Академический Документы

Профессиональный Документы

Культура Документы

MasterSeal 599 TDS

Загружено:

Stephen Ogalo0 оценок0% нашли этот документ полезным (0 голосов)

650 просмотров3 страницыMasterSeal 599 TDS

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документMasterSeal 599 TDS

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

650 просмотров3 страницыMasterSeal 599 TDS

Загружено:

Stephen OgaloMasterSeal 599 TDS

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

MasterSeal® 599 (Formerly known as Thoroseal FX 122)

An elastomeric, cement-based waterproof coating for concrete and masonry

DESCRIPTION OF PRODUCT EASY TO APPLY:

MasterSeal 599 part 1 is a blend of Portland Can be applied to damp substrates

cements, selected silica, micro-fibres and Thin layer application

modifying agents. When mixed to a slurry Equipment to be cleaned simply with water

consistency with the acrylic polymer emulsion

MasterSeal 599 part 2, it can be easily applied by ENVIRONMENTALLY FRIENDLY:

brush or spray equipment. It cures to give an Contains no solvent, safe to handle and

use

elastomeric flexible membrane.

Fiber mesh is a fabric which can be used in strip

PRODUCT DATA TYPICAL PHYSICAL

form over joints and cracks or as reinforcement for PROPERTIES (A)

the whole application.

Maximum particle size: 0.63mm

Water vapour permeability (μH2O): 985

USES Water resistance:

For waterproofing water-retaining positive pressure 1.5 bar

structures which may be subject to negative pressure 1.0 bar

movement like water tanks, pools, Elongation (28 days)

reservoires, etc. Ambient: 45%

Freeze/thaw resistance: no scaling

As part of the MasterSeal basement- (ISO/DIS 4846.2) after 56 cycles

waterproofing system, in areas sensitive to Strength at 28 days N/mm²

movement, vibrations and slight settlement Tensile: 0.9

To protect concrete from water, Adhesive: 1.1

carbonation and de-icing salts

Suitable for internal and external use, (a) Typical values; all tests were carried out

against positive and negative water under temperature controlled conditions of

pressure 21°C

Once cured, a 2 mm thick MasterSeal 599 COLOURS

membrane will accommodate movement up to 0.5 Standard: White and grey

mm, or 1.2 mm when reinforced with FIBERL

mesh COVERAGE

0.75-1 kg/m2/coat; 2 coats normally recommended.

BENEFITS DURABLE

Retains flexible when submerged PACKAGING

Good chemical resistance against soft MasterSeal 599 part 1 25kg pails or sacks

water, domestic waste water, manure or MasterSeal 599 part 2 10ltr cans FIBER mesh

other liquids moderately aggressive to

50m roll (200mm or 1000 mm width)

mineral substrates

Freeze-thaw resistant

Water vapour permeable STORAGE

CO2 barrier Both components should be stored under cover,

Crack bridging. clear of the ground and stacked not more than 2

UV stable pails, 3 cans or 6 sacks high. Protect the materials

from all sources of moisture and frost (+5°C).

COST EFFECTIVE: Rotate stock in order not to exceed the shelf life of

Simple and fast method of treating cracks 12 months for pails and MasterSeal 599 part 2

and joints

and 6 months for sacks. Rolls of mesh should be

Quick and easy brush or spray application

stood on end.

MasterSeal® 599 (Formerly known as Thoroseal FX 122)

APPLICATION SUBSTRATE PREPARATION: APPLICATION:

The surface to be coated must be clean and Do not apply MasterSeal 599 to frozen substrates

sound. Remove all traces of formwork, release or if the ambient temperature is below 5ºC or

agents, previous coatings, laitance, organic growth expected to fall below 5ºC within 24 hours.

and any other contaminant that may affect the Avoid application in direct sunlight.

bond adversely. Suitable cleaning methods include Always apply the mix to a pre-dampened surface.

high-pressure water treatment and grit blasting. High-suction substrates require more dampening

NOT recommended are aggressive percussive then dense substrates. However, make sure there

methods such as scabbling. After the above is no free-standing water. Mixed material must be

treatment, surfaces must be thoroughly rinsed with used within 60 minutes, or less under hot weather

clean potable water to remove all dust and loose conditions

particles.

For Cracks and bolt holes please consulted BASF FIRST COAT:

technical team for repair Brush, broom or spray the mix onto the pre-

dampened, prepared surface, brushing well into

MIXING: the surface. Strike off with the brush or broom in

Wet density 1750 kg/m³ one direction for a neat appearance. Care must be

Pot life 60 minutes taken not to spread the material too thinly. Typical

Drying time 120 minutes coverage 0.75-1kg/m2/coat. When the material

Mixing Liquid ±10.0ltr (9.37-10.8) begins to drag or “ball”, do not add more liquid, but

MasterSeal 599 part 2 / 25kg part 1 dampen the surface again.

MasterSeal 599 should be power mixed only, Spray through a ±4 mm nozzle at a pressure of

using a special mixer attachment in a slow-speed 3.0-5.0 bar.

drill (400-600 rpm). DO NOT use a bricklayer’s

mortar mixer. REINFORCING WITH MESH IF REQUIRED:

Mesh is embedded in the first coat when it is still

Blend 25 kilograms of part 1 into approximately wet.

10.0 litres of part 2. The quantity may vary slightly

depending upon the ambient conditions. Mix SECOND COAT

maximum 3 minutes to a lump-free consistency. Allow to cure at least 6 hours at 20°C before

applying subsequent coats. Low temperatures and

Allow the mix to saturate for ±5 minutes and remix high humidity will delay setting and curing.

for maximum 2 minutes adding powder or liquid Humidification of the previous coat is only allowed

when necessary to obtain the correct consistency. in extremely dry conditions. Remove as above,

finishing in one direction, eventual condensation.

Do not exceed the maximum liquid demand. Do Brush, roll or spray the mix onto the surface at a

not over-mix. For colour uniformity always mix with similar coverage to the first coat preferably at right

the same amount of liquid. angles to the previous layer.

Provide adequate ventilation when mixing and CURING:

applying MasterSeal 599 Under hot or excessive drying conditions adequate

protective shielding should be foreseen.

In cold and humid areas it may be necessary to

leave the application for a longer curing period.

MasterSeal 599 needs to dry under air-dry

circumstances.

MasterSeal® 599 (Formerly known as Thoroseal FX 122)

Additional heating and/or ventilation can assist QUALITY STATEMENT

proper curing. NEVER use dehumidifiers during All products manufactured by BASF Egypt, or

curing periods. imported from BASF affiliate companies world-

wide, are manufactured to procedures certified to

CLEAN UP AND SPILLAGES: conform to the quality, environment, health &

Not hardened material may simply be removed safety management systems described in the ISO

with water. 9001:2008, ISO 14001:2004 & OHSAS

18001:2007 standards.

OVERPAINTING:

Do not overpaint MasterSeal 599 in basements or

other structures where the membrane is subject to * Properties listed are based on laboratory controlled tests.

negative water pressure. ® = Registered trademark of the BASF-Group in many countries

Never use solvent based paints

HEALTH AND SAFETY

MasterSeal 599 powder is cement based and may

be irritating to the skin and eyes. Gloves and eye

protection should be worn. The use of dust masks

is recommended.

MasterSeal 599 Liquid is non toxic, but should not

be ingested as it is based on acrylic polymers.

Accidental splashes of the material to the skin or

eyes should be immediately washed off with clean

water. In the event of prolonged irritation, seek

medical advice. In the case of ingestion give water

or milk to drink and treat symptomatically. Medical

advice should be sought.

A Material Safety Data Sheet for this product is

available on request.

NOTE

Field service, where provided, does not constitute

supervisory responsibility. For additional

information, contact your local BASF

representative.

BASF reserves the right to have the true cause of

any difficulty determined by accepted test

methods.

BASF_CC-EG/Seal_599_02_13/v1/08_15

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Masterseal 501 Wa TdsДокумент2 страницыMasterseal 501 Wa TdsStephen Ogalo100% (1)

- Aar Insurance Panel of Providers 2017 PDFДокумент68 страницAar Insurance Panel of Providers 2017 PDFStephen OgaloОценок пока нет

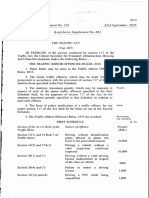

- Traffic Act 2016Документ5 страницTraffic Act 2016Stephen OgaloОценок пока нет

- DCP DrawingsДокумент1 страницаDCP DrawingsStephen OgaloОценок пока нет

- Axle Load Limits - KenyaДокумент3 страницыAxle Load Limits - KenyaStephen OgaloОценок пока нет

- Kenya BuildersДокумент2 страницыKenya BuildersStephen OgaloОценок пока нет

- CP3 Code of Basic Data For The Design of Buildings and Lattice TowersДокумент51 страницаCP3 Code of Basic Data For The Design of Buildings and Lattice TowersSteve Jsob100% (7)

- Mom DistДокумент8 страницMom DistMthokozisi MbibaОценок пока нет

- Wind LoadingДокумент18 страницWind LoadingStephen Ogalo100% (1)

- Schmidt Hammer AbbeyДокумент4 страницыSchmidt Hammer AbbeyStephen OgaloОценок пока нет

- Harmonised Draft Constitution of Kenya Rel 17-11-2009Документ196 страницHarmonised Draft Constitution of Kenya Rel 17-11-2009Stephen OgaloОценок пока нет

- Bolt Bond LengthДокумент1 страницаBolt Bond LengthStephen OgaloОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Cosmetic-Regulations, Research & Marketing Challenges and Global Compliance: An OverviewДокумент19 страницCosmetic-Regulations, Research & Marketing Challenges and Global Compliance: An Overviewmaria sepulvedaОценок пока нет

- Iso 657 14 2000 en FR PDFДокумент11 страницIso 657 14 2000 en FR PDFVivekanandh00333 VivekОценок пока нет

- Astm D6321-98-2004Документ3 страницыAstm D6321-98-2004Thyagu LingamurthyОценок пока нет

- Eng Mech Lesson 1-2 PDFДокумент17 страницEng Mech Lesson 1-2 PDFAlliza Kaye CasullaОценок пока нет

- Estericlean Agroalimentaria Registro NSFДокумент1 страницаEstericlean Agroalimentaria Registro NSFwilber jovany monzon uriasОценок пока нет

- Homework 3rd SteelДокумент4 страницыHomework 3rd SteelPiseth HengОценок пока нет

- List of Japanese Company in IndiaДокумент2 страницыList of Japanese Company in Indiakaushalshinde317Оценок пока нет

- Our School Broke Up For The Winter VacationsДокумент7 страницOur School Broke Up For The Winter VacationsprinceОценок пока нет

- Elementary Statistics A Step by Step Approach 9th Edition Bluman Solutions ManualДокумент23 страницыElementary Statistics A Step by Step Approach 9th Edition Bluman Solutions Manuala305894328100% (3)

- Morris 2Документ22 страницыMorris 2IsmaelLouGomezОценок пока нет

- V260 Control ValveДокумент12 страницV260 Control ValvenwabukingzОценок пока нет

- Constructing 30deg AngleДокумент4 страницыConstructing 30deg AngleArthur ChewОценок пока нет

- MV Lec PDFДокумент102 страницыMV Lec PDFJonas Datu100% (1)

- Routes of Medication AdministrationДокумент2 страницыRoutes of Medication AdministrationTracy100% (6)

- SRS Cheat CodesДокумент9 страницSRS Cheat CodesnurhayatiОценок пока нет

- The Proof of Agricultural ZakatДокумент7 страницThe Proof of Agricultural ZakatDila Estu KinasihОценок пока нет

- Poems by Cawein, Madison Julius, 1865-1914Документ126 страницPoems by Cawein, Madison Julius, 1865-1914Gutenberg.orgОценок пока нет

- EN 14103 - ThermoДокумент4 страницыEN 14103 - ThermoLuciana TrisnaОценок пока нет

- Warm and Humid GREEN BUILDING CASE STUDYДокумент8 страницWarm and Humid GREEN BUILDING CASE STUDYPooja PrakashОценок пока нет

- Designing New Vanillin Schiff Bases and Their Antibacterial StudiesДокумент4 страницыDesigning New Vanillin Schiff Bases and Their Antibacterial StudiesAvinash PurohitОценок пока нет

- Lab Assignment-1 1. Create Table Student (Rno, Name, DOB, Gender, Class, College, City, Marks)Документ7 страницLab Assignment-1 1. Create Table Student (Rno, Name, DOB, Gender, Class, College, City, Marks)supreetОценок пока нет

- Aakash Zoology Study Package 3 SolutionsssssssДокумент104 страницыAakash Zoology Study Package 3 SolutionsssssssRishika PaulОценок пока нет

- Salvado de Arroz Fermentado: Una Alternativa de Ingrediente para PanificaciónДокумент10 страницSalvado de Arroz Fermentado: Una Alternativa de Ingrediente para PanificaciónAnelise RibeiroОценок пока нет

- List BRG TGL 12Документ49 страницList BRG TGL 12Rizal MuhammarОценок пока нет

- Animal Cells PDFДокумент4 страницыAnimal Cells PDFFalah HabibОценок пока нет

- DH-IPC-HDBW1231E: 2MP WDR IR Mini-Dome Network CameraДокумент3 страницыDH-IPC-HDBW1231E: 2MP WDR IR Mini-Dome Network CameraDeltaz AZОценок пока нет

- 2022 Specimen Paper 1 Mark Scheme 1Документ4 страницы2022 Specimen Paper 1 Mark Scheme 1Herman HermanОценок пока нет

- Accomplishment Report: Gass/Mfo Success Indicators Actual Accomplishments RemarksДокумент1 страницаAccomplishment Report: Gass/Mfo Success Indicators Actual Accomplishments RemarksGlenn HernandezОценок пока нет

- SWOT Analysis Textile IndustryДокумент23 страницыSWOT Analysis Textile Industrydumitrescu viorelОценок пока нет

- C8 Flyer 2021 Flyer 1Документ7 страницC8 Flyer 2021 Flyer 1SANKET MATHURОценок пока нет