Академический Документы

Профессиональный Документы

Культура Документы

Connection No: 34: LOADS (Worst Case Group No.112 & Element No.1120800)

Загружено:

Stephen JamesИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Connection No: 34: LOADS (Worst Case Group No.112 & Element No.1120800)

Загружено:

Stephen JamesАвторское право:

Доступные форматы

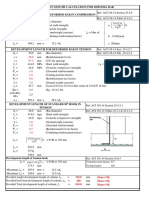

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 1

CONNECTION NO : 34 ( Typical outer & inner strut end detail to main truss along grid TR-13 to TR-22 in upper -

East flood light gantry walkway , Refer dwg no. AAS-SBP-SUS-STD-R1-DWG-00071 -

Rev.01)

LOADS ( worst case Group no.112 & Element No.1120800 )

Beam (CHS159x7.1)

Axial Fa := 132kN

NOTES:-

All welds are 6mm CFW., U.N.O

All welds shall be Electrode E70XX (or) Equivalent, U.N.O

All Connection plates are ASTM A572 GRADE-50 (or) Equivalent, U.N.O

All Rolled shapes are ASTM A-572 GRADE-50 (or) Equivalent, U.N.O

All Pins are hot dip galvanize as per clause 9.1.5 of Technical Specification

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 2

SECTIONAL PROPERTIES

Bracing B := "CHS 159 x 7.1 "

2

Dbr := 159mm Tbr := 7.1mm Abr := 3390mm

MATERIAL PROPERTIES

N N

Design yield strength of ASTM A572 Fy572 := 345 Tensile strength of ASTM A572 Fu572 := 450

2 2

mm mm

N N

Design yield strength 34 CrNiMo 6 + QT Fy341 := 900 ⋅ Tensile strength of Fu341 := 1100 ⋅

(Mat.-No.1.6582) (EN 10083-3) 2 34 CrNiMo 6 + QT 2

mm mm

(Thickness 16mm ~ 40mm) (Mat.-No.1.6582) (EN 10083-3)

(Thickness 16mm ~ 40mm)

N N

Design yield strength 34 CrNiMo 6 + QT Fy342 := 800 ⋅ Tensile strength of Fu342 := 1000 ⋅

(Mat.-No.1.6582) (EN 10083-3) 2 34 CrNiMo 6 + QT 2

mm mm

(Thickness 40mm ~ 100mm) (Mat.-No.1.6582) (EN 10083-3)

(Thickness 40mm ~ 100mm)

Nominal strength of fillet weld - N

Fvw := 217

for Electrodes E 70XX 2

(ANSI/AISC 360-10 Table J2.5) mm

DIMENSIONAL REQUIREMENTS (ANSI/AISC 360-10,Clause D5.2)

Diameter of Pin d := 40mm

Diameter of Pin Hole dh := d + 2mm dh = 42 ⋅ mm

Thickness of spade plate tsp := 10mm

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 3

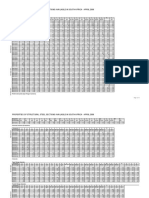

Plate Dimension b := 58mm

b(58 mm) > 2tsp+16 (36 mm): Therefore O.K.

Plate Dimension be := 2tsp + 16mm be = 36 ⋅ mm

b (58 mm) > be (36 mm): Therefore O.K.

Plate Dimension a := 59mm

a(59 mm) > 1.33be (47.9 mm): Therefore O.K.

Plate Dimension c := 59mm

(conservatively)

c(59 mm) > a (59 mm): Therefore O.K.

Width of Plate wsp := 179mm

wsp (179 mm) > 2be+d (112 mm): Therefore O.K.

CHECK FOR PIN

Check - Bearing on projected area of pin

Thickness of lug plate tlp := 20mm

2

Area Apb1 := d ⋅ tlp Apb1 = 800 ⋅ mm

Bearing strength Rn1 := 0.75 ⋅ 1.8 ⋅ Apb1 Fy342 Rn1 = 864 ⋅ kN

Rn1 (864 kN) > Fa (132 kN): Therefore O.K.

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 4

Check - Shear yielding on the pin

2

π ⋅d 2

Area A1 := A1 = 1256.6 ⋅ mm

4

Double shear yielding capacity Pn1 := 0.9 ⋅ 0.6A1 ⋅ Fy342 ⋅ 2 Pn1 = 1085.7 ⋅ kN

Pn1 (1085.7 kN) > Fa (132 kN): Therefore O.K.

Check - Bending yield line in pin

4

π ⋅d 4

Moment of Inertia Ix := Ix = 125663.7 ⋅ mm

64

Ix

3

Section modulus Zx := Zx = 6283.2 ⋅ mm

d ⋅ 0.5

Moment yielding capacity Mc := 0.9 ⋅ Zx ⋅ Fy342 Mc = 4.5 ⋅ kN ⋅ m

Spacing between Plates s := 2mm

Fa

Maximum moment in pin M1 :=

8

(

⋅ tlp + 4 ⋅ s + 2tsp ) M1 = 0.79 ⋅ kN ⋅ m

Mc (4.5 kN) > M1(0.8 kN): Therefore O.K.

Check - Combined shear & moment

2 2

⎛⎜ Fa ⎞⎟ ⎛ M1 ⎞⎟

Combined shear and moment R := +⎜ R = 0.21

⎜⎝ Pn1 ⎟⎠ ⎜⎝ Mc ⎟⎠

1.0 > R ( 0.21 ) : Therefore O.K.

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 5

CHECK FOR SPADE PLATE (ANSI/AISC 360-10,Clause D5.1)

Check - Bearing on the projected area (ANSI/AISC 360-10,Clause J7)

Projected area in bearing Apb2 := d ⋅ tsp ⋅ 2 2

Apb2 = 800 ⋅ mm

Bearing strength Rn2 := 0.75 ⋅ 1.8 ⋅ Apb2 ⋅ Fy572 Rn2 = 372.6 ⋅ kN

Rn2 (372.6 kN) > Fa (132 kN): Therefore O.K.

Check - Shear rupture on the effective area

⎡ ⎛ d ⎞⎤ 2

Area on shear failure path Asf := ⎢2 ⋅ tsp ⋅ ⎜ a + ⎟⎥ ⋅ 2 Asf = 3160 ⋅ mm

⎣ ⎝ 2 ⎠⎦

Nominal shear strength Pn2 := 0.75 ⋅ 0.6 ⋅ Asf ⋅ Fu572 Pn2 = 639.9 ⋅ kN

Pn2 (639.9 kN) > Fa (132 kN): Therefore O.K.

Check - Tensile rupture on the net effective area

Plate dimension be1 := b be1 = 58 ⋅ mm

Net effective area (

Anet := 2be1 ⋅ tsp ⋅ 2) Anet = 2320 ⋅ mm

2

Design tensile strength Pn3 := 0.75 ⋅ Anet ⋅ Fu572

Pn3 = 783 ⋅ kN

Pn3 (783 kN) > Fa (132 kN): Therefore O.K.

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 6

Check - Yield on the gross section of the plate (ANSI/AISC 360-10,Clause D2-a)

2

Gross Area Ag := wsp ⋅ tsp ⋅ 2 Ag = 3580 ⋅ mm

Tensile yeilding in the gross section Pn4 := 0.9 ⋅ Ag ⋅ Fy572 Pn4 = 1111.6 ⋅ kN

Pn4 (1111.6 kN) > Fa (132 kN): Therefore O.K.

Check - Buckling capacity (ANSI/AISC 360-10 Clause E3 )

Eff. length of spade plate (max) lg := 150mm K := 1.2

(conservatively)

Eff. width of spade plate wg := 179mm

2

tsp

Min. radius of gyration ry := ry = 2.89 ⋅ mm

12

K ⋅ lg N E

5

Slenderness ratio λyy := λyy = 62.35 E := 2.05 ⋅ 10 Cc := 4.71 Cc = 114.8

ry 2 Fy572

mm

2

π ⋅E N

Elastic critical buckling stress Fe := Fe = 520.4 ⋅

2 2

λyy mm

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 7

N

Compressive strength Fcr := 0.877 ⋅ Fe if λyy > Cc Fcr = 261.4 ⋅

2

mm

⎛ Fy572 ⎞

⎜ ⎟

⎜ Fe ⎟

⎝ 0.658 ⎠ ⋅ Fy572 otherwise

Compression capacity Pc := Fcr ⋅ wg ⋅ tsp ⋅ 0.9 ⋅ 2 Pc = 842.2 ⋅ kN

Pc (842.2 kN) > Fa (132 kN): Therefore O.K.

Weld - Spade plate & CHS

Slot Length ls := 175mm

Length of Weld Lw := 4 ⋅ ls Lw = 700 ⋅ mm

Fa kN

Shear per mm on weld FL := FL = 0.1 ⋅

2Lw mm

FL

Size of fillet weld reqd. s reqd := s reqd = 0.62 ⋅ mm

0.7 ⋅ Fvw

Adopt 6mm CFW

CHECK FOR LUG PLATE (ANSI/AISC 360-10,Clause D5.1)

Check - Bearing on the projected area (ANSI/AISC 360-10,Clause J7)

Projected area in bearing Apb3 := d ⋅ tlp 2

Apb3 = 800 ⋅ mm

Bearing strength Rn3 := 0.75 ⋅ 1.8 ⋅ Apb3 ⋅ Fy572 Rn3 = 372.6 ⋅ kN

Rn3 (372.6 kN) > Fa (132 kN): Therefore O.K.

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 8

Check - Shear rupture on the effective area

⎛ d⎞ 2

Area on shear failure path Asf1 := 2 ⋅ tlp ⋅ ⎜ a + ⎟ Asf1 = 3160 ⋅ mm

⎝ 2⎠

Nominal shear strength Pn5 := 0.75 ⋅ 0.6 ⋅ Asf1 ⋅ Fu572 Pn5 = 639.9 ⋅ kN

Pn5 (639.9 kN) > Fa (132 kN): Therefore O.K.

Check - Tensile rupture on the net effective area

Plate dimension be2 := b be2 = 58 ⋅ mm

2

Net effective area Anet1 := 2be2 ⋅ tlp Anet1 = 2320 ⋅ mm

Design tensile strength Pn6 := 0.75 ⋅ Anet1 ⋅ Fu572

Pn6 = 783 ⋅ kN

Pn6 (783 kN) > Fa (132 kN): Therefore O.K.

Check - Yield on the gross section of the plate (ANSI/AISC 360-10,Clause D2-a)

2

Gross Area Ag1 := wsp ⋅ tlp Ag1 = 3580 ⋅ mm

Tensile yeilding in the gross section Pn7 := 0.9 ⋅ Ag1 ⋅ Fy572 Pn7 = 1111.6 ⋅ kN

Pn4 (1111.6 kN) > Fa (132 kN): Therefore O.K.

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 9

Check - Buckling capacity (ANSI/AISC 360-10 Clause E3 )

Eff. length of gusset (max) lg := 150mm K := 1.2

(conservatively)

Eff. width of gusset wg := 250mm

(conservatively)

2

tlp

Min. radius of gyration ry := ry = 5.77 ⋅ mm

12

K ⋅ lg N E

5

Slenderness ratio λyy := λyy = 31.18 E := 2.05 ⋅ 10 Cc := 4.71 Cc = 114.8

ry 2 Fy572

mm

2

π ⋅E N

Elastic critical buckling stress Fe := Fe = 2081.6 ⋅

2 2

λyy mm

N

Compressive strength Fcr := 0.877 ⋅ Fe if λyy > Cc Fcr = 321.9 ⋅

2

mm

⎛ Fy572 ⎞

⎜ ⎟

⎜ Fe ⎟

⎝ 0.658 ⎠ ⋅ Fy572 otherwise

Compression capacity Pc := Fcr ⋅ wg ⋅ tlp ⋅ 0.9 Pc = 1448.5 ⋅ kN

Pc (1448.5 kN) > Fa (132 kN): Therefore O.K.

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Client : AAFAQ HOLDINGS LLC Date : OCT'12

Project : AL AIN STADIUM & MIXED USE Calc'd by : BND

DEVELOPMENT PHASE 1.1 Checked by : JKG

Job No. : F900

Sheet no : ROOF / 34 / 10

CHECK FOR BRACE BAR

Check - Shear capacity of wall

2

Av := ls ⋅ Tbr ⋅ 8 Av = 9940 ⋅ mm

Shear area of wall

shear capacity of wall ( )

Fsw := min 0.6 ⋅ Fy572 ⋅ Av , 0.45 ⋅ Fu572 ⋅ Av Fsw = 2012.9 ⋅ kN

Fsw (2012.8 kN) > Fa(132 kN): Therefore O.K.

Weld - Gusset plate & Beam

Weld Length ls1 := 250mm

Fa kN

Tension per mm on weld FT := FT = 0.3 ⋅

2ls1 mm

FT

Size of fillet weld reqd. s reqd1 := s reqd1 = 1.74 ⋅ mm

0.7 ⋅ Fvw

Adopt 6mm CFW

By inspection, All other checks are O.K for adopted detail.

Variation no: Rev. / Date Description

1 / JAN'13 Client comment Incorporation

Вам также может понравиться

- Mathcad - C06-C9 PDFДокумент7 страницMathcad - C06-C9 PDFKrish ChandОценок пока нет

- Anchor Bolt Design (AISC) - Tt100Документ2 страницыAnchor Bolt Design (AISC) - Tt100Jennifer HudsonОценок пока нет

- Zamil Sample CalculationsДокумент108 страницZamil Sample CalculationsAshraf KhalifaОценок пока нет

- Column Properties:-: Due To UplitДокумент2 страницыColumn Properties:-: Due To UplitRohit SinghОценок пока нет

- Result Summary: Pass PassДокумент11 страницResult Summary: Pass PassAmedeo SbacchiОценок пока нет

- 2 MeshingДокумент105 страниц2 MeshingMohanОценок пока нет

- Wind CalculatorДокумент12 страницWind Calculatorilyasmd7Оценок пока нет

- Pedestal DesignДокумент11 страницPedestal DesignNikhil TawadeОценок пока нет

- Mezz Portal 10 StoriesДокумент4 страницыMezz Portal 10 StoriesthiệnОценок пока нет

- Design of Shear Wall (Pier P1) : Check For MomentДокумент6 страницDesign of Shear Wall (Pier P1) : Check For MomentNishan GajurelОценок пока нет

- Tabel of Standard ProfilesДокумент55 страницTabel of Standard ProfilesJesus GscОценок пока нет

- LowRiseBuilding (MBMA 2002) V2Документ54 страницыLowRiseBuilding (MBMA 2002) V2Chea VannaiОценок пока нет

- Purlin - Roof DesignДокумент4 страницыPurlin - Roof DesignOng George SammyОценок пока нет

- Project Shabra C Location Al-AinДокумент4 страницыProject Shabra C Location Al-AinHareesh KilaruОценок пока нет

- Design of I-Shape Column Base Plate With Moment and Axial CompressionДокумент2 страницыDesign of I-Shape Column Base Plate With Moment and Axial CompressionAndro RebuyasОценок пока нет

- Result Summary - Overall: Moment Connection - Beam Splice Code AISC 360-16 LRFDДокумент6 страницResult Summary - Overall: Moment Connection - Beam Splice Code AISC 360-16 LRFDMichenerparkОценок пока нет

- KW 17449 PDFДокумент770 страницKW 17449 PDFTrungNguyen100% (1)

- ASCE7 05 WindДокумент7 страницASCE7 05 WindRakesh SharmaОценок пока нет

- Design of Temporary Horizontal Life Line (HLL) A. Material Properties Steel MemberДокумент2 страницыDesign of Temporary Horizontal Life Line (HLL) A. Material Properties Steel MemberNp Pw0% (1)

- Prof M G Gadgil Building Designed As Per Old Code and IS 16700-2017 PDFДокумент128 страницProf M G Gadgil Building Designed As Per Old Code and IS 16700-2017 PDFankit kadamОценок пока нет

- Platform-Report FinaleДокумент24 страницыPlatform-Report FinaleFeroz Khan PatthanОценок пока нет

- BS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BДокумент1 страницаBS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BmodarthОценок пока нет

- Exhibition Stand - REV 0Документ12 страницExhibition Stand - REV 0shibu4321Оценок пока нет

- SDA-08-001 Gusset Plate Design PDFДокумент81 страницаSDA-08-001 Gusset Plate Design PDFdanlemakОценок пока нет

- Wind Loading Based On EC 1991-4Документ4 страницыWind Loading Based On EC 1991-4janethОценок пока нет

- Cranebeam v1 2 AramadaДокумент1 страницаCranebeam v1 2 AramadaronyОценок пока нет

- PB 1621 Building 1 (MALL)Документ906 страницPB 1621 Building 1 (MALL)ranjitОценок пока нет

- ReportДокумент52 страницыReportFeroz Khan PatthanОценок пока нет

- Final Soil Test ReportДокумент7 страницFinal Soil Test ReportPrateek JhanjiОценок пока нет

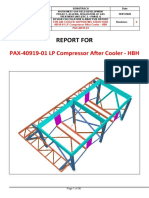

- Report For: PAX-40919-01 LP Compressor After Cooler - HBHДокумент36 страницReport For: PAX-40919-01 LP Compressor After Cooler - HBHRajasekar MeghanadhОценок пока нет

- The - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcreteДокумент9 страницThe - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcretejscuencaОценок пока нет

- Design Calculation For Lifting Hook Rev00Документ29 страницDesign Calculation For Lifting Hook Rev00layaljamal2Оценок пока нет

- Stair Stringer DesignДокумент2 страницыStair Stringer DesignTerry CheukОценок пока нет

- WIND02 v2-21: Detailed Wind Load Analysis Per ASCE 7-10Документ3 страницыWIND02 v2-21: Detailed Wind Load Analysis Per ASCE 7-10gmontesroy100% (1)

- Miscellaneous DesignДокумент5 страницMiscellaneous DesignShaun PattersonОценок пока нет

- RCC Column Calc Good MahfuzДокумент1 страницаRCC Column Calc Good Mahfuzkim lokОценок пока нет

- Dog Legged Stair CaseДокумент15 страницDog Legged Stair Casemathews josephОценок пока нет

- Ep HSSДокумент191 страницаEp HSSJane NishaОценок пока нет

- Project Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionДокумент2 страницыProject Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionmaheshbandhamОценок пока нет

- Wind LoadДокумент5 страницWind LoadPATEL JIGARОценок пока нет

- GRC Design and LoadsДокумент4 страницыGRC Design and Loadsmohamed rafiОценок пока нет

- Development Length Calculation For 20Mm Dia Bar: B y C DC RДокумент2 страницыDevelopment Length Calculation For 20Mm Dia Bar: B y C DC RkarthiОценок пока нет

- Base Plate and Anchor Bolt Design - MailДокумент5 страницBase Plate and Anchor Bolt Design - MailMiguelRagasОценок пока нет

- Est SHTДокумент26 страницEst SHTselvakumarОценок пока нет

- UB Fin Plate DesignДокумент8 страницUB Fin Plate DesignWin ThanОценок пока нет

- Base Plate - Silo Supporting R1Документ10 страницBase Plate - Silo Supporting R1soumi bhattacharyaОценок пока нет

- Job#: 2015-052 Chain Link Fence: Line Post Calculator: Q .00256K K K V Q 0.6qДокумент1 страницаJob#: 2015-052 Chain Link Fence: Line Post Calculator: Q .00256K K K V Q 0.6qLogan James HowlettОценок пока нет

- Design of Wall Girt: Input DataДокумент3 страницыDesign of Wall Girt: Input DataAnonymous V6up3d0QGОценок пока нет

- Idn - 3Документ6 страницIdn - 3Anh KyОценок пока нет

- Anchor Bolt CheckДокумент1 страницаAnchor Bolt CheckihpeterОценок пока нет

- Design of Roof Purlin at Mid Bay: KX 0.995 Ky 0.100Документ3 страницыDesign of Roof Purlin at Mid Bay: KX 0.995 Ky 0.100Utkarsh BhardwajОценок пока нет

- Beam - Section Classification Is 800-2007Документ6 страницBeam - Section Classification Is 800-2007ranjitОценок пока нет

- Cantiver Beam DesignДокумент2 страницыCantiver Beam DesignRathinavel VenkateshwaranОценок пока нет

- XyzДокумент64 страницыXyzP S HARSHITAОценок пока нет

- r0 St-01 Parking Shed Details Dt310319 BWДокумент1 страницаr0 St-01 Parking Shed Details Dt310319 BWSatyen RamaniОценок пока нет

- Fillet Weld Connection DesignДокумент1 страницаFillet Weld Connection Designbalaji gmscОценок пока нет

- Circular WeldДокумент12 страницCircular WeldJohn Paul UmaliОценок пока нет

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateДокумент10 страницR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkОценок пока нет

- 0 - BASE SHEAR REDISTRIBUTION BETWEEN THE RC DUAL SYSTEM STRUCTURAL COMPONENTS - V.Sigmund Itd. - 2008 - 8158 PDFДокумент8 страниц0 - BASE SHEAR REDISTRIBUTION BETWEEN THE RC DUAL SYSTEM STRUCTURAL COMPONENTS - V.Sigmund Itd. - 2008 - 8158 PDFnebojsadj6411Оценок пока нет

- Baseplate-Kolom wf250Документ79 страницBaseplate-Kolom wf250Gary JonathanОценок пока нет

- Purlin For 2 Bays RNDДокумент64 страницыPurlin For 2 Bays RNDStephen JamesОценок пока нет

- Equal Angles: BS 5950-1: 2000 BS EN 10056-1: 1999Документ4 страницыEqual Angles: BS 5950-1: 2000 BS EN 10056-1: 1999Stephen JamesОценок пока нет

- Communication Process: Communication Prepared by Revele SДокумент22 страницыCommunication Process: Communication Prepared by Revele SStephen JamesОценок пока нет

- Hangar Design ReferenceДокумент5 страницHangar Design ReferenceStephen James100% (1)

- Connection Design SheetДокумент47 страницConnection Design SheetStephen James100% (1)

- Practical Placement Report - James DevassyДокумент42 страницыPractical Placement Report - James DevassyStephen JamesОценок пока нет

- Internship Report. - James DevassyДокумент41 страницаInternship Report. - James DevassyStephen JamesОценок пока нет

- Steel Members DesignДокумент195 страницSteel Members DesignStephen JamesОценок пока нет

- Equal Angles: BS 5950-1: 2000 BS EN 10056-1: 1999Документ4 страницыEqual Angles: BS 5950-1: 2000 BS EN 10056-1: 1999Stephen JamesОценок пока нет

- Staad 4Документ37 страницStaad 4saisssms9116100% (2)

- Properties of Steel SectionsДокумент10 страницProperties of Steel SectionsHayder Al TaaiОценок пока нет

- Lifetime Extension of Flexible Pipe Systems: Extend OperationДокумент24 страницыLifetime Extension of Flexible Pipe Systems: Extend OperationAaron ChristopherОценок пока нет

- Dowel BarsДокумент70 страницDowel Barsesprindia100% (1)

- 2015 Rohn Full Catalog PDFДокумент328 страниц2015 Rohn Full Catalog PDFImranОценок пока нет

- CV of Tanvir IqbalДокумент2 страницыCV of Tanvir IqbalThe-Tanvir IqbalОценок пока нет

- L4Документ14 страницL4Jayesh DeshmukhОценок пока нет

- Tool Engineering Jigs and FixturesДокумент312 страницTool Engineering Jigs and FixturesMike100% (5)

- Master Aerospace Engineering ASM TuDelft StudyguideДокумент110 страницMaster Aerospace Engineering ASM TuDelft StudyguideSamuel DemianОценок пока нет

- Retaining Wall Stability 2.05 DocumentationДокумент21 страницаRetaining Wall Stability 2.05 DocumentationrowatersОценок пока нет

- Structural Behaviour of Concrete With Replacement of FevicolДокумент8 страницStructural Behaviour of Concrete With Replacement of FevicolGRD JournalsОценок пока нет

- 5 - Electrical Installation Certificate 17th Edition BS7671Документ4 страницы5 - Electrical Installation Certificate 17th Edition BS7671Shobhit Tomar KrishnaОценок пока нет

- Date Sheet DAE Annual 2016Документ5 страницDate Sheet DAE Annual 2016alibankerОценок пока нет

- Lecture - 1 ELECTRICAL TECHNOLOGYДокумент19 страницLecture - 1 ELECTRICAL TECHNOLOGYsakibОценок пока нет

- RWF55 Temperature Pressure Burner Controller User Manual U7867enДокумент94 страницыRWF55 Temperature Pressure Burner Controller User Manual U7867enGarry Bernard NelsonОценок пока нет

- Unpriced BOQ EAST Storage TankДокумент27 страницUnpriced BOQ EAST Storage TankwasОценок пока нет

- PIP STC01015 PreviewДокумент8 страницPIP STC01015 PreviewAnonymous WeDXoM1QОценок пока нет

- Issa Batarseh, Ahmad Harb - Power Electronics - Circuit Analysis and Design (2018, Springer) PDFДокумент689 страницIssa Batarseh, Ahmad Harb - Power Electronics - Circuit Analysis and Design (2018, Springer) PDFtaufiqishak09100% (4)

- Tarea IntegradoraДокумент2 страницыTarea IntegradoraDaniel AndoneguiОценок пока нет

- Civil Specification Vol-IIIДокумент266 страницCivil Specification Vol-IIIIrshad KhanОценок пока нет

- Ultimate Load Capacity of Reinforced Concrete SlabДокумент8 страницUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- Skin Effect Current TracingДокумент6 страницSkin Effect Current TracingabubackersiddieqОценок пока нет

- Ecu TestingДокумент3 страницыEcu TestingPablo NuñezОценок пока нет

- Voltage Drop GuidelinesДокумент4 страницыVoltage Drop Guidelinesindira_tungОценок пока нет

- Series 7000 - Tolerances, Testing and Quality ControlДокумент27 страницSeries 7000 - Tolerances, Testing and Quality ControlKamagara Roland AndrewОценок пока нет

- Capital Controls For Major Projects - EPCM Contract ManagementДокумент40 страницCapital Controls For Major Projects - EPCM Contract ManagementDavid PrastyanОценок пока нет

- Robert Melby ResumeДокумент2 страницыRobert Melby ResumeSarah DelgadoОценок пока нет

- Tech-2: Technical Proposal For General Consultant For Chennai Metro Rail Phase-2 Project - Corridor 4Документ4 страницыTech-2: Technical Proposal For General Consultant For Chennai Metro Rail Phase-2 Project - Corridor 4Samridh GuptaОценок пока нет

- Kanada CVДокумент3 страницыKanada CVPera PericОценок пока нет

- Catalog Medicale enДокумент196 страницCatalog Medicale envizanteaОценок пока нет

- Wny 210 157 Part 6Документ222 страницыWny 210 157 Part 6lamondbrownОценок пока нет

- Voltage FlickerДокумент7 страницVoltage FlickerAnonymous xaeuoo4Оценок пока нет

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincОт EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincРейтинг: 3.5 из 5 звезд3.5/5 (137)

- ICH Quality Guidelines: An Implementation GuideОт EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleОценок пока нет

- Chemistry for Breakfast: The Amazing Science of Everyday LifeОт EverandChemistry for Breakfast: The Amazing Science of Everyday LifeРейтинг: 4.5 из 5 звезд4.5/5 (14)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactОт EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactРейтинг: 5 из 5 звезд5/5 (5)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsОт EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsРейтинг: 5 из 5 звезд5/5 (3)

- It's Elemental: The Hidden Chemistry in EverythingОт EverandIt's Elemental: The Hidden Chemistry in EverythingРейтинг: 4 из 5 звезд4/5 (10)

- Chemistry: a QuickStudy Laminated Reference GuideОт EverandChemistry: a QuickStudy Laminated Reference GuideРейтинг: 5 из 5 звезд5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactОт EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactРейтинг: 5 из 5 звезд5/5 (1)

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesОт EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesОценок пока нет

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideОт EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideОценок пока нет

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeОт EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeРейтинг: 4 из 5 звезд4/5 (1)

- The Production of Volatile Oils and Perfumery Plants in the United StatesОт EverandThe Production of Volatile Oils and Perfumery Plants in the United StatesОценок пока нет

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableОт EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Essential Chemistry for Formulators of Semisolid and Liquid DosagesОт EverandEssential Chemistry for Formulators of Semisolid and Liquid DosagesРейтинг: 5 из 5 звезд5/5 (2)

- Guidelines for Integrating Process Safety into Engineering ProjectsОт EverandGuidelines for Integrating Process Safety into Engineering ProjectsОценок пока нет

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeОт EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeОценок пока нет

- The Nature of Drugs Vol. 2: History, Pharmacology, and Social ImpactОт EverandThe Nature of Drugs Vol. 2: History, Pharmacology, and Social ImpactОценок пока нет