Академический Документы

Профессиональный Документы

Культура Документы

ASTM D1452 - 09, Soil Exploration and Sampling by Auger Borings

Загружено:

Luis ContrerasОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ASTM D1452 - 09, Soil Exploration and Sampling by Auger Borings

Загружено:

Luis ContrerasАвторское право:

Доступные форматы

Designation: D1452 − 09

Standard Practice for

Soil Exploration and Sampling by Auger Borings1

This standard is issued under the fixed designation D1452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

1.1 This practice covers equipment and procedures for the 2.1 ASTM Standards:2

use of earth augers in shallow depth geotechnical exploration. D653 Terminology Relating to Soil, Rock, and Contained

This practice does not apply to hollow-stem augers. Uses of Fluids

hollow-stem auger drilling methods for geotechnical explora- D1586 Test Method for Penetration Test (SPT) and Split-

tion are addressed in Test Method D6151. Barrel Sampling of Soils

D1587 Practice for Thin-Walled Tube Sampling of Soils for

1.2 This practice does not include considerations for geoen- Geotechnical Purposes

vironmental site characteristics and installation of monitoring D2488 Practice for Description and Identification of Soils

wells which are discussed in Guide D5784. (Visual-Manual Procedure)

1.3 The values stated in inch-pound units are to be regarded D5434 Guide for Field Logging of Subsurface Explorations

as standard. The values given in parentheses are mathematical of Soil and Rock

conversions to SI units that are provided for information only D4750 Test Method for Determining Subsurface Liquid

and are not considered standard. Levels in a Borehole or Monitoring Well (Observation

Well) (Withdrawn 2010)3

1.4 All observed and calculated values shall conform to the D5784 Guide for Use of Hollow-Stem Augers for Geoenvi-

guidelines for significant digits and rounding established in ronmental Exploration and the Installation of Subsurface

Practice D6026 unless superseded by this method. Water-Quality Monitoring Devices

D6026 Practice for Using Significant Digits in Geotechnical

1.5 This standard does not purport to address all of the

Data

safety concerns, if any, associated with its use. It is the

D6151 Practice for Using Hollow-Stem Augers for Geotech-

responsibility of the user of this standard to establish appro-

nical Exploration and Soil Sampling

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3. Terminology

1.6 This practice offers a set of instructions for performing

one or more specific operations. This document cannot replace 3.1 Definitions—For common definitions of terms in this

education or experience and should be used in conjunction standard, refer to Terminology D653.

with professional judgment. Not all aspects of this practice may

be applicable in all circumstances. This ASTM standard is not 4. Significance and Use

intended to represent or replace the standard of care by which 4.1 Auger borings often provide the simplest method of soil

the adequacy of a given professional service must be judged, exploration and sampling. They may be used for any purpose

nor should this document be applied without consideration of where disturbed samples can be used and are valuable in

a project’s many unique aspects. The word “Standard” in the connection with groundwater level determination and indica-

title of this document means only that the document has been tion of changes in strata and advancement of hole for split-

approved through the ASTM consensus process. barrel penetration tests and sampling (Test Method D1586) and

1 2

This practice is under the jurisdiction of ASTM Committee D18 on Soil and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Rock and is the direct responsibility of Subcommittee D18.02 on Sampling and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Related Field Testing for Soil Evaluations. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 15, 2009. Published March 2009. Originally the ASTM website.

3

approved in 1957. Last previous edition approved in 2007 as D1452 – 07a. DOI: The last approved version of this historical standard is referenced on

10.1520/D1452-09. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

D1452 − 09

thin-walled tube sampling (Practice D1587). Equipment re- 5.1.3.2 Iwan Type, (Fig. 2(b)) consisting of two tubular steel

quired is simple and readily available. Depths of auger explo- segments, connected at the top to a common member to form

rations are, however, limited by groundwater conditions, soil a nearly complete tube, but with diametrically opposed open-

characteristics, and the equipment used. ings. It is connected at the bottom by two radial blades pitched

to serve as cutters which also block the escape of contained

5. Apparatus

soil. Attachment of handle or extension is at the top connector.

5.1 Hand-Operated Augers:

5.2 Machine-Operated Augers:

5.1.1 Helical Augers, (Fig. 1(a)) small lightweight augers

generally available in sizes from 1 through 3 in. (25.4 through 5.2.1 Helical Augers, (Fig. 3(a)) generally 4 through 48 in.

76.2 mm). (101.6 through 1219 mm), consisting essentially of a center

5.1.1.1 Spiral-Type Auger, consisting of a flat thin metal shaft fitted with a shank or socket for application of power, and

strip, machine twisted to a spiral configuration of uniform having one to six complete 360° (6.28-rad) spirals for convey-

pitch; having at one end, a sharpened or hardened point, with ance and storage of cut soil. Cutter bits and pilot bits are

a means of attaching a shaft or extension at the opposite end. available in moderate and hard formation types and normally

5.1.1.2 Ship-Type Auger—Similar to a carpenter’s wood bit. replaceable in the field. They are normally operated by

It is generally forged from steel and machined to the desired heavy-duty, high-torque machines, designed for heavy con-

size and configuration. It is normally provided with sharpened struction work.

and hardened nibs at the point end and with an integral shaft 5.2.2 Stinger Augers, generally 3 through 30 in. (76.2

extending through its length for attachment of a handle or through 762 mm), are similar to the helical auger in 5.2.1, but

extension at the opposite end. lighter and generally smaller. They are commonly operated by

5.1.2 Open Tubular Augers, (Fig. 1(b)) ranging in size from light-duty machines for post and power pole holes.

1.5 through 8 in. (38.1 through 203.2 mm) and having the 5.2.3 Disk Augers, (Fig. 3(b)) generally 10 through 30 in.

common characteristic of appearing essentially tubular when (254 through 762 mm), consisting essentially of a flat, steel

viewed from the digging end. disk with diametrically opposed segments removed and having

5.1.2.1 Orchard-Barrel Type, (Fig. 1(c)) consisting essen- a shank or socket located centrally for application of power.

tially of a tube having cutting lips or nibs hardened and Replaceable cutter bits, located downward from the leading

sharpened to penetrate the formation on one end and an adaptor edges of the remaining disk, dig and load soil that is held on the

fitting for an extension or handle on the opposite end. disk by valves or shutters hinged at the disk in order to close

5.1.2.2 Open-Spiral Type, consisting of a flat thin metal strip the removed segments. The disk auger is specifically designed

that has been helically wound around a circular mandrel to to be operated by machines having limited vertical clearance

form a spiral in which the flat faces of the strip are parallel to between spindle and ground surface.

the axis of the augered hole. The lower helix edges are 5.2.4 Bucket Auger, (Fig. 3(c)) generally 12 through 48 in.

hard-faced to improve wear characteristics. The opposite end is (304.8 through 1219 mm), consisting essentially of a disk

fitted with an adaptor for extension. auger, without shank or socket, but hinge-mounted to the

5.1.2.3 Closed-Spiral Type—Nearly identical to the open- bottom of a steel tube or bucket of approximately the same

spiral type except the pitch of the helically wound spiral is diameter as the disk auger. A socket or shank for power

much less than that of the open-spiral type. application is located in the top center of the bucket diametral

5.1.3 Post-Hole Augers, generally 2 through 8 in. (50.8 cross piece provided for the purpose.

through 203.2 mm), and having in common a means of

5.3 Casing (when needed), consisting of pipe of slightly

blocking the escape of soil from the auger.

larger diameter than the auger used.

5.1.3.1 Clam-Shell Type, (Fig. 2(a)) consisting of two

halves, hinged to allow opening and closing for alternately 5.4 Accessory Equipment—Labels, field log sheets, sample

digging and retrieving. It is not usable deeper than about 3.5 ft jars, sealing wax, sample bags, and other necessary tools and

(1.07 m). supplies.

FIG. 1 Hand Augers

Copyright by ASTM Int'l (all rights reserved); 2

D1452 − 09

FIG. 2 Post-Hole Augers

FIG. 3 Machine-Operated Augers

6. Procedure 6.4 Monitoring Water Level—It is advisable to monitor

6.1 Make the auger boring by rotating and advancing the groundwater levels, if present, in the drill hole during and after

desired distance into the soil. Withdraw the auger from the hole removal of the drilling equipment. Groundwater elevation

and remove the soil for examination and test. Return the empty should be measured and documented during drilling to include

auger to the hole and repeat the procedure. Continue the datum, date and time measured. Method or equipment used to

sequence until the required depth is reached. determine depth of groundwater level, such as Test Method

D4750 should also be noted. If groundwater is not encountered

6.2 Casing is required in unstable soil in which the bore hole or if the level is of doubtful reliability, such information should

fails to stay open and especially when the boring is extended also be documented.

below the groundwater level. The inside diameter of the casing 6.4.1 The user is cautioned that there are many factors

must be slightly larger than the diameter of the auger used. The which can influence borehole water level measurements and

casing shall be driven to a depth not greater than the top of the the interpretation of borehole water level measurements. These

next sample and shall be cleaned out by means of the auger. factors are not described or discussed in this practice. The

The auger can then be inserted into the bore hole and turned interpretation and application of borehole water level informa-

below the bottom of the casing to obtain a sample. tion should be done by a trained specialist. Installation of

6.3 The soil auger can be used both for boring the hole and piezometers should be considered where complex groundwater

for bringing up disturbed samples of the soil encountered. The conditions prevail.

structure of a cohesive soil is completely destroyed and the

moisture may be changed by the auger. Seal all samples in a jar 7. Data Sheet/Form

or other airtight container and label appropriately. If more than 7.1 Report information in accordance with Guide D5434.

one type of soil is picked up in the sample, prepare a separate The data obtained in boring shall be recorded on the field logs

container for each type of soil. and shall include the following:

Copyright by ASTM Int'l (all rights reserved); 3

D1452 − 09

7.1.1 Date of start and completion of boring, 7.1.8 Datum, date and time of borehole water-level mea-

7.1.2 Identifying number of boring, surement and method or equipment used, and

7.1.3 Reference datum including direction and distance of 7.1.9 Condition of augered hole upon removal of auger, that

boring relative to reference line of project or other suitable is, whether the hole remains open or the sides cave, when such

reference points, can be observed.

7.1.4 Type and size of auger used in boring,

7.1.5 Depth of changes in strata, 8. Keywords

7.1.6 Description of soil in each major stratum in accor-

dance with Practice D2488, 8.1 auger borings; geotechnical exploration; sampling; soil

7.1.7 Groundwater elevation and location of seepage zones, explorations

when found,

APPENDIX

(Nonmandatory Information)

X1. EXAMPLE DATA SHEET

X1.1 Fig. X1. provides an example data sheet.

Copyright by ASTM Int'l (all rights reserved); 4

D1452 − 09

Copyright by ASTM Int'l (all rights reserved); 5

D1452 − 09

SUMMARY OF CHANGES

Committee D18 has identified the location of selected changes to this standard since the last issue

(D1452 – 07a) that may impact the use of this standard. (Approved Feb. 15, 2009.)

(1) Added Referenced Documents. (3) Other minor revisions throughout.

(2) Added Figs. 1-3.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 6

Вам также может понравиться

- Astm D2573 D2573M 15Документ8 страницAstm D2573 D2573M 15Wilson KoОценок пока нет

- Performing The Flat Plate Dilatometer: Standard Test Method ForДокумент16 страницPerforming The Flat Plate Dilatometer: Standard Test Method Formohammed karasnehОценок пока нет

- Astm D 2488 Visual UscsДокумент12 страницAstm D 2488 Visual UscsAndrew MutuaОценок пока нет

- Anexo 5.4 Astm d5092Документ16 страницAnexo 5.4 Astm d5092marvin060517Оценок пока нет

- Astm D2573 D2573M 15Документ8 страницAstm D2573 D2573M 15Wilson KoОценок пока нет

- Density of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsДокумент7 страницDensity of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsIonut VasilescuОценок пока нет

- D 5079 - 08Документ7 страницD 5079 - 08Rakesh7770Оценок пока нет

- Astm d5778 12Документ20 страницAstm d5778 12farquinОценок пока нет

- D 6519 - 02-Sampling of Soil Usingthe Hydraulic OperatedStationary Piston SamplerДокумент8 страницD 6519 - 02-Sampling of Soil Usingthe Hydraulic OperatedStationary Piston SamplerJamie MooreОценок пока нет

- Standard Practice For Preserving and Transporting Soil Samples D 4220Документ10 страницStandard Practice For Preserving and Transporting Soil Samples D 4220Akkshay ChadhaОценок пока нет

- BS EN ISO 22282-3 - 2012 Geotechnical Investigation and Testing. Geohydraulic Testing PDFДокумент2 страницыBS EN ISO 22282-3 - 2012 Geotechnical Investigation and Testing. Geohydraulic Testing PDFOm Bun0% (1)

- Peat Samples by Laboratory Testing: Standard Classification ofДокумент3 страницыPeat Samples by Laboratory Testing: Standard Classification ofirsanОценок пока нет

- Equivalence DPSH (B) and SPT - 2007Документ4 страницыEquivalence DPSH (B) and SPT - 2007eduardomanar1224100% (1)

- ASTM.D2850-03.Triaxial UU PDFДокумент6 страницASTM.D2850-03.Triaxial UU PDFFernando Navarro100% (1)

- Astm D1558 PDFДокумент3 страницыAstm D1558 PDFLeonelBerlin100% (1)

- Astm d5311m 13 CyclicДокумент11 страницAstm d5311m 13 CyclicSiwadol Dejphumee100% (1)

- Influence of Vane Size and Equipment On The Results in The Vane Shear TestДокумент7 страницInfluence of Vane Size and Equipment On The Results in The Vane Shear TestNabucodonosor1980Оценок пока нет

- Astm D4546Документ9 страницAstm D4546Black Goku100% (1)

- ASTM D5778-12 - Standard Test Method For Electronic Friction Cone and Piezocone Penetration Testing of SoilsДокумент20 страницASTM D5778-12 - Standard Test Method For Electronic Friction Cone and Piezocone Penetration Testing of SoilsMariaОценок пока нет

- Consolidation of Soils Testing and Evaluation Editor(s), Yong Townsend STP 892Документ383 страницыConsolidation of Soils Testing and Evaluation Editor(s), Yong Townsend STP 892Dương NguyễnОценок пока нет

- ASTM D 6951 Cono Dinámico PDFДокумент7 страницASTM D 6951 Cono Dinámico PDFIvan Mora100% (2)

- ASTM D2435 - D2435M - 11 One Dimensional Consolidation Properties of SoilsДокумент15 страницASTM D2435 - D2435M - 11 One Dimensional Consolidation Properties of Soilsrajal11Оценок пока нет

- ASTM D 4959-00, ASTM D653-02aДокумент39 страницASTM D 4959-00, ASTM D653-02aPedro Rivera100% (1)

- ASTM D5298-10 - Ensaio de SucçãoДокумент6 страницASTM D5298-10 - Ensaio de SucçãoBruna Barbosa100% (1)

- Astm D5777Документ13 страницAstm D5777sujeeth kumarОценок пока нет

- ASTM D1194 94 Bearing Capacity of Soils For Static Load Amp Spread Footings PDFДокумент3 страницыASTM D1194 94 Bearing Capacity of Soils For Static Load Amp Spread Footings PDFRyan Achmad FadhillahОценок пока нет

- Downhole Seismic Testing: Standard Test Methods ForДокумент10 страницDownhole Seismic Testing: Standard Test Methods ForzariaОценок пока нет

- D4645 HidrofracДокумент7 страницD4645 HidrofracMiguelAngelSuttaCcahuana100% (1)

- d5878 (Clasificacion Rocas)Документ30 страницd5878 (Clasificacion Rocas)Victor HernandezОценок пока нет

- ASTM.D4767-04.Triaxial CU PDFДокумент13 страницASTM.D4767-04.Triaxial CU PDFFernando NavarroОценок пока нет

- D5084 Standard Test Methods For Measurement of Hydraulic Conductivity of Saturated PorousДокумент23 страницыD5084 Standard Test Methods For Measurement of Hydraulic Conductivity of Saturated Porousandaech100% (1)

- D-6169-98 Selection of Soil and Rock Sampling Devices Used With Drill Rigs For Environmental InvestigationsДокумент19 страницD-6169-98 Selection of Soil and Rock Sampling Devices Used With Drill Rigs For Environmental InvestigationsWaqas Ahmad AbbasiОценок пока нет

- D 2974 - 00 PDFДокумент4 страницыD 2974 - 00 PDFashrafОценок пока нет

- D4546Документ12 страницD4546chanito23Оценок пока нет

- Load Controlled Cyclic Triaxial Strength of SoilДокумент11 страницLoad Controlled Cyclic Triaxial Strength of SoilJiji Krishnan100% (1)

- Determination of Maximum Dry Unit Weight and Water Content Range For Effective Compaction of Granular Soils Using A Vibrating HammerДокумент11 страницDetermination of Maximum Dry Unit Weight and Water Content Range For Effective Compaction of Granular Soils Using A Vibrating HammerJesús Luis Arce Guillermo50% (2)

- Astm D4633 PDFДокумент7 страницAstm D4633 PDFwafikmh4100% (2)

- D4546 SwellДокумент7 страницD4546 SwellAlysson SantosОценок пока нет

- D 4631 - 95 (Lefranc)Документ7 страницD 4631 - 95 (Lefranc)veronicaata100% (1)

- Astm D4829 PDFДокумент5 страницAstm D4829 PDFGuillermo Luque Pampamallco100% (1)

- ISO 12956 - Geotextiles and Geotextile Related Product PDFДокумент16 страницISO 12956 - Geotextiles and Geotextile Related Product PDFJuzonguyenОценок пока нет

- Correlating Standard Penetration Test and Dynamic Probe Super Heavy Penetration Resistance Values in Sandy Soils PDFДокумент9 страницCorrelating Standard Penetration Test and Dynamic Probe Super Heavy Penetration Resistance Values in Sandy Soils PDFignacio mejiaОценок пока нет

- 05 Mazier Retractable Core Barrels PDFДокумент1 страница05 Mazier Retractable Core Barrels PDFCut MutiaОценок пока нет

- D 5783 - 95 R00 - Rdu3odmДокумент7 страницD 5783 - 95 R00 - Rdu3odmEmiliano AgostiniОценок пока нет

- ASTM D4645-08 Standard Test Method For Determination of In-Situ Stress in Rock Using Hydraulic Fracturing MethodДокумент2 страницыASTM D4645-08 Standard Test Method For Determination of In-Situ Stress in Rock Using Hydraulic Fracturing MethodpawitraОценок пока нет

- Standard Test Method For Unconsolidated-Undrained Triaxial Compression Test On Cohesive SoilsДокумент5 страницStandard Test Method For Unconsolidated-Undrained Triaxial Compression Test On Cohesive SoilsAli KhanОценок пока нет

- ASTM D7625 - 10 Standard Test Method For Laboratory Determination of AbrasiveneДокумент2 страницыASTM D7625 - 10 Standard Test Method For Laboratory Determination of AbrasiveneNatoya Adams0% (1)

- Astm D4943.27594Документ7 страницAstm D4943.27594Andrés RicseОценок пока нет

- Astmd 6241 PDFДокумент6 страницAstmd 6241 PDFchandrima baruah mahantaОценок пока нет

- Particle-Size Distribution (Gradation) of Soils Using Sieve AnalysisДокумент34 страницыParticle-Size Distribution (Gradation) of Soils Using Sieve AnalysisJP SALDAÑAОценок пока нет

- Astm D1140 PDFДокумент4 страницыAstm D1140 PDFcatalina_tudosa0% (1)

- Geotechnical Investigation Program Mumbai Metro Line Package-3 UGC-02 (Tunnels)Документ199 страницGeotechnical Investigation Program Mumbai Metro Line Package-3 UGC-02 (Tunnels)sugurpraveen100% (2)

- ATM E965-15 (Reapproved 2019)Документ4 страницыATM E965-15 (Reapproved 2019)anant11235Оценок пока нет

- ISRM Suggested Methods For Land Geophysics in Rock EngineeringДокумент30 страницISRM Suggested Methods For Land Geophysics in Rock EngineeringLeonardo Octavio Olarte SánchezОценок пока нет

- D 5334 - 92 - RduzmzqtukveДокумент8 страницD 5334 - 92 - Rduzmzqtukvegrats_singcoОценок пока нет

- Astm D1452 - 09Документ6 страницAstm D1452 - 09Anna Dewi100% (1)

- Norma Suelos 1Документ7 страницNorma Suelos 1Jesus DiazОценок пока нет

- ASTM D 5783-95 (2012) - Use of Direct Rotary Drilling With Water-Based Drilling FluidДокумент7 страницASTM D 5783-95 (2012) - Use of Direct Rotary Drilling With Water-Based Drilling FluidRACHMATОценок пока нет

- ASTM D 5784-D 5784M-13-Use of Hollow-Stem Augers For GeoenvironmentalДокумент7 страницASTM D 5784-D 5784M-13-Use of Hollow-Stem Augers For GeoenvironmentalRACHMATОценок пока нет

- ASTM D425 88 (Reapproved 2008), Centrifuge Moisture Equivalent of Soils PDFДокумент4 страницыASTM D425 88 (Reapproved 2008), Centrifuge Moisture Equivalent of Soils PDFMarcosОценок пока нет

- ASTM D4648-D4648M - 13, Laboratory Miniature Vane Shear Test For Saturated Fine-Grained Clayey Soil PDFДокумент7 страницASTM D4648-D4648M - 13, Laboratory Miniature Vane Shear Test For Saturated Fine-Grained Clayey Soil PDFMarcosОценок пока нет

- ASTM D1140 − 00 (Reapproved 2006), Amount of Material in Soils Finer than No. 200 (75-μm) SieveДокумент4 страницыASTM D1140 − 00 (Reapproved 2006), Amount of Material in Soils Finer than No. 200 (75-μm) SieveMarcosОценок пока нет

- ASTM D7762 - 11, Design of Stabilization of Soil and Soil-Like Materials With Self-Cementing Fly Ash PDFДокумент4 страницыASTM D7762 - 11, Design of Stabilization of Soil and Soil-Like Materials With Self-Cementing Fly Ash PDFMarcos100% (1)

- ASTM D6066 - 11, Determining The Normalized Penetration Resistance of Sands For Evaluation of Liquefaction PotentialДокумент16 страницASTM D6066 - 11, Determining The Normalized Penetration Resistance of Sands For Evaluation of Liquefaction PotentialMarcosОценок пока нет

- Norma ASTM D2166Standard Test Method For Unconfined Compressive Strength of Cohesive SoilДокумент6 страницNorma ASTM D2166Standard Test Method For Unconfined Compressive Strength of Cohesive SoilMarcosОценок пока нет

- ASTM D1586 - 11, Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils PDFДокумент9 страницASTM D1586 - 11, Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils PDFMarcos67% (3)

- Who Should Take Cholesterol-Lowering StatinsДокумент6 страницWho Should Take Cholesterol-Lowering StatinsStill RageОценок пока нет

- The Example of Text That Contains Present Perfect TenseДокумент2 страницыThe Example of Text That Contains Present Perfect TenseRahmiSyariif100% (1)

- NotesДокумент2 страницыNotesNoella Marie BaronОценок пока нет

- Vip90 2021 Deso10Документ6 страницVip90 2021 Deso10Đỗ KhangОценок пока нет

- Call Me by Your Name-SemioticsДокумент2 страницыCall Me by Your Name-SemioticsJoevic FranciaОценок пока нет

- Notification On Deemed Examination Result NoticeДокумент2 страницыNotification On Deemed Examination Result Noticesteelage11Оценок пока нет

- Principles of Natural Justice Justice Brijesh Kumar: Judge, Allahabad High CourtДокумент7 страницPrinciples of Natural Justice Justice Brijesh Kumar: Judge, Allahabad High CourtTarake DharmawardeneОценок пока нет

- Making Effective Pres. Academic Lit I. Weeks 4 5Документ27 страницMaking Effective Pres. Academic Lit I. Weeks 4 5irfanaОценок пока нет

- Chapter 1Документ13 страницChapter 1Jerard AnciroОценок пока нет

- Brenda Alderman v. The Philadelphia Housing Authority, 496 F.2d 164, 3rd Cir. (1974)Документ16 страницBrenda Alderman v. The Philadelphia Housing Authority, 496 F.2d 164, 3rd Cir. (1974)Scribd Government DocsОценок пока нет

- Agvan DorzhievДокумент7 страницAgvan DorzhievMichael FelicianoОценок пока нет

- Sanjay Seth - Once Was Blind But Now Can See Modernity and The Social SciencesДокумент16 страницSanjay Seth - Once Was Blind But Now Can See Modernity and The Social SciencesQuelen GuedesОценок пока нет

- I. Revised Penal Code (RPC) and Related Special Laws: Riminal AWДокумент11 страницI. Revised Penal Code (RPC) and Related Special Laws: Riminal AWMc Vharn CatreОценок пока нет

- Gein, EdДокумент10 страницGein, Edpetru_k1Оценок пока нет

- ShakespeareДокумент12 страницShakespeareapi-510189551Оценок пока нет

- Constitution & By-LawsДокумент15 страницConstitution & By-LawsMichael C. AndradeОценок пока нет

- Level - 1: Expansion of DeterminantsДокумент13 страницLevel - 1: Expansion of DeterminantsAtomitronОценок пока нет

- Vocabulary ListДокумент2 страницыVocabulary List謝明浩Оценок пока нет

- Grade 3 MathematicsДокумент3 страницыGrade 3 Mathematicsailaine grace alapОценок пока нет

- Smith Vs CaДокумент11 страницSmith Vs CaIrene QuimsonОценок пока нет

- The Holy See: Benedict XviДокумент4 страницыThe Holy See: Benedict XviAbel AtwiineОценок пока нет

- Chapter02 AnglesДокумент40 страницChapter02 Angleslen16328100% (1)

- VoorbeeldДокумент99 страницVoorbeeldRobin VosОценок пока нет

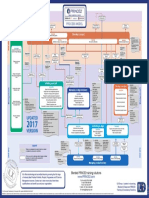

- p2 Process Model 2017Документ1 страницаp2 Process Model 2017Miguel Fernandes0% (1)

- MULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The QuestionДокумент6 страницMULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The QuestionBoshra BoshraОценок пока нет

- Derivative Analysis HW1Документ3 страницыDerivative Analysis HW1RahulSatijaОценок пока нет

- Tapan Pathak Case StudiesДокумент33 страницыTapan Pathak Case StudiesNeelee SoniОценок пока нет

- Fill in The Blank Spaces With The Correct PrepositionДокумент20 страницFill in The Blank Spaces With The Correct PrepositionDora Aguirre GutierrezОценок пока нет

- Στέργος Νεκτάριος-Μικκιος-CVДокумент4 страницыΣτέργος Νεκτάριος-Μικκιος-CVNektarios MikkiosОценок пока нет

- High-Frequency Injection-Based SensorlessДокумент12 страницHigh-Frequency Injection-Based SensorlessRiad BOUZIDIОценок пока нет