Академический Документы

Профессиональный Документы

Культура Документы

Caesar II Broucher V1.00

Загружено:

MohammedBujairАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Caesar II Broucher V1.00

Загружено:

MohammedBujairАвторское право:

Доступные форматы

OIL AND GAS SERVICES PRIVATE LIMITED

OIL

UNITED OIL AND GAS ENGINEERING

DRIVING TECHNOLOGIESPRIVATE LIMITED

DRIVING TECHNOLOGIES

TRAINING COURSES

United Oil & Gas Engineering Pvt Ltd

Plot No 130, Rathinam Street, Vasudevan Nagar,

Plot No 130,Chennai

Jafferkhanpet, Rathinam Street, Vasudevan Nagar,

- 600083.

Tel No: 044-43501332

Jafferkhanpet, Chennai - 600083.

www.ogschennai.com

Ct No: 044-43501332

www.oilandgasservices.co.in

CAESAR II

CAESAR II is the Pipe Stress Analysis standard against which all others are measured and compared. The

spreadsheet input technique revolutionized the way piping models are built, modified, and verified.

CAESAR II was the first pipe stress program specifically designed for the PC environment. The interactive

capabilities permit rapid evaluation of both input and output, thereby melding seamlessly into the "design

- analyze" iteration cycle.

CAESAR II incorporates a wide range of capabilities, from numerous piping codes, to expansion joint, valve

& flange and structural data bases, to structural and buried pipe modeling, to equipment and vessel nozzle

evaluation, to spectrum and time history analysis. Most of the features of CAESAR II are available at a

keystroke, but at the same time are not imposed upon the analyst.

CAESAR II is continuously maintained and improved by the engineering staff, who have worked in

industry for engineering and consulting firms. This experience not only guides program development, but

provides users with knowledgeable support. This allows CAESAR II to work the way a typical engineer

thinks and solves a problem.

Scope of CAESAR II

Piping Loads – Static & Dynamic

Static & Dynamic Analysis

Forces, Moments & Stress Calculations

Classification of Loads

Pipe Span Calculations Flexibility Analysis using

ASME B 31.3 Code Equations

Sustained Loads – Internal Pressure &

Longitudinal Stresses

Occasional Load Stresses

Who Should Attend?

• This training is for the person who wants to enter

into their respective core in oil and gas sector.

• This training is ideal for Mechanical,

Civil, Chemical and Electrical engineers,

Project engineers and managers, operations and

Maintenance engineers.

• Eligibility: Diploma and Degree in /EEE/

MECH/CIVIL/CHEMICAL

Course Duration:

80 Hours

Course Outline:

Normal Track : 2 Hours/Day,

General modeling Monday-Friday : 30 Days

System redesign Fast Track : 4 Hours / Day,

Nozzle flexibility Monday-Friday : 15 days

Pipe stress theory Week End : Saturday and Sunday

Pump evaluation (API, NEMA)

Structural steel

Training Features

Stress analysis

Load-based piping design Engineering Design courses syllabus as per standard and

Expansion joints code of API & ASME.

Hager sizing 100 % job oriented training program.

Re-design for expansion Our trainers have 10 years of industrial experience in

Reporting Pipe Stress engineering.

Training based upon live projects on Pipe Stress Design

engineering.

Assessment:

All assessments will be conducted in the workplace. Assessment tasks consist of e.g.: practical discussions,

case studies, on-site exercises, hands-on.

Certificates:

Certificates will be awarded to the learners who completed and pass in the assessments and who completed

at least 80% of the attendance report.

Course Language: English

Progress Reports:

Progress and attendance reports linked to the specifications for the reporting period will be sent to the

company for each learner. This report will list learner’s progress and achievements with respect to the

appropriate section of the syllabus, indicating the progress made towards the training objective.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Nfpa 1142Документ38 страницNfpa 1142Sebastián Lagos100% (1)

- Cert Fact Sheet CMQ OeДокумент2 страницыCert Fact Sheet CMQ OeMohammedBujairОценок пока нет

- Cat - Iii: VA ISO 18436 Category IIIДокумент3 страницыCat - Iii: VA ISO 18436 Category IIIMohammedBujairОценок пока нет

- Energy Academy Training Overview 2022: About DNVДокумент2 страницыEnergy Academy Training Overview 2022: About DNVMohammedBujairОценок пока нет

- S.Arivoli Nabisudeen: QC Inspector-WeldingДокумент3 страницыS.Arivoli Nabisudeen: QC Inspector-WeldingMohammedBujairОценок пока нет

- Why Become A Certified Quality Inspector?: What Are The Core Competencies of A CQI?Документ2 страницыWhy Become A Certified Quality Inspector?: What Are The Core Competencies of A CQI?MohammedBujairОценок пока нет

- B.A. English Literature (Journalism and Public Relations)Документ171 страницаB.A. English Literature (Journalism and Public Relations)MohammedBujairОценок пока нет

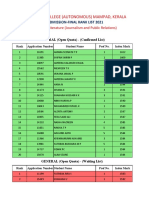

- PG Admission 2017 Final Allotment Rank List M.A. English Open Merit - Sure ListДокумент6 страницPG Admission 2017 Final Allotment Rank List M.A. English Open Merit - Sure ListMohammedBujairОценок пока нет

- Name: Vivek Vadake Veettil: Academic QualificationДокумент6 страницName: Vivek Vadake Veettil: Academic QualificationMohammedBujairОценок пока нет

- Vibration Analysis For Non-Vibration EngineersДокумент4 страницыVibration Analysis For Non-Vibration EngineersMohammedBujair100% (1)

- Ultra-Rugged Smartphone: Sonim XP8Документ2 страницыUltra-Rugged Smartphone: Sonim XP8MohammedBujairОценок пока нет

- C A & P A Auguste Escoffier School of Culinary Arts Supplement To The Student Catalog 2019 - 2020Документ20 страницC A & P A Auguste Escoffier School of Culinary Arts Supplement To The Student Catalog 2019 - 2020MohammedBujairОценок пока нет

- Pipeline Pigging Operation Procedure: Operations OperationsДокумент16 страницPipeline Pigging Operation Procedure: Operations OperationsMohammedBujairОценок пока нет

- Thomas Algorithm Questions and Answers - SanfoundryДокумент5 страницThomas Algorithm Questions and Answers - SanfoundryMohammedBujairОценок пока нет

- Mobile No: +91-8526351664: Post Applied For QC Welding Inspector Career GoalДокумент3 страницыMobile No: +91-8526351664: Post Applied For QC Welding Inspector Career GoalMohammedBujairОценок пока нет

- Degeneracy of Energy Levels of Pseudo-Gaussian Oscillators: Articles You May Be Interested inДокумент6 страницDegeneracy of Energy Levels of Pseudo-Gaussian Oscillators: Articles You May Be Interested inMohammedBujairОценок пока нет

- Austin Student Programs CatalogДокумент40 страницAustin Student Programs CatalogMohammedBujairОценок пока нет

- ManpowersupplytenderdocF 21042021 9400Документ57 страницManpowersupplytenderdocF 21042021 9400MohammedBujairОценок пока нет

- Adtnl Short List - Post Code 06 - MT - Chemical - Recruitment Notification No.1 2020 - 769Документ3 страницыAdtnl Short List - Post Code 06 - MT - Chemical - Recruitment Notification No.1 2020 - 769MohammedBujairОценок пока нет

- Discipline, Number of Vacancies, Educational Qualification and ExperienceДокумент8 страницDiscipline, Number of Vacancies, Educational Qualification and ExperienceMohammedBujairОценок пока нет

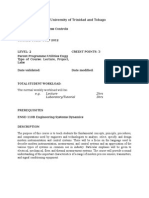

- CTLP 2012 Process Controls Course Outline Sept 2013Документ3 страницыCTLP 2012 Process Controls Course Outline Sept 2013Kendall BirjueОценок пока нет

- USGS Design Maps Summary Report Universal Hollywood Site Class CДокумент7 страницUSGS Design Maps Summary Report Universal Hollywood Site Class CDan Dela Peña0% (1)

- Technical Specification Combustiom Modifications Lot 1 For TenderДокумент184 страницыTechnical Specification Combustiom Modifications Lot 1 For TendervrajtilakОценок пока нет

- 5 SoftwareTestingStrategiesДокумент47 страниц5 SoftwareTestingStrategiesSandy CyrusОценок пока нет

- Service Call Attendent SheetДокумент8 страницService Call Attendent Sheetkuldip awasthiОценок пока нет

- Os E406 - 2010 04Документ131 страницаOs E406 - 2010 04Kishor ShriyanОценок пока нет

- Assignment 1 Clb40002 Engineering SocietyДокумент10 страницAssignment 1 Clb40002 Engineering SocietyJamal FitriОценок пока нет

- Climbing FormworkДокумент5 страницClimbing Formworksanjeev2812Оценок пока нет

- Engineering ProfessionДокумент45 страницEngineering ProfessionUpender DhullОценок пока нет

- DatasheetДокумент7 страницDatasheetJoel DesmaraisОценок пока нет

- Dimensional Engineering PDFДокумент71 страницаDimensional Engineering PDFAvneet MaanОценок пока нет

- Pipe DesignДокумент48 страницPipe Designdineshkumar1234Оценок пока нет

- BLDG Laws NBCДокумент158 страницBLDG Laws NBCBeverly Luthe MorteraОценок пока нет

- Basics of Pipe Stress Analysis A Presentation-Part 2 of 2Документ6 страницBasics of Pipe Stress Analysis A Presentation-Part 2 of 2iaft100% (1)

- EDU Detailed Drawings Exercises 2017Документ51 страницаEDU Detailed Drawings Exercises 2017SmrileОценок пока нет

- ST - Mother Theresa Engineering College Subject Wise Result AnalysisДокумент36 страницST - Mother Theresa Engineering College Subject Wise Result AnalysisSiva RamanОценок пока нет

- Advantages of Bladder Surge TanksДокумент8 страницAdvantages of Bladder Surge TanksChrisHogbenОценок пока нет

- Jis G3472 o Stam 440G PDFДокумент13 страницJis G3472 o Stam 440G PDFAxel TorresОценок пока нет

- Mobile Car Racing (3D Game)Документ12 страницMobile Car Racing (3D Game)Abdullah khanОценок пока нет

- Articificial IntelligenceДокумент19 страницArticificial IntelligenceDivyanshiОценок пока нет

- Syabas Guidelines Draft Final 080620071Документ53 страницыSyabas Guidelines Draft Final 080620071Seh Yong100% (1)

- Boeing Human FactorsДокумент5 страницBoeing Human Factorsaske7sp8055100% (1)

- Introduction of PPICДокумент16 страницIntroduction of PPICsuciОценок пока нет

- VAxx 132 GYk 1 CH MHAHyut 1630730394Документ32 страницыVAxx 132 GYk 1 CH MHAHyut 1630730394Jerald LatorreОценок пока нет

- Post HydrotestingДокумент7 страницPost HydrotestingVineet SinghОценок пока нет

- Broken Earth Neutral Faults in Distribution Systems With Traffic Signal LoadsДокумент13 страницBroken Earth Neutral Faults in Distribution Systems With Traffic Signal LoadsRajendra Prasad ShuklaОценок пока нет

- Wood FramingДокумент92 страницыWood FramingBarjam KafexhiuОценок пока нет

- Aero PDFДокумент93 страницыAero PDFImranKabirОценок пока нет

- Justin Culver Resume 1Документ3 страницыJustin Culver Resume 1Chris CamarilloОценок пока нет