Академический Документы

Профессиональный Документы

Культура Документы

Pqr-Band Ring PDF

Загружено:

amitИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pqr-Band Ring PDF

Загружено:

amitАвторское право:

Доступные форматы

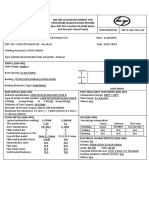

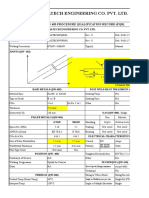

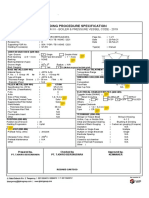

MEECO ENGINEERING

DURGAPUR,N.N BOSE ROAD

WELDER PROCEDURE QUALIFICATION RECORD AS PER ASME-IX-2015

Company Name : GE Power India Limited PG-1 OF 2

Project : NTPC RIHAND

PQR NO. : ME/GE/PQR/001 REV-0 Date : 20/07/2019

WPS No. : ME/GE/WPS/001 REV-0 Date : 18/07/2019

Welding Process : SMAW

Type :MANUAL

JOINTS ( QW 402 )

BASE METALS ( QW 403 )

P . No. 1 Group No.: 1

Material Specification IS2062 Gr. BR to IS2062 Gr. BR

Thickness of Test Coupon: :20 mm

Max.Pass Thickness Range : 20 mm Diameter of test coupon :N/A

FILLER METALS ( QW 404 )

F. No. A. No. SFA NO AWS No.(Class) : SIZE Filler wire product from Make/Brand

4 1 A5.1 E-7018 4 mm ADORE WELDING LTD Superbase X PLUS

Positions (QW 405 )

Positions of Groove :3G

Welding Progression : UPHILL

Preheat ( QW 406 )

Preheat Temp. (min.) :- : Ambient Temp.(30°c) Interpass Temp.(max.) :-: 250° C max

Post Weld Heat Treatment (QW 407 ) :N/A

Gas ( QW 408 )

Type of Gas: CO² (Shielding) N/A

Electrical Characteristics ( QW 409 )

Current Polarity Amps Volts Heat input Mode of Metal Transfer Othaers

DC Reverse 110-180 amp 20-28 v 1330 J /mm Globular na

Technique ( QW 410 )

Travel Speed :70-110mm/ min

Stringer / weave bead : :Root Run String Bead ,subsequent Weave bead where as required

Single or Multiple Electrode :Multipass

Oscillation :None

Contact Tube to Work Distance :N/A

Orifice or Gas Cup Size : :N/A

Initial and interpass Cleaning : ByWire Brushing / Grinding

Method of Gouging : By Grinding

Electrode Feed Rate :NA

Prepared By Submitted By Approved By

MEECO ENGINEERING GE POWER LTD CLIENT

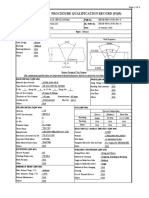

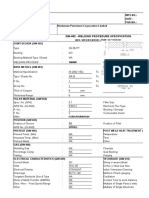

PQR NO : ME/GE/LT/PQR/001 REV-0 PG-2 OF 2

Tensile Test (QW-150)

Specimen Width Gauge size/ Ultimate Tensile Ultimate Unit Stress, Type of Failure

Area(Sq.mm)

No. in mm Thickness(mm) Total Load(kn) Mpa,N/mm² & Location

T1 19.02 20.02 380.40 180.00 478.19 At Haz

T2 19.02 20.00 380.78 185.00 485.84 At Haz

Guided- Bend Tests (QW-160)

Type of Fegure No. Bend at 180° (4t) Result

Face Bend-1 10.00 mm(t) X 20.4 mm (W) No Open Defect Satisfactory

Face Bend-2 10.02 mm(t) X 20.00 mm (W) No Open Defect Satisfactory

Root Bend-3 10.00 mm(t) X 20.00 mm (W) No Open Defect Satisfactory

Root Bend-4 10.00 mm(t) X 20.02 mm (W) No Open Defect Satisfactory

Toughness Tests (QW-170)

Specimen Specimen Test Impact Values

Noatch Location Drop Weight Break (Y/N)

No. Size Temperature ft-lb or J % Shear Mils (in). Or mm

Fillet -Weld Test (QW-180)

Result-Satisfactory: yes……NA … No……NA ………… Penetration into Parent Metal: Yes……… NA …… No……NA ……

Macro-Results …………………………NA …………………………………………………………………………………………………………….

Other Tests

Type of Test :- RADIOGRAPHY TEST

Deposite Analysis :-……As Per Reqire.

Result :-Acceptable

Other………………………………………………… NA ………………………………………………………………………………………………..

Welder's Name SAMBHU KALINDI Clock No. W-001 Stamp No. N/A

Test Conducted by :-….. TECHNO WELD,DURGAPUR-713201 Laboratory Test No:-TW/LAB/TR/204, DT- 20/07/2019

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

Test Witness By: AMIT KUMAR DUTTA

Manufacturer -MEECO ENGINEERING

Date:-20/07/2019 Certified by:-

(Detail of record of tests are illustrative only and may be modified to conform to the type and number of tests required by the Code.)

Prepared By Submitted By Approved By

MEECO ENGINEERING GE POWER LTD CLIENT

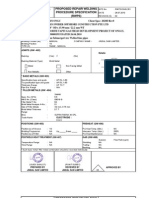

MEECO ENGINEERING

DURGAPUR,N.N BOSE ROAD

LIQUID PENETRANT TEST REPORT

Report No: ME/GE/NTPC/LPT/-01

NTPC RIHAND (Restraining Band For 12E10 Mill)

Date of Testting: 20/07/2019

Main Contractor: GE POWER INDIA LTD. Manufacturer: MEECO ENGINEERING, DURGAPUR-713211

Material Spec: IS 2062 E250 A to IS 2062 E250 A Wekding Process-SMAW

QAP No & Rev no: GEPIL/ QA /FAB/12E10MILL/01 REV-02

Drawing No & rev no: SW-FMS-F-123, REV-04

date: 15.01.2019

Test Procedure:- ASME Sec-V Article -6 CL No- 8.3 & 8.4 Acceptance Criteria :-ASME Sec. VIII Division 1, Appendix-8

Item Make Batch NO Exppiry Date Surface Temperature 33°C-35°C

Cleaner ORION 115 C R/004/2018 Nov-19 Humidity (Rh) 70-80%

Penetrant ORION 115 P P/003/2018 Dec-19 Penetration Time 10 Minutes

Developer ORION 115 D D/010/2018 Nov-19 Developing Time 10 Minutes

Surface Condition : As welded As Machine : As Ground

: others……

Time of Execution : As welding After PWHT : other………..

Scope of Examination : Base Metal Edge Preparation : Back Chipping

: Weld Part Repair Weld : other………..

Post Cleaning :- Yes (cleaning done in one direction only)

Sl. Part No/ Type remarks

No Identification of Joint Extent of Check Observation

Butt No Significant

100% Satisfactory

Test Sample (IS 2062 E 250 BR TO E 250 BR) weld joint Defects Observed.

1

Ref- : ME/GE/PQR/001 REV-0 No Significant

VT 100% Satisfactory

Defects Observed.

sketch (if any)

MEECO ENGINEERING GE POWER LTD CLIENT

signature AMIT KUMAR DUTTA

date 7/20/2019

Вам также может понравиться

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- PQR With-PwhtДокумент2 страницыPQR With-PwhtKarthikОценок пока нет

- PQR 03 2014Документ2 страницыPQR 03 2014vinuОценок пока нет

- PQR GmawДокумент4 страницыPQR GmawEr Sumant Kumar Singh0% (1)

- Bdde PQR CS 001Документ2 страницыBdde PQR CS 001mainur mechanical engineer0% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Документ2 страницыPhuBia-WPS-AWS D1.1-8-6-2011poulmackОценок пока нет

- Procedure Qualification RecordДокумент6 страницProcedure Qualification RecordGaurang PandyaОценок пока нет

- QW 482 WPSДокумент2 страницыQW 482 WPSsmit patelОценок пока нет

- Gta+sma PQRДокумент3 страницыGta+sma PQRRahul MoottolikandyОценок пока нет

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaДокумент5 страницBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaОценок пока нет

- WPS CuNiДокумент4 страницыWPS CuNiSripathyОценок пока нет

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeДокумент2 страницыWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraОценок пока нет

- Rev 2 - Proposed Repair WPSДокумент2 страницыRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Документ20 страницWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Документ10 страницForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamОценок пока нет

- Arl-Al - WPS-001 PDFДокумент2 страницыArl-Al - WPS-001 PDFrajuajiОценок пока нет

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Документ4 страницыWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86Оценок пока нет

- Page No: 01: SA 240 GR 304 SA 240 GR 304Документ5 страницPage No: 01: SA 240 GR 304 SA 240 GR 304jobertОценок пока нет

- KP WPS PQR GTAW FCAWДокумент1 страницаKP WPS PQR GTAW FCAWwahyuОценок пока нет

- QW 483 - PQR (Gtaw+smaw) 04.01.17Документ8 страницQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiОценок пока нет

- PQR Format PDFДокумент2 страницыPQR Format PDFHarshit Adwani100% (2)

- WCBДокумент5 страницWCBSuresh KrishnanОценок пока нет

- 37507022-WPS-PQR-SS-316 LДокумент5 страниц37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- PQR - Camsa-02Документ1 страницаPQR - Camsa-02Jean Carlo Gutarra SocualayaОценок пока нет

- PQR A106 HAL-1Документ1 страницаPQR A106 HAL-1Budi Setia RahmanОценок пока нет

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Документ23 страницыTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderОценок пока нет

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Документ2 страницыASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- PQR - PipeДокумент3 страницыPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Документ3 страницыWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanОценок пока нет

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateДокумент3 страницыJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanОценок пока нет

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewДокумент4 страницы(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaОценок пока нет

- WPS 01 - Pipe - SSДокумент1 страницаWPS 01 - Pipe - SSAdvanced Quality Centre AQCОценок пока нет

- Final PQRДокумент130 страницFinal PQRAhamed Naufal CaОценок пока нет

- WPS PQRДокумент126 страницWPS PQRBuditama ChandranegaraОценок пока нет

- PhuBia-WPS-AWS D1.1-8-6-2011Документ3 страницыPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- WpsДокумент3 страницыWpsPankaj KumarОценок пока нет

- Manual Joints (QW - 402) : Page 1 of 12Документ12 страницManual Joints (QW - 402) : Page 1 of 12miteshpatel191Оценок пока нет

- WPS BhelДокумент2 страницыWPS BhelpradhankruhsnaОценок пока нет

- WPS 10Документ2 страницыWPS 10Arab WeldersОценок пока нет

- WC9Документ5 страницWC9Suresh KrishnanОценок пока нет

- Procedure Qualification SpecificationДокумент4 страницыProcedure Qualification Specificationriyas.hvacworkОценок пока нет

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelДокумент3 страницыWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanОценок пока нет

- WPS Dissimilar 11.08 MM Max.Документ4 страницыWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Документ2 страницыBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyОценок пока нет

- 03 WPS PQR For FCAWДокумент3 страницы03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Welding Procedure Specification (WPS) : Supporting PQR 01Документ2 страницыWelding Procedure Specification (WPS) : Supporting PQR 01duyanhОценок пока нет

- Swathi Industries: JOINT (QW 402)Документ10 страницSwathi Industries: JOINT (QW 402)Mustu AkolawalaОценок пока нет

- PQR PT Bse WPS 07Документ2 страницыPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraОценок пока нет

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeДокумент4 страницыQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86Оценок пока нет

- QW-483 (Green) PQR No.: Tme 356Документ1 страницаQW-483 (Green) PQR No.: Tme 356Sudhir KotkarОценок пока нет

- MHC Conveying System Private Limited: JOINTS (QW-402)Документ3 страницыMHC Conveying System Private Limited: JOINTS (QW-402)Lipika GayenОценок пока нет

- WPS-ASME-007-1 Rev0Документ1 страницаWPS-ASME-007-1 Rev0Ahmed LepdaОценок пока нет

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Документ6 страницMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaОценок пока нет

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Документ6 страницMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajОценок пока нет

- QW-483 (BACK) PQR No.: Tme 356Документ1 страницаQW-483 (BACK) PQR No.: Tme 356Sudhir KotkarОценок пока нет

- QW-483 (Red) PQR No.: Tme 358Документ1 страницаQW-483 (Red) PQR No.: Tme 358Sudhir KotkarОценок пока нет

- WpsДокумент2 страницыWpssamer8saifОценок пока нет

- WPS-ASME-009-1 Rev1Документ1 страницаWPS-ASME-009-1 Rev1Ahmed LepdaОценок пока нет

- GelDoc XR Sole Source SpecificationsДокумент3 страницыGelDoc XR Sole Source SpecificationsdnajenОценок пока нет

- Biochemistry & Molecular Biology Journal - Open Access JournalДокумент2 страницыBiochemistry & Molecular Biology Journal - Open Access JournalManjida RahmanОценок пока нет

- Bolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Документ2 страницыBolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Manoj MulikОценок пока нет

- Gas Arc Welding - GMAW and GTAW Gas Arc Welding - GMAW and GTAWДокумент3 страницыGas Arc Welding - GMAW and GTAW Gas Arc Welding - GMAW and GTAWJulioОценок пока нет

- Food Che. W1-4Документ177 страницFood Che. W1-4mihael jhnsОценок пока нет

- Gas Laws Practice Test - Ans. KeyДокумент4 страницыGas Laws Practice Test - Ans. Keycabbiemartinez100% (1)

- Rser D 16 02436R1Документ88 страницRser D 16 02436R1Jitender KaushalОценок пока нет

- Pre-Lab 8Документ1 страницаPre-Lab 8SaulS.DiazОценок пока нет

- Digital PH Sensor Orbisint CPS11D: Memosens Glass Electrode For Standard ApplicationsДокумент3 страницыDigital PH Sensor Orbisint CPS11D: Memosens Glass Electrode For Standard ApplicationsAchmad KОценок пока нет

- Icml Mla IДокумент3 страницыIcml Mla IDeepak100% (1)

- LIB (Lithium Ion Battery)Документ27 страницLIB (Lithium Ion Battery)Ericke Nandita MaharaniОценок пока нет

- Datasheet For Vent ScrubberДокумент5 страницDatasheet For Vent ScrubbercliffrajjoelОценок пока нет

- Ecofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaДокумент22 страницыEcofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaARYAN RATHOREОценок пока нет

- Petronas Samur PL PDFДокумент38 страницPetronas Samur PL PDFJessica Ward100% (1)

- Elements and Compounds PowerPointДокумент19 страницElements and Compounds PowerPointRelayer 66Оценок пока нет

- GDL 10 Series Gas Diffusion Layer: SigracetДокумент2 страницыGDL 10 Series Gas Diffusion Layer: SigracetAhmed Emad AhmedОценок пока нет

- How To Make An Atomic BombДокумент30 страницHow To Make An Atomic Bombarjun vijay100% (3)

- Fiitjee PDT Courseware FTRE - 8th Moving To 9th-PHY-ColourДокумент10 страницFiitjee PDT Courseware FTRE - 8th Moving To 9th-PHY-ColourYASHОценок пока нет

- COMEDK Important Topics and Revised SyllabusДокумент49 страницCOMEDK Important Topics and Revised SyllabusVishal VermaОценок пока нет

- Pureit Excella User Manual PDFДокумент31 страницаPureit Excella User Manual PDFengrmfawadazharОценок пока нет

- Focuse Ion BeamДокумент34 страницыFocuse Ion BeamAhsan SaleemОценок пока нет

- Isolation of Caffeine From A Tea BagДокумент7 страницIsolation of Caffeine From A Tea BagShahriman Radzi67% (6)

- Surface Tension Article 1Документ3 страницыSurface Tension Article 1Dr-Aqsa KhannОценок пока нет

- SorptionДокумент44 страницыSorptionluckyprimeОценок пока нет

- Ishrae PPT On RefrigerantДокумент9 страницIshrae PPT On RefrigerantJigar ShahОценок пока нет

- CPP & Cqa PDFДокумент71 страницаCPP & Cqa PDFanon_695264516100% (1)

- Green Pesticides For Organic Farming Occurrence and Properties of Essential Oils For Use in Pest ControlДокумент25 страницGreen Pesticides For Organic Farming Occurrence and Properties of Essential Oils For Use in Pest ControlteguhwidiartoОценок пока нет

- 206 ManualДокумент16 страниц206 ManualNikshit RafaliyaОценок пока нет

- hssc0500t Chaptest AДокумент6 страницhssc0500t Chaptest AAseel AburajabОценок пока нет

- Chitin and Chitosan: Structure, Properties and Applications in Biomedical EngineeringДокумент14 страницChitin and Chitosan: Structure, Properties and Applications in Biomedical EngineeringTrần QuangОценок пока нет