Note 1: The pattress may also

be used in conjunction with Note: the test key must remain inserted for at least 2 seconds to ensure the correct CIE response.

general-purpose installation

boxes having 60mm centres. LED Indicator

Use holes “B” for this purpose,

with M3.5 screws. ! Illuminated red (under CIE control) when call point is operated

Note 2: Alternative wall fixing Routine testing

C A RED BLACK holes “C” may be used to fit the Insert the test key into the hole at the bottom of the call point. Observe routine test requirements as specified

To MCP pattress over an existing 60mm in BS5839: Part 1 or the applicable local code.

diameter box.

Fig 3. Pattress Connection Diagram

2 3

Вам также может понравиться

- تحليل البول بالصور والشرحДокумент72 страницыتحليل البول بالصور والشرحDaouai TaaouanouОценок пока нет

- The 9 Laws of Health: Key to Wellbeing Management Grow Healthier - Live Smarter - Live longerОт EverandThe 9 Laws of Health: Key to Wellbeing Management Grow Healthier - Live Smarter - Live longerРейтинг: 3 из 5 звезд3/5 (1)

- Chemical HazardousДокумент31 страницаChemical HazardousGummie Akalal SugalaОценок пока нет

- US Air Force Document AF 2025 Final Report - Weather Modification Extract - Part 3.pdf - 958-1009Документ52 страницыUS Air Force Document AF 2025 Final Report - Weather Modification Extract - Part 3.pdf - 958-1009TUTO TUTOОценок пока нет

- Words To Live by / How To Survive in A Police State.Документ3 страницыWords To Live by / How To Survive in A Police State.gerardangeОценок пока нет

- Interview With Al BielekДокумент11 страницInterview With Al BielekprivitorОценок пока нет

- Alien Breeding Program FossilsДокумент5 страницAlien Breeding Program FossilsbasharfanОценок пока нет

- The Proper Protection of Human Thought TN ElWikosian BookДокумент169 страницThe Proper Protection of Human Thought TN ElWikosian Bookvulture53Оценок пока нет

- Contractor Search ReportДокумент10 страницContractor Search ReportjavenacostaОценок пока нет

- "The Brain Is A Biological Machine With Over A: ESP Enigma (.) The Scientific Case For Psychic Phenomena, (New YorkДокумент13 страниц"The Brain Is A Biological Machine With Over A: ESP Enigma (.) The Scientific Case For Psychic Phenomena, (New YorkNLОценок пока нет

- Antichrist Prince Charles and IslamДокумент4 страницыAntichrist Prince Charles and IslamsterhowardОценок пока нет

- Alex Collier Andromedan Update InterviewДокумент11 страницAlex Collier Andromedan Update InterviewAlienraces1Оценок пока нет

- Babel Tower and New World OrderДокумент4 страницыBabel Tower and New World OrderThe Rabbithole WikiОценок пока нет

- BOOKSДокумент5 страницBOOKSMark Goforth100% (1)

- Red Pill ManifestoДокумент6 страницRed Pill ManifestoJulie Hatcher-Julie Munoz JacksonОценок пока нет

- By Arjun WaliaДокумент24 страницыBy Arjun Waliabigwill35Оценок пока нет

- Occult Economies, Revisited: Jean Comaroff and John L. ComaroffДокумент32 страницыOccult Economies, Revisited: Jean Comaroff and John L. ComaroffLucas Parreira Álvares100% (1)

- Bill Cooper - Mystery BabylonДокумент2 страницыBill Cooper - Mystery BabylonPatrick GiguereОценок пока нет

- شريحه 1 مصطلحات طبيةДокумент37 страницشريحه 1 مصطلحات طبيةMohamed WahidОценок пока нет

- Walt SmithДокумент3 страницыWalt SmithkpdxhamОценок пока нет

- BooklistДокумент50 страницBooklistonline4bdОценок пока нет

- XP95 Input/Output Unit Installation GuideДокумент2 страницыXP95 Input/Output Unit Installation GuideNguyenTrungKienОценок пока нет

- Crosley 302 WallДокумент2 страницыCrosley 302 WallPayphone.comОценок пока нет

- TM40 Touch Interface Quick Install GuideДокумент2 страницыTM40 Touch Interface Quick Install GuideAngel CalderonОценок пока нет

- Apoolo XP95 AFA O&MДокумент2 страницыApoolo XP95 AFA O&Mac fkОценок пока нет

- ACONT800AS11AA Touch Screen Programmable Comfort Control: ApplicationДокумент12 страницACONT800AS11AA Touch Screen Programmable Comfort Control: ApplicationYilam PadillaОценок пока нет

- VSX-409RDS: Audio/Video Multi-Channel ReceiverДокумент40 страницVSX-409RDS: Audio/Video Multi-Channel ReceiverJosé SomozaОценок пока нет

- Installation Manual KZ705RДокумент12 страницInstallation Manual KZ705Rginesrm89Оценок пока нет

- Start Guide: E N D E F R N L E S I T D A F I N O S VДокумент44 страницыStart Guide: E N D E F R N L E S I T D A F I N O S VPraga-1Оценок пока нет

- Manual Ingersoll RandДокумент96 страницManual Ingersoll RandJr BravoОценок пока нет

- Motion Sensing Coach Lights: RequirementsДокумент24 страницыMotion Sensing Coach Lights: RequirementsGeorge GobelОценок пока нет

- AE Smart Geared Prewired System Installation Manual v1 0Документ20 страницAE Smart Geared Prewired System Installation Manual v1 0ben omar HmidouОценок пока нет

- Wiring Diagram: Programmable Room ThermostatДокумент2 страницыWiring Diagram: Programmable Room ThermostatAndy CrissellОценок пока нет

- USSLxxxWPL Installation InstructionДокумент6 страницUSSLxxxWPL Installation InstructionHarlen Joan Pardo BergaminОценок пока нет

- 4101SN Installation Instructions PDFДокумент2 страницы4101SN Installation Instructions PDFDuniesky Soto MoralesОценок пока нет

- Aiwa Av D77Документ80 страницAiwa Av D77Ron DinОценок пока нет

- Product Information Specifications: DescriptionДокумент4 страницыProduct Information Specifications: DescriptionAndresGalvisSarmientoОценок пока нет

- SONY Compact Disc Player cdpcx153 PDFДокумент93 страницыSONY Compact Disc Player cdpcx153 PDFJULIUSОценок пока нет

- 7SR45 Argus Quick Reference: WarningДокумент2 страницы7SR45 Argus Quick Reference: WarningKunjan DalwadiОценок пока нет

- BELANKOДокумент24 страницыBELANKOshriramrnrОценок пока нет

- 990-091 - 1215 Addressable Call Point (MCP) DatasheetДокумент4 страницы990-091 - 1215 Addressable Call Point (MCP) DatasheetMuhammad Azizi SubariОценок пока нет

- Manual Instalacion PQRCVCL0Q Simple EngДокумент28 страницManual Instalacion PQRCVCL0Q Simple EngManuel Ricardo PardoОценок пока нет

- Pace MSP 995Документ14 страницPace MSP 995bacteriaaaОценок пока нет

- G310SBK Product ManualДокумент2 страницыG310SBK Product ManualJuan David Alonso VillamilОценок пока нет

- KX206 - Installation Manual PDFДокумент40 страницKX206 - Installation Manual PDFИва-Благомир МариновиОценок пока нет

- AWK-4121 QIG 4eДокумент13 страницAWK-4121 QIG 4eJonathan Montes coronaОценок пока нет

- Adaptatone 5540M Tone Generator and 5532M Speaker/Amplifier Installation SheetДокумент10 страницAdaptatone 5540M Tone Generator and 5532M Speaker/Amplifier Installation SheetDonizetty AyalaОценок пока нет

- XP95 Mini Switch Monitor Installation Guide: Functional Test DataДокумент2 страницыXP95 Mini Switch Monitor Installation Guide: Functional Test DataNguyenTrungKienОценок пока нет

- Guard Phone For Apartment Unit: WarrantyДокумент6 страницGuard Phone For Apartment Unit: Warrantylokuras de la vidaОценок пока нет

- Aiwa AV D67 Owners Manual PDFДокумент67 страницAiwa AV D67 Owners Manual PDFWebSpare PartsОценок пока нет

- Installation Manual: BMS Gateway (BAG)Документ15 страницInstallation Manual: BMS Gateway (BAG)LeonardusОценок пока нет

- Features: Idnet Communicating Devices External Addressable Manual CallpointДокумент4 страницыFeatures: Idnet Communicating Devices External Addressable Manual CallpointStalin P MaranduОценок пока нет

- Operation Manual: Micromotor For Laboratory WorkДокумент2 страницыOperation Manual: Micromotor For Laboratory WorkMinaОценок пока нет

- Panasonic Electronic Modular Switching SystemДокумент40 страницPanasonic Electronic Modular Switching SystemJohn NonakaОценок пока нет

- A Honeywell Company: Certified QualitysystemДокумент6 страницA Honeywell Company: Certified QualitysystemLisaОценок пока нет

- Sony SA-W10Документ24 страницыSony SA-W10Jim MackОценок пока нет

- Legrand BelankoДокумент24 страницыLegrand BelankoJasonОценок пока нет

- DOP 110CS: Instruction SheetДокумент2 страницыDOP 110CS: Instruction SheetAydın ZekiОценок пока нет

- Ad 28 XMVДокумент20 страницAd 28 XMVcorsini999Оценок пока нет

- B0400ee BДокумент22 страницыB0400ee BRogerio SOUZAОценок пока нет

- Triconex 2006Документ89 страницTriconex 2006Rogerio SOUZAОценок пока нет

- EntryДокумент32 страницыEntryRogerio SOUZAОценок пока нет

- 2500-RBC Profibus Remote Base ControllerДокумент45 страниц2500-RBC Profibus Remote Base ControllerRogerio SOUZAОценок пока нет

- Catalogue Distributor 2013 January WebДокумент15 страницCatalogue Distributor 2013 January Webpatrick1009Оценок пока нет

- P-95 DIGITAL PIANO - Service Manual PDFДокумент24 страницыP-95 DIGITAL PIANO - Service Manual PDFJosé Alejandro100% (2)

- Amperes Circuital LawДокумент14 страницAmperes Circuital LawMeenaChi VermaОценок пока нет

- IIR FilterДокумент50 страницIIR FilterWan Ting100% (1)

- OMICRON CPL 542 543 Measuring Impedance DatasheetДокумент2 страницыOMICRON CPL 542 543 Measuring Impedance DatasheetHany KamelОценок пока нет

- Service Manual A3300M ....Документ59 страницService Manual A3300M ....QooОценок пока нет

- 10kV and 15kV MEGOHMMETERS: User ManualДокумент72 страницы10kV and 15kV MEGOHMMETERS: User ManualMartin NОценок пока нет

- Lab 1 Answer Sheet (ELEC201)Документ9 страницLab 1 Answer Sheet (ELEC201)KHAN BROTHERSОценок пока нет

- PrabhatCables Listprice ConsolidatedДокумент4 страницыPrabhatCables Listprice Consolidatedusama zedanОценок пока нет

- Royal Enfield and Amal Spares Guide to Checking Bullet ElectricsДокумент2 страницыRoyal Enfield and Amal Spares Guide to Checking Bullet Electricsmanri77Оценок пока нет

- Datasheet LED ChipДокумент40 страницDatasheet LED ChipRamez FaroukОценок пока нет

- A Multiband Doublet For 10-18-24 MHZДокумент4 страницыA Multiband Doublet For 10-18-24 MHZIrfanJFОценок пока нет

- Trigger ModuleДокумент33 страницыTrigger ModuleMenna NagyОценок пока нет

- Chapter 1 - SELEX DVOR 1150AДокумент12 страницChapter 1 - SELEX DVOR 1150ANEILОценок пока нет

- 1763 Aprilia RSV 1000R 1000RFactory 2004 2008 100 EngДокумент4 страницы1763 Aprilia RSV 1000R 1000RFactory 2004 2008 100 Engjesus de bergeracОценок пока нет

- Partial Discharge AnalysisДокумент28 страницPartial Discharge AnalysisRemya Manuel100% (3)

- Led DisplayДокумент61 страницаLed DisplayTanvi Khurana100% (1)

- Nagaraj CV UpdatedДокумент4 страницыNagaraj CV UpdatedNagaraj VjОценок пока нет

- DatasheetДокумент21 страницаDatasheetziya tutuОценок пока нет

- Yonah CPU Schematic Block DiagramДокумент45 страницYonah CPU Schematic Block DiagramWilgen GarciaОценок пока нет

- Installation and Operating Instructions Level-Radar: KROHNE 06/2004 7.02230.32.00Документ28 страницInstallation and Operating Instructions Level-Radar: KROHNE 06/2004 7.02230.32.00Arun KumarОценок пока нет

- MB Manual Intel700series-Bios eДокумент29 страницMB Manual Intel700series-Bios eVanessa MartínesОценок пока нет

- Zone Selective Interlocking On Instantaneous (I-ZSI) PDFДокумент7 страницZone Selective Interlocking On Instantaneous (I-ZSI) PDFjumpingjack229Оценок пока нет

- Control 3V DC Voltage from 9V Battery Using SwitchesДокумент15 страницControl 3V DC Voltage from 9V Battery Using Switchesraghu_chandra_3Оценок пока нет

- Restricted Earth FaultДокумент26 страницRestricted Earth FaultAfsar AliОценок пока нет

- EL3052 2-channel analog input terminal 4...20 mA, 12 bitДокумент1 страницаEL3052 2-channel analog input terminal 4...20 mA, 12 bitprojetos_automacao_industrial2733Оценок пока нет

- Control Valves (ABB Kent)Документ816 страницControl Valves (ABB Kent)anhkietvt100% (1)

- Rochester Gauges DLCCДокумент20 страницRochester Gauges DLCCx01001932100% (1)

- AS4000 Installation Manual 925600Документ142 страницыAS4000 Installation Manual 925600Brandon100% (1)