Академический Документы

Профессиональный Документы

Культура Документы

Design Practices and Standards Summary Data Sheet: 1.0 New/Updated Standard

Загружено:

DhanushИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design Practices and Standards Summary Data Sheet: 1.0 New/Updated Standard

Загружено:

DhanushАвторское право:

Доступные форматы

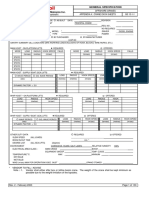

DESIGN PRACTICES AND STANDARDS

DIM XX GS

SUMMARY DATA SHEET

1.0 NEW/UPDATED STANDARD

TITLE: GS 00-05-21: Loadout and Tiedown

REVISION DATE & NO.: February,. 2003 Rev. 2

2.0 SPEC(S) USED PRIOR TO NEW/UPDATED STANDARD

TITLE: GS 00-05-21: Loadout and Tiedown

REVISION DATE & NO.: December 1997 Rev. 1

3.0 PRIMARY AUTHOR(S):

(Name / Dept) Rick Birdwell / DPD-CSD

4.0 REVIEWERS:

(Name / Dept) V. K Raja/ DPD-GuE

Chee Weng Kong / DPD-CSD

Choong Chee Keong / DPD-SFD III

GS 0-5-21 - Summary Datasheet

DESIGN PRACTICES AND STANDARDS

DIM XX GS

SUMMARY DATA SHEET

5.0 SUMMARY OF CHANGES

CHANGE IMPACT

Blank = None, P=Positive, D=Detrimental

NATIONAL STANDARDS EXCEPTION

INTERNATIONAL STANDARDS

ENVIRONMENTAL

EMEP EXCEPTION

SAFETY/HEALTH

OPERABILITY

CORROSION

EXCEPTION

SCHEDULE

CONSIDER CHANGE DESCRIPTION

COST FOR (Indicate Para # from new/updated DIM/GS) REASON FOR CHANGE

IMPACT RETROACTIVE

RISK

APPLICATION

(USD K) (YES/NO)

No Revised company name and format Company name change and new formatting standards.

P No 4.3 TRANSPORTER shall furnish grillage and tiedown Transporter not fabricator to furnish tie down material.

materials (other than those specified in 7.3.5) to secure the Reduce cost and facilitate disposal.

components and appurtenances on barge deck per drawings

supplied by TRANSPORTER and approved by EMEPMI.

Welding shall be approved by EMEPMI and EMEPMI Marine

Surveyor. All tiedown materials provided by TRANSPORTOR

shall remain the property of TRANSPORTER.

No 5.1.4-7 Added requirement that Erector witness Insure erector confirms that testing is adequate

No 6.2 Tiedown drawings (IFC) shall be provided 45 days prior Clarified when deliverable required.

to loadout

GS 0-5-21 - Summary Datasheet

DESIGN PRACTICES AND STANDARDS

DIM XX GS

SUMMARY DATA SHEET

5.0 SUMMARY OF CHANGES

CHANGE IMPACT

Blank = None, P=Positive, D=Detrimental

NATIONAL STANDARDS EXCEPTION

INTERNATIONAL STANDARDS

ENVIRONMENTAL

EMEP EXCEPTION

SAFETY/HEALTH

OPERABILITY

CORROSION

EXCEPTION

SCHEDULE

CONSIDER CHANGE DESCRIPTION

COST FOR (Indicate Para # from new/updated DIM/GS) REASON FOR CHANGE

IMPACT RETROACTIVE

RISK

APPLICATION

(USD K) (YES/NO)

P P No Added following requirements to FABRICATOR's loadout Recommended per lesson learned 543 SFD Gate 5 #1

procedure requirement

6.3.14 Method to control personnel access to cargo bare

(e.g. personnel tag system)

6.3.15 Emergency Response Plan for Man overboard and

Fire on Cargo Barge including method of fire

fighting (e.g. adequate fire fighting equipment) and

egress.

6.3.16 Safety Surveillance plan (24 hour coverage)

6.3.17 When loadout is by multiwheeled transporters,

plans for load testing, oil leak testing and verifying

functionality of transporter prior to use.

GS 0-5-21 - Summary Datasheet

DESIGN PRACTICES AND STANDARDS

DIM XX GS

SUMMARY DATA SHEET

5.0 SUMMARY OF CHANGES

CHANGE IMPACT

Blank = None, P=Positive, D=Detrimental

NATIONAL STANDARDS EXCEPTION

INTERNATIONAL STANDARDS

ENVIRONMENTAL

EMEP EXCEPTION

SAFETY/HEALTH

OPERABILITY

CORROSION

EXCEPTION

SCHEDULE

CONSIDER CHANGE DESCRIPTION

COST FOR (Indicate Para # from new/updated DIM/GS) REASON FOR CHANGE

IMPACT RETROACTIVE

RISK

APPLICATION

(USD K) (YES/NO)

P P No 6.4 All lifting slings used shall be permanently tagged with its Made sling and shackle testing same as offshore

permissible safe working load. All slings and shackles shall specification.

be certified within the previous 6 months by a recognized

certifying authority such as ABS, Lloyds or DNV. Slings

shall be certified by load testing to two times the safe working

load (SWL) or the maximum anticipated load. For slings with

SWL of 250 metric tons or more the sling test load may be

reduced to 1.25 times the SWL if CONTRACTOR can

demonstrate a limitation in regionally available sling testing

facilities. Shackle bodies and pins shall be inspected by

magnetic particle. Slings and shackles for heavy lifts

(>800MT) shall be inspected prior to each use. Sling

certificates and shackle inspection records shall be submitted

to EMEPMI for review.

In no case shall design load exceed manufacturer's rated safe

working load.

Shackles shall be Crosby Laughlin high tensile type or equal.

Shackle pins shall have a clearance in padeye holes, not

exceeding 5% of the pin diameter or 5mm whichever is

smaller. The jaw width of shackles shall not be greater than

1.25 times the overall thickness of padeyes.

GS 0-5-21 - Summary Datasheet

DESIGN PRACTICES AND STANDARDS

DIM XX GS

SUMMARY DATA SHEET

5.0 SUMMARY OF CHANGES

CHANGE IMPACT

Blank = None, P=Positive, D=Detrimental

NATIONAL STANDARDS EXCEPTION

INTERNATIONAL STANDARDS

ENVIRONMENTAL

EMEP EXCEPTION

SAFETY/HEALTH

OPERABILITY

CORROSION

EXCEPTION

SCHEDULE

CONSIDER CHANGE DESCRIPTION

COST FOR (Indicate Para # from new/updated DIM/GS) REASON FOR CHANGE

IMPACT RETROACTIVE

RISK

APPLICATION

(USD K) (YES/NO)

P P D, $3K/ No 6.6 Updated Loadout durations per Safety Committee Updated Loadout durations per Safety Committee

recommendations. recommendations to reduce the rush at loadout.

barge

For combinations of components on the same cargo barge not

addressed above, the duration for the loadout shall be

determined by adding the individual component durations

together minus 48 hours times one less the number of

individual components durations used.

No 7.3.3 MSF/BSF/deck legs, tiedown braces between the legs Added requirement for doubler plate.

and barge shall be connected to doubler plates welded to the

legs.

GS 0-5-21 - Summary Datasheet

DESIGN PRACTICES AND STANDARDS

DIM XX GS

SUMMARY DATA SHEET

6.0 LIST OF UPDATED INTERNATIONAL & NATIONAL STANDARDS AND PRACTICES

REFERENCED IN THE DIM/GS.

The GS 0-5-21 refers to API RP 2A latest addition. Other GS's are referred that refer to several

international standards. There are no known conflicts and these GSs require that the latest revision

of the standards and practices be used. These GSs also requires any conflicts to be resolved by

EMEPMI.

GS 0-5-21 - Summary Datasheet

DESIGN PRACTICES AND STANDARDS

DIM XX GS

SUMMARY DATA SHEET

7.0 CHECKLIST FOR NEW/UPDATED STANDARDS

Item No. Yes/No/NA Notes*

1. Does this DIM/GS require approval from Steering No

Committee or Deputy Production Manager?

2. Is this new/revised standard really necessary? Yes Meet the 5 year revision cycle

requirement

3. Conform to applicable International standards Yes International Standards incorporated

by reference

4. Conform to applicable National standards NA

5. Conform to EMEP NA

6. Meet or exceed applicable regulatory requirements or NA

PETRONAS guidelines

7. Embody responsible requirements where regulations Yes

do not exist

8. Reflect latest developments and lessons learned Yes LL 543 SFD Gate 5 #3 incorporated

New Loadout durations

recommended by Safety Committee

incorporated.

9. Consider facilities abandonment requirements (Refer NA

to PETRONAS Guidelines for Platform

Decommissioning)

10. Consider Human Factor requirements (Refer to MOH NA

Industrial Hygiene Checklist)

11. Consider effects of new/updated industry standards Yes Refer to section 6 above.

12. Consider applicable Project Change Notice (PCN) NA

forms

13. Incorporate approved DIM/GS Permanent Change NA

Recommendation Forms

14. Consider relevant DIM/GS Bulletins NA

Notes* - Include PCN No., Safety Bulletin Ref. No., Lesson Learned Ref. No. and GS/DIM Bulletin Ref. No.

8.0 APPROVAL TO ISSUE THE NEW/UPDATED STANDARD

(Refer to Section 4.3 in DIM 0-1 / GS 0-0-1 for approval level required)

Approved by: _____________________________ Date: 27/1/2003

(Hussein Ismail CSD Manager)

GS 0-5-21 - Summary Datasheet

Вам также может понравиться

- Build A 10 Ton Hydraulic PressДокумент10 страницBuild A 10 Ton Hydraulic PressManuel SterlingОценок пока нет

- Gehc SP - Brivo XR385 - 1 146FДокумент9 страницGehc SP - Brivo XR385 - 1 146FRodrigo Botelho de LimaОценок пока нет

- Mil-Std 2003-2Документ137 страницMil-Std 2003-2Dan McGrathОценок пока нет

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsДокумент6 страницSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedОценок пока нет

- Material Submittal Schedule JafcoДокумент8 страницMaterial Submittal Schedule Jafcovtalex100% (1)

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsДокумент6 страницSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedОценок пока нет

- Emergency Rescue Plan Cgc082c07Документ17 страницEmergency Rescue Plan Cgc082c07sawkariqbal75% (4)

- Gehc SP - Brivo XR385 - 1 146FДокумент9 страницGehc SP - Brivo XR385 - 1 146FJavier PayáОценок пока нет

- 01-19 Diagnostic Trouble Code Table PDFДокумент40 страниц01-19 Diagnostic Trouble Code Table PDFmefisto06cОценок пока нет

- DE-119954 - Procedure For Fabrication and Installation of Submarine PipelinesДокумент47 страницDE-119954 - Procedure For Fabrication and Installation of Submarine PipelinesAmr MahmoudОценок пока нет

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsОт EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsРейтинг: 5 из 5 звезд5/5 (1)

- GS 19-1-2 - MainbodyДокумент50 страницGS 19-1-2 - MainbodyDhanushОценок пока нет

- Supplier'S Document Cover Page (For A4/A3 Documents Only)Документ5 страницSupplier'S Document Cover Page (For A4/A3 Documents Only)Tanveer Ahmed QuadriОценок пока нет

- Process Control in SpinningДокумент31 страницаProcess Control in Spinningapi-2649455553% (15)

- Pmi Testing ProcedureДокумент4 страницыPmi Testing ProcedureDhanushОценок пока нет

- Tailless AircraftДокумент17 страницTailless AircraftVikasVickyОценок пока нет

- General Specification: NO. 10-1-3 Firewater Pump PackageДокумент17 страницGeneral Specification: NO. 10-1-3 Firewater Pump PackageDhanushОценок пока нет

- Chap 08Документ63 страницыChap 08Sam KashОценок пока нет

- d9 VolvoДокумент57 страницd9 Volvofranklin972100% (2)

- Fiat 9.57409 - 2007-04 - ZINC - NICKEL ALLOY ELECTROLYTICДокумент13 страницFiat 9.57409 - 2007-04 - ZINC - NICKEL ALLOY ELECTROLYTICMiguel QueirosОценок пока нет

- Design Practices and Standards Summary Data Sheet GS: Change ImpactДокумент2 страницыDesign Practices and Standards Summary Data Sheet GS: Change ImpactDhanushОценок пока нет

- Design Practices and Standards Summary Data Sheet: 1.0 New/Updated StandardДокумент5 страницDesign Practices and Standards Summary Data Sheet: 1.0 New/Updated StandardDhanushОценок пока нет

- ARC01016-Building Data SheetДокумент12 страницARC01016-Building Data SheetCamilo CastilloОценок пока нет

- SAE-J200 - Classification System For Rubber Materials-2005Документ65 страницSAE-J200 - Classification System For Rubber Materials-2005Tom BrownОценок пока нет

- DP 05 TocДокумент1 страницаDP 05 TocAHMED AMIRAОценок пока нет

- 1tb01005-005c17-Hah-Xx-Xx-Sdw-Me-05005-C0-Projected Floor LoadingДокумент2 страницы1tb01005-005c17-Hah-Xx-Xx-Sdw-Me-05005-C0-Projected Floor LoadingMAZHAR ALIОценок пока нет

- (LS) ANNEX - 2 - Compliance - and - Deviation - TableДокумент3 страницы(LS) ANNEX - 2 - Compliance - and - Deviation - TableVô CảmОценок пока нет

- Design Practices and Standards Summary Data Sheet GS: O DimДокумент5 страницDesign Practices and Standards Summary Data Sheet GS: O DimDhanushОценок пока нет

- Surface Vehicle Recommended Practice: Rev. NOV2003Документ55 страницSurface Vehicle Recommended Practice: Rev. NOV2003bigtone2001100% (1)

- Material Approval Submission: Jazz City KulimДокумент28 страницMaterial Approval Submission: Jazz City KulimMuhamad Yazid Bin Md YatinОценок пока нет

- CARV - AKM To TI (ECN 72S-0597)Документ1 страницаCARV - AKM To TI (ECN 72S-0597)gaurav kumarОценок пока нет

- Pressure VesselДокумент4 страницыPressure VesselVasanth KumarОценок пока нет

- Engineering Engineering Engineering Engineering Standard Standard Standard StandardДокумент12 страницEngineering Engineering Engineering Engineering Standard Standard Standard StandardgustavoОценок пока нет

- Eeaa090571-2 - r0.24.02.2022 - Layout and RCC Details of Columns 1Документ1 страницаEeaa090571-2 - r0.24.02.2022 - Layout and RCC Details of Columns 1Mohd RosleeОценок пока нет

- Erosion Control Materials: Product DataДокумент4 страницыErosion Control Materials: Product Datasean_dibartolo3668Оценок пока нет

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaДокумент1 страницаSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitОценок пока нет

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsДокумент6 страницSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedОценок пока нет

- EG-A-415E Roofing Wall Cladding Rev 3Документ12 страницEG-A-415E Roofing Wall Cladding Rev 3Vicente Aparecido Pineda Ferrari Jr.Оценок пока нет

- Design Practices and Standards Summary Data Sheet: Dim GsДокумент3 страницыDesign Practices and Standards Summary Data Sheet: Dim GsDhanushОценок пока нет

- Revisions: ISSUED. ERN 2000000333Документ3 страницыRevisions: ISSUED. ERN 2000000333abdel taibОценок пока нет

- General Specification For Lining For Floor Finish EG - A - 412E 1/13Документ13 страницGeneral Specification For Lining For Floor Finish EG - A - 412E 1/13Opencae EngenhariaОценок пока нет

- G.V & AIR VALVE-ModelДокумент1 страницаG.V & AIR VALVE-ModelAnand KP100% (1)

- Lp173wd1 Tla1 LGДокумент32 страницыLp173wd1 Tla1 LGdinnhowОценок пока нет

- Faa Form 8070-1Документ2 страницыFaa Form 8070-1api-520948779Оценок пока нет

- Expansion Joint For EvaporateurДокумент2 страницыExpansion Joint For EvaporateurLAKHTIRIОценок пока нет

- API Standard 2350-2012Документ3 страницыAPI Standard 2350-2012Erin Johnson0% (1)

- EG-B-406E Concrete Pipes Rev 1Документ29 страницEG-B-406E Concrete Pipes Rev 1Vicente Aparecido Pineda Ferrari Jr.Оценок пока нет

- NCGM-DU-XX-D-AEC-DR-930-1154 C9: Stage E Vinci Construction Uk LTDДокумент1 страницаNCGM-DU-XX-D-AEC-DR-930-1154 C9: Stage E Vinci Construction Uk LTDyusufuОценок пока нет

- 0964消防管布置图qme 00 g 141b 000 Ei 085 en b Ppg Arr, Fire Protection Turb Cmpt(119t8347)Документ6 страниц0964消防管布置图qme 00 g 141b 000 Ei 085 en b Ppg Arr, Fire Protection Turb Cmpt(119t8347)ALAMGIR HOSSAINОценок пока нет

- 9.55655-01-2007 - Septum Carton Tarred FeltДокумент12 страниц9.55655-01-2007 - Septum Carton Tarred Feltclaudio5475100% (1)

- Approved - 400kV LAДокумент22 страницыApproved - 400kV LAGuru MishraОценок пока нет

- E132 - Raceways and Tubing Installation Checklist Rev 00 11.11Документ2 страницыE132 - Raceways and Tubing Installation Checklist Rev 00 11.11bobby CanaresОценок пока нет

- Lc420euf Fep1 LGДокумент44 страницыLc420euf Fep1 LGAnonymous eGjPsFzx3Оценок пока нет

- 06 Loya Zi Mew QB Sub STR Ramps 02 Ra5 Str. Loop 04Документ1 страница06 Loya Zi Mew QB Sub STR Ramps 02 Ra5 Str. Loop 04Maham QureshiОценок пока нет

- 1833-307-01 RLregister 20231101 1Документ1 страница1833-307-01 RLregister 20231101 1Батбаяр БямбасүрэнОценок пока нет

- Man Mod DateДокумент2 страницыMan Mod DateRPSG Resources QMОценок пока нет

- Draft Spec RDSO-CG-18003 For AMDBS 200kmphДокумент37 страницDraft Spec RDSO-CG-18003 For AMDBS 200kmphMS kunalОценок пока нет

- Automotive Turbocharger Compressor CFD and Extension Towards Incorporating Installation EffectsДокумент10 страницAutomotive Turbocharger Compressor CFD and Extension Towards Incorporating Installation EffectsMuhtasim FuadОценок пока нет

- Allegati - ALGM - 14881 - FMTR01 REQUISITI TECNICI ENGДокумент6 страницAllegati - ALGM - 14881 - FMTR01 REQUISITI TECNICI ENGrafaelberaldiОценок пока нет

- FOR Approval Specification: 32.0" Wxga TFT LCD TitleДокумент42 страницыFOR Approval Specification: 32.0" Wxga TFT LCD TitleJulio Alberto Cabrera RodriguezОценок пока нет

- Saej3000v003 Thermoplastic Elastomer Classification SystemДокумент16 страницSaej3000v003 Thermoplastic Elastomer Classification SystemDaniel FarfanОценок пока нет

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedДокумент1 страницаThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110Оценок пока нет

- 1416 MC MDS V 104 - Rev.0Документ5 страниц1416 MC MDS V 104 - Rev.0KrunalОценок пока нет

- Azspu Major ProjectsДокумент9 страницAzspu Major ProjectsMirzaОценок пока нет

- (2485-1-HYA-CUR-001) Overfluxing Withstand Duration Curve (GTG) - Rev.4Документ2 страницы(2485-1-HYA-CUR-001) Overfluxing Withstand Duration Curve (GTG) - Rev.4Entzelec SAОценок пока нет

- Low SupportДокумент1 страницаLow SupportMDhana SekarОценок пока нет

- REV Description Date Approval: RevisionsДокумент2 страницыREV Description Date Approval: RevisionsLONG Trương MinhОценок пока нет

- RE739434001-Produced Water Injection PumpsДокумент7 страницRE739434001-Produced Water Injection PumpsBilel MahjoubОценок пока нет

- Quarter-Turn On/Off Actuators: ManualДокумент32 страницыQuarter-Turn On/Off Actuators: ManualDhanushОценок пока нет

- Optimised Pump RoutingДокумент6 страницOptimised Pump RoutingDhanushОценок пока нет

- Full Assemblies: Complete Subsea PLR SolutionsДокумент2 страницыFull Assemblies: Complete Subsea PLR SolutionsDhanushОценок пока нет

- Master Engineering Engineering ManagementДокумент4 страницыMaster Engineering Engineering ManagementDhanushОценок пока нет

- Hydraulic & Offshore Supplies: Pipe Sizing NomogramДокумент2 страницыHydraulic & Offshore Supplies: Pipe Sizing NomogramDhanushОценок пока нет

- ErrorДокумент1 страницаErrorDhanushОценок пока нет

- The Dimension From Elbow To Reducer Should Be 306mm With Reference To Co-Ordinates. Please ClarifyДокумент1 страницаThe Dimension From Elbow To Reducer Should Be 306mm With Reference To Co-Ordinates. Please ClarifyDhanushОценок пока нет

- GS 10-6-1 - MainbodyДокумент12 страницGS 10-6-1 - MainbodyDhanushОценок пока нет

- Pig Launcher and ReceiverДокумент2 страницыPig Launcher and ReceiverDhanushОценок пока нет

- Instrument and Essential Services IP 16-8-1 Power Supplies: ScopeДокумент17 страницInstrument and Essential Services IP 16-8-1 Power Supplies: ScopeDhanushОценок пока нет

- Design Practices and Standards Summary Data Sheet: Dim GsДокумент3 страницыDesign Practices and Standards Summary Data Sheet: Dim GsDhanushОценок пока нет

- GS 13-1-1 - Appendix AДокумент13 страницGS 13-1-1 - Appendix ADhanushОценок пока нет

- Design Practices and Standards Summary Data Sheet GS: O DimДокумент5 страницDesign Practices and Standards Summary Data Sheet GS: O DimDhanushОценок пока нет

- GS 19-5-1 - MainbodyДокумент11 страницGS 19-5-1 - MainbodyDhanushОценок пока нет

- Quality Programs IP 20-1-3: ScopeДокумент2 страницыQuality Programs IP 20-1-3: ScopeDhanushОценок пока нет

- Eemua144 PDFДокумент30 страницEemua144 PDFDhanushОценок пока нет

- Temperature Instruments IP 15-2-1: ScopeДокумент7 страницTemperature Instruments IP 15-2-1: ScopeDhanushОценок пока нет

- Ip 16 12 1Документ12 страницIp 16 12 1DhanushОценок пока нет

- UT TransducersДокумент20 страницUT TransducersSamanyarak AnanОценок пока нет

- DualityДокумент27 страницDualitySuprabhat TiwariОценок пока нет

- Cable Ties DatasheetДокумент7 страницCable Ties DatasheetGovind ChaudhariОценок пока нет

- JAVA Stack Installation in ERPДокумент2 страницыJAVA Stack Installation in ERPsai_balaji_8Оценок пока нет

- 9C606C.64 To 65Документ24 страницы9C606C.64 To 65SHIRISHA YADAVОценок пока нет

- 2 Strokes 4 Strokes: 1 CylinderДокумент2 страницы2 Strokes 4 Strokes: 1 CylinderariffОценок пока нет

- Notes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsДокумент4 страницыNotes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsArif HidayatОценок пока нет

- Student Manual of Damped & Un DampedДокумент3 страницыStudent Manual of Damped & Un DampedaqibОценок пока нет

- Omron ManualДокумент44 страницыOmron ManualHaroDavidОценок пока нет

- Cinegy User ManualДокумент253 страницыCinegy User ManualNizamuddin KaziОценок пока нет

- April 2016Документ68 страницApril 2016Treatment Plant Operator MagazineОценок пока нет

- Fire Protection Design For Healthcare FacilitiesДокумент34 страницыFire Protection Design For Healthcare Facilitiesapi_fabianОценок пока нет

- Economics BasisДокумент14 страницEconomics BasiskumarОценок пока нет

- RDBMS and HTML Mock Test 1548845682056Документ18 страницRDBMS and HTML Mock Test 1548845682056sanjay bhattОценок пока нет

- 4 MPM Scope - OutputДокумент45 страниц4 MPM Scope - OutputSajid Ali MaariОценок пока нет

- CE 411 Lecture 03 - Moment AreaДокумент27 страницCE 411 Lecture 03 - Moment AreaNophiОценок пока нет

- 96 Tacoma SpecsДокумент10 страниц96 Tacoma SpecsFerran AlfonsoОценок пока нет

- To Dmaic or Not To DmaicДокумент1 страницаTo Dmaic or Not To Dmaicritch99Оценок пока нет

- Adequate Bearing Material and Heat TreatmentДокумент20 страницAdequate Bearing Material and Heat TreatmentdavideОценок пока нет

- (Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)Документ66 страниц(Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)양종렬Оценок пока нет

- Tectubi Raccordi Nuclear Ref ListДокумент8 страницTectubi Raccordi Nuclear Ref Listpomabe13Оценок пока нет

- M Block PDFДокумент45 страницM Block PDFKristina ViskovićОценок пока нет

- Libeskind Daniel - Felix Nussbaum MuseumДокумент6 страницLibeskind Daniel - Felix Nussbaum MuseumMiroslav MalinovicОценок пока нет

- Mandat 040310062548 21Документ379 страницMandat 040310062548 21Sujeet BiradarОценок пока нет