Академический Документы

Профессиональный Документы

Культура Документы

AAR Manual of Standards and Recommended Practices

Загружено:

Fabiano OliveiraИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AAR Manual of Standards and Recommended Practices

Загружено:

Fabiano OliveiraАвторское право:

Доступные форматы

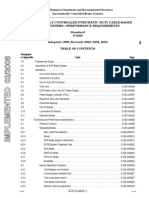

SECTION 9

FREIGHT VEHICLE COUPLERS AND DRAFT GEAR

ROA MANUAL

SCHEDULE OF AMENDMENTS

SECTION 9

AMENDMENT PAGES AMENDMENT DATE

NUMBER AMENDED SUMMARY ISSUED

TABLE OF CONTENTS

Section Description Page No.

9.1 SCOPE........................................................................................................................................................ 9-1

9.2 COUPLERS ................................................................................................................................................ 9-1

9.2.2 Types........................................................................................................................................................... 9-1

9.3 COUPLER LENGTHS ................................................................................................................................ 9-2

9.4 UNCOUPLING OPERATION ..................................................................................................................... 9-2

9.5 OFFSET SHANKS...................................................................................................................................... 9-2

9.6 YOKE .......................................................................................................................................................... 9-2

9.7 YOKE PIN ................................................................................................................................................... 9-2

9.8 DRAFT GEAR FOLLOWER....................................................................................................................... 9-3

9.9 RIGID DRAWBARS.................................................................................................................................... 9-3

9.10 SLACKLESS DRAWBARS........................................................................................................................ 9-3

9.11 ARTICULATED CONNECTOR .................................................................................................................. 9-4

9.12 DRAFT GEAR............................................................................................................................................. 9-4

9.13 CUSHIONING DEVICES ............................................................................................................................ 9-4

Diagram 9-1 Standard Coupler.................................................................................................................................................... 9-5

Diagram 9-2 Interlocking Coupler ................................................................................................................................................ 9-6

Diagram 9-3 Standard Yoke ........................................................................................................................................................ 9-7

Diagram 9-4 Yoke Pin.................................................................................................................................................................. 9-8

Diagram 9-5 Standard Follower ................................................................................................................................................... 9-9

Diagram 9-6 Interlocking Follower ............................................................................................................................................. 9-10

9.1 SCOPE

9.1.1 This Section describes the minimum requirements for drawgear components for new freight vehicles including

those which have been substantially modified or reconstructed.

9.1.2 It includes requirements for couplers, yokes, pins, draft gear, followers, draw bars, articulated connectors and

cushioning devices.

9.1.3 Except where stipulated otherwise, all components described herein shall comply with the relevant requirements

of Sections B and BII of the AAR Manual of Standards and Recommended Practices.

9.2 COUPLERS

9.2.1.1 The coupler shall be in accordance with Diagrams 9-1 or 9-2 as specified hereafter.

9.2.1.2 The coupler shown on Diagram 9-1 is based on the AAR E/F Coupler with the shank, butt and pin hole modified

as shown for Australian operations. Relevant AAR specifications are:

(a) S-108: Standard 'E/F' Coupler

(b) S-109: Standard 'E/F' Coupler

(c) S-155: Standard 'E' Coupler, Double Shelf

(d) S-165: Standard 'E' Coupler, Bottom Shelf

(e) S-170: Standard 'E' Coupler, Bottom Shelf

9.2.1.3 The coupler shown on Diagram 9-2 is identical to the AAR 'F' Interlocking Coupler except for the shank length.

Relevant AAR Specifications are:

(a) S-110: Standard 'F' Coupler (29.25")

(b) S-112: Standard 'F' Coupler (43")

(c) S-114: Standard 'F' Coupler (60")

9.2.1.4 Couplers to Diagram 9-1 shall have the No.10A contour to AAR Standard S-106.

Couplers to Diagram 9-2 shall have the 'F' Interlocking contour to AAR Standard S-117.

9.2.1.5 Coupler material shall be cast steel to:

AAR Specification M-201 Grade E - with the impact test at 0Oc acceptable

or alternatively

AS 2074 Grade L6B2 - with Charpy impact test at 0oC to AS 1544, Part 2, 3 tests required, average energy 27J

minimum, and no individual test less than 20J

9.2.2 TYPES

New or substantially modified vehicles shall be fitted only with the following types of couplers.

9.2.2.1 All vehicles, except tank cars for the conveyance of dangerous goods in bulk, shall conform to the requirements of

Diagram 9-1 with a bottom shelf or Diagram 9-2 with bottom shelf if interlocking couplers are required.

9.2.2.2 Tank cars for the conveyance of dangerous goods in bulk shall be fitted with couplers conforming to Diagram 9-1

with top and bottom shelves (double shelf type).

9.2.2.3 The use of interlocking couplers to Diagram 9-2 requires a flexible coupler carrier to be fitted to the vehicle to

accommodate relative vertical displacement of the coupled vehicles.

9.2.2.4 Special purpose couplers for rotary-dump operations etc may be fitted where required. These couplers shall

comply with all relevant aspects of this section and AAR requirements, with the impact and Charpy tests as

specified in Clause 9.2.1.5.

9-1 Adopted 18/9/91

9.3 COUPLER LENGTHS

9.3.1 The length of the coupler shall be in accordance with the dimensions given on Diagrams 9-1 and 9-2, and

selected to ensure compliance with the operational parameters of the L/V ratio and curve negotiability specified in

Section 8 of this Manual.

9.4 UNCOUPLING OPERATION

9.4.1 Top operated couplers, straight lift, shall be fitted to all vehicles except where the protrusion of the uncoupling

mechanism above the coupler may:

(a) Render the mechanism prone to damage or fouling, eg flat cars, container cars etc

OR

(b) Interfere with or hinder normal loading, unloading or operation of the vehicle, eg TOFC cars, motor car

carriers, livestock cars with end doors, etc. In these circumstances, couplers with rotary lift bottom

operation shall be used.

9.5 OFFSET SHANKS

9.5.1 The minimum deck/floor heights specified in other Sections of this Manual provide for the use of straight shank

couplers. Couplers with offset shanks are not required for vehicles which comply with these requirements.

9.5.2 Special purpose vehicles, for which a deck height lower than that specified is desired, may be fitted with couplers

having a vertical offset between coupler head and shank of 35 mm.

9.5.3 The use of offset couplers is undesirable and vehicle design shall incorporate, wherever possible, the structural

alternatives which permit straight shank couplers to be installed at the standard coupler height.

9.6 YOKE

9.6.1 The yoke for use with couplers to Diagrams 9-1 and 9-2 shall conform to Diagram 9-3. It shall comply with AAR

Standard S-149, except that the pin hole shall be bushed and a manganese steel wear plate fitted as shown. The

material shall be as specified in Clause 9.2.1.5.

9.6.2 Yokes for use with special purpose couplers shall also comply with 9.6.1 where appropriate, modified as required

to suit the coupler design.

9.6.3 Manufacture and acceptance shall be generally in accordance with AAR Specifications S-118 and M-211.

9.7 YOKE PIN

9.7.1 The yoke pin for use with couplers to Diagrams 9-1 and 9-2 shall be of 89 mm nominal diameter as shown on

Diagram 9-4.

9.7.2 The yoke pin for use with special-purpose couplers shall have a load capacity, as installed, at least equivalent to

that of the pin specified in 9.7.1.

9-2 Adopted 18/9/91

9.7.3 Pins shall comply with AAR Specification M-118. Alternative materials to that specified are:

(a) AS 2506/4140T

(b) AS 2506/X9931T

9.8 DRAFT GEAR FOLLOWER

9.8.1 The follower for use with couplers to Diagram 9-1 shall conform to the requirements of Diagram 9-5.

9.8.2 The follower for use with couplers to Diagram 9-2 shall conform to AAR Standard S-119, catalogue number

Y46AE, as indicated on Diagram 9-6.

9.8.3 Followers for use with special purpose couplers shall be designed and manufactured to suit the installation.

9.8.4 All followers shall be manufactured from cast steel with the material as specified in Clause 9.2.1.5.

9.9 RIGID DRAWBARS

9.9.1 Rigid drawbars are permitted to permanently connect two or more vehicles where the facility for uncoupling in

service is not required.

9.9.2 The rigid drawbar may be connected to a standard yoke and draft gear in each vehicle with standard pins, or to

end-of-car cushioning devices.

9.9.3 The drawbar ends and shank dimensions shall be identical to those of the interlocking coupler, Diagram 9-2. The

length of the drawbar shall be selected to comply with the parameters of the L/V ratio and curve negotiability

specified in Section 8 of this Manual, and to provide the required operational clearance between adjacent

vehicles.

9.9.4 The drawbars shall be manufactured from cast steel with the material as specified in Clause 9.2.1.5. or be

fabricated from steel.

9.9.5 The drawbar and components shall be designed to withstand longitudinal buff and draft forces equivalent to those

of the couplers, Clause 9.2.

9.10 SLACKLESS DRAWBARS

9.10.1 Slackless drawbars are permitted to permanently connect two or more vehicles where the facility for uncoupling in

service is not required and where there is a need to minimise train slack.

9.10.2 The slackless drawbar shall connect to each vehicle with an assembly incorporating components for load transfer

and self adjustment of wear induced slack, without draft gear.

9.10.3 The drawbar shall be designed to permit movement in the vertical and lateral planes.

9.10.4 The length of the drawbar shall be selected to comply with the parameters of L/V ratio and curve negotiability

specified in Section 8 of this Manual, and to provide the required operational clearance between adjacent

vehicles.

9.10.5 The slackless drawbars shall be manufactured from cast steel with the material as specified in Clause 9.2.1.5, or

be fabricated from steel.

9.10.6 The slackless drawbar and components shall be designed to withstand longitudinal buff and draft forces

equivalent to those of the couplers, Clause 9.2.

9-3 Adopted 18/9/91

9.11 ARTICULATED CONNECTOR

9.11.1 Articulated connectors are used to permanently couple adjacent units sharing a common bogie and forming part

of an articulated vehicle.

9.11.2 The connectors shall consist of inter-connecting male and female components, each permanently attached to the

end structure of the vehicle units. The two components shall be permanently coupled at assembly by means of a

vertical pin with positive retention.

9.11.3 The connector shall be designed to permit rotation in the longitudinal, vertical and lateral planes, with sufficient

internal clearance to permit the vehicle to be lifted clear of the bogie.

9.11.4 Longitudinal buff forces shall be transmitted by direct contact between the mating components; draft forces shall

be transmitted through the connecting pins.

9.11.5 The connector assembly shall incorporate components for load transfer and self-adjustment of wear induced

slack.

9.11.6 The female component shall incorporate a spigot, equivalent to a body centre plate, to mate with the bogie centre

plate and include provision for a bogie centre pin.

9.11.7 The minimum capacity for angular rotation when installed shall be:

(a) Vertical plane (concave and convex) : 7o30'

(for undulations and lifting)

(b) Horizontal plane : ±18o

(for curving)

(c) Lateral roll : ±5o

(for twist)

9.11.8 The connector and components shall be designed to withstand longitudinal buff and draft forces equivalent to

those of the couplers, Clause 9.2.

9.12 DRAFT GEAR

9.12.1 All draft gear shall comply with the requirements of AAR Specifications M-901E and M-901F, M-901G or M-901H.

9.12.2 Draft gears purchased as second-hand or reconditioned shall be certified as complying with the requirements of

AAR Specification M-901B.

9.13 CUSHIONING DEVICES

9.13.1 Cushioning devices provide energy absorption over a greater travel than that provided by standard draft gear, and

may be installed at the centre of the car or at the end of the car.

9.13.2 New cushioning devices shall comply with the requirements of AAR Specification M-921A and have AAR

approval.

9.13.3 Devices purchased as reconditioned shall be certified as complying with the requirements of AAR Specification M-

921C.

9-4 Adopted 18/9/91

DIAGRAM 9-1

STANDARD COUPLER

9-5 Adopted 18/9/91

DIAGRAM 9-2

INTERLOCKING COUPLER

9-6 Adopted 18/9/91

DIAGRAM 9-3

STANDARD YOKE

PAGE NOT IN ORIGINAL

PRINTED DOCUMENT

9-7 Adopted 18/9/91

DIAGRAM 9-4

YOKE PIN

9-8 Adopted 18/9/91

DIAGRAM 9-5

STANDARD FOLLOWER

9-9 Adopted 18/9/91

DIAGRAM 9-6

INTERLOCKING FOLLOWER

9-10 Adopted 18/9/91

Вам также может понравиться

- AAR Manual of Standards and Recommended PracticesДокумент610 страницAAR Manual of Standards and Recommended PracticesFabiano Oliveira100% (9)

- UIC 510-2 4th Edition - 2004 Trailing Stock Wheels and Wheelsets - Conditions Concerning The Use of Wheels of Various Diameters PDFДокумент75 страницUIC 510-2 4th Edition - 2004 Trailing Stock Wheels and Wheelsets - Conditions Concerning The Use of Wheels of Various Diameters PDFDouglas100% (1)

- Aar M 101-2016 PDFДокумент20 страницAar M 101-2016 PDFigportales86% (7)

- AAR M201 SpecificationДокумент8 страницAAR M201 Specificationigormetaldata67% (3)

- Capacity UIC 406Документ26 страницCapacity UIC 406terre100% (1)

- Uic 505 Rolling StockДокумент122 страницыUic 505 Rolling StockJose Saravia67% (3)

- AAR Spec S-4200Документ58 страницAAR Spec S-4200wizlish100% (1)

- Manual For Railway EngineeringДокумент2 страницыManual For Railway EngineeringTAMIL0% (3)

- ANSI - HI 9.6.2-2001 Centrifugal and Vertical Pumps For Allowable Nozzle Loads PDFДокумент46 страницANSI - HI 9.6.2-2001 Centrifugal and Vertical Pumps For Allowable Nozzle Loads PDFRoro83% (6)

- Aar M-101Документ180 страницAar M-101Marcos PerezОценок пока нет

- Indonesian Railway Technical Standard For Track WorkДокумент41 страницаIndonesian Railway Technical Standard For Track WorkLatifa Pradipta100% (1)

- Norma AAR Rodas EixosДокумент164 страницыNorma AAR Rodas Eixosnandoreis123100% (2)

- AAR Section A - Part I - 2016Документ110 страницAAR Section A - Part I - 2016GstavinОценок пока нет

- Norma AAR Rodas Eixos PDFДокумент164 страницыNorma AAR Rodas Eixos PDFRafael Schelbauer100% (3)

- Association of American Railroads: Manual of Standards Recommended Practices Section A, Part IДокумент76 страницAssociation of American Railroads: Manual of Standards Recommended Practices Section A, Part IShiv Pandey0% (1)

- 2018 Aar - MSRP A1Документ118 страниц2018 Aar - MSRP A1wilian_coelho33090% (1)

- MSRP-K2 05Документ390 страницMSRP-K2 05Daniel VargasОценок пока нет

- MSRP I04Документ218 страницMSRP I04Daniel Vargas100% (2)

- MSRP-S 10Документ366 страницMSRP-S 10Diógenes da Silva Pereira100% (1)

- Aar S2 (2007)Документ470 страницAar S2 (2007)wilian_coelho330950% (2)

- AAR - M 107 - M 208 2009 Wheels, Carbon SteeLДокумент36 страницAAR - M 107 - M 208 2009 Wheels, Carbon SteeLUlises Quintana Carhuancho100% (1)

- Volume 1 - Bogie Maintenance ManualДокумент276 страницVolume 1 - Bogie Maintenance ManualManjunath AithalОценок пока нет

- AAR StandsДокумент218 страницAAR Standslinh caca huynhОценок пока нет

- Railroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975От EverandRailroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975Arnold D. KerrРейтинг: 5 из 5 звезд5/5 (1)

- Astm d1250 Petroleum Measurement TablesДокумент3 страницыAstm d1250 Petroleum Measurement TablesMalayarasan Silo Ratnam75% (4)

- MSRP A1 PDFДокумент92 страницыMSRP A1 PDFFelora Mangawang100% (1)

- Norma AAR M101 Axle 2007Документ22 страницыNorma AAR M101 Axle 2007CarlosОценок пока нет

- Association of American RailroadsДокумент350 страницAssociation of American Railroadsanandandmeena100% (1)

- Aar M 101 PDFДокумент180 страницAar M 101 PDFRafael Schelbauer100% (2)

- Para Conhecimento: Manual of Standards Recommended Practices Section S-IiiДокумент108 страницPara Conhecimento: Manual of Standards Recommended Practices Section S-Iiiwilian_coelho3309Оценок пока нет

- Air Brakes For TrainsДокумент28 страницAir Brakes For Trainsmakili8Оценок пока нет

- Aar H (2009)Документ150 страницAar H (2009)Rogerio Tropia GranjaОценок пока нет

- AAR Manual of StandardsДокумент40 страницAAR Manual of StandardsKristian Marchena100% (3)

- MSRP A1Документ96 страницMSRP A1ashishkesharwaniОценок пока нет

- Capitulo BasicoДокумент82 страницыCapitulo BasicoAnonymous aZrC1EZ100% (1)

- Seccion AДокумент76 страницSeccion ACELUZZ100% (1)

- Rail SectionsДокумент32 страницыRail Sectionsdarkwing888100% (1)

- Association of American Railroads: Manual of Standards Recommended Practices Section A, Part IДокумент92 страницыAssociation of American Railroads: Manual of Standards Recommended Practices Section A, Part ILaurence MichaelОценок пока нет

- Detalle de Enganches y Abrazaderas Msrp-s3 - 07Документ108 страницDetalle de Enganches y Abrazaderas Msrp-s3 - 07Francisco ReyesОценок пока нет

- Simpack Wheel-Rail Training BASICДокумент88 страницSimpack Wheel-Rail Training BASICbalaji817150100% (5)

- LATEST RWF-Prop-1-cast-vs-forge-modifiedДокумент8 страницLATEST RWF-Prop-1-cast-vs-forge-modifiedDevarshi GaurОценок пока нет

- Coil Spring Groups: Engineering Standard Rolling StockДокумент10 страницCoil Spring Groups: Engineering Standard Rolling Stockoliveira1305Оценок пока нет

- Association of American Railroads: Manual of Standards Recommended PracticesДокумент20 страницAssociation of American Railroads: Manual of Standards Recommended PracticesFabiano OliveiraОценок пока нет

- ESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockДокумент57 страницESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockRafael SchelbauerОценок пока нет

- M-1002 MSRP-C3 - 2014Документ664 страницыM-1002 MSRP-C3 - 2014A Reed100% (1)

- Aar M-201-00 Steel CastingsДокумент10 страницAar M-201-00 Steel CastingsfeelingsudoОценок пока нет

- I S En13231-3-2012Документ8 страницI S En13231-3-2012Ali BdaОценок пока нет

- AAR Manual of Standards and Recommended PracticesДокумент37 страницAAR Manual of Standards and Recommended PracticesFabiano OliveiraОценок пока нет

- EN 13261-2009 EnglezaДокумент57 страницEN 13261-2009 EnglezaTanase FanelОценок пока нет

- Go To IndexДокумент38 страницGo To IndexAMIT KUMARОценок пока нет

- Must Change Item During ROH & POHДокумент25 страницMust Change Item During ROH & POHRakesh JainwalОценок пока нет

- Wabtec Freight Car Components Truck System Overview Rev 1 OCT 21Документ14 страницWabtec Freight Car Components Truck System Overview Rev 1 OCT 21bgnyvawrОценок пока нет

- EN 13749pr - en - 2008-11Документ47 страницEN 13749pr - en - 2008-11Zainal MahfudОценок пока нет

- AAR - G Section 2 - WHEEL & AXLE MANUALДокумент200 страницAAR - G Section 2 - WHEEL & AXLE MANUALManoj KumarОценок пока нет

- Braking DistanceДокумент11 страницBraking Distancekr_abhijeet72356587100% (1)

- Bec in CouplerДокумент27 страницBec in Couplerbec foundryОценок пока нет

- EC135 P2+ Section 9.1 Rev 11Документ132 страницыEC135 P2+ Section 9.1 Rev 11Giordano DassiОценок пока нет

- Detail Design of Crane Runway Girders - bk105 PDFДокумент6 страницDetail Design of Crane Runway Girders - bk105 PDFTiago CastelaniОценок пока нет

- Vessel Lifting Lugs: Two-Plate Type: Engineering StandardДокумент9 страницVessel Lifting Lugs: Two-Plate Type: Engineering StandardJamil AhmadОценок пока нет

- CP Propeller Equipment PDFДокумент22 страницыCP Propeller Equipment PDFHtet Myat SoeОценок пока нет

- Boiler Parts - List CB CB 250 350Документ46 страницBoiler Parts - List CB CB 250 350zacccccОценок пока нет

- AUTODYN - Chapter 11 - Parallel - Processing PDFДокумент42 страницыAUTODYN - Chapter 11 - Parallel - Processing PDFFabiano OliveiraОценок пока нет

- AUTODYN - Chapter 2 - AUTODYN - User - Interface PDFДокумент17 страницAUTODYN - Chapter 2 - AUTODYN - User - Interface PDFFabiano OliveiraОценок пока нет

- AUTODYN - Chapter 7 - ALE - SolverДокумент9 страницAUTODYN - Chapter 7 - ALE - SolverFabiano OliveiraОценок пока нет

- AUTODYN - Chapter 10 - Eul - Lag - Int PDFДокумент33 страницыAUTODYN - Chapter 10 - Eul - Lag - Int PDFFabiano OliveiraОценок пока нет

- Itd Ti T Ansys Introduction To ANSYS Autodyn: CH T 6 Euler Blast (Ideal Gas) SolverДокумент11 страницItd Ti T Ansys Introduction To ANSYS Autodyn: CH T 6 Euler Blast (Ideal Gas) SolverFabiano OliveiraОценок пока нет

- AUTODYN - Chapter 8 - MeshFree - SolverДокумент16 страницAUTODYN - Chapter 8 - MeshFree - SolverFabiano OliveiraОценок пока нет

- AUTODYN - Chapter 9 - Material - Models PDFДокумент47 страницAUTODYN - Chapter 9 - Material - Models PDFFabiano OliveiraОценок пока нет

- AUTODYN - Chapter 5 - MM - Euler - Solver PDFДокумент13 страницAUTODYN - Chapter 5 - MM - Euler - Solver PDFFabiano OliveiraОценок пока нет

- WB StatesДокумент10 страницWB Statesfajar_dОценок пока нет

- Autodyn Chapter 1 Intro To AutodynДокумент28 страницAutodyn Chapter 1 Intro To AutodynwwwwwwwОценок пока нет

- Autodyn Chapter 3 Autodyn BasicsДокумент32 страницыAutodyn Chapter 3 Autodyn Basicschristiandroguett100% (2)

- AUTODYN - Chapter 4 - AUTODYN - and - Workbench PDFДокумент11 страницAUTODYN - Chapter 4 - AUTODYN - and - Workbench PDFFabiano OliveiraОценок пока нет

- Introduction WBДокумент21 страницаIntroduction WBBarathan RamachandranОценок пока нет

- WB Connections PDFДокумент15 страницWB Connections PDFFabiano OliveiraОценок пока нет

- Stuck Draft Gear Procedure ManualДокумент9 страницStuck Draft Gear Procedure ManualFabiano OliveiraОценок пока нет

- ASCProductGuideRev7 PDFДокумент101 страницаASCProductGuideRev7 PDFFabiano OliveiraОценок пока нет

- TG-001 2 PDFДокумент6 страницTG-001 2 PDFoliveira1305Оценок пока нет

- Autodesk Inventor Nastran Editor 2020 User's ManualДокумент60 страницAutodesk Inventor Nastran Editor 2020 User's Manualoliveira1305Оценок пока нет

- TG 002 PDFДокумент6 страницTG 002 PDFoliveira1305Оценок пока нет

- SK-3103 SBX InstallationДокумент1 страницаSK-3103 SBX InstallationFabiano OliveiraОценок пока нет

- Investigations of Derailments 2015Документ418 страницInvestigations of Derailments 2015Fabiano OliveiraОценок пока нет

- ASCProductGuideRev7 PDFДокумент101 страницаASCProductGuideRev7 PDFFabiano OliveiraОценок пока нет

- Dumitriu 2018 IOP Conf. Ser. Mater. Sci. Eng. 400 042020 PDFДокумент10 страницDumitriu 2018 IOP Conf. Ser. Mater. Sci. Eng. 400 042020 PDFFabiano OliveiraОценок пока нет

- 1568988364tabela Classificao de Tubos Ao Carbono Tubos ABCДокумент4 страницы1568988364tabela Classificao de Tubos Ao Carbono Tubos ABCFabiano OliveiraОценок пока нет

- Association of American Railroads: Manual of Standards Recommended PracticesДокумент20 страницAssociation of American Railroads: Manual of Standards Recommended PracticesFabiano OliveiraОценок пока нет

- Investigations of Derailments 2015Документ418 страницInvestigations of Derailments 2015Fabiano OliveiraОценок пока нет

- MSRP-H Manual: AAR Web SiteДокумент1 страницаMSRP-H Manual: AAR Web SiteFabiano OliveiraОценок пока нет

- AAR Manual of Standards and Recommended PracticesДокумент37 страницAAR Manual of Standards and Recommended PracticesFabiano OliveiraОценок пока нет

- ASCProductGuideRev7 PDFДокумент101 страницаASCProductGuideRev7 PDFFabiano OliveiraОценок пока нет

- MSRP A1Документ96 страницMSRP A1ashishkesharwaniОценок пока нет

- Throttle Valve With Actuator ReassemblyДокумент5 страницThrottle Valve With Actuator ReassemblySreepriodas RoyОценок пока нет

- Torres de Iluminación MagnusДокумент64 страницыTorres de Iluminación MagnusMiguel Angel Del Carpio ZuñigaОценок пока нет

- I-Lock CM2 Coupler BrochureДокумент2 страницыI-Lock CM2 Coupler BrochureW MoralesОценок пока нет

- CBCДокумент52 страницыCBCOmaroMohsenОценок пока нет

- TM 9-892 SEMI-TRAILER 10-TON, 1944Документ127 страницTM 9-892 SEMI-TRAILER 10-TON, 1944Advocate100% (1)

- AAR Manual of Standards and Recommended Practices Brakes and Brake EquipmentДокумент12 страницAAR Manual of Standards and Recommended Practices Brakes and Brake EquipmentDaniel Santacruz100% (1)

- Marine CouplersДокумент52 страницыMarine Couplersdk4monjure50% (2)

- Rail King Mobile Railcar MoversДокумент8 страницRail King Mobile Railcar Moversrogelio palaciosОценок пока нет

- QB 1Документ135 страницQB 1abhishekОценок пока нет

- Rail Lexicon Mk24Документ60 страницRail Lexicon Mk24serzo75Оценок пока нет

- H Type CouplerДокумент10 страницH Type CouplerSantosh Sharma50% (2)

- Complete Design of A Microstrip Line CouplerДокумент6 страницComplete Design of A Microstrip Line CouplerJoe MullerОценок пока нет

- Serie 092 RTC CouplingsДокумент4 страницыSerie 092 RTC CouplingsHIDRAFLUIDОценок пока нет

- Running Gear PDFДокумент54 страницыRunning Gear PDFByron CheleОценок пока нет

- 1840 e G 2221 e Eco10639 VT PB Schaku 2011-06Документ2 страницы1840 e G 2221 e Eco10639 VT PB Schaku 2011-06Lazar MihailОценок пока нет

- Catalogo Swivel-LinkДокумент17 страницCatalogo Swivel-LinkManuel HTОценок пока нет

- Instruction Manual: Car DoorДокумент58 страницInstruction Manual: Car Doorekrem kayaОценок пока нет

- 56 BD 07Документ39 страниц56 BD 07Mayur Urkude100% (1)

- CBC Coupling Indian RailwayДокумент14 страницCBC Coupling Indian RailwayArijitNandi75% (4)

- Serie 097 RTC CouplingsДокумент4 страницыSerie 097 RTC CouplingsHIDRAFLUIDОценок пока нет

- Catalogo Brazos de Cargue OPWДокумент40 страницCatalogo Brazos de Cargue OPWCARLITOS 25Оценок пока нет

- TM9-892 10ton Trailer and 10ton Dolly PDFДокумент127 страницTM9-892 10ton Trailer and 10ton Dolly PDFdieudecafeОценок пока нет

- Nato Type Camlock Fittings: July 2008Документ12 страницNato Type Camlock Fittings: July 2008Rockny310Оценок пока нет

- Wabco 1 PDFДокумент192 страницыWabco 1 PDFdottorgt584590% (10)

- Maintenance of Enhanced Drawgear - CMI9901Документ7 страницMaintenance of Enhanced Drawgear - CMI9901Dwijamani SinghaОценок пока нет

- MRT3 Train Operation ReportДокумент50 страницMRT3 Train Operation ReportImperator FuriosaОценок пока нет

- Refrigerated BoxcarДокумент1 страницаRefrigerated BoxcarAlexandraFurtzОценок пока нет

- Lukas LS Series User ManualДокумент15 страницLukas LS Series User ManualBoris Enrique Chandia LibbrechtОценок пока нет