Академический Документы

Профессиональный Документы

Культура Документы

PIC/S Assessment & Joint Reassessment Programme

Загружено:

sppИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PIC/S Assessment & Joint Reassessment Programme

Загружено:

sppАвторское право:

Доступные форматы

PHARMACEUTICAL INSPECTION CONVENTION

PHARMACEUTICAL INSPECTION CO-OPERATION SCHEME

PS/W 1/2005 (Rev. 2)

Annex

20 October 2014

PIC/S Assessment & Joint Reassessment Programme

REVISED PIC/S AUDIT CHECKLIST

based on

Evaluation Guide for GMP Regulatory Compliance Programme

(by Health Canada)

Editor: PIC/S Secretariat

14, rue du Roveray

CH-1207 Geneva

Tel. +41 22 738 92 16

Fax +41 22 738 92 17

e-mail: info@picscheme.org

web site: http://www.picscheme.org

PS/W 1/2005 (Rev. 2) 1 of 15 20 October 2014

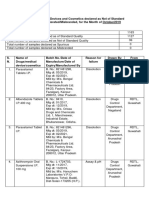

Summary of the Audit Checklist

Component Sub-component Importance Evaluation method

1 - Legislative and Regulatory 1A - Empowering legislation Critical Documentation review

Requirements and Scope 1B - Conflict of interest Very important Documentation review

On-site evaluation at Inspectorate

2 - Regulatory directives and 2A - Procedures for designating inspectors Very important Documentation review

policies 2B - Enforcement Policies - Evaluated as part of sub-component 7B

2C - Code of conduct/ Code of ethics Very important Documentation review

2D - Training certification policies/guidelines - Evaluated as part of sub-component 4C

2E - Alert/crisis management - Evaluated as part of sub-component 8A

policies/procedures/guidelines

2F - Organisational structure - Evaluated as part of sub-component 11A

3 - GMP Standards 3A - Details/ scope of GMP Critical Documentation review

3B - Process validation - Evaluated as part of sub-component 3A

4 - Inspection resources 4A - Staffing: Initial qualification Very important Documentation review

On-site evaluation at Inspectorate

4B - Number of inspectors Very important Documentation review

On-site evaluation at Inspectorate

4C - Training programme Very important Documentation review

On-site evaluation at Inspectorate

4D - QA mechanism to assure effectiveness of - Evaluated as part of sub-component 4C

training programme

5 - Inspection procedures 5A - Inspection strategy Very important Documentation review

On-site evaluation at Inspectorate

5B - Pre-inspection preparation Very important Documentation review

On-site evaluation at Inspectorate

Observed inspections

5C - Format and content of inspection reports Very important Documentation review

Observed inspections

5D - Inspection methodology - Evaluated as part of sub-components 5E

5E - SOP for conducting inspections Critical Documentation review

Observed inspections

5F - Inspection procedures - Post-inspection Very important Documentation review

activities On-site evaluation at Inspectorate

Observed inspections

5G - Inspection procedures – Storage of inspection Important Documentation review

data Observed inspections

6 - Inspection performance standard 6A - Performance standards Very important Evaluated as part of sub-component 11A

7 - Enforcement powers and 7A - Provision for written notice of violations - Evaluated as part of sub-component 7B

procedures 7B - Non-compliance management Critical Documentation review

On-site evaluation at Inspectorate

7C - Appeal mechanism Important Documentation review

On-site evaluation at Inspectorate

7D - Other measures - Evaluated as part of sub-components 7B

8 – Alert and crisis systems 8A - Alert mechanisms Critical Documentation review

On-site evaluation at Inspectorate

8B - Crisis management mechanisms - Evaluated as part of sub-component 8A

8C - Alert performance standards Important Documentation review

9 - Analytical capability 9A - Access to laboratories Critical Documentation review

On-site evaluation at Laboratory

On-site evaluation at Inspectorate

9B - SOPs for analytical support Very important Documentation review

On-site evaluation at Laboratory

9C - Validation of analytical methods Very important Documentation review

On-site evaluation at Laboratory

Cont’d

PS/W 1/2005 (Rev. 2) 2 of 15 20 October 2014

Component Sub-component Importance Evaluation method

10 - Surveillance programme 10A - Sampling and audit procedure Very important Documentation review

On-site evaluation at Laboratory

On-site evaluation at Inspectorate

10B - Recall monitoring - Evaluated as part of sub-component 7B

10C - Consumer complaint system Critical Documentation review

On-site evaluation at Inspectorate

10D - Adverse reaction reporting system/ - Not evaluated - not considered within the scope of a

procedures GMP regulatory compliance programme.

10E - Medicinal product defect reporting system/ - Evaluated as part of sub-component 10C

procedures

11 - Quality management system 11A - Quality management system Critical Documentation review

On-site evaluation at Inspectorate

On-site evaluation at Laboratory

PS/W 1/2005 (Rev. 2) 3 of 15 20 October 2014

Glossary

Articles = Any item such as products (active pharmaceutical ingredient, finished medicinal products, investigational medicinal products, or any

intermediates), containers, packages, labels, documentation, etc.

Component/Sub-Component = Elements of a GMP regulatory compliance programme. For additional information on the level of importance and the

evaluation methods, refer to the table “Summary of the Audit Checklist” provided at the beginning of this document.

Dosage form = Pharmaceutical form

Equivalent = Not necessarily identical, but leading to the same result.

GMP regulatory compliance programme = Includes components such as the supporting infrastructure of legislative and regulatory requirements, GMP

standards, inspection/enforcement resources and procedures, performance standards, alert and crisis system, analytical capability, surveillance

programme and quality management systems.

Key performance indicators (KPI) = Performance indicators established for planning and reporting on the components/sub-components of a GMP

regulatory compliance programme.

Manufacture = Fabricate as defined in relevant GMP guidelines 1.

Medicinal products = Drug products

Official Medicines Control Laboratories (OMCL) = Laboratories used for the purpose of official testing.

Pharmacovigilance = Surveillance of adverse reactions reporting.

Product = Active pharmaceutical ingredient, finished medicinal product, investigational medicinal products, or any intermediate.

Product defect = Quality defect related to a product such as Out-of-Specifications (OOS), etc.

General Notes

The entire checklist must be used for the assessment/evaluation of GMP regulatory compliance programme as regards active pharmaceutical ingredients

and medicinal products.

This checklist is used as a high level document. It is meant to detail the “WHAT” and not the “HOW”. The “HOW” is expected to be covered in a lower

level document such as a guidance document or a procedure.

1 Manufacture = all operations of purchase of materials and products, production, quality control, release, storage, distribution and related controls

PS/W 1/2005 (Rev. 2) 4 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

Sub-component 1A Legislative and regulatory requirements and scope - Empowering legislation (Critical)

1 The legislation identifies key delegations/functions in the organisation/regulatory authority X

assigned for overall responsibility of the GMP regulatory compliance programme.2

2 The authority to designate inspectors is vested in legislation. X

3 The identity of designated inspectors and scope of jurisdiction of legislation are available to X

companies being inspected.

4 There is legal authority for an inspector to enter at any reasonable time in any place where active X

pharmaceutical ingredients and medicinal products are manufactured, imported and exported.

5 There is legal authority for taking samples and submitting them to designated laboratories. X

6 There is legal authority for obtaining evidence such as documents, photographs/videos of X

premises and equipment.

7 There is legal authority to open and examine any article subjected to legislation. X .

8 There is the legal authority to seize or detain articles believed to be in violation. X

9 The legislation allows entry to a private dwelling.3 X

2 For PIC/S, the main issue is whether there is someone responsible for the compliance of the assessed authority with the Scheme’s requirements.

3 Property

PS/W 1/2005 (Rev. 2) 5 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

10 Legislation requires that the person who has the responsibility of the site where active X

pharmaceutical ingredients and medicinal products are manufactured, imported and exported, to

cooperate and not obstruct an inspector.

11 Legislation requires a marketing authorisation holder and a manufacturer of medicinal product to X .

report to the regulatory authority any serious adverse medicinal product reactions.

12 Legislation requires a marketing authorisation holder and a manufacturer of active X

pharmaceutical ingredients or of medicinal product to document any product defect impacting its

quality.

13 Legislation requires the marketing authorisation holder and the manufacturer to notify a

competent regulatory authority upon commencement of a recall of medicinal product and to X

submit pertinent information.

14 All companies that manufacture, import, export medicinal products are required to hold a

manufacturing authorisation or be identified as holder of a manufacturing authorisation or as a X

registered company for active pharmaceutical ingredients.

15 The holder of the manufacturing authorisation is required to notify the regulatory authority of

significant changes or of conditions, which may affect the quality, safety or efficacy of a X

medicinal product.

16 Legislation requires that the manufacturing authorisation include: the address of each site, the

X

manufacturing activities, the category of medicinal products and the dosage form.

17 Legislation prohibits the sale and processing of active pharmaceutical ingredients and medicinal

X

products under unsanitary conditions or leading to adulteration.

PS/W 1/2005 (Rev. 2) 6 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

18 GMPs are legal requirements. X

19 The legislation specifies that a manufacturer and/or a person is liable for a defective medicinal

X

product and provides for prosecution and/or penalties upon conviction

20 There is legislative authority to suspend, revoke or amend a manufacturing authorisation. X

21 Active pharmaceutical ingredients and medicinal products intended for exportation only are

X

covered in the legislation the same way as products intended for the domestic market.

Sub-component 1B Legislative and regulatory requirements and scope - Conflict of interest (Very important)

22 A policy/guideline exists that details the situations regarded as conflict of interest. X

23 Employees are required to declare their compliance with the conflict of interest policy. X X X

Sub-component 2A Regulatory directives and policies - Procedures for designating inspectors (Very important)

24 A process for designation of inspectors exists. X

Sub-component 2B Regulatory directives and policies - Enforcement Policies

Included under sub-component 7B. Enforcement powers and procedures - Non-compliance management.

Sub-component 2C Regulatory directives and policies - Code of conduct/ Code of ethics (Very important)

25 A policy/guideline exist that details situations regarded as Code Of Conduct/Code Of Ethics. X

Sub-component 2D Regulatory directives and policies - Training certification policies/guidelines

Included under sub-component 4C. Inspection resources - Training programme.

Sub-component 2E Regulatory directives and policies - Alert/crisis management policies/procedures/guidelines

PS/W 1/2005 (Rev. 2) 7 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

Included under sub-component 8A. Alert and crisis systems - Alert mechanisms.

Sub-component 2F Regulatory directives and policies - Organisational structure

Included under sub-component 11A. Quality management system

Sub-component 3A GMP Standards - Details/ scope of GMP (Critical)

26 GMPs are covered within a regulatory framework. X

The GMP regulatory framework covers all GMP requirements including but not limited to: X

27 Quality management, premises, equipment, personnel, sanitation, raw material testing,

manufacturing control, quality control department, packaging material testing, finished product

testing, records, samples, stability and sterile products.

Sub-component 3B GMP Standards - Process validation

Included under sub-component 3A GMP Standards - Details/ scope of GMP.

Sub-component 4A Inspection resources - Staffing: Initial qualification (Very important)

28 The minimum qualifications for GMP inspectors are defined X

29 Duties of staff involved in the GMP regulatory compliance programme are defined. X X

30 Evidence exists that the GMP inspectors meet the minimum qualifications. X

Sub-component 4B Inspection resources - Number of inspectors (Very important)

31 The number of inspectors dedicated to the GMP inspection programme is sufficient to meet the

X X

prescribed inspection frequency/inspection programme.

PS/W 1/2005 (Rev. 2) 8 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

Sub-component 4C Inspection resources - Training programme (Very important)

32 A training programme for inspectors is established and records are maintained. X X

33 A mechanism to evaluate the effectiveness of training exists. X X

Sub-component 4D Inspection resources - QA mechanism to assure effectiveness of training programme

Included under sub-component 4C Inspection resources - Training programme.

Sub-component 5A Inspection procedures - Inspection strategy (Very important)

34 Documents that describe the work expected, anticipated results and resources applied to fulfil the X X

functions of GMP inspections are available.

35 A scheduling system identifies companies due for inspections within a set time frame. X X

Sub-component 5B Inspection procedures - Pre-inspection preparation (Very important)

36 A procedure details the requirements for pre-inspection activities, and is followed. X X X

37 The inspection plan is based on the company’s GMP compliance history, critical activities and X X

type(s) of dosage forms or products manufactured.

Sub-component 5C Inspection procedures - Format and content of inspection reports (Very important)

38 A procedure for the format and content of inspection reports is available. X

39 Observations are factual and are based on proper interpretation of applicable legislation. X

40 Observations are classified/categorised according to risk. X X

41 Assessment of the company’s overall compliance rating is in line with the inspection findings. X

PS/W 1/2005 (Rev. 2) 9 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

42 Inspection reports are completed in the required reporting format and timeframe. X

Sub-component 5D Inspection procedures - Inspection methodology

Included under sub-components 5E. Inspection procedures - SOP for conducting inspections

Sub-component 5E Inspection procedures - SOP for conducting inspections (Critical)

43 A procedure details the requirements for conducting inspections and is followed. X X

44 Critical stages and parameters of manufacturing processes are assessed. X

45 Qualification and validation are assessed. X

46 The inspection plan is adjusted, where warranted, based on the findings of the inspection. X

47 The depth of the inspection is in line with the inspection findings. X

Sub-component 5F Inspection procedures - Post-inspection activities (Very important)

48 A procedure details the requirements for post-inspection activities, and is followed. X X X

49 Inspection findings and conclusions are subject to an internal review. X X X

Sub-component 5G Inspection procedures - Storage of inspection data (Important)

50 A policy/procedure is available for the storage of inspection data. X

51 An inspection report database (or archive) is maintained in a secure and controlled manner. X

Sub-component 6A Inspection performance standard - Performance standards (Very important)

Included under sub-component 11A Quality Management System - Quality management system

PS/W 1/2005 (Rev. 2) 10 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

Sub-component 7A Enforcement powers and procedures - Provision for written notice of violations

Included under sub-component 7B Enforcement powers and procedures - Non-compliance management

Sub-component 7B Enforcement powers and procedures - Non-compliance management (Critical)

52 There is provision for written notice of violations to be sent to the company. X X

53 Recall procedures/mechanisms and records are available. X X

54 GMP certificates, manufacturing authorisation suspension/withdrawal procedures/mechanisms

X X

are available and a list of suspended/withdrawn authorisations/GMP certificates is maintained.

55 Seizure procedures/mechanisms and records are available. X X

56 Prosecution procedures/mechanisms and records are available. X X

Sub-component 7C Enforcement powers and procedures - Appeal mechanism (Important)

57 Appeal procedures/mechanisms and records are available. X X

Sub-component 7D Enforcement powers and procedures - Other measures

Included under sub-components 7B Enforcement powers and procedures - Non-compliance management

Sub-component 8A Alert and crisis systems - Alert mechanisms (Critical)

58 Two-Way alert procedures/mechanisms and records are available. X X

Sub-component 8B Alert and crisis systems - Crisis management mechanisms

Included under sub-component 8A Alert and Crisis systems - Alert mechanisms

PS/W 1/2005 (Rev. 2) 11 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

Sub-component 8C Alert and crisis systems - Alert performance standards (Important)

59 Performance standards for the transmission of two-way alert and management of crisis system are X X

established and are followed.

Sub-component 9A Analytical capability - Access to laboratories (Critical)

60 The regulatory authority has access to laboratories capable of conducting necessary analyses for X X

the purpose of official testing.

61 Regulatory Authority’s or contract laboratories are qualified according to a recognised standard. X X

62 All reported products defects are documented and investigated. X X

Sub-component 9B Analytical capability - SOPs for analytical support (Very important)

63 Documents are available that detail the work expected, anticipated results and resources applied X X

to fulfil the functions of the laboratories.

64 Procedures covering all elements of laboratory operations are available and are followed. X X

Sub-component 9C Analytical capability - Validation of analytical methods (Very important)

65 The test method validation guideline is equivalent to the ICH standard and records are available. X X

Sub-component 10A Surveillance programme - Sampling and audit procedure (Very important)

66 The market surveillance programme for active pharmaceutical ingredients and medicinal X X X

products is developed involving at least the inspection and laboratory departments using risk

management principles and covers dosage forms of different medicinal product types.

67 The market surveillance programme performance is reviewed annually and records of review are X X

PS/W 1/2005 (Rev. 2) 12 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

available.

Sub-component 10B Surveillance programme - Recall monitoring

Included under sub-component 7B Enforcement powers and procedures - Non-compliance management

Sub-component 10C Surveillance programme - Consumer complaint system (Critical)

68 A consumer complaint system/procedure and records are available. X X

69 Issues of high risk are investigated immediately. X X

70 Compliance staff and or inspection staff can access complaint information. X

71 All reported products defects are documented and investigated. X

Sub-component 10D Surveillance programme - Adverse reaction reporting system/ procedures

Not evaluated - not considered within the scope of a GMP regulatory compliance programme.4

Sub-component 10E Surveillance programme - Drug Medicinal product defect reporting system/procedures

Included under sub-component 10C Surveillance programme - Consumer complaint system

Sub-component 11A Quality management system - Quality management system (Critical)

72 The quality management system is defined based on a recognised international standard. X

73 The quality manual covers all elements of GMP regulatory compliance programme. X

74 Key performance indicators (KPI) for the overall GMP regulatory compliance programme are X X X

established and available.

4 Pharmacovigilance is outside the scope of the GMP compliance programme with the exception of indicator 11.

PS/W 1/2005 (Rev. 2) 13 of 15 20 October 2014

Indicator Indicators Method of Evaluation

Number DR: Documentation Review

OSEI: On-Site Evaluation at Inspectorate

OSEL: On-Site Evaluation at Laboratory

OI: Observed Inspection

DR OSEI OSEL OI Comment

75 The quality management system has been implemented and is followed. X X

76 A documentation control system is in place. X X

77 Quality audit plans and records are available. X X

78 Management reviews ensure the performance of the quality management system on an annual X X

basis.

PS/W 1/2005 (Rev. 2) 14 of 15 20 October 2014

ANNEX TO AUDIT CHECKLIST

PIC/S ASSESSMENT & JOINT REASSESSMENT PROGRAMME

PIC/S SPECIFIC REQUIREMENTS

PIC/S requirement

Indicator Subject Comment

Where mentioned Manufacturing authorisation PIC/S accepts any equivalent system

5 Designated laboratory E.g. OMCL or other recognised

organisations

18, 26 & 27 GMP requirements PIC/S GMP Guide (or equivalent)

Additional What languages are the inspectors able to To be checked during on-site

speak? Knowledge in English? evaluation of inspectorate

Additional Availability of funds and ability to attend

PIC/S Committee meetings (twice a year),

seminars (1x / year), other training events To be checked during on-site

(Expert Circles, Joint Visits Programme, evaluation of inspectorate

etc.) as well as to participate in the

(re)assessment of authorities?

Additional Ability to pay the PIC/S annual fee? To be checked during on-site

evaluation of inspectorate

PS/W 1/2005 (Rev. 2) 15 of 15 20 October 2014

Вам также может понравиться

- Validation Protocol, HVAC I O PQДокумент52 страницыValidation Protocol, HVAC I O PQSf BztprkОценок пока нет

- Gi-Apprentice-Presentation Bf-Update-07th-March-2022-1 CompressedДокумент30 страницGi-Apprentice-Presentation Bf-Update-07th-March-2022-1 Compressedapi-190023710Оценок пока нет

- Provon 395 SFL DTA - 0719-3 PDFДокумент1 страницаProvon 395 SFL DTA - 0719-3 PDFGomez AndreОценок пока нет

- Batch Records HandoДокумент39 страницBatch Records HandoNiranjan SinghОценок пока нет

- GNCДокумент235 страницGNCyeaperОценок пока нет

- Compliance Program Program: Chapter 56: Drug Quality AssuranceДокумент29 страницCompliance Program Program: Chapter 56: Drug Quality AssuranceMin Thura OoОценок пока нет

- GMP PartiДокумент39 страницGMP ParticpkakopeОценок пока нет

- Organization Structure: L L M L L MДокумент9 страницOrganization Structure: L L M L L MNasef Mohd0% (1)

- BIS Stan 29 06 2016Документ34 страницыBIS Stan 29 06 2016reflectprakash3610Оценок пока нет

- Compliance Program Program: Chapter 56: Drug Quality AssuranceДокумент29 страницCompliance Program Program: Chapter 56: Drug Quality Assurancequality assuranceОценок пока нет

- Coriolis Firm Dairy 03 0909 Fonterra Options Going Forward 101aДокумент103 страницыCoriolis Firm Dairy 03 0909 Fonterra Options Going Forward 101acoriolisresearchОценок пока нет

- WHOPIR LPR 04-06dec2019Документ13 страницWHOPIR LPR 04-06dec20196E.57Pawar RushiОценок пока нет

- Medical Device Quality Systems Manual: A Small Entity Compliance GuideДокумент468 страницMedical Device Quality Systems Manual: A Small Entity Compliance GuideScott BeachОценок пока нет

- White Paper On UNIDO's GMP Roadmap ConceptДокумент24 страницыWhite Paper On UNIDO's GMP Roadmap Conceptiabureid7460Оценок пока нет

- Pharma Manual PDFДокумент25 страницPharma Manual PDFElena TrofinОценок пока нет

- Hep AДокумент13 страницHep ARakesh SharmaОценок пока нет

- CGMP GuidelinesДокумент23 страницыCGMP GuidelinesRyan 1112Оценок пока нет

- Protocol PQDX 241 v4 Capillary BloodДокумент18 страницProtocol PQDX 241 v4 Capillary Bloodludi100% (1)

- Herba 111Документ7 страницHerba 111Elisan BrasilОценок пока нет

- Manuf Overseas Medicines GMP Clearance 17Документ39 страницManuf Overseas Medicines GMP Clearance 17Vikram ChauhanОценок пока нет

- SamiDirect ProductsДокумент19 страницSamiDirect ProductsSamiDirectОценок пока нет

- Regulatory Affairs Strategies For C M CДокумент5 страницRegulatory Affairs Strategies For C M CfadliОценок пока нет

- Pharma CovegelenceДокумент46 страницPharma CovegelenceTilak DharОценок пока нет

- GSOP 331038 - Handling - of - Pharmaceutical - Technical - Complaints - (PTC)Документ33 страницыGSOP 331038 - Handling - of - Pharmaceutical - Technical - Complaints - (PTC)vinay patidarОценок пока нет

- Max LiquicarnДокумент2 страницыMax LiquicarnDeAnne MooreОценок пока нет

- An Overview of The US Regulatory System For OTC ProductsДокумент6 страницAn Overview of The US Regulatory System For OTC Productsanimeluis100% (1)

- APIC RSM Auditing - 201802 PDFДокумент23 страницыAPIC RSM Auditing - 201802 PDFAl RammohanОценок пока нет

- Procedure Conducting Pharmacovigilance Inspections Requested CVMP enДокумент10 страницProcedure Conducting Pharmacovigilance Inspections Requested CVMP enJasper Buss HubОценок пока нет

- Ilovepdf Merged PDFДокумент25 страницIlovepdf Merged PDFSf BztprkОценок пока нет

- Aurobindo Pharma Limited - 577033 - 062F202F2019 FDAДокумент7 страницAurobindo Pharma Limited - 577033 - 062F202F2019 FDAChandan ShahОценок пока нет

- CDRR Qpira Training: Workshop On Labeling RequirementsДокумент68 страницCDRR Qpira Training: Workshop On Labeling RequirementsAidee SmithОценок пока нет

- Assay and Dissolution EtoricoxibДокумент8 страницAssay and Dissolution Etoricoxibsesilia dyah novitrianiОценок пока нет

- Data Integrity Issues and ConcernsДокумент54 страницыData Integrity Issues and ConcernsDholakiaОценок пока нет

- Recall Program TemplateДокумент2 страницыRecall Program TemplateJanara Aline RochaОценок пока нет

- SOP On Data Integrity and Security ProcedureДокумент6 страницSOP On Data Integrity and Security Procedureislampes9100% (1)

- Mistakes in The Document PDFДокумент14 страницMistakes in The Document PDFSRI VYJAYANTHI QAОценок пока нет

- Pharmaceutical Quality Audits: A ReviewДокумент9 страницPharmaceutical Quality Audits: A ReviewHema PepakayalaОценок пока нет

- BPOG's ProtocolДокумент11 страницBPOG's ProtocolRadha Krishna B VОценок пока нет

- Pharmaceutical Product Complaints:: Causes Behind The Market ComplaintsДокумент15 страницPharmaceutical Product Complaints:: Causes Behind The Market ComplaintsKakon AhmedОценок пока нет

- Excipact StandardsДокумент96 страницExcipact Standardselighi100% (1)

- Product ComplaintsДокумент9 страницProduct ComplaintsAlejandro LlccОценок пока нет

- Avoiding Errors With The Batch Release ProcessДокумент11 страницAvoiding Errors With The Batch Release ProcessAnthony CollierОценок пока нет

- PIRIMS - Operations Manual Ver. 1.1 - Pharmaceutical CompanyДокумент38 страницPIRIMS - Operations Manual Ver. 1.1 - Pharmaceutical CompanyBilal AhmadОценок пока нет

- Data Integrity Related Observation PDFДокумент27 страницData Integrity Related Observation PDFHemant SankhalaОценок пока нет

- UV Light Efficacy TestДокумент5 страницUV Light Efficacy TestPrabha PawanОценок пока нет

- Arco Pharma Pvt. LTDДокумент16 страницArco Pharma Pvt. LTDnimeshОценок пока нет

- Medical Device Import PoliciesДокумент4 страницыMedical Device Import PoliciesRavia SharmaОценок пока нет

- Presentation Track Trace Jan 2017Документ24 страницыPresentation Track Trace Jan 2017OdunlamiОценок пока нет

- Initiation Phase Input Process OutputДокумент16 страницInitiation Phase Input Process OutputcsrinivasulureddyОценок пока нет

- SOP For Handling of Market ComplaintДокумент32 страницыSOP For Handling of Market Complaintsubbu_281Оценок пока нет

- Hazard Analysis Critical Control Point (HACCP) Standard: Prerequisite Programs ChecklistДокумент9 страницHazard Analysis Critical Control Point (HACCP) Standard: Prerequisite Programs ChecklistMar3201Оценок пока нет

- Facility DefinitionДокумент11 страницFacility DefinitionMelissa FassbenderОценок пока нет

- Regulation of Cosmetics in Japan PDFДокумент32 страницыRegulation of Cosmetics in Japan PDFMucharla Praveen KumarОценок пока нет

- Comparative Dossier Filling Procedure in The Asean, Cis and The GCC RegionДокумент35 страницComparative Dossier Filling Procedure in The Asean, Cis and The GCC Regionsandeepver88100% (1)

- Documentation Pharmaceutical IndustryДокумент102 страницыDocumentation Pharmaceutical IndustryRagulОценок пока нет

- GS002-T02 Computer System Validation Checklist v4.0Документ2 страницыGS002-T02 Computer System Validation Checklist v4.0prakashОценок пока нет

- CSV Training Course DetailsДокумент1 страницаCSV Training Course DetailsAbdul KalimОценок пока нет

- Sterlization ProtocolsДокумент10 страницSterlization ProtocolsSarathchandran BalachandranОценок пока нет

- ECDD 37th Report FINAL PrelayoutДокумент45 страницECDD 37th Report FINAL PrelayoutsppОценок пока нет

- Formulation 2Документ38 страницFormulation 2sppОценок пока нет

- US8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentsДокумент10 страницUS8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentssppОценок пока нет

- DPS 2012 3 2 300 304Документ5 страницDPS 2012 3 2 300 304sppОценок пока нет

- Zhang Asu 0010E 15975Документ148 страницZhang Asu 0010E 15975sppОценок пока нет

- CN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentsДокумент3 страницыCN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentssppОценок пока нет

- CN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentsДокумент3 страницыCN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentssppОценок пока нет

- PERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFДокумент5 страницPERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFsppОценок пока нет

- KB003Документ4 страницыKB003sppОценок пока нет

- Rapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductsДокумент12 страницRapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductssppОценок пока нет

- Studies On Cleaning Validation For A Cream and Ointment Manufacturing LineДокумент7 страницStudies On Cleaning Validation For A Cream and Ointment Manufacturing LinesppОценок пока нет

- Dareoct 19Документ6 страницDareoct 19sppОценок пока нет

- Optimization and Use of Talc in Direct Compression Tablet FormulaДокумент307 страницOptimization and Use of Talc in Direct Compression Tablet FormulasppОценок пока нет

- Composition of A Dossier To Register A Drug: The ContraindicationsДокумент2 страницыComposition of A Dossier To Register A Drug: The ContraindicationssppОценок пока нет

- Risk Assessments and Sourcing Strategies For Excipients and ApisДокумент2 страницыRisk Assessments and Sourcing Strategies For Excipients and ApissppОценок пока нет

- (PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacesДокумент16 страниц(PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacessppОценок пока нет

- MICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological LaboratoryДокумент11 страницMICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological Laboratoryspp100% (1)

- List of Units Indore SEZ PithampurДокумент4 страницыList of Units Indore SEZ PithampursppОценок пока нет

- Levofloxacin: The International PharmacopoeiaДокумент7 страницLevofloxacin: The International PharmacopoeiasppОценок пока нет

- Beta Lactam Inactivation PDFДокумент11 страницBeta Lactam Inactivation PDFsppОценок пока нет

- RAMS Example 1Документ11 страницRAMS Example 1sppОценок пока нет

- tr2608 Toc PDFДокумент10 страницtr2608 Toc PDFspp100% (1)

- Article Wjpps 1470014870Документ14 страницArticle Wjpps 1470014870sppОценок пока нет

- Intro To OptionsДокумент9 страницIntro To OptionsAntonio GenОценок пока нет

- Personal LoanДокумент49 страницPersonal Loantodkarvijay50% (6)

- Basic Tax EnvironmentДокумент8 страницBasic Tax EnvironmentPeregrin TookОценок пока нет

- Fearing GodДокумент5 страницFearing GodAnonymous d79K7PobОценок пока нет

- Charlotte BronteДокумент4 страницыCharlotte BronteJonathan BorlonganОценок пока нет

- John Carroll University Magazine Winter 2008Документ69 страницJohn Carroll University Magazine Winter 2008johncarrolluniversityОценок пока нет

- Education Rules 2012Документ237 страницEducation Rules 2012Veimer ChanОценок пока нет

- David - sm15 - Inppt - 01Документ33 страницыDavid - sm15 - Inppt - 01ibeОценок пока нет

- Oxford University Colleges' ProfilesДокумент12 страницOxford University Colleges' ProfilesAceS33Оценок пока нет

- S F R S (I) 1 - 2 1: Accounting For The Effects of Changes in Foreign Currency Exchange RatesДокумент40 страницS F R S (I) 1 - 2 1: Accounting For The Effects of Changes in Foreign Currency Exchange RatesRilo WiloОценок пока нет

- Mastery Problem (L04, 5, 6), 27: 2,500 500 0 200 100 1,300 1,500 (Expense) 2,000 0 200 100 1,300 1,000Документ2 страницыMastery Problem (L04, 5, 6), 27: 2,500 500 0 200 100 1,300 1,500 (Expense) 2,000 0 200 100 1,300 1,000Paulina OlivaresОценок пока нет

- 35 Childrens BooksДокумент4 страницы35 Childrens Booksapi-710628938Оценок пока нет

- University of Lagos: Akoka Yaba School of Postgraduate Studies PART TIME 2017/2018 SESSIONДокумент5 страницUniversity of Lagos: Akoka Yaba School of Postgraduate Studies PART TIME 2017/2018 SESSIONDavid OparindeОценок пока нет

- Unit 14 Opinion Full EssayДокумент1 страницаUnit 14 Opinion Full EssayQuân Lê ĐàoОценок пока нет

- MANUU UMS - Student DashboardДокумент1 страницаMANUU UMS - Student DashboardRaaj AdilОценок пока нет

- Final PPT of FTPДокумент29 страницFinal PPT of FTPamansrivastava007Оценок пока нет

- Bekaert BrochureДокумент14 страницBekaert BrochurePankaj AhireОценок пока нет

- MC - Unit 2Документ3 страницыMC - Unit 2pnpt2801Оценок пока нет

- Duke, Managing The Learning UniversityДокумент17 страницDuke, Managing The Learning UniversityOgarrio RojasОценок пока нет

- Determinate and GenericДокумент5 страницDeterminate and GenericKlara Alcaraz100% (5)

- 04 Chapter 3Документ13 страниц04 Chapter 3Danica Marie Baquir PadillaОценок пока нет

- James Jagger AffidavitДокумент3 страницыJames Jagger Affidavitmary engОценок пока нет

- The Power of GodДокумент100 страницThe Power of GodMathew CookОценок пока нет

- Jimenez Vizconde Lozcano V VeranoДокумент2 страницыJimenez Vizconde Lozcano V VeranoEscanorОценок пока нет

- Walt DisneyДокумент56 страницWalt DisneyDaniela Denisse Anthawer Luna100% (6)

- Rothkopf, in Prase of Cultural ImperialismДокумент17 страницRothkopf, in Prase of Cultural Imperialismmystery1871Оценок пока нет

- Oracle IRecruitment Setup V 1.1Документ14 страницOracle IRecruitment Setup V 1.1Irfan AhmadОценок пока нет

- Catalogue of CCP Publications 2021Документ75 страницCatalogue of CCP Publications 2021marcheinОценок пока нет

- Commercial Banks in IndiaДокумент14 страницCommercial Banks in IndiaAnonymous UwYpudZrAОценок пока нет

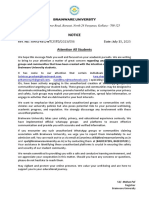

- Student Notice 2023-07-15 Attention All StudentsДокумент1 страницаStudent Notice 2023-07-15 Attention All StudentsTanmoy SinghaОценок пока нет