Академический Документы

Профессиональный Документы

Культура Документы

Short-Circuit Coordination Harmonic Studies

Загружено:

parthaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Short-Circuit Coordination Harmonic Studies

Загружено:

parthaАвторское право:

Доступные форматы

Bruce L.

Graves

A

ccording to the IEEE Brown Book

(ANSI/IEEE Standard 399-1990),

“The planning, design and operation of

a power system requires continual and

comprehensive analyses to evaluate current system

performance and to establish the effectiveness of al-

ternative plans for system expansion.”

Defining a Power System

A power system is an assembly of generators, trans-

formers, power lines, fuses, circuit breakers, pro-

tective devices, cables, and associated apparatus

used to generate and deliver electrical energy to the

intended load. A power system’s reliability is in-

fluenced by a number of factors, some of which are

environmental, weather, human error, equipment

quality, maintenance, and equipment application.

The purpose of a power system is to generate and

©1997 PhotoDisc, Inc.

deliver electrical energy safely, reliably, efficiently,

and economically to the intended load. Each of these

factors (safety, efficiency, reliability, and economy)

plays a major role in the design, modification, or ex-

Bruce L. Graves is with World Wide Technologies, Inc.

of Greenville, South Carolina. This article appeared in

its original form at the 2000 IEEE IAS Pulp and Paper

Industry Technical Conference.

14 IEEE Industry Applications Magazine ■ March/April 2001 1077-2618/01/$10.00©2001 IEEE

pansion of a power system. If any of these factors is

left unattended, it can jeopardize the future profit-

ability of the facility. Here’s how:

■ Safety: If ignored, can cause injury, loss of life,

property damage, and destruction.

■ Reliability: If ignored, can cause needless in-

terruption of power, resulting in costly man-

ufacturing outages.

■ Efficiency: If ignored, can cause excessive

equipment and energy costs, reducing the

overall profitability of the manufacturing

operation.

■ Economy: If ignored, economy or false econ-

omy can influence the initial installation

costs and long-term maintenance and repair

costs, either of which reduce the profitability

of the facility.

Performance Problems

Factors that keep a power system from doing its job

can be divided into two categories: equipment or

component failures and equipment or component

operation (intentional or unintentional).

■ Equipment or component that can fail include

cable insulation, bus insulation, transformers,

circuit breakers, and motors. Some of these

failures may be related to the original system

design and equipment or device failure.

■ Equipment, component, or erratic operation

are represented by actions such as circuit

breaker trips, fuses blowing, switch opera-

tion, and protective relay operation. Some of

those operations are correctly doing their job,

and others are operating on conditions that

should not cause power system interruptions.

Any factor that prevents a power system from

doing its job reduces the productivity of the power

system and ultimately the facility that it serves.

Improving the Productivity

Implementing the results and recommendations of

power system studies will improve the productiv-

ity of a power system.

Chapter 2 of ANSI/IEEE 399-1990 states the

following: “The planning, design, and operation of

industrial power systems require engineering

studies to evaluate existing and proposed system

performance, reliability, safety, and economics.

Studies, properly conceived and conducted, are a

cost-effective way to prevent surprises and to opti-

mize equipment selection. In the design stage, the

studies identify and avoid potential deficiencies in

the system before it goes into operation. In existing

systems, the studies locate the cause of equipment

failure and misoperation and determine corrective

measures for improving system performance.”

The most common system studies done on

power systems includes: load flow, short-circuit,

stability, motor starting, harmonic analysis,

switching transient, reliability, cable ampacity,

IEEE Industry Applications Magazine ■ March/April 2001 15

ground mat, and coordination studies. The three ■ Tabulate the results of the protective device

studies addressed in this article are short-circuit, evaluation, which should include recommen-

coordination, and harmonic studies. dations for corrective actions where they may

be required.

Short-Circuit Studies

A short-circuit study is the analysis of a power sys- Results

tem that determines the magnitude of the currents The result of a short-circuit study is a compilation

that flow during a fault. These magnitudes are de- of data (usually from a computer analysis) indicat-

termined at various points in time after the fault ing the available fault current at all major compo-

inception. They are then compared to the ratings of nents of a power system. These results are then

the electrical components in the power system. compared to the ratings of the equipment (existing

The comparison determines the suitability of the or proposed). The comparison is commonly called a

equipment for use in the analyzed power system. protective device evaluation. The protective device

evaluation is made to determine where and if the

Components electrical components are exposed to current mag-

The list below outlines the various components nitudes greater than the ratings of the equipment.

that comprise a short-circuit study. With the This portion of the study should also provide rec-

availability of computer software that can com- ommendations on corrective actions.

plete the calculations, some of these components

may actually be performed by the software: Why a Short-Circuit Study?

■ Define the study scope (what are the bound- The specification and purchase of new electrical

ary points of the study scope?). power equipment is dependent on selecting the

■ Gather data on the power system (including equipment with the proper ratings for the applica-

that of the utility serving the facility) and the tion. The selection of the equipment is partially

associated equipment (either in the field for based on the magnitude of the fault currents that

existing power systems or from manufactur- can flow through the equipment. The equipment

ers’ data sheets for new systems). selected must be designed and built so that it can

■ Categorize and tabulate the data. successfully handle (carry and interrupt) the fault

■ Create a power system one-line diagram (or currents that flow during a short circuit. A short-

update an existing one). circuit study is needed to determine the magnitude

■ Convert the raw data into usable data. of these fault currents. It is imperative that the rat-

■ Create or construct needed impedance diagrams. ings of the selected equipment equal or exceed the

■ Calculate the fault current flows throughout magnitude of the calculated values of the short-cir-

the power system, especially at major points cuit currents that can flow during a fault.

of interest (usually related to equipment or After the initial design work is completed suc-

device ratings). cessfully, many power systems experience changes

■ Read and compare the results of the calcula-

that result in the need for new short-circuit studies.

tions to the ratings of the associated equip-

Table I lists a few of the various types of equip-

ment (this is commonly called a protective

ment and their ratings. This table is not intended to

device evaluation).

be complete. It is suggested that the reader refer to

the appropriate manufacturers’ data sheets and the

appropriate equipment standard (IEEE, ANSI,

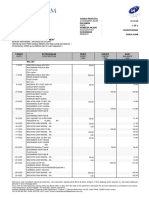

Table I. Typical Electrical Equipment Fault NEMA, or UL) for a complete listing of ratings.

Current Ratings

How Often Is a Short-Circuit Study Performed?

Type of Equipment Typical Fault Current Ratings Short-circuit studies should be performed as a

in kilo amps

part of the initial design of an electrical power sys-

Fuses (600-V class) 10 kA, 50 kA, 100 kA, etc. tem and at any time a significant modification is

anticipated. The original or base study must be

Molded case circuit breakers 14 kA, 25 kA, 35 kA and up completed so that the electrical power system com-

(600-V class)

ponents can be properly selected.

Air power circuit breakers 35 kA, 50 kA, 65 kA and up After a power system design has been com-

(600-V class) pleted and placed into operation, the usual expec-

tation is that the loads will grow with the

Switchgear bus bracing (600-V class) 35 kA, 50 kA, 65 kA, 100 kA, etc.

expansion and growth of the facility. The expan-

Motor control center bus bracing 35 kA, 50 kA, 65 kA, 100 kA, etc. sion and growth will usually involve the addition

(600-V class) of new motors and loads, necessitating the installa-

tion of new motor control centers, circuit breakers,

Medium voltage switchgear Momentary and interrupting ratings

of 58 and 28 kA

switchgear, switchboards, transformers, and asso-

ciated electrical system components.

16 IEEE Industry Applications Magazine ■ March/April 2001

As motor loads increase, their fault contribu- nate their electrical system in a manner so that elec-

tion to the existing system increases, exposing the trical equipment damage is minimized and the

existing power equipment to higher available fault power system outage is limited to the smallest se-

current magnitudes. These additions can reach a lected portion of the power system.

point where the fault currents equal or exceed the

ratings of the installed electrical equipment. Components

Adding load to a power system must not expose the The list below outlines the various components

existing equipment to fault current magnitudes in that make up a coordination study. Computer soft-

excess of the equipment ratings. ware may be able to perform many of these tasks.

Continued evaluation of the short-circuit cur- ■ Define the study scope (what are the bound-

rents associated with the modifications must be ary points of the system included in the study

completed to ensure that the fault current magni- scope?).

tudes are not allowed to increase to a point above ■ Gather data on the power system (including

the equipment ratings. If modifications to a facil- that of the utility serving the facility) and the

ity are constant, then short-circuit studies must be associated equipment (either in the field for

completed regularly in anticipation of the modifi- existing power systems or from manufactur-

cations. The frequency of the studies should follow ers’ data sheets for new systems).

the frequency of the modifications to the facility. ■ Categorize the data.

Some facility owners have adopted a regular sched- ■ Create a power system one-line diagram (or

ule of updating their studies every five years, when revise an existing one).

little or no change is made to a facility. Planned ■ Review the protective device characteristics,

regular updates will catch changes made by the ratings and settings.

utility as well as the plant. ■ Define the desired results (level of selectivity).

Some facility owners prepare five-year plans for ■ Select preliminary device characteristic, rat-

their facility’s operation and growth. Short-circuit ing or setting.

studies should be used as a tool in assisting in the ■ Prepare the final settings and/or time current

preparation of these plans. They can be used to as- curves.

sist in evaluating proposed changes and additions ■ Tabulate the results and recommendations.

to facilities and determine how the facility can best Several of the above items are similar to those of a

spend capital for new electrical equipment. De- short-circuit study. One usually gathers field data

pending on the magnitude of the proposed for both a short-circuit and a coordination study at

changes, the costs of the new electrical equipment the same time.

can impact the costs of the project significantly. The results of a coordination study are recom-

Short-circuit tables and curves are found in ap- mendations on the proper protective device charac-

plication literature. These tables and curves are of- teristic, rating, or setting selection for all of the

ten used as a quick means of determining short- system protective devices. These recommendations

circuit currents. They are based on assumptions un- should provide, when implemented, a power system

known to the user and do not cover the entire power whose protection devices will provide the level of

system being evaluated. Some of these may match system protection and selectivity planned.

equipment ratings to transformer ratings. A word of

caution is in order: tables and curves do not replace Why a Coordination Study?

exact engineering calculations. A coordination study and the implementation of

the resulting recommendations will minimize de-

Coordination Studies vice erratic operation and (i.e., nuisance power out-

A coordination study is the process of determining ages) electrical equipment damage and provide

the optimum characteristics, ratings, and settings improved power system reliability.

of the power system protective devices. The opti- A coordination study is needed:

mum settings are focused on providing systematic ■ When the initial power system is designed,

interruptions to the selected power system seg- ■ When new loads are added to the power system,

ments during fault conditions. ■ When existing equipment is replaced with

Engineers in process-related industries whose equipment whose ratings are higher,

processes can cause equipment damage and/or hu- ■ When a fault on the periphery of the system

man injury in case of an unplanned shutdown will shuts down a major portion of the system,

design the protective system on the operating phi- ■ When the utility or source short-circuit cur-

losophy consistent with the safety of the process. rent changes, and

Design and coordination of these systems requires ■ When new relays are installed to replace or

special considerations that are beyond the scope of upgrade the existing relays.

this article. Properly coordinated power system protective

Those industries’ engineers whose processes can devices will result in a power system that is highly

afford limited outages generally design and coordi- reliable and minimizes equipment damage during

IEEE Industry Applications Magazine ■ March/April 2001 17

faults. It will also afford operation with the least ■ Plant expansions that include large amounts

exposure to outages. of harmonic generating loads,

In many cases, coordination studies reveal areas ■ Installation of power-factor-correction ca-

where exact coordination between two devices is not pacitors on power systems that contain large

possible. In these cases, engineering judgment is used harmonic generating loads, and

to select the most desirable configuration—usually ■ History of capacitor fuse failures.

one that will minimize equipment damage.

What Completes a Harmonic Analysis?

Harmonic Analyses

The same data needed to complete the short-circuit

A harmonic analysis evaluates the steady-state ef-

fects of nonsinusoidal voltages and currents on the study is needed for this work. In addition to that

power system and its components. Some of the data, a good understanding of the power system

sources of these wave shape disturbances are: DC serving the facility is needed by the engineer per-

rectifiers, adjustable-speed drives, arc furnaces, forming the analysis. The engineer must know if

welding machines, static power converters of all there are capacitors on the utility system that may

kinds, and transformer saturation. affect the results of the study. Additionally, he or

she must also know: 1) the utility harmonic voltage

Why Harmonic Analysis? spectrum at the point of common coupling, 2) data

Electrical equipment used to generate, distribute, on all system capacitors, 3) specific system config-

and utilize electrical energy is designed for use on urations and operating characteristics and proce-

power systems that supply pure sine waves. When a dures on all converter circuits to be studied, and 4)

voltage or current wave shape is distorted, it causes any utility limitations on distortion limit.

abnormal operating conditions in the system and

equipment. Various types of equipment are affected Results

differently by these wave shape distortions. The result or solution to a harmonic problem is to

Some examples are: shift the harmonic resonant point to some other

■ Voltage distortion can cause additional heat-

frequency not generated by the equipment in the

ing in induction and synchronous motors and system. Through the course of the evaluation, the

generators.

system power factor may also be adjusted to an im-

■ Voltage distortion with high peak values can

proved point. The use of filters may be required to

weaken insulation in cables, windings, and

capacitors. shift the resonant point. The analysis may reveal

■ Voltage wave shape distortion can also cause

that some system components require derating due

malfunction of electronic devices that use to the heating caused by harmonic currents.

wave shape for timing. The net result of the harmonic analysis, once the

■ Harmonic currents in motor windings can recommendations of the analysis are implemented,

cause higher noise emissions. is a power system whose components are not ex-

■ Harmonic currents cause additional heating posed to voltages or currents that exceed their ca-

in transformers. pability or the mill or utility requirements.

■ Harmonic currents flowing through cables It is important that these studies, along with

cause higher heating over and above the heat- others, be given the attention needed at the appro-

ing expected from rms currents. priate times throughout the life of a facility.

■ Harmonic currents flowing through switch-

gear can increase heating and losses in the References

switchgear and circuit breakers. [1] IEEE Recommended Practice for Power Systems Analysis, IEEE

■ Resonant current flows can cause capacitor Std. 399, 1990.

failures and/or fuse failures in the capacitor or [2] IEEE Recommended Practice for Electric Power Distribution for

other electrical equipment. Industrial Plants, IEEE Std. 141, 1993.

■ Protective relays and circuit breakers can trip [3] D. L. Beeman, Ed, Industrial Power Systems Handbook. New

York: McGraw-Hill, 1955.

falsely due to harmonic currents. [4] J.L. Blackburn, Protective Relaying Principles and Applications.

New York: Marcel Dekker, 1987.

When Is a Harmonic Analysis Needed? [5] IEEE Recommended Practice for Protection and Coordination of

A harmonic analysis is usually needed when any of Industrial and Commercial Power Systems, IEEE Std. 242,

the following conditions exists: 1986.

■ During the design phase of a facility that con- [6] IEEE Recommended Practices for Harmonic Control in Electric

sists of a large harmonic-generating load (arc Power Systems, IEEE Std. 519, 1992.

[7] C.K. Duffey, “ESA’s Practical Guide To Power System Har-

furnaces, rectifier lines, a large concentration monics,” ESA seminar notes.

of variable-speed drives), [8] R.H. McFadden, “Power-System Analysis: What It Can Do

■ When a utility limits its distortion to the sys- for Industrial Plants,” IEEE Trans. Ind. Applicat., Mar./Apr.

tem voltages and currents, 1971.

18 IEEE Industry Applications Magazine ■ March/April 2001

Вам также может понравиться

- Significant Ships 1994Документ96 страницSignificant Ships 1994Joe Tahir100% (2)

- Tutorial NEPLAN V543Документ23 страницыTutorial NEPLAN V543alexkero100% (1)

- Newton Programmer's Guide (Alpha Draft 1.1)Документ894 страницыNewton Programmer's Guide (Alpha Draft 1.1)pablo_marxОценок пока нет

- A Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Документ8 страницA Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Ritaban R. BanerjeeОценок пока нет

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesОт EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesОценок пока нет

- Fault Analysis of 11kv Distribution SystemДокумент10 страницFault Analysis of 11kv Distribution SystemDanielAlejandroRamosQueroОценок пока нет

- Tg8614a P342, P343 PDFДокумент298 страницTg8614a P342, P343 PDFErick FalconiОценок пока нет

- Voltage Sag Analysis Case StudiesДокумент7 страницVoltage Sag Analysis Case Studiesmonirul_ahmedОценок пока нет

- IEEE519 Guide ToshibaДокумент3 страницыIEEE519 Guide ToshibaVanshika MasandОценок пока нет

- Multilin: Synchronism Check EquipmentДокумент26 страницMultilin: Synchronism Check EquipmentĐức Nguyễn XuânОценок пока нет

- Tele-Protection: Fundamentals and ApplicationsДокумент92 страницыTele-Protection: Fundamentals and ApplicationsYasirOsmanОценок пока нет

- Circuit Breaker Fundamental CharacteristicДокумент8 страницCircuit Breaker Fundamental CharacteristicMaj RodriguezОценок пока нет

- Sel-411l - Line DifferentialДокумент21 страницаSel-411l - Line DifferentialRatheesh KumarОценок пока нет

- Transformer Inrush CurvesДокумент2 страницыTransformer Inrush CurvessudirmanpriyoОценок пока нет

- The Dangers of DC High Voltage Test For XLPE Cables at SiteДокумент4 страницыThe Dangers of DC High Voltage Test For XLPE Cables at SiteLTE002Оценок пока нет

- IEEE Recommended Settings For Generator ProtectionДокумент7 страницIEEE Recommended Settings For Generator ProtectionBruno SamosОценок пока нет

- Overcurrent Coordination Setting Guidelines ConductorsДокумент7 страницOvercurrent Coordination Setting Guidelines ConductorsrobertoseniorОценок пока нет

- Inverter Based DG Fault CalculationДокумент13 страницInverter Based DG Fault CalculationhassanОценок пока нет

- High-Power-Rectifier-Systems-CATALOGO TECNICOДокумент16 страницHigh-Power-Rectifier-Systems-CATALOGO TECNICOEdgardo Kat ReyesОценок пока нет

- Power Quality and Harmonic Analysis in Three PhaseДокумент7 страницPower Quality and Harmonic Analysis in Three PhaseMarcos PessanhaОценок пока нет

- Sag SwellДокумент149 страницSag Swellfurqan mahmudОценок пока нет

- ABB 63 WPO BreakerCoordination FinalДокумент4 страницыABB 63 WPO BreakerCoordination FinalCA Cole100% (1)

- Khu 10 Ye - Efe Ea - 000Документ51 страницаKhu 10 Ye - Efe Ea - 000Parag AhsanОценок пока нет

- APC White PapersДокумент27 страницAPC White Papersmonarch_007100% (1)

- McompДокумент9 страницMcompSrikanth NakkaОценок пока нет

- Protection Coordination in MV Distribution System of Sri Lanka PDFДокумент120 страницProtection Coordination in MV Distribution System of Sri Lanka PDFJulioОценок пока нет

- Automation and Integration Solutions For Electric Power SystemsДокумент16 страницAutomation and Integration Solutions For Electric Power SystemsMadhusudhan SrinivasanОценок пока нет

- IEEE Standard For AC High Voltage Circuit Breakers Rated On Symmetrical Current BasisДокумент60 страницIEEE Standard For AC High Voltage Circuit Breakers Rated On Symmetrical Current BasisdaperroОценок пока нет

- Modeling and Simulation of A Dynamic Voltage Restorer (DVR)Документ49 страницModeling and Simulation of A Dynamic Voltage Restorer (DVR)Subodh Sharma100% (1)

- System Protection SchemesДокумент54 страницыSystem Protection Schemeslisused0% (1)

- 7SD610 Line Diff Protn Relay Version 4.0Документ502 страницы7SD610 Line Diff Protn Relay Version 4.0vseenivasan_6Оценок пока нет

- Guide For Selective CoordinationДокумент12 страницGuide For Selective CoordinationAlbert TuazonОценок пока нет

- ANSI Device NumbersДокумент7 страницANSI Device Numbersrajpre1213Оценок пока нет

- Influence of Instrument Transformers On Power System ProtectionДокумент142 страницыInfluence of Instrument Transformers On Power System Protection1453hОценок пока нет

- Neg Seq Diff ThesisДокумент193 страницыNeg Seq Diff Thesisjimbbeaa22Оценок пока нет

- One Line RV 10 Users ManualДокумент505 страницOne Line RV 10 Users ManualMiguelAngelCedanoBurrola100% (2)

- 1Документ127 страниц1majid_abkoohiОценок пока нет

- Network Protection Automation Guide Areva 1Документ915 страницNetwork Protection Automation Guide Areva 1eliaseee100% (1)

- RER615 Engineering ManualДокумент152 страницыRER615 Engineering ManualРоман ВоеводаОценок пока нет

- Synchronization Checklist PDFДокумент8 страницSynchronization Checklist PDFAdhyartha KerafОценок пока нет

- TransformerProtection by Hands On Relay SchoolsДокумент63 страницыTransformerProtection by Hands On Relay SchoolshiteshkelaОценок пока нет

- EATON Protection and Control RelaysДокумент8 страницEATON Protection and Control RelaysRazvan MaresОценок пока нет

- Coordination of Relays, Reclosers, and Sectionalizing Fuses For Overhead Lines in The Oil PatchДокумент8 страницCoordination of Relays, Reclosers, and Sectionalizing Fuses For Overhead Lines in The Oil PatchluhusapaОценок пока нет

- Voltage Sags.... 2020Документ13 страницVoltage Sags.... 2020Dr Hafiz Mudassir Munir - Assistant ProfessorОценок пока нет

- Auto-Reclosing On Ehv Lines.: Y. K. PandharipandeДокумент12 страницAuto-Reclosing On Ehv Lines.: Y. K. PandharipandeJai GuptaОценок пока нет

- Technical Complementary Guide 2013Документ256 страницTechnical Complementary Guide 2013brightstardustОценок пока нет

- Application Notes For Micom P12X High Impedance ProtectionДокумент29 страницApplication Notes For Micom P12X High Impedance ProtectionHaleelu Abdul Jaleel100% (1)

- Littelfuse Protection Relay Protection Relays White Paper PDFДокумент6 страницLittelfuse Protection Relay Protection Relays White Paper PDFRamphani NunnaОценок пока нет

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsОт EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsОценок пока нет

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsОт EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsОценок пока нет

- Computer Power System AnalysisДокумент155 страницComputer Power System AnalysisSamir ElabasiryОценок пока нет

- Trafo Manual - Erctn, Maint & CommsnДокумент32 страницыTrafo Manual - Erctn, Maint & CommsnparthaОценок пока нет

- MathДокумент111 страницMathparthaОценок пока нет

- Chemistry FE ExamДокумент35 страницChemistry FE ExamRobby RenzОценок пока нет

- Power System HarmonicsДокумент5 страницPower System HarmonicsAN.ADAMMSОценок пока нет

- Eye Med SummaryДокумент2 страницыEye Med SummaryparthaОценок пока нет

- How To Apply Capacitors To Low Voltage Power Systems.Документ13 страницHow To Apply Capacitors To Low Voltage Power Systems.Ahmed Reda Abdou MohamedОценок пока нет

- Comprehensive Asset Management PolicyДокумент6 страницComprehensive Asset Management PolicyparthaОценок пока нет

- RE - 316 4 and RE. 216: Coupling To The MVB Interbay BusДокумент42 страницыRE - 316 4 and RE. 216: Coupling To The MVB Interbay BusparthaОценок пока нет

- RE - 316 4 and RE. 216: Coupling To The MVB Interbay BusДокумент42 страницыRE - 316 4 and RE. 216: Coupling To The MVB Interbay BusparthaОценок пока нет

- 6623 ProtectingMutually DT 20140210 WebДокумент22 страницы6623 ProtectingMutually DT 20140210 WebparthaОценок пока нет

- Electro-Acoustic Detection Identificatio PDFДокумент10 страницElectro-Acoustic Detection Identificatio PDFparthaОценок пока нет

- ISO 55000 - What You Need To KnowДокумент26 страницISO 55000 - What You Need To KnowSidney Pereira Junior100% (3)

- AIES Protection Standard Revision 0 2004-12-01Документ65 страницAIES Protection Standard Revision 0 2004-12-01parthaОценок пока нет

- SAMДокумент19 страницSAMOnita Dwi AgustinОценок пока нет

- Extensibility Guide For JIT-EWM IntegrationДокумент18 страницExtensibility Guide For JIT-EWM IntegrationAltamir Nunes JuniorОценок пока нет

- Estatement-202310 20240118082918Документ3 страницыEstatement-202310 20240118082918jooamir70Оценок пока нет

- Notifications 984Документ12 страницNotifications 984kishorebondada78Оценок пока нет

- Ags20 Series Universal Aggregation PlatformДокумент7 страницAgs20 Series Universal Aggregation PlatformGonzalo FloresОценок пока нет

- Sonifier SFX250 and SFX550 Cell Disruptors and HomogenizersДокумент6 страницSonifier SFX250 and SFX550 Cell Disruptors and HomogenizersAlison AlcarazОценок пока нет

- HTML, CSS & Javascript NotesДокумент144 страницыHTML, CSS & Javascript NotesSteve MorfawОценок пока нет

- Grandstream Networks, Inc.: Analog Telephone Adaptor With FXS/FXO PortДокумент20 страницGrandstream Networks, Inc.: Analog Telephone Adaptor With FXS/FXO PortJulian RamirezОценок пока нет

- Washer Tech Data SheetДокумент16 страницWasher Tech Data SheetDavid LovatoОценок пока нет

- Programmable Logic Controllers Lab 4 JucticeДокумент11 страницProgrammable Logic Controllers Lab 4 JucticeSamuel AdenijiОценок пока нет

- Packaging and LabellingДокумент32 страницыPackaging and LabellingVishal100% (1)

- H.R.Steel Industries: Job Card For M 20X2.5X 155 MM Hex Bolt (HSFG)Документ1 страницаH.R.Steel Industries: Job Card For M 20X2.5X 155 MM Hex Bolt (HSFG)mahesh agarwalОценок пока нет

- Shichun Yang Xinhua Liu Shen Li Cheng Zhang: Advanced Battery Management System For Electric VehiclesДокумент318 страницShichun Yang Xinhua Liu Shen Li Cheng Zhang: Advanced Battery Management System For Electric VehiclesDennis FielОценок пока нет

- German Malaysian Institute: Matrix of Course Learning Outcomes & Course ContentДокумент6 страницGerman Malaysian Institute: Matrix of Course Learning Outcomes & Course ContentAnonymous 5YMOxVQОценок пока нет

- 9852 1007 01d Maintenance Instr COP 1840HE, HEXДокумент19 страниц9852 1007 01d Maintenance Instr COP 1840HE, HEXButnariu CristianОценок пока нет

- Removal of Default Vbe 8 - BBB GraphicsДокумент4 страницыRemoval of Default Vbe 8 - BBB Graphicsmario nogueraОценок пока нет

- KX-TGFA30: Additional Digital Cordless HandsetДокумент16 страницKX-TGFA30: Additional Digital Cordless HandsetAntonio OrtizОценок пока нет

- Deposits Can ManualДокумент17 страницDeposits Can ManualAndré QuirinoОценок пока нет

- Lab # 5 Objective:Analyze Queue Variables Queue Variables DescriptionДокумент8 страницLab # 5 Objective:Analyze Queue Variables Queue Variables Descriptionkamran khanОценок пока нет

- Visual AidsДокумент20 страницVisual AidsAngela Dudley100% (2)

- Blinc 360 and Ajna TechДокумент14 страницBlinc 360 and Ajna TechAlkame IncОценок пока нет

- Ugc Net Updated Syllabus For Library and Information ScienceДокумент4 страницыUgc Net Updated Syllabus For Library and Information SciencePrince JОценок пока нет

- Scala Rider Q1 Owner ManualДокумент16 страницScala Rider Q1 Owner ManualFabio GalloОценок пока нет

- EE 466/586 VLSI Design: School of EECS Washington State University Pande@eecs - Wsu.eduДокумент32 страницыEE 466/586 VLSI Design: School of EECS Washington State University Pande@eecs - Wsu.eduPhạm Đức ThuậnОценок пока нет

- Light and Lighting - Lighting of Work Places - Part 1: Indoor Work PlacesДокумент9 страницLight and Lighting - Lighting of Work Places - Part 1: Indoor Work Placesrakib.techlinkОценок пока нет

- Case StudyДокумент7 страницCase StudyShrishti AgarwalОценок пока нет

- Cooling System Electrolysis: Ron Davis Racing Products IncДокумент2 страницыCooling System Electrolysis: Ron Davis Racing Products IncLazarus GutaОценок пока нет

- MCC Control Schemes Comments - Rev-1Документ1 страницаMCC Control Schemes Comments - Rev-1vigneshwarannnОценок пока нет