Академический Документы

Профессиональный Документы

Культура Документы

SEO-Optimized Title for Muck Disposal Plan Chapter

Загружено:

tchangmaiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SEO-Optimized Title for Muck Disposal Plan Chapter

Загружено:

tchangmaiАвторское право:

Доступные форматы

CHAPTER – 6

MUCK DISPOSAL PLAN

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

6 MUCK DISPOSAL PLAN

6.1 GENERAL

For construction of different components of the project, substantial surface and

underground excavation in over burden and rock for Barrage intake structure, intake

tunnel, desilting chambers, silt flushing tunnel, headrace tunnel, surge shaft, pressure

shaft, powerhouse and tailrace tunnel would be generated. The excavation shall result

in large quantity of excavated material i.e. muck which have to be evacuated,

disposed off and roller compacted or laid on mild slopes pari-passu with the

excavation work to such designated areas where the muck piles do not substantially

interfere with either environment / ecology or the river flow regime and do not cause

turbidity impairing the quality of water. The disposal of muck has to be scientifically

planned keeping in view the economic aspects necessitating nearness to the muck

generating component of work, which understandably reduce the travel time of

dumpers, less interference to surface flow and ground water aquifer and disposition of

habitation.

Based on the quantities of surface and underground excavation including 10% over

break a muck management plan, therefore, has been formulated to manage the

disposal of muck and restore such areas from further degradation of the environment.

During construction of the project, huge quantities of excavation will be carried out

from the underground and surface components and shall be dumped in designated

areas to provide stable slopes. The quantity of muck to be disposed has been worked

out on the basis of 63% swell factor for rock and 83% for overburden.

6.2 QUANTITY OF MUCK GENERATED AND ITS CONSUMPTIVE USE

During construction of the various components of the project, muck is generated both

from soil or slide material and from rock excavation. Total quantity of muck / debris,

generated due to the project, shall be 4,24,219 cum which shall amount to 5,97,375

cum with swell factor. Out of the total muck generated, 3,06,369 cum shall be utilized

on project work leaving 2,91,007 cum to be dumped with 20% compaction at

designated sites. It is proposed to utilize about 51.29% of the excavated material as

construction material for back fill, shotcreting and for construction of various project

components. The balance 48.71% shall have to be disposed off away from sites to

make available the site clear. The muck shall be properly roller compacted and

dumped on slopes and treated to mix and match with the surrounding environment

with least change in landscape.

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-1

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

Table 6-1: Abstract of Muck Generated and its Disposal

Effective

Quantity of Estimated Muck to be Name of Capacity

Quantity of muck

muck/debris quantity of muck/ Balance quantity of dumped the of the

Project Component due to swell factor

generated debris proposed to muck/debris (cum) (cum) dumping dumping

(cum) be utilized (cum) (with 20% site site (cum)

(cum)

compaction)

Rock Soil

Rock Soil Rock Soil Rock Soil

(63%) (83%)

Cofferdam 47,533 0 57,269 65,464 0 -8195*

Barrage & Desilting 30,240 73,427

Site 48,000 88,466 1,67,693 -119693* 88466

1,89,785

Muck

Intake 77,710 0 93,626 8,107 -8107* 93626

Dump

Feeder Tunnel 1,119 1,776 482 1295 0 Yard 1

Head race Tunnel 80,348 1,27,536 28,137 99399 0

Adits 23,467 37,249 4,802 32447 0

Surge Shaft 3,637 5,773 2,222 3551 0

Pressure shaft 5,918 9,394 4,860 4533 0 Muck

Power House & 72,703 Dump

Transformer Cavern 1,15,402 16,431 98971 0 Yard 2 1,23,856

Tail Race Tunnel 8,118 12,886 8,170 4715 0 2,32,805

TOTAL 2,25,549 1,98,669 3,58,015 2,39,361 2,40,905 65,464 1,17,110 1,73,897

*Balance quantities of muck will be utilised from muck generated at other project components.

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-2

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

6.3 SELECTION OF MUCK DISPOSAL SITE

The selection of muck disposal sites was carried out considering the quantity of the

muck, landscape, cost effectiveness, nearness to source of generation, absence of

ground and surface water, relief and scope for afforestation works. All the dumping

locations shall be well supported at base and at higher elevation by suitable retaining

structures. Subsequently all the spoil tips (muck disposal sites) will be developed by

taking up plantation through bio-technological methods to generate a thick forest

canopy over them. Two (2) muck dumping sites have been identified matching the

criteria. The details of dumping sites along with their total capacity and amount of

muck to be disposed are enumerated in Table 6-2.

Table 6-2: Details of Muck Disposal Sites

Sl. Name of Dumping Site Location of Dumping Site Area in Capacity Vol. of

No. Ha in cum muck to

be

dumped

1. Muck Disposal Area 1 Approx. 3603 m downstream 3.14 1,89,785

from Barrage axis, Right

Bank 2,32,805

2. Muck Disposal Area 2 Approx. 2240 m downstream 1.81 1,23,856

from Barrage axis, Right

Bank

Total 4.95 3,13,641

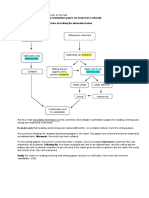

The layout plans of Muck Disposal Sites are shown in Figure 6-1 and Figure 6-2.

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-3

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

Figure 6-1: Layout Plan of Muck Disposal Site -1

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-4

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

Figure 6-2: Layout Plan of Muck Disposal Site -2

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-5

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

6.4 DESCRIPTION ON MUCK DISPOSAL SITES

6.4.1 MUCK DISPOSAL SITE D-1

The proposed muck disposal site 1 is located about 3603 m downstream of barrage axis

on Right bank of Mago Chu, just upstream of TRT discharge point. The site is located

approx. 48 m away from the river bank at HFL. The plan area of the site is 3.14 ha.

6.4.2 MUCK DISPOSAL SITE D-2

The proposed muck disposal site 2 is located about 2240 m downstream of barrage

axis on right bank of Mago Chu, near. The site is located more than 33 m away from

the river bank at HFL. The plan area of the site is 1.81 ha.

In total 2,32,805 cum shall be dumped in Muck Disposal Site 1 and 2 and properly

roller compacted. After the capacity of any disposal area is exhausted, the top surface

would be levelled, graded and provided a gradual slope for efficient drainage. The

surface so available would be put to greenery development.

6.5 IMPLEMENTATION OF ENGINEERING MEASURES AT MUCK

DISPOSAL SITE

It has been observed that after disposal of muck, it creates problem as it is susceptible

to scattering unless the muck disposal yards are supported with engineering measures

such as gabions. All the dumping sites need proper handling to avoid spilling of muck

into the river water while dumping and in the post dumping stages. All the muck

disposal sites have to be developed from the ground level either by providing stone

masonry or by gabion structure. The costing of engineering measures has been

worked out based on gabion structure. In all the muck dump sites, the muck brought

in dumpers shall be dumped and manually spread behind the crates and roller

compacted in such a manner that rock mass is properly stacked behind the crates with

minimum of voids.

6.6 IMPLEMENTATION OF BIOLOGICAL MEASURES AT MUCK DISPOSAL

SITE

Biological measures, however, require special efforts as the disposed muck will be

devoid of nutrients and soil contents to support vegetation. The selection of soil for

spreading over such an area would require nutrient profiling of soil for different base

elements. Suitable mixture of nutrients would be done before placing the soil on the

top surface of muck disposal areas to have administered growth of forest canopy.

6.6.1 PLANTATION TECHNIQUE

In view of the peculiar site conditions, particularly the soil conditions, the planting

technique for all the categories of the plants has to be very site specific and suited to

the stress conditions as anticipated and discussed above. The planting substrates

would need to be considerably improved to support the plants in their initial stages of

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-6

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

establishment. The moisture retention capability, availability of nutrients and soil

aeration, permeability and porosity would require intervention and assistance.

Multi-level and multipurpose plantations are proposed to be raised on the muck

dumping sites as also in road side strips using grasses, shrubs and bushes in the under

story and trees in the upper story. Nursery raised grass slips, seedlings of shrubs &

bushes and tree species would be planted in the area combined with grass sowing in

patches. In addition, cuttings of bushes and shrubs can also be planted to supplement

the nursery raised stock but this would substitute requirement of raising the nursery of

these species. Intimate mixture of species would be avoided right at the planning stage

and would be strictly followed during planting. Grasses would be mixed by groups in

rows, shrubs and bushes by group again in rows.

Grass slip planting and grass seed sowing would be done in strips at 0.10 m x 0.10 m

spacing in the prepared staggered patches of 1 m x 0.5 m with a depth of 0.30 m. Soil

mixture would be used while filling the patches.

Shrubs and bushes would be planted in elongated strips of 1.5 m x 0.5 m with a depth

of 0.45m. Soil mixture would be used while filling the patches. Each patch would

have two rows of planting.

Planting of trees would be done in pits of 0.60 m x 0.60 m x 0.60 m size. Soil mixture

would be used while filling the pits. Balance dug up soil/ muck will be stacked on

downhill side of the pit for trapping the rain water and allowing it to percolate in the

pit.

It is proposed to use soil mixture in the pits & patches consisting of soil imported

from nearby areas mixed with compost or vermin-compost manually. The ratio for the

mix would be 5 parts: Compost/manure 2 parts: Sand 2 part: and humus or vermin-

compost 1 part. This will make nutrients available for the plants in the preliminary

stages and also help increase soil aeration, porosity & permeability and improved

moisture available for the plants.

The stabilization sites from the time of execution of biological measures would be

protected with barbed wire fencing on 2m high RCC posts and provided with

inspection paths. Since the muck dumping sites are being provided with the wire crate

(gabion) wall on the valley side (towards river) which is not negotiable by animals

and human beings, fencing would not be required along the entire perimeter. Hence, it

would be done on the vulnerable sections i.e. towards the hillside only.

The plantations under biological measures would be maintained for a period of 3

years by watering the plantation during dry seasons, mortality replacement and repair

of fencing & inspection paths within the area. The task of irrigation would be

performed by the watchmen provided in the cost estimate.

The proposed costs include raising plants, grass seedlings and also for mortality

replacement.

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-7

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

Although the sites would be either levelled or finished in a grade, yet due to rain and

sliding etc., they tend to develop rills and gulley. As such, while carrying out

plantation; suitable soil conservation measures would also be taken.

6.6.2 SPECIES FOR PLANTATION

Afforestation with suitable plant species of high ecological and economic value and

adaptable to local conditions will be undertaken in accordance with canopy cover

requirement. Some plant species have been suggested in the Table 6-3. The selection

of plant species, propagation and cultivation technique would be done in co-

ordination with the institutes like State Forest Research Institute, Itanagar; Rajiv

Gandhi University, Itanagar and North-Eastern Regional Institute of Science and

Technology, Nirjuli.

Table 6-3: Suggested Species for Plantation

Sl. No. Name of species Family

1. Abies densa Pinaceace

2. Achyranthes aspera Amaranthaceae

3. Alangium alpinum Alangianaceae

4. Alnus nepalensis Betulaceae

5. Aristolochia griffithii Aristolochiaceae

6. Berberis aristrata Berberidaceae

7. Betula alnoides Betulaceae

8. Daphnae papyracea Thymelaeaceae

9. Lyonia ovalifolia Ericaceae

10. Pinus roxburghi Pinaceae

11. Pinus wallichiana Pinaceae

12. Populus sp. Salicaceae

13. Rhododendron campanulatum Ericaceae

14. Rhododendron cinnabarium Ericaceae

15. Salix sp. Salicaceae

16. Tsuga dumosa Pinaceae

17. Zanthoxylum armatum Rutaceae

6.7 BUDGET FOR MUCK DISPOSAL PLAN

An estimation has been made for engineering measures of muck disposal plan as Rs.

48.05 Lakhs whereas biological measures as Rs. 32.21 Lakhs. The cost break-up of

engineering and biological measures are detailed in Table 6-4 and 6-5.

Table 6-4: Cost Estimate for Engineering Measures

Amount

S. No. Name of the work Quantity Unit Rate

(Rs.Lakhs)

A. Muck Disposal Site – 1

1 Gabion Wall construction 315 m 5750 18.11

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-8

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

Amount

S. No. Name of the work Quantity Unit Rate

(Rs.Lakhs)

2 Filling of earth /Top Soil 18000 sq. m 20 3.6

3 Levelling 3.14 ha 2000 0.03

Sub-Total 21.74

Contingencies @ 10% 2.17

Total (A) 23.92

B. Muck Disposal Site – 2

1 Gabion Wall construction 344 m 5750 19.78

2 Filling of earth /Top Soil 10600 sq. m 20 2.12

3 Levelling 1.81 ha 2000 0.04

Sub-Total 21.94

Maintenance Cost @10% 2.19

Total (B) 24.13

Grand Total T1 = (A + B) 48.05

Table 6-5: Cost Estimate for Biological Measures

Sl. Amount

Name of the work Unit Qty Rate

No. (Rs. Lakhs)

Muck Disposal Site – 1

Raising of Plantation (Creation Cost)

Survey/ demarcation/plantation planning/site

Days 49 150 0.074

clearance

1

Pit Digging /Soil working/ Manuring &

Days 90 150 0.135

Planting

Seedling cost Number 3330 8.25 0.275

0.483

Maintenance of Plantation Cost for 3 years

Seedling casualty replacement (2nd year 15%

Number 833 8.25 0.069

and 3rd Year 10%)

Tending Operation (1st Year Operation)

2 3 weeding (1 DLS per weeding for 100 plants) Days 100 150 0.150

Tending Operation (2nd Year Operation)

2 weeding (1 DLS per weeding for 100 plants) Days 67 150 0.101

Tending Operation (3rd Year Operation)

1 weeding (1 DLS per weeding for 100 plants) Days 33 150 0.050

0.369

Fencing Cost

3 i) Erection of barbed wire fencing (1.2 m) cost Meter 847 227.85 1.930

ii) Maintenance of barbed wire fencing @5 % of erection cost for

0.193

2nd and 3rd year

2.123

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-9

MUCK DISPOSAL PLAN VOL II: FINAL EMP REPORT

SEW New Melling Power Corporation Ltd.

Sl. Amount

Name of the work Unit Qty Rate

No. (Rs. Lakhs)

4 Grass carpeting cost for ha Ha. 3.14 30000 0.942

Total (1+2+3+4) 3.917

Contingency@ 5 % 0.196

Grand Total 4.113

Muck Disposal Site – 2

1 Raising of Plantation (Creation Cost)

Survey/ demarcation/plantation planning/site

Days 30 150 0.045

clearance

Pit Digging /Soil working/ Manuring &

Days 54 150 0.081

Planting

Seedling cost Number 2009 8.25 0.166

0.292

2 Maintenance of Plantation Cost for 3 years

Seedling casualty replacement (2nd year 15%

Number 502 8.25 0.041

and 3rd Year 10%)

Tending Operation (1st Year Operation)

3 weeding ( 1 DLS per weeding for 100 plants) Days 60 150 0.090

Tending Operation (2nd Year Operation)

2 weeding ( 1 DLS per weeding for 100 plants) Days 40 150 0.060

Tending Operation (3rd Year Operation)

1 weeding ( 1 DLS per weeding for 100 plants) Days 20 150 0.030

0.221

3 Fencing Cost

i) Erection of barbed wire fencing (1.2 m) Meter 755 227.85 1.720

ii) Maintenance of barbed wire fencing @5 % of erection cost for

0.172

2nd and 3rd year

1.892

4 Grass carpeting cost for ha Ha. 1.81 30000 0.543

Total (1+2+3+4) 2.948

Contingency@ 5 % 0.147

Grand Total 3.096

Provision for maintenance

1 Wages for 2 persons for 5 years Month 15000 18.00

2 Consumables and Tools cost 5.00

3 Miscellaneous expenditure 2.00

Total (1+2+3) 25.00

Grand Total Cost For Biological Treatment 32.21

Thus, total budget for muck disposal plan has been estimated as Rs. 80.26 Lakhs.

New Melling HEP 90 MW, Arunachal Pradesh Page | 6-10

Вам также может понравиться

- Spellbound by KatrinaДокумент55 страницSpellbound by KatrinaAzaan Kamau100% (3)

- Migrating From MX To OpenRoads DesignerДокумент21 страницаMigrating From MX To OpenRoads DesignertchangmaiОценок пока нет

- Journal of The New Alchemists 1 (1973)Документ78 страницJournal of The New Alchemists 1 (1973)samsilvr0% (1)

- Nhai Circular On Design Features For Bridges File2360Документ2 страницыNhai Circular On Design Features For Bridges File2360nagaraj_qce3499Оценок пока нет

- Muck Disposal Scheme - CH - KM 375+000Документ1 страницаMuck Disposal Scheme - CH - KM 375+000Shivendra KumarОценок пока нет

- Specification, Analysis and Estimate On Road Works in OdishaДокумент71 страницаSpecification, Analysis and Estimate On Road Works in OdishaTarandeep KaurОценок пока нет

- EOI For WSAДокумент4 страницыEOI For WSAGaurav SrivastavaОценок пока нет

- Civil Engineer Resume Aniket WakhareДокумент1 страницаCivil Engineer Resume Aniket WakhareMahindra DeshmukhОценок пока нет

- Net Work Survey VehicleДокумент26 страницNet Work Survey VehiclegurvinderkumarОценок пока нет

- As Inspected by Mr. N.Dhamarajan Senior Pavement SpecialistДокумент14 страницAs Inspected by Mr. N.Dhamarajan Senior Pavement SpecialistKISHANОценок пока нет

- Laying Practices of Ofc Hdpe DuctДокумент71 страницаLaying Practices of Ofc Hdpe DuctAroop Ratan Sen50% (2)

- Mohammad Taha CVДокумент1 страницаMohammad Taha CVmd taha100% (1)

- Rural Road Construction Project ReportДокумент33 страницыRural Road Construction Project ReportNandu KingsОценок пока нет

- HDM Software)Документ93 страницыHDM Software)mariyapadeva100% (1)

- GT Manual 17CVL57 PDFДокумент99 страницGT Manual 17CVL57 PDFAkshaykumar RathodОценок пока нет

- Schedule C - DVRP - 26Документ1 страницаSchedule C - DVRP - 26kanagarajodishaОценок пока нет

- Research Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDAДокумент4 страницыResearch Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDAAyush GoyalОценок пока нет

- NICMAR Distance Education Programs Advance Your CareerДокумент22 страницыNICMAR Distance Education Programs Advance Your CareerChhavi SadanОценок пока нет

- DSR ReportДокумент451 страницаDSR ReportPramod Gaikwad100% (2)

- Naidupeta DCA ModifiedДокумент207 страницNaidupeta DCA ModifiedChristopher Swanson100% (1)

- Assignment 21.1Документ22 страницыAssignment 21.1Nilesh SondigalaОценок пока нет

- Irc - Gov.in.080.1981pickup Bus StopsДокумент14 страницIrc - Gov.in.080.1981pickup Bus StopsAnonymous ESjaOhiОценок пока нет

- Procedure for project approval in Indian road transport ministryДокумент4 страницыProcedure for project approval in Indian road transport ministrypvijayabharathiОценок пока нет

- Highway Engineering Finance Administration PPP ModelsДокумент39 страницHighway Engineering Finance Administration PPP ModelsAbhishekОценок пока нет

- Road Safety Measures on National HighwaysДокумент4 страницыRoad Safety Measures on National HighwaysDhiren PatelОценок пока нет

- NHDP Phase II Concrete Mix Design SummaryДокумент6 страницNHDP Phase II Concrete Mix Design SummaryikreddyОценок пока нет

- TN-12-CNN - Transforming Chennai through Smart and Sustainable DevelopmentДокумент92 страницыTN-12-CNN - Transforming Chennai through Smart and Sustainable DevelopmentGOKULОценок пока нет

- Quality Control for Subgrade ConstructionДокумент8 страницQuality Control for Subgrade Constructionabhishekks26Оценок пока нет

- Executing a Complex Website Development Project Within a MonthДокумент5 страницExecuting a Complex Website Development Project Within a MonthBharani KrishnaОценок пока нет

- Project Report for Maintenance of National HighwaysДокумент6 страницProject Report for Maintenance of National HighwaysSuyog GoreОценок пока нет

- Venkat Apdss ReadДокумент181 страницаVenkat Apdss ReadV Venkata Narayana100% (3)

- Earth Work Calculation PDFДокумент12 страницEarth Work Calculation PDFMalik BilalОценок пока нет

- 6sec.600 (Concrete Pavement)Документ35 страниц6sec.600 (Concrete Pavement)aalignup arc & const. pvt ltdОценок пока нет

- Smiu Volume IIIДокумент83 страницыSmiu Volume IIIjunaid112Оценок пока нет

- Concord - July10Документ56 страницConcord - July10iyappanthiagarajanОценок пока нет

- NHAI DPR Project Corridors Status UpdateДокумент51 страницаNHAI DPR Project Corridors Status UpdateLakhan BeniwalОценок пока нет

- Is 4464 1985Документ21 страницаIs 4464 1985rajenkoleyОценок пока нет

- Computer-Aided District Road Network Planning in NepalДокумент31 страницаComputer-Aided District Road Network Planning in NepalChandra Bahadur ShresthaОценок пока нет

- GAIL Gas Limited invites bids for laying steel pipelines in VaranasiДокумент443 страницыGAIL Gas Limited invites bids for laying steel pipelines in VaranasiRanjan KumarОценок пока нет

- tOLL pLAZA FOR NH353DДокумент19 страницtOLL pLAZA FOR NH353DBILLING TIRORAОценок пока нет

- Pavement Maintenance ManagementДокумент16 страницPavement Maintenance ManagementKellesia WilliamsОценок пока нет

- Role of consulting engineersДокумент2 страницыRole of consulting engineersSuvarnaОценок пока нет

- Ballast Formation and DrainageДокумент71 страницаBallast Formation and DrainageVijay Kumar ChoudharyОценок пока нет

- PMGSY Operations ManualДокумент252 страницыPMGSY Operations ManualMuniswamaiah Mohan100% (1)

- Capacity and Quality of Service of Two-Lane HighwaysДокумент180 страницCapacity and Quality of Service of Two-Lane HighwaysDavidPadillaGeorggeОценок пока нет

- Akhtar Mahmood: Linguistic Profile: Urdu Excellent - Arabic and English FunctionalДокумент2 страницыAkhtar Mahmood: Linguistic Profile: Urdu Excellent - Arabic and English FunctionalShahbaz AhmadОценок пока нет

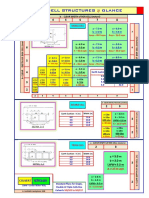

- Box Cell Structures at a GlanceДокумент3 страницыBox Cell Structures at a GlanceV Venkata NarayanaОценок пока нет

- 640 File228729760 PDFДокумент278 страниц640 File228729760 PDFAbhishek MathurОценок пока нет

- 08 Change in TCS - As Per SSR 18-19Документ26 страниц08 Change in TCS - As Per SSR 18-19johnОценок пока нет

- Monthly Progress Report: Frischmannprabhu (India) Pvt. LTDДокумент54 страницыMonthly Progress Report: Frischmannprabhu (India) Pvt. LTDshravan38Оценок пока нет

- Flexible pavement design methods and IRC guidelinesДокумент41 страницаFlexible pavement design methods and IRC guidelinesRaghuram Vadiboyena VОценок пока нет

- Final Training Report VishvendraДокумент27 страницFinal Training Report VishvendraNamo Narayan MeenaОценок пока нет

- Appendix-IV List of Empanelled Safety ConsultantsДокумент5 страницAppendix-IV List of Empanelled Safety ConsultantsUmakanta PaniОценок пока нет

- NEW Estimate-Shiggon-14-08.2022-FinalДокумент107 страницNEW Estimate-Shiggon-14-08.2022-FinalVaibhavi ShashidharОценок пока нет

- Chapter 7-8&9 PDFДокумент38 страницChapter 7-8&9 PDFKirpak DiniОценок пока нет

- No Penggunaan Lahan Luas Eksisting (M) Luas Pengembangan (M)Документ5 страницNo Penggunaan Lahan Luas Eksisting (M) Luas Pengembangan (M)LeonardusHSijabatОценок пока нет

- Proposed Bridge Construction Across River GowthamiДокумент4 страницыProposed Bridge Construction Across River Gowthamisantosh yevvariОценок пока нет

- M2M Toromocho Site SAG Conference 2023 1699484174Документ22 страницыM2M Toromocho Site SAG Conference 2023 1699484174vladimirОценок пока нет

- Integrated M2M Optimization Toromocho Operation MCP Perú-2Документ29 страницIntegrated M2M Optimization Toromocho Operation MCP Perú-2achint GoelОценок пока нет

- BAHU PATIL - NEW BUDGET 15TH With 18GStДокумент12 страницBAHU PATIL - NEW BUDGET 15TH With 18GStAkash JagtapОценок пока нет

- Project Title: Box Culvert Owner: Seaoil Location: San Juan, Mabini Batangas Contractor K&F Construction Development CorporationДокумент8 страницProject Title: Box Culvert Owner: Seaoil Location: San Juan, Mabini Batangas Contractor K&F Construction Development CorporationDarius Frane MarasiganОценок пока нет

- Plate Girder BridgeДокумент12 страницPlate Girder BridgeRAYEES NABI NAQASHBANIОценок пока нет

- Boq For Tyco RoofДокумент3 страницыBoq For Tyco Roofragu ramanОценок пока нет

- Total Station Surveying Components, Types, AdvantagesДокумент28 страницTotal Station Surveying Components, Types, AdvantagesNeatha ChimОценок пока нет

- Control PointsДокумент4 страницыControl PointstchangmaiОценок пока нет

- Schedule of TCSДокумент1 страницаSchedule of TCStchangmaiОценок пока нет

- Handover Land DetailsДокумент3 страницыHandover Land DetailstchangmaiОценок пока нет

- Super Elevation DesignДокумент16 страницSuper Elevation DesignSantosh RaiОценок пока нет

- SCH Vol1 151214.pdf Sri PDFДокумент136 страницSCH Vol1 151214.pdf Sri PDFSehaj DhillonОценок пока нет

- Documents Required For Forest ClearanceДокумент23 страницыDocuments Required For Forest ClearanceSurendra Kumar SharmaОценок пока нет

- Refraction Through PrismДокумент8 страницRefraction Through PrismKabeer Golechha100% (2)

- Abutment Design Data and CalculationsДокумент55 страницAbutment Design Data and CalculationstchangmaiОценок пока нет

- S.No Project Name Tender No Tender Date Tender Start Date Tender End Date DocumentДокумент2 страницыS.No Project Name Tender No Tender Date Tender Start Date Tender End Date DocumenttchangmaiОценок пока нет

- S.No Project Name Tender No Tender Date Tender Start Date Tender End Date DocumentДокумент2 страницыS.No Project Name Tender No Tender Date Tender Start Date Tender End Date DocumenttchangmaiОценок пока нет

- Notice For Coronavirus CrisisДокумент2 страницыNotice For Coronavirus CrisistchangmaiОценок пока нет

- Si Khrong Mu Thot (Deep Fried Pork Ribs)Документ2 страницыSi Khrong Mu Thot (Deep Fried Pork Ribs)tchangmaiОценок пока нет

- MPR Oct 3Документ26 страницMPR Oct 3tchangmaiОценок пока нет

- RFP Traffic Diligence - ConsultantДокумент19 страницRFP Traffic Diligence - ConsultanttchangmaiОценок пока нет

- Mars Is The FourthДокумент1 страницаMars Is The FourthANMOLОценок пока нет

- Hydrology ReportДокумент11 страницHydrology ReporttchangmaiОценок пока нет

- Appendix D - Alignment and SuperelevationДокумент22 страницыAppendix D - Alignment and SuperelevationMarc MathieuОценок пока нет

- Epc Contract DetailsДокумент1 страницаEpc Contract DetailstchangmaiОценок пока нет

- Sor AbrplДокумент4 страницыSor AbrpltchangmaiОценок пока нет

- 3.0M High Gabion Wall C - SДокумент1 страница3.0M High Gabion Wall C - StchangmaiОценок пока нет

- SHEET No. 83 E/9 SHEET No. 83 E/5: Joram Kolloriang Road (KM 70.00 To KM 138.00)Документ1 страницаSHEET No. 83 E/9 SHEET No. 83 E/5: Joram Kolloriang Road (KM 70.00 To KM 138.00)tchangmaiОценок пока нет

- Typical Cross SectionДокумент1 страницаTypical Cross SectiontchangmaiОценок пока нет

- Design Work ProgramДокумент5 страницDesign Work ProgramtchangmaiОценок пока нет

- Annexure I and RefДокумент7 страницAnnexure I and ReftchangmaiОценок пока нет

- @Ch.26+532 1x28 AbutДокумент178 страниц@Ch.26+532 1x28 AbuttchangmaiОценок пока нет

- Guided Exercise - Mendel's Peas: NameДокумент9 страницGuided Exercise - Mendel's Peas: NameStephanie Jane AndoyОценок пока нет

- Maruthamalai Hills of Western Ghats, Coimbatore District, Tamil Nadu - A Potential Ecosystem For Medicinal Plants.Документ15 страницMaruthamalai Hills of Western Ghats, Coimbatore District, Tamil Nadu - A Potential Ecosystem For Medicinal Plants.researchplantscienceОценок пока нет

- Resume Selva RathinamДокумент9 страницResume Selva RathinamSelvaОценок пока нет

- Making Cooking Oil AccessibleДокумент2 страницыMaking Cooking Oil AccessibleJase GeraldОценок пока нет

- Dhanvantary Bioscience PVT LTD Dogachhia, P.S.: Naihati, Dist: 24 Pgs (N), Pin - 743130Документ3 страницыDhanvantary Bioscience PVT LTD Dogachhia, P.S.: Naihati, Dist: 24 Pgs (N), Pin - 743130aparna tiwariОценок пока нет

- Cover Crop SpeciesДокумент5 страницCover Crop Species1ab4cОценок пока нет

- Total carotenoid content, α-carotene and β-carotene, of landrace pumpkins (Cucurbita moschata Duch) : A preliminary studyДокумент4 страницыTotal carotenoid content, α-carotene and β-carotene, of landrace pumpkins (Cucurbita moschata Duch) : A preliminary studyGalinaОценок пока нет

- Condensate Tank WELDING LOGДокумент6 страницCondensate Tank WELDING LOGhasan shahriarОценок пока нет

- A321 Technical Training Manual CFM56-5B Engine FamiliarizationДокумент92 страницыA321 Technical Training Manual CFM56-5B Engine FamiliarizationAnas AbandehОценок пока нет

- Osmotic Dehydration of Fruits and Vegetables - Review PDFДокумент20 страницOsmotic Dehydration of Fruits and Vegetables - Review PDFRoque VirgilioОценок пока нет

- Crome969 HeartwoodДокумент8 страницCrome969 HeartwoodAlcatrazz Albion OnlineОценок пока нет

- Science and Technology V 2020Документ2 страницыScience and Technology V 2020Daines MtonoОценок пока нет

- RejuveniixДокумент3 страницыRejuveniixapi-96089034Оценок пока нет

- Gliricidia GliricidiaДокумент18 страницGliricidia GliricidiaChamil Suranga SilvaОценок пока нет

- Form One Biology Notes: Introduction to ClassificationДокумент49 страницForm One Biology Notes: Introduction to ClassificationRaphael DikhandaОценок пока нет

- Classification IGCSEДокумент55 страницClassification IGCSEelizabethОценок пока нет

- Alergia de Contact 2008Документ150 страницAlergia de Contact 2008Jean BoutiereОценок пока нет

- Body Beast Food ListsДокумент5 страницBody Beast Food ListsSthefany Almanzar100% (1)

- A Vine On A House by Ambrose BierceДокумент6 страницA Vine On A House by Ambrose BierceEnviando TareasОценок пока нет

- Lesson 7: Stocks, Sauces, and SoupsДокумент16 страницLesson 7: Stocks, Sauces, and SoupsSean Lester PantallaОценок пока нет

- TBB's Wedding Color Guide + ThemesДокумент33 страницыTBB's Wedding Color Guide + ThemesKathleenJoyEnSagun100% (1)

- We Are What We Eat - A Sherpa CookbookДокумент78 страницWe Are What We Eat - A Sherpa Cookbookjayesh11Оценок пока нет

- Soil Testing and Adjusting pH, Nutrients for Vegetable GardenДокумент3 страницыSoil Testing and Adjusting pH, Nutrients for Vegetable GardenAnonymous 1VhXp1Оценок пока нет

- Menu ProjectДокумент1 страницаMenu Projectapi-357256089Оценок пока нет

- IELTS ACADEMIC WRITING TASK 1 SampleДокумент55 страницIELTS ACADEMIC WRITING TASK 1 SamplerayОценок пока нет

- Reading Essentials - Mendelian GeneticsДокумент4 страницыReading Essentials - Mendelian GeneticsBlack arab GaladimaОценок пока нет

- Marker For Wheat Stem Rust ResistanceДокумент9 страницMarker For Wheat Stem Rust Resistancesaurav100% (1)