Академический Документы

Профессиональный Документы

Культура Документы

CP Design Iranian Plant PDF

Загружено:

William Rojo CalderonИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CP Design Iranian Plant PDF

Загружено:

William Rojo CalderonАвторское право:

Доступные форматы

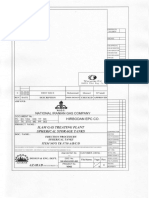

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 1 of 46

RP 1718 999 6300 5002 8

FOR CONSTRUCTION

DOCUMENT TITLE

GENERAL REQUIREMENTS FOR CATHODIC PROTECTION

(ONSHORE FACILITIES)

8 13.Dec.10 Approved for construction IDRO MG A.S KM MF

7 25.Apr.10 Approved for construction IDRO FP KM KM MF

6 09.Jun.09 Issued for Approval IDRO FP KM KM MF

5 20.Jan.09 Issued for Approval IDRO FP KM KM MF

4 28.Oct.08 Issued for Comment IDRO FP KM KM MF

3 30/08/2008 Approved for Design (AFD) IDRO FM HM AGH AKH

2 13/02/2008 Approved for Design (AFD) WP HLM RD RD MS

1 13/06/2007 Approved for Design (AFD) WP RD MS RD MS

0 16/05/2007 Issued for Company Approval (ICA) WP RD MS RD MS

REV. DATE DESCRIPTION ORIG. PRPD. CHKD. APP’D. AUTH’D.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 2 of 46

RP 1718 999 6300 5002 8

TABULATION OF REVISED PAGES

Page REV.3 REV.4 REV.5 REV.6 REV.7 REV.8 Page REV.3 REV.4 REV.5 REV.6 REV.7 REV.8

1. X X X X X X 28. X X X X

2. X X X X X X 29. X

3. X 30. X X

4. X 31. X

5. X 32.

6. X 33. X

7. 34.

8. 35. X

9. X 36. X

10. X 37.

11. X 38.

12. 39.

13. X 40.

14. X X 41. X

15. X X 42.

16. X 43.

17. X X 44.

18. X 45.

19. X X X X 46. X

20. X 47.

21. X

22. X X

23.

24. X X X

25.

26.

27. X X X X

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 3 of 46

RP 1718 999 6300 5002 8

Contents

1. DOCUMENT SCOPE ................................................................................ 6

2. INTRODUCTION....................................................................................... 7

3. PROJECT OVERVIEW ............................................................................. 7

3.1 Plant Description ................................................................................... 8

4. CODES AND STANDARDS ...................................................................... 9

4.1 General Requirements .......................................................................... 9

4.2 Codes and Standards ........................................................................... 9

5. REFERENCE DOCUMENTS .................................................................. 11

6. ABBREVIATIONS ................................................................................... 11

7. DEFINITIONS.......................................................................................... 13

8. PRECEDENCE ....................................................................................... 14

9. USE OF LANGUAGE .............................................................................. 14

10. CATHODIC PROTECTION GENERAL ................................................... 15

10.1 Overview ............................................................................................. 15

11. CATHODIC PROTECTION DESIGN CRITERIA..................................... 15

11.1 Design Life .......................................................................................... 15

11.2 Current Density ................................................................................... 16

11.3 Soil/Sea Water/Water Conditions........................................................ 18

11.4 Current Drain....................................................................................... 19

11.5 CP Protection Potential Ranges.......................................................... 19

11.6 Protection Current Demand and Anode Distribution ........................... 20

12. DESIGN CONSIDERATIONS ................................................................. 20

12.1 At Grade Storage Tank Bottoms ......................................................... 20

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 4 of 46

RP 1718 999 6300 5002 8

12.2 Internal Tank Protection ...................................................................... 22

12.3 Reinforcement Steel and Electrical Earthing Material (Uninsulated Copper or

Steel)................................................................................................... 23

12.4 Cathodic Protection Plant Piping......................................................... 24

12.5 Electrical Continuity and Isolation ....................................................... 24

12.6 Cased Crossings................................................................................. 25

12.7 Temporary Cathodic Protection System.............................................. 25

12.8 Interaction and Induced Effects........................................................... 25

13. MATERIALS ............................................................................................ 26

13.1 Transformer Rectifier Requirements ................................................... 26

13.2 Anode Materials .................................................................................. 26

13.3 Impressed Current Anodes ................................................................. 28

13.4 Zinc Anodes ........................................................................................ 29

13.5 Magnesium Anodes ............................................................................ 29

13.6 Anode Backfill ..................................................................................... 30

13.7 Reference Electrodes.......................................................................... 31

13.8 Cables ................................................................................................. 31

13.9 Distribution Boxes ............................................................................... 32

13.10 Isolation Joints .................................................................................... 32

13.11 Over Voltage Protective Devices......................................................... 33

13.12 Polarisation Cell Replacement ............................................................ 33

13.13 Test Stations ....................................................................................... 33

14. INSTALLATION & TESTING ................................................................... 34

14.1 Cable Connections to Buried Piping and Tank Bottom ....................... 34

14.2 Sacrificial Anodes................................................................................ 35

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 5 of 46

RP 1718 999 6300 5002 8

14.3 Electrical Isolation ............................................................................... 35

15. ELECTRICAL INTERFERENCE ............................................................. 35

16. DOCUMENTATION................................................................................. 36

16.1 Detail Design Report ........................................................................... 36

16.2 CP Layout Drawings and Detail Drawings .......................................... 36

16.3 Equipment Datasheets........................................................................ 37

16.4 Cable Schedule and Test Post Schedule............................................ 37

16.5 Material Take off List........................................................................... 37

17. PRE-COMMISSIONING .......................................................................... 37

18. COMMISSIONING .................................................................................. 38

Appendices

APPENDIX 1. – CATHODIC PROTECTION BASIC DESIGN CALCULATION

METHODS

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 6 of 46

RP 1718 999 6300 5002 8

1. DOCUMENT SCOPE

This specification defines the minimum requirements for design, supply, installation and commissioning of

the Cathodic Protection Systems for the Onshore Facilities.

The cathodic protection shall be applied to all external surfaces of metallic structures within the boundary

limits of the Plant, which will be buried and/or in contact with the soil and shall include but not be limited to

the following:

· External surfaces of above ground storage tanks in contact with soil

· External surfaces of buried metallic piping including metallic risers associated with firewater

hydrants, monitors on non-metallic piping systems

· External surfaces of buried metallic vessels

· Miscellaneous parts such as steel piles, rebar of reinforced concrete and etc. which are in direct

contact with the soil or electrolyte media.

· The onshore portion of the offshore pipelines coming, where they are in direct contact with soil ,sea

water or electrolyte media.

· All equipment related to earthing system which are in direct contact with soil or electrolyte media

Cathodic protection shall also be applied to the internals surfaces of the following items of equipment

· Internal surfaces of hydrocarbon tanks containing discrete water phase.

· Internal surfaces of above ground storage tanks containing conductive water such as fire water and

potable water tanks

· Internal surfaces of hydrocarbon vessels containing a discrete water phase

At the detailed engineering stage, the VENDOR shall compile a complete list of all structures to be

protected in accordance with the final project data and drawings and shall submit the list for approval to

the CONTRACTOR.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 7 of 46

RP 1718 999 6300 5002 8

2. INTRODUCTION

The IDRO/OIEC/IOEC Consortium has been contracted by the National Iranian Oil Company (NIOC) to

conduct the EPCC for South Pars Phases 17 & 18 Project. This Project includes Offshore Facilities,

platform and undersea pipelines, and Onshore Facilities for the processing of the reservoir fluid.

WorleyParsons Pty Ltd has in turn been contracted by the IDRO/OIEC Consortium to conduct the Basic

Engineering and FEED for South Pars Phases 17 & 18 for the Onshore facilities.

The South Pars Phases 17 & 18 Project offshore work-scope is being carried out by a separate Offshore

Consultant. WorleyParsons will lead, identify and coordinate deliverables required to manage the physical

interfaces between the Onshore and Offshore Design Consultants.

3. PROJECT OVERVIEW

The Iranian South Pars field is the largest discovered offshore gas field in the world, located 100 km

offshore in the Persian Gulf. Reservoir fluids are transported to shore via two sealines to the mainland

(ASSALUYEH) at a distance of approximately 105 km for further treatment.

South Pars Phases 17 & 18 are a further development of the South Pars gas field consisting of two

1000 MMSCFD phases.

The facilities shall be developed on the basis of supplying treated lean gas to the domestic gas network

and ethane gas to the nearby petrochemical complex at the required specifications while maximising liquid

recovery as propane and butane and stabilised hydrocarbon condensate for export.

A new interconnecting pipeline shall transport the lean gas produced to the domestic gas distribution

network via fiscal metering facilities.

The produced condensate shall be stored in dedicated storage facilities, periodically pumped through a

condensate export pipeline to a SBM via fiscal metering facilities.

The treated propane and butane shall be stored separately in refrigerated atmospheric double wall

storage tanks, periodically pumped through a dedicated loading pipelines network to LPG carriers berthed

at a jetty via fiscal metering facilities.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 8 of 46

RP 1718 999 6300 5002 8

3.1 Plant Description

The main functions of the Onshore processing facilities are:

· Reception facilities for the HP fluids and separation of the raw gas and condensate/water/MEG

mixture.

· Condensate stabilisation producing stabilised condensate for storage and export. The light ends

are recycled to the HP gas system. One condensate flashing unit, normally not operated, is

provided as a back-up to the stabilisation facilities.

· Gas treatment facilities producing sales gas, gaseous ethane and NGL’s consisting of:

- H2S removal from gas / CO2 partial removal from gas.

- Dehydration unit, using molecular sieves technology.

- Mercury guard.

- Ethane extraction unit, producing sales gas, gaseous ethane and NGL.

· Ethane treatment for CO2 removal and drying for further export.

· NGL fractionation facilities to produce sour liquid propane, butane and condensate. This

condensate is routed to the condensate stabilisation system for treatment.

· Propane and butane treatment for mercaptans removal and drying for storage and export.

· Propane and butane separate atmospheric storage tanks, double wall, and full containment,

refrigerated with reinforced concrete external walls.

· MEG regeneration and injection unit.

· Sulphur recovery producing liquid sulphur for solidification, granulation and export.

· Utilities, offsites as required for operation.

· Gas export compression.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 9 of 46

RP 1718 999 6300 5002 8

4. CODES AND STANDARDS

All work shall be completed in accordance with engineering codes and standards listed in document:

DB-1718-999-P332-0203: List of Applicable Codes & Industry Standards.

4.1 General Requirements

The cathodic protection design for the plant shall be based on the codes, standards, documents and

drawings referred to in Sections 4.2 and 5 using the last revision before February 2005.

4.2 Codes and Standards

The cathodic protection system shall meet when applicable the requirements of the following Standards

and Codes in their latest edition.

API RP 1632 Cathodic Protection of Underground Petroleum Storage Tanks and Piping Systems.

API RP 651 Cathodic Protection of Aboveground Petroleum Storage Tanks.

ASTM G 97 Laboratory Evaluation of Magnesium Sacrificial Anode Test Specimens for

Underground Applications.

ASTM G57 Field Measurement of Soil Resistivity Using Wenner Four-Electrode Method.

BS 1377 Part 1 Methods of test for soils for civil engineering purposes. General requirements and

sample preparation.

BS 1377 Part 3 Methods of test for soils for civil engineering purposes. Chemical and electro-

chemical tests.

BS 1377 Part 9 Methods of test for soils for civil engineering purposes. In-situ tests.

BS 7430 Code of practice for earthing.

BSI, BS 7361: Part 1 Cathodic Protection, part 1 code of practice for land and marine applications.

IEC 60076 Power Transformers.

IEC 60076-11 Power Transformers –Part 11:Dry-Type Power Transformers

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 10 of 46

RP 1718 999 6300 5002 8

IEC 60296 Insulation Oils for Transformers and Switch Gear.

IEC 60529 Degree of protection provided by Enclosure.

IEC 60726 Dry-Type Power Transformers.

IEC 60947 Low voltage Switch Gear and Control Gear.

NACE RP 0169 Control of External Corrosion on Underground or Submerged Metallic Piping

Systems.

NACE RP 0575 Internal Cathodic Protection Systems in oil-Treating Vessels.

NACE RP 0675 Control of external corrosion on offshore steel pipelines.

NACE RP0388 Impressed current protection of internal submerged surfaces of carbon steel water

storage tanks

NACE RP0177 Mitigation of Alternating Current and Lightning Effects on Metallic Structures and

Corrosion Control Systems.

NACE RP0193 External Cathodic Protection of on Grade Metallic Storage Tank Bottoms.

NACE RP0196 Galvanic Anode Cathodic Protection of Internal Submerged Surfaces of Steel Water

Storage Tanks.

NACE RP0285 Corrosion Control of Underground Storage Tank Systems by Cathodic Protection.

NACE RP0387 Metallurgical and Inspection Requirements for Cast Sacrificial Anodes for Offshore

Applications.

NACE RP0388 Impressed Current Cathodic Protection of Internal Submerged Surfaces of Steel

Water Storage Tanks.

NACE-RP-0286 The Electrical Isolation of Cathodically Protected Pipelines.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 11 of 46

RP 1718 999 6300 5002 8

5. REFERENCE DOCUMENTS

This document is complemented by the following documents:

· RP-1718-999-1300-0001 Piping Material Classes.

· RP-1718- 999-1630-0017 Specification for Transformer-Rectifier Units for Cathodic

Protection.

· RP-1718-999-6600-0001 Specification for Shop and Field Painting.

· DB-1718-999-P332-0204 Basic Engineering Design Data for Onshore Facilities.

· To be issued during detail design Cathodic Protection Isolating Joints.

· RP-1718-999-2500-0001 Cylindrical Storage Tanks Small and Medium Size.

· RP-1718-999-1630-0007 Onshore Electrical Design Criteria.

· RP-1718-999-1630-0029 Electrical Cables Specification.

· SP-1718-999-1630-0008 Electrical Installation Specification.

· RP-1718-999-1630-5012 Specification for Electrical Junction Boxes

6. ABBREVIATIONS

IDRO Industrial Development and Renovation Organisation

IOEC Iranian Offshore Engineering and Construction Company

NIOC National Iranian Oil Company

OIEC Oil Industries Engineering and Construction Company

POGC Pars Oil and Gas Company

AC Alternating Current

AFC Approved for Construction

AFD Approved for Design

Ag/AgCl Silver/Sliver chloride Reference Electrode

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 12 of 46

RP 1718 999 6300 5002 8

ASA Advanced Safety Audit

bbl Barrels

CP Cathodic Protection

EPCC Engineering, Procurement, Construction and Commissioning

FEED Front End Engineering Design

HMWPE High Molecular Weight Polyethylene

HSE Health, Safety & Environment

ICCP Impressed Current Cathodic Protection

IR Soil Voltage Drop

ISO International Organisation for Standardisation

MFD Material Flow Diagram

Mg Magnesium

MMO Mixed Metal Oxide

MMSCFD Million standard cubic feet per day

NaCl Sodium chloride

OVP Over Voltage Protection

PCR Polarisation Cell Replacement

PDB Positive Distribution Box

PVC Polyvinyl chloride

PVDF Polyvinylidene Fluoride

SBM Single Buoy Mooring

SCADA Supervisory Control and Data Acquisition

SRB Sulphate Reducing Bacteria

STBPD Stock tank barrels per day

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 13 of 46

RP 1718 999 6300 5002 8

TDS Total Dissolved Solids

TR Transformer Rectifier

WP WorleyParsons Services Pty Ltd

XLPE Cross Linked Polyethylene

7. DEFINITIONS

Within this specification the following definitions shall apply:

COMPANY: Shall mean NATIONAL IRANIAN OIL COMPANY (NIOC-POGC)

CONTRACTOR: Shall mean the Consortium of IDRO, OIEC and IOEC (IOIC) in charge of EPCC

realisation of SOUTH PARS Phases 17 & 18 in the CONTRACT with COMPANY, or his representative.

CONSTRUCTION CONTRACTOR: Shall mean the party sub-contracted by CONTRACTOR for

Construction WORK, or his representative.

INSPECTION AGENCY: This term designates the inspection bodies as third party agencies which will be

nominated by CONTRACTOR and approved by COMPANY to carry out the inspection and certification

tasks independently based on the approved Inspection & Test Plans.

SUB-CONTRACTOR: Shall mean the party sub-contracted by the CONTRACTOR for Engineering,

Construction WORK.

SITE: Shall mean the premises and places on, under, in, over or through which the WORK is to be

executed or carried out including CONTRACTOR’s engineering office and the PLANT.

SUPPLIER or VENDOR: Shall mean any person, firm or business which manufacture or supply material,

equipment or services for the performance of any item of WORK.

SUB-SUPPLIER or SUB-VENDOR: Shall mean any person, firm or business which is in CONTRACT with

SUPPLIER/VENDOR to manufacture or supply material, equipment or services for the performance of any

item of WORK.

WORK: Shall mean all and any of the works and / or services and/or materials required to be provided by

the CONTRACTOR or CONSTRUCTION CONTRACTOR.

QUALITY: Shall mean the degree to which a set of inherent characteristics fulfil requirements.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 14 of 46

RP 1718 999 6300 5002 8

QUALITY MANAGEMENT SYSTEM: Shall mean the management system that directs and controls an

organisation with regard to quality.

CONTINUED IMPROVEMENT: Shall mean a culture that encourages each team member to try to

increase Project quality at every opportunity.

PREVENTATIVE ACTION: Shall mean an action taken to eliminate the cause of a potential non-

conformity or other potentially undesirable situation.

CORRECTIVE ACTION: Shall mean an action taken to eliminate the cause of a detected non-conformity

or other undesirable situation.

VERIFICATION: Shall mean confirmation, by the provision of objective evidence, that specified

requirements have been fulfilled.

VALIDATION: Shall mean confirmation, by the provision of objective evidence, that the requirements for

an intended use have been fulfilled.

8. PRECEDENCE

In case of conflict between requirements specified herein and the requirements of any other referenced

document, the order of precedence shall be:

- This specification

- Particular specification

- Applicable technical codes industrial standards

- Data sheet

- Material requisition

9. USE OF LANGUAGE

Throughout this specification, the words "will", "may", "shall" and "should” when used, have meaning as

follows:

· "Will" is used normally in conjunction with a request from CONTRACTOR;

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 15 of 46

RP 1718 999 6300 5002 8

· "May" is used where alternatives are equally acceptable;

· "Shall” is used where a provision is mandatory;

· "Should" is used where a solution is preferred.

10. CATHODIC PROTECTION GENERAL

10.1 Overview

The sacrificial anode/impressed current cathodic protection systems for the onshore facilities of the

SOUTH PARS Phase 17/18 project will be generally applied to structures and surfaces which have been

coated with a high quality coating. The items to be protected are indicated in Section 1 of this

specification. All coating shall be in accordance with document RP-1718-999-6600-0001. All coatings

used will have their suitability for use in conjunction with cathodic protection confirmed by documented

cathodic disbondment testing and a demonstrated track record in the proposed environment whilst under

cathodic protection.

The cathodic protection system for the different areas shall be in accordance with the design criteria

given in the following sections.

11. CATHODIC PROTECTION DESIGN CRITERIA

11.1 Design Life

The design life for the cathodic protection systems shall be as follows:

· Permanent impressed current CP systems shall be 25 years.

· Permanent sacrificial anodes buried in the ground shall be 5 years minimum, see note below.

· Sacrificial anodes used in tank internals shall be 5 years minimum.

· Temporary Sacrificial anode system shall be 2 years or the same as the time delay between

installing the pipe and power on the transformer rectifiers

Note: Normally packed sacrificial anodes for use in the ground will only have a life span of 10 – 12 years

maximum. This is often due to self corrosion due to low resistivity of backfill.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 16 of 46

RP 1718 999 6300 5002 8

Note: The Sacrificial Anodes shall be designed for minimum 5 years life span and the relevant

calculations shall be carried out during detail stage.

11.2 Current Density

The current density values for cathodic design shall be based on the following table.

Table 1 Current Density Values

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 17 of 46

RP 1718 999 6300 5002 8

Design Current Density Design Current Density

Structure

Uncoated Steel, (mA/m2) Coated Steel, (mA/m2)

At grade tank bottoms 20 4

Plant piping bare steel 30

Coated plant pipeline:

3 Layer Polyethylene 0.01

3 Layer Polypropylene

Fusion Bonded Epoxy

Liquid applied

0.01

Coatings

Coal Tar Enamel

Bitumen

0.3

Tape Wrap system

Water tank internal 20 (fresh water) 2

40 (seawater/produced

4

water)

Concrete rebar (where

applicable) 10 N/A

Electrical earthing 150 (galvanised steel) N/A

500 (copper) N/A

For structures and tanks operating at elevated temperatures the current density values shall be increased

by 25% for each 10 deg. C rise in operating temperature above 30 deg. C.

The current densities given in Table 1 are indicative and valid for moderately corrosive soils. Should the

soil survey indicate a very corrosive or non corrosive soil, then the above current densities should be

adjusted accordingly during detail design.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 18 of 46

RP 1718 999 6300 5002 8

The expected coating breakdown in water tank internals will be typically in the range 5-10% and it is

assumed that the coating will be regularly inspected and maintained in order to ensure that the exposed

steel in these tanks is always less than 10% of the overall wetted tank area. Detail design of the CP

system for the tanks shall take into consideration the specific operating conditions, coating system and

estimate coating breakdown factors for each individual tank.

11.3 Soil/Sea Water/Water Conditions

Preliminary geotechnical survey data, including soil and water resistivity data will be provided by

CONTRACTOR/COMPANY.

During the early stages of CP design VENDOR shall perform a soil survey establish soil corrosivity. The

survey shall include soil resistivity measurements and chemical analysis of the soil for the actual sites

where piping, structure and/or vessels are proposed to be installed. The survey shall also take into

consideration the presence of any oil contaminated soil.

The soil resistivity shall be measured by the 4-pin Wenner method using 4 pins of equal separation in

accordance with ASTM G57. The survey frequency and survey depths shall be established during detail

design but as minimum resistivities shall be recorded at depths of 1, 2 and 3 meters, resistivities at greater

depths shall be required if deep groundbeds are selected.

Soil analysis is required for each of the soil resistivity locations as follows:

· pH – by indicator papers in the field and by glass electrode in conjunction with a high impedance

milli-voltmeter in the laboratory

· Bacteria – the level of sulphate reducing bacteria in the soil assessed by a field test such as

“RapidChek II SRB Detection System” or equivalent and reported as SRB per ml. As an alternative

an incubation technique in a culture media may be used (refer NACE/CEA document 0288).

· NaCl content - Water soluble and acid soluble chloride salts in the soil in accordance with BS 1377

Part 3.

In addition, VENDOR shall review at site all CP interfaces with existing systems not only on this plant but

also on adjacent pants, if in close proximity, to ensure the CP design has no interaction effects.

Additionally the conductivity ,temperature and make up of waters to be contained within all tankage and

other pertinent information including age and history of the tank ,and whether the tank is of welded ,bolted

or etc. construction will also be required for design purposes and will be provided by CONTRACTOR. The

water make up data required should as a minimum contain details of TDS, Conductivity, pH and chloride

content

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 19 of 46

RP 1718 999 6300 5002 8

Where tanks are constructed on ring beams the infill shall be selected washed sand and crushed rock.

The resistivity of this material shall be taken in the range 250 to 500 ohm m for design purposes.

Bituminous sand or asphaltic layers shall not be used and the tank floor will rest directly on the sand or

crushed rock infill. In this manner the CP system will be able to more effectively protect the floor plates.

11.4 Current Drain

CP of steel reinforcement within concrete is not considered here as concrete quality and below grade

coating should negate its requirement. However, the effect of current drain to steel reinforcement on the

CP system shall be considered at detail design along with the effect of stray current corrosion on the steel

reinforcement and other structures and in particular in areas where steel or concrete pile foundations are

to be used. All parts of steel reinforced which are in contact with soil or electrolyte media shall be

considered in scope of cathodic protection system.

Current drainage to coated and buried onshore piping, which are not included in the CP design, and un

insulated buried electrical earthing should also be addressed in the detailed design. Particular attention

should be taken to the high current drain of copper in low resistivity soils. It is preferred that copper

earthing rods and un insulated buried copper earthing cables not to be used, if not, all parts of earthing

network which are in direct contact with soil or electrolyte media shall be considered in cathodic protection

system scope. Earthing rods shall be galvanised steel.

11.5 CP Protection Potential Ranges

The target IR free potential value for protection shall be:

Steel in soil -0.850 to -1.200 Volts versus copper/copper sulphate half-cell

Steel in soil/water -0.800 to -1.150 Volts versus silver /silver chloride half cell

In cases where silver /silver chloride half-cells are used these shall be of the sealed low ion type.

IR free potentials onshore shall be measured after disconnection of all bonds and sacrificial anodes (if

practical) and instantaneously following the switching off all transformer rectifiers.

Other methods of recording IR free potentials may also be used if approved by COMPANY e.g. waveform

analyser or CP analyser.

[Deleted]

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 20 of 46

RP 1718 999 6300 5002 8

For in-plant areas the complicated nature, which often exists in conjunction with the combination of

materials used in some locations, can influence the potential levels. It may therefore be necessary to allow

some flexibility in the protection potential criteria required. For example the 100mV polarisation decay test

method (ref. NACE RP0169) may be used in congested areas, subject toCOMPANY approval, or in areas

subject to cathodic shielding to determine that adequate protection has been achieved.

11.6 Protection Current Demand and Anode Distribution

The protection current for all structures will be determined taking into account the applicable applied

current density, the surface area and geometry of the structure and any allowances for current drainage to

other metallic items in the vicinity of the structure intended to be protected. In the case of at grade storage

tanks, due consideration shall be given to uncoated surfaces of the floor plates at the welding junctions.

The use of the coating systems on the structures will result in a lower protection current demand at

cathode surfaces in the initial phases of the life of the structure and this will facilitate polarisation of the

structure. Towards the latter stages of the structures’ life the current demand will increase due to coating

breakdown, anode distribution shall take this condition into account.

When the total current requirement is calculated, a 50% safety margin shall be added.

12. DESIGN CONSIDERATIONS

12.1 At Grade Storage Tank Bottoms

Where the external surfaces of the bases of at grade storage tanks will be constructed on a ring beam the

external tank bottom plate shall be protected from corrosion by means of coating in combination with

cathodic protection. The coating system will improve current distribution and decrease current demand

initially. The coating system shall be an immersion grade epoxy coating material applied directly over a

prepared substrate without primer prior to installation.

Appropriate provision shall be considered for welding works which may come in future.

Bituminous sand or asphaltic layers between the tank floor and the foundation surface shall not be used

as this interferes with the application of cathodic protection.

Where the tank base will be constructed on thermal insulation material or full concrete pad foundations the

need for CP is to be reviewed in each case.

CP system design for the external coated surfaces of at grade storage tanks bases shall be by impressed

current MMO anodes using closely distributed linear anode or grid system installed within the tank

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 21 of 46

RP 1718 999 6300 5002 8

foundation. The calculation of current requirements, anode type, final siting of anodes, interconnection of

tanks by bond cables and use of electrical isolation devices shall be addressed within the detailed design

taking into account of the referenced codes and standards and due recognition of the service conditions

likely to be encountered.

Monitoring of the effectiveness of the CP systems shall be by potential measurement using permanent

reference electrodes installed at time of construction beneath the tank floor. Electrodes shall be placed as

close as possible to the tank floor to minimise the IR drop in the soil path. Numbers and distribution of

reference electrodes for various tank diameters are given below:

Tank Number of Reference Reference Electrode

Diameter(D/m) Electrodes Location

30<D≤80 1 Central

3 1/3D at 120 Degree

4 2/3D at 90 degree

18<D≤30 1 Central

2 1/3D opposite

3 2/3D at 120 degree

10<D≤18 1 Central

2 1/3D opposite

2 2/3D opposite

8<D≤10 1 Central

2 1/2D opposite

5<D≤8 1 Central

D≤5 None --

D = Tank diameter

Further monitoring facilities shall be provided at the tank periphery in the form of test cell access tubes

penetrating the tank foundation. The access tubes shall be installed under the tank base and shall be in

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 22 of 46

RP 1718 999 6300 5002 8

the form of slotted plastic tubes. These access points will be used in conjunction with portable monitoring

equipment. This is particularly important where a secondary containment liner is used under the tank base

as it allows a cross check of permanent electrodes with field measurements.

12.2 Internal Tank Protection

12.2.1 Internal Sacrificial Anodes for Aboveground Storage Tanks

and Vessels

Internal corrosion protection of the tanks and vessels shall be achieved by lining (coating) of the tanks in

conjunction with a cathodic protection system. Internal cathodic protection shall be provided for all

submerged surfaces exposed to natural waters or contaminated waters (brines). The water resistivity

shall determine the type of CP system to be installed.

For water resistivities less than 10 ohm.m (i.e. water phase in the bottom of hydrocarbon tanks) zinc

anodes shall be used. In general, aluminium anodes shall only be used in brines with resistivities of 1

ohm.m or less.

Conventional zinc anodes as detailed in section 13.4 shall be used in the water phase of condensate

tanks for temperatures <60°C. Permanent monitoring within tanks shall be accomplished by provision of

special connections on the side of the tank which allows insertion and retrieval of reference electrodes into

the tank. The design of this connection shall be developed during detailed design.

Proprietary “Noranode” zinc anodes, or approved equivalent, shall be used in vessels where the

temperature is less than 80oC. Zinc anodes shall not be used in water systems providing water for human

or animal consumption.

The coating system shall be inspected and repaired at regular intervals. Coating breakdown shall not

exceed 5 – 10% in the wetted areas. The anodes shall be located to ensure even current distribution over

the whole water wetted area. Bolted or screwed connections shall be used to permit anode replacement at

future inspections. The anodes shall be attached to plates or bosses that are pre-welded to the tank floor.

Bolted and screwed connections, pads or mounting brackets shall be coated but shall not interfere with

the electrical connection between the tank and the anode insert. Electrical continuity between the

tank/vessel and the anode shall be checked and the resistance shall be less than 0.01 ohms.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 23 of 46

RP 1718 999 6300 5002 8

12.2.2 Internal Impressed Current Cathodic Protection for

Aboveground Water Storage Tanks

For aboveground water storage tanks where the water resistivity is greater than 10 ohm.m, this may

include the potable water and firewater storage tanks, sacrificial anodes will not be able to provide a

practical CP system and an ICCP system shall be used.

MMO anode wire strings shall be used for the impressed current system. The anode wires shall be

suspended from the tank roof as an anode string through access hatches. The impressed current anodes

shall be MMO coated titanium anode/copper wire strings. The quantity of anode wire strings and anode

loop-to-tank and anode loop-to anode loop spacing will be dependent upon the tank diameter and water

level.

The anode wires shall be suspended from the hatch cover on a polypropylene rope wire with a cable

connection to each anode. The cable shall be routed back to a junction box on the tank roof containing a

suitably sized shunt.

The anode strings shall be cabled back to a positive distribution box and this box shall be fed via a

dedicated transformer rectifier unit. For tanks with internal and external impressed current the transformer

rectifier unit for the internal CP and external CP systems shall be totally separate.

Provision shall be made within the transformer rectifier unit for monitoring the DC current output and tank-

to-water potential via the SCADA system. Signal converters (4-20mA) shall be used for this purpose.

Facilities shall be provided for each above ground water tank to enable internal monitoring of the

structure-to-electrolyte potentials.

Permanent monitoring within tanks with impressed current system installed shall be accomplished by

permanent CU/CUSO4 reference electrodes in accordance with NACE RP0196 installed within each

tank. In addition to these permanent devices, access ports around the roof periphery shall be provided to

allow the insertion of portable reference electrodes for measuring tank shell potentials.

All below and above cable runs shall be in accordance with SP-1718-999-1630-0008 Electrical Installation

Specification.

12.3 Reinforcement Steel and Electrical Earthing Material

(Uninsulated Copper or Steel)

Where ICCP is used the effect of CP on the corrosion rates of steel within concrete foundations and other

structures shall be considered and allowances made for current losses. Generally in the case of in-plant,

it is advantageous to use uncoated reinforcing steel so that interaction between individual sections is kept

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 24 of 46

RP 1718 999 6300 5002 8

to a minimum. Depending upon the anode type and distribution used the reinforcing steel and electrical

grounding shall be made deliberately continuous with the tank to ensure interaction and accelerated

corrosion of either one is avoided.

To minimise current drainage and cathodic shielding galvanised steel or stainless steel earthing rods shall

be used rather than copper rods or copper earthing grids. Wherever possible, a proximity distance of at

least 6 metres shall be maintained between earthing rods and protected steel structures and earthing rods

and anodes. Under no circumstances shall earthing electrodes be installed between anodes and the

structures they are intended to protect.

12.4 Cathodic Protection Plant Piping

Buried plant piping shall be cathodically protected using a distributed impressed current cathodic

protection arrangement utilising MMO anodes. The anodes shall be placed locally to the buried piping.

The CP design shall be based on a distributed anode arrangement, within close proximity to any buried

piping. The actual anode placement shall be determined by calculation in detailed design.

To ensure that a fully functional cathodic protection system is installed and that shorting does not occur,

electrical isolation in plant will not be applied. Electrical continuity between all buried items shall ensure

that there are no locations, where under-protection occurs. However, a fully bonded cathodic protection

system shall result in current drain to earthing, rebar, foundations etc, which will be accounted for in the

detailed design.

Steel risers associated with hydrants etc on buried non-metallic piping systems (e.g. HDPE or GRE) shall

be protected using magnesium sacrificial anodes. The anodes shall be in accordance with section 13.5.

12.5 Electrical Continuity and Isolation

To ensure that the buried plant facilities are fully electrical continuous, and that stray current interaction is

minimised the plant CP system will be based on a fully bonded CP system.

Flange insulation kits, such as Pikotek, shall not be installed anywhere within the plant.

Monobloc isolation joint shall be installed on all pipelines and piping entering or exiting the plant. This will

ensure that all buried steel structures inside the plant area are isolated from pipelines/steelwork outside

the plant boundary.

The monobloc isolation joints shall be in accordance with section 13.10.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 25 of 46

RP 1718 999 6300 5002 8

12.6 Cased Crossings

Steel cased crossings shall not be used, however where required due to loading, concrete casings or pipe

with extra wall thickness shall be used.

Should cased crossings be required the concrete shall be conductive and suitable non-metallic spacers

shall be attached to the casing pipe at regular intervals within the annular space to electrically isolate the

pipeline from the rebar in the casing. The anode wire shall follow the pipeline inside the casing. Test posts

shall be installed at each end of the casing.

12.7 Temporary Cathodic Protection System

If there is a time delay between installing the pipe and switching on the ICCP system then a temporary

cathodic protection system consisting of magnesium anodes shall be installed at all test posts.

All temporary anodes shall be disconnected immediately prior to installing the permanent ICCP system.

12.8 Interaction and Induced Effects

12.8.1 Foreign Service Crossings

At all locations where a buried line crosses existing metallic and buried foreign services, facilities shall be

installed to allow testing to determine whether resistive bonding is required.

Bonding facilities, if necessary, shall include resistors or diodes and current measuring shunts.

Given the high integrity of the coating system to be applied on the pipelines, bonding to foreign pipelines

should only be undertaken if all other mitigation measures are found to be ineffective. If such bonding is

carried out consideration should be given to the possibility of over protection from existing CP systems

that may be providing high current outputs to old or poorly coated pipeline systems.

12.8.2 Parallelisms with High Voltage AC

Interaction at points where pipelines run parallel with other services such as high voltage overhead power

transmission lines (>11kV) shall also be addressed. This interaction due to induced AC or short term

interference effects (e.g. grounding fault) can lead to safety concerns with regards to personnel subject to

electric shocks, accelerated corrosion of the pipeline and damage to the coating.

As the pipeline coatings will be of high integrity it should be anticipated that induced AC may be

problematic. AC interference effects should be investigated by survey to estimate the magnitude of the

effects. If such surveys in conjunction with calculations demonstrate that there is a possibility of harmful

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 26 of 46

RP 1718 999 6300 5002 8

voltages then mitigation measures should be provided. These mitigation measures may consist of one or

a combination of the following:

· Dedicated pipeline earthing such as zinc ribbon

· Installation of solid state polarisation cells to allow AC current to flow (low impedance to AC) to

earthing devices but to prevent flow from DC current (high resistance) from CP systems

· Installation of buried steel coupons in the affected section

· Installation of monobloc isolating joints at each end of the parallelism

13. MATERIALS

13.1 Transformer Rectifier Requirements

Transformer Rectifiers shall comply with the specification for Transformer-Rectifier Units for Cathodic

Protection RP-1718- 999-1630-0017 and latest standards. Measuring unit shall provide facility as data

logger for minimum 5 days.

13.2 Anode Materials

Cathodic protection for surfaces in contact with soil or corrosive water shall generally be based on the

following:

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 27 of 46

RP 1718 999 6300 5002 8

ANODE ANODE

ITEM TO BE PROTECTED BACKFILL

MATERIAL CONFIGURATION

Calcined petroleum

Plant piping MMO Wire type Horizontal coke or approved

equivalent

At grade storage tank bottoms MMO Loops or grid Washed sand

Mg anodes only:

Bentonite clay +

Firewater Hydrants Mg Vertical

Gypsum + Sodium

sulphate

Internal tanks:

Water storage tanks resistivity

Al Stand-off or flush N/A

≤ 1 ohm.m)

Water storage tanks

Zn Stand-off or flush N/A

1ohm.m<resistivity < 10 ohm.m)

Suspended single

Water storage tanks

MMO anodes or anode N/A

(resistivity ≥ 10 ohm.m)

loops

Hydrocarbon tanks

Zn Flush mounted N/A

(With discrete water phase)

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 28 of 46

RP 1718 999 6300 5002 8

13.3 Impressed Current Anodes

Impressed current anodes shall be of the Mixed Metal Oxide type (MMO) on a titanium or titanium copper

core substrate.

The anodes type shall be as follows:

· Centre connected and sealed tubular type for Pipeline

· Wire or tubular for Piping

· Ribbon Type for Tanks

13.3.1 Wire Anodes

Wire anodes shall be of the MMO titanium type. Copper cored MMO titanium anodes shall be used where

there are long anode runs and where current attenuation along the wire is of a concern. The wire anodes

shall comply with the following:

Substrate Titanium or Titanium/copper

Anode coating type MMO

Anode coating thickness Rated for maximum current output for full design

life

Wire diameter 3mm (min)

Maximum anode current density (to 3 A/m2 in soil

be verified by MMO anode

50 A/m2 in petroleum coke

VENDOR)

50 A/m2 in fresh water

13.3.2 Tubular Anodes

Tubular anodes shall be MMO/Titanium type in a “LIDA” type arrangement and comply with the following:

Substrate Titanium

Anode coating type MMO

Anode coating thickness Rated for maximum current output for full

design life

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 29 of 46

RP 1718 999 6300 5002 8

Tube diameter 25mm (min)

Tube length 1000mm (min)

Maximum anode current density 3 A/m2 in soil

(to be verified by MMO anode VENDOR) 50 A/m2 in petroleum coke

13.4 Zinc Anodes

Zinc anodes shall be a high purity grade. Composition shall comply with ISO 15589 – 1 as follows:

Element Min % Max %

Cu - 0,005

Al 0,10 0,50

Fe - 0,005

Cd 0,025 0,07

Pb - 0,006

Zn Remainder

The maximum amount of other elements shall be 0.02 % each.

Alloy Potential -1.050 Volts (vs Cu/CuSO4 ref cell)

Alloy Capacity 780 Amp.hour / kg

Zinc anodes should not be used if the resistivity of the electrolyte is higher than 30 Ωm unless the

engineering evaluation or field test confirm that the design requirements can be met.

13.5 Magnesium Anodes

Magnesium anodes shall be performance tested in accordance with ASTM G 97 – 89. The values

obtained from the testing shall be the basis for the design of the system. Composition shall comply with

ASTM B843 as follows:

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 30 of 46

RP 1718 999 6300 5002 8

Element Min % Max %

Cu - 0,02

Al 5,3 6,7

Si - 0,1

Fe - 0,003

Mn 0,15 -

Ni - 0,002

Zn 2,5 3,5

Mg Remainder

The maximum amount of other elements shall be 0,005 % each.

Magnesium anode shall be selected as grade B.

Alloy Potential -1.75 Volts (vs Cu/CuSO4 ref cell)

Alloy Capacity 1230 Amp.hour / kg

Magnesium should not be used if the resistivity of the electrolyte is higher than 150 Ω.m unless the

engineering evaluation or field test confirm that the design requirements can be met.

13.6 Anode Backfill

13.6.1 Calcined Petroleum Coke

Calcined petroleum coke (only for tubular anodes) for use with impressed current anodes shall comply

with the following requirements:

Resistivity 0.001 ohm.m

Fixed carbon 99.1% min

Ash content 0.1% max

Moisture content 0.2% max

Volatile content 0.6% max

Particle size 100% passing 1mm

<10% retained 0.1mm

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 31 of 46

RP 1718 999 6300 5002 8

13.6.2 Chemical Backfill

Chemical backfill for use with sacrificial anodes shall comply with the following composition:

Hydrated gypsum 75%

Bentonite 20%

Sodium sulphate 5%

13.7 Reference Electrodes

Permanent reference electrodes shall be of the sealed silver/silver chloride or copper/copper sulphate

type. The electrode shall provide +/- 10mV stability with a 3 microampere load and shall be suitable for a

minimum period of 20 years. The electrodes shall be supplied by a specialist VENDOR who has a proven

track record of supplying quality electrodes, which can meet the service conditions and life expectancy.

13.8 Cables

Impressed current anode cables shall be tin-coated, stranded single core copper with HMWPE/PVDF

primary insulation and high molecular weight black polyethylene. All other cables shall be tin-coated,

stranded single core copper with XLPE/PVC insulation.

The minimum rating for all cables and wires shall be 600/1000 Volt grade. The minimum cable sizes shall

be as follows:

· Positive and negative cathodic protection station cables: 35 mm2.

· Equi-potential bonding cables: 16 mm2.

· Monitoring cables:10 mm2.

· Impressed current anode cable tails: 10 mm2.

· Magnesium/Zinc anode cable tail: 10 mm2.

· Bonding cable: 10 mm2.

· Reference electrode cable tails: 6 mm2.

· Surge diverter (Over Voltage Protection) cable tails: 25 mm2.

Negative cable shall be black and positive cables shall be red. Direct buried negative and positive cables

shall be armoured.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 32 of 46

RP 1718 999 6300 5002 8

All above ground cables shall be suitably identified with stainless steel tags to show their origin and

function. All below ground cables shall be suitably identified with concrete cable markers.

Individual cable sizes shall be calculated at detailed design and a schedule included in the calculation

package for each run.

13.9 Distribution Boxes

Distribution boxes including positive, negative and bonding boxes shall be in accordance with the

Specification for Electrical Junction Boxes RP-1718-999-1630-5012.

Positive distribution boxes shall be fitted with coil type resistors and shunts on each anode circuit rated to

the full anode current output. The box shall be sized to allow dissipation of maximum heat from resistors.

13.10 Isolation Joints

Isolation joints shall be of the monobloc type. They shall be supplied with pup-pieces of same material as

the mother pipe.

The isolating joints shall be installed above ground or in non-floodable manholes on a straight section of

the pipe and should be in an inclined plan to avoid settling of deposits which may short circuit the joints.

When the pipeline/piping contains a conductive fluid the isolation joint shall be coated internally over a

sufficient length to minimise the risk of short circuiting the cathodic protection current. The coating length

depends on the electrolyte resistivity and on the pipe diameter and shall be calculated in accordance with

the formula given below:

D

L = 400 (cm)

r

Where:

L = Internal coated length cm

D = Nominal diameter of pipe cm

ρ = Electrolyte resistivity Ohm.cm

Isolation joints shall be installed at the following locations:

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 33 of 46

RP 1718 999 6300 5002 8

· Condensate and LPG pipelines.

· Lean gas export pipelines.

· Ethane export pipelines.

· Propane and butane circulation/vapour return lines.

· Between offshore pipe lines and on shore pipe lines in battery limits

The isolation joints shall be positioned with particular attention to avoid short circuiting that might be

caused by a support, walkway fittings, valves and actuators or any other metallic structures whether

permanently or temporarily installed.

All isolation joints shall be in accordance with project specification to be developed during detail design

and shall have over voltage protective devices installed in accordance with section 13.11 below.

13.11 Over Voltage Protective Devices

Over voltage protective (OVP) devices should be installed across all isolating joints. They shall be suitable

for hazardous area classifications Zone 0, 1 or 2 as required. The OVP shall have independent design

type approval by an official test laboratory of the supplier’s country (CESI for Italy, PTB for Germany,

BASEEFA for UK, lCIE or INERIS for France). Certificates shall be in English or be accompanied with an

exact English translation. The Vendor shall ensure that OVPs meet all the applicable requirements,

preferably of the ATEX Directive (94/9/EC), and preferably have the symbol clearly fixed to indicate

compliance. Certification to IEC Standards, either under the IECEx scheme, or by way of current

certificates of conformance issued by a recognised national testing authority acceptable to

CONTRACTOR is an acceptable alternative certification to ATEX certification. Other certifications shall

be subject to approval by CONTRACTOR.

13.12 Polarisation Cell Replacement

Polarisation cell replacements (PCR) devices shall be of the solid state type. PCR shall not be used

wherein the isolating joints are principally used for isolating duties [Deleted. The PCR shall have

independent design type approval by CENELEC, BASEEFA, and to European standard and shall be CE

stamped.

13.13 Test Stations

Test stations shall be a polycarbonate (proprietary test station) or equivalent. The test post shall comprise

of a 75mm thick test post to a minimum thickness of 3mm. All test posts shall have a permanent reference

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 34 of 46

RP 1718 999 6300 5002 8

electrode installed. In complex area where shielding of the cathodic protection system may occur, the test

stations shall also have a coupon installed for local ON/OFF potential measurements. The coupon shall

be of the same material as the pipe.

Test stations shall be installed at the following locations:

· Every 100-150 meters of pipeline/piping run and at every change of pipe direction. The test station

should generally be installed above the pipeline/piping.

· 2 per tank.

· At all isolation joints.

· At every foreign service crossing.

· At road crossings.

· At points of parallelism with high voltage AC.

From each monitoring station two separate cables as a minimum shall be attached to the pipeline/piping.

All cables shall be identified by colour coding or tags.

14. INSTALLATION & TESTING

14.1 Cable Connections to Buried Piping and Tank Bottom

Cable connections (up to and including 16 mm2) to buried piping or at grade tank bottoms for test, bond

and drain cables shall be by means of drawn arc pin brazing. Negative cable connection shall be by a

welded doubler plate with welded threaded stud. Pin brazing procedure and operators shall be qualified in

accordance with project procedure to be developed during detail design.

Cadweld or thermit welding shall not be used.

Impressed current anodes cables shall be connected to positive feeder cables in above ground positive

distribution boxes to enable individual anode control and monitoring by means of grid coil resistors and

shunts, and shall be terminated above ground to allow for current monitoring and disconnection.

Where current carrying cables run outside of the pipe trench they shall be buried in a narrow excavation

and laid on a bed of soft sand. They shall be marked with cable warning tape and the route shall be

marked with concrete cable markers every 30 meters (minimum) and at each point where there is a

change of direction. If cables are to be laid in areas used by vehicular traffic or where earth-moving

machinery is used, cabling shall be suitably protected against damage or exposure.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1

GENERAL REQUIREMENTS DOC. TYPE PROJECT UNIT NO. MAT. CODE S/N REV.

FOR CATHODIC PROTECTION

Page 35 of 46

RP 1718 999 6300 5002 8

The electrical current rating of a cable shall not be exceeded for the temperature of use. Cable cross-

section shall be selected to suit the condition of use.

14.2 Sacrificial Anodes

The sacrificial anodes shall be inspected and tested in accordance with NACE RP0387.

14.3 Electrical Isolation

Isolation joints should be tested to establish their functionality in accordance with NACE RP0286.

All isolation joints should be protected from voltage transients and ac fault current by means of correctly

rated and selected solid state over voltage protection devices.

Total electrical isolation shall be ensured, i.e. no short circuits should be allowed to exist at pipe supports,

control piping, etc.

15. ELECTRICAL INTERFERENCE

Corrosion caused by electrical interference on buried metallic structures differs from other causes of

corrosion damage in that the current, which causes the corrosion, has a source foreign to the affected

structure. Usually the interfering current from a foreign source, not electrically continuous with the affected

structure is drained from the soil by the affected structure. Detrimental effects of interference currents

occur at locations where the currents are subsequently discharged from the affected pipeline to the earth.

Types of DC interference are:

· Constant current sources such as from CP rectifiers, and

· Fluctuating current sources such as direct current electrified railway systems and transit systems,

coal mine haulage systems and pumps, welding machines and direct current power systems.

Types of AC interference are:

· Short term interference caused by faults in a.c. power systems and electrified railways

· Long term interference caused by inductive or conductive coupling between the pipeline and high

voltage lines or electrified railways

· Telluric currents.

This document is the sole property of N.I.O.C, all information contained herein may neither be reproduced, used, disclosed, transmitted

nor in any way made public without permission of the owner.

NATIONAL IRANIAN OIL COMPANY

SOUTH PARS GAS FIELD DEVELOPMENT

N I O C

PHASES 17 & 18

Pars Oil and Gas Company

DOCUMENT TITLE DOCUMENT No. Doc. Class: 1