Академический Документы

Профессиональный Документы

Культура Документы

Qap MS Aprd

Загружено:

Naveen NagisettiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Qap MS Aprd

Загружено:

Naveen NagisettiАвторское право:

Доступные форматы

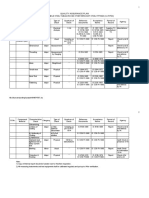

QUALITY ASSURANCE PLAN

FOR MANUFACTURE OF M.S. PIPES, INSPECTION AND TESTING PLAN

Agency

Sl. Characteristics Type of Quantum of Format of

Component / Material Category Reference Documents Acceptance Norms Remarks

No. Check Check Check Record

M TPI B

1.0 RAW MATERIAL CONTROL

1.1 Steel Pipes/Coils a. Chemical Critical Chemical 1/section / lot IS 3589 - 2001 IS 3589-2001 MTC R R R

Analysis

b. Physical

1. Tensile Critical UTM One sample IS 3589 - 2001 IS 3589-2001 Lab report W R R

for every 40 T

2. Bend Test Critical UTM One Sample IS 3589 - 2001 IS 3589-2001 Lab report W R R

per Batch

c. Dimension Major Measuring 100% IS 3589 - 2001and customer IS 3589 - 2001and Manufacturer's W R R

Instrument specification, if any customer specification, if Register /

any Report

d. Surface Defect Major Visual 100% IS 3589 - 2001 IS 3589 - 2001 Manufacturer's W R R

Register /

Report

2.0 PROCESS CONTROL

2.1 Cutting the plate to size Dimension Minor Measuring 100% Manufacturer's Drawing Manufacturer's Drawing - W R R

Instrument

2.2 Edge preparation to size Dimension Minor Measuring 100% Manufacturer's Drawing Manufacturer's Drawing - W R R

Instrument

2.3 Rolling and bending to Dimension Minor Measuring 100% Manufacturer's Drawing Manufacturer's Drawing - W R R

cylindrical shape Instrument

2.4 Tack welding for welding Alignment, root gap Major Gauges 50% Manufacturer's Drawing Manufacturer's Drawing - W R R

etc.,

2.5 Welding Procedure Current, Voltage & Critical Indicating 50% Manufacturer's welding Manufacturer's welding - W R R

Speed Instruments procedure procedure

CONTRACTOR EMPLOYER / ENGINEER

Agency

Sl. Characteristics Type of Quantum of Format of

Component / Material Category Reference Documents Acceptance Norms Remarks

No. Check Check Check Record

M TPI B

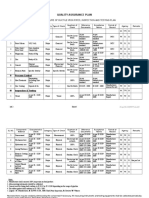

3.0 FINAL INSPECTION & TESTING

3.1 Inspection of welded Pipes a. Dimension Critical Measuring 100% Manufacturers Drawing / Manufacturers Drawing / Inspection W W R

Instrument Purchaser's Specification Purchaser's Specification Report

b. Welding Critical Visual 100% As per standard welding As per standard welding Inspection W W R

practice (IS 816 & IS 822) practice (IS 816 & IS 822) Report

c. Soundness of Weld Critical Ultrasonic 5% IS 4258 IS 4258 Ultrasonic Test W W R

Report

d. Mechanical Test Critical Root & Face Sampling as IS 3589 IS 3589 Inspection W W R

Bend test per IS 4711 Report

e. Hydraulic Pressure Critical Hydraulic 100% IS 3589 IS 3589 Inspection W W R

Test Pressure at Report

manufacturer's

works

4.0 INNER LINING & OUTER COATING

4.1 1. Dimension Major Measuring 100% IS 3589/2001 IS 3589/2001 Manufacturer's W R R

Instrument Register/

Report

2. Surface Defect Major Visual 100% IS 3589/2001 IS 3589/2001 Manufacturer's W R R

Register/

Report

4.2 Cement a. Chemical Critical Chemical One sample IS 269 / IS 8112/ IS 12330 IS 269 / IS 8112/ IS Suppliers TC W R R

Analysis for every 200 12330

bags

b. Physical

1. Fineness -do- By Sieve -do- -do- -do- Lab report W R R

2. Standard -do- Lab test -do- -do- -do- Lab report W R R

Consistency

3. Setting time -do- Lab test -do- -do- -do- Lab report W R R

Initial, Final

CONTRACTOR EMPLOYER / ENGINEER

Agency

Sl. Characteristics Type of Quantum of Format of

Component / Material Category Reference Documents Acceptance Norms Remarks

No. Check Check Check Record

M TPI B

4. Soundness -do- Lab test -do- -do- -do- Lab report W R R

5. Compressive -do- Lab test -do- -do- -do- Lab report W R R

Strength

4.3 Aggregate a. Deleterious Major Lab test 1/lot IS 383 IS 383 1. Supplier's W R R

Material TC

2. Lab report.

b. Soundness -do- -do- -do- -do- -do- -do- W R R

c. Specific Gravity -do- -do- -do- -do- -do- -do- W R R

d. Grading & Size -do- -do- -do- -do- -do- -do- W R R

4.4 Weld Mesh for outer Coating Dimension Minor Measuring AQL 4.0 I.L.II As per customer Manufacturer's Register/ Manufacturer/ W R R

Instrument D.S.P of IS specification Inspection/ Record IA

2500

4.5 Water Suitability of water Major Lab test Once in a year IS 456 IS 456 Lab TC W R R

for concrete works

4.6 Outer Coating Mix a. Mix design Major Measurement 1/Batch Manufacturer's own Manufacturer's own -do- W W R

standard standard

b. Cube Strength Critical Compressive 3/Batch IS 784 and purchaser's IS 784 and purchaser's Manufacturer's W R R

strength specification specification Register

4.7 Outside Coating Coating thickness Major Spike gauges 5% Purchaser's specification Purchaser's specification -do- W W R

4.80 Curing Proper curing Critical 1. Visual 100% Purchaser's specification Purchaser's specification -do- W W R

2.

Co-relating

with cube

strength

5.0 FINAL INSPECTION AND TESTING

5.1 Fabricated, lined and coated a. Surface defects Major Visual 100% Purchaser's specification/ Purchaser's specification/ Test Reports W W R

pipe IS 1916 IS 1916

b. Dimension Major Measuring 100% Purchaser's specification/ Purchaser's specification/ -do- W W R

Instrument and IS 1916

Gauges IS 1916

CONTRACTOR EMPLOYER / ENGINEER

Agency

Sl. Characteristics Type of Quantum of Format of

Component / Material Category Reference Documents Acceptance Norms Remarks

No. Check Check Check Record

M TPI B

c. Marking Major Visual 100% Purchaser's specification/ Purchaser's specification/ -do- W W R

IS 1916 IS 1916

6.0 SEALING AND STAMPING

6.1 Stenciling IA stamp Legibility of Stamp Major Visual 100% --- --- Test Reports W W R Samples

inspected by

TPI are double

stamped

7.0 PACKING AND DESPATCH

Each pipes is handled only by flat canvas belt to avoid damages during handling and properly stacked to avoid damages during transport and unloading.

Note :- No Negetive tolerence in respect of thickness is permissible

R = Review

W = Witness

M = Manufacturer

B = Board

TPI = Third Party Inspection agency

Reviewed items may be randamly witnessed by the concerned if necessary. All measuring instruments and testing equipments shall be calibrated periodically

and put up for verification to Third Party Inspection agency.

CONTRACTOR EMPLOYER / ENGINEER

Вам также может понравиться

- Sable Island National Park Reserve Water Infrastructure UpgradeДокумент18 страницSable Island National Park Reserve Water Infrastructure UpgradeNaveen NagisettiОценок пока нет

- T2 Tender Notice 23.9.19Документ15 страницT2 Tender Notice 23.9.19Naveen NagisettiОценок пока нет

- VOL 1 0.1 Index-MYLMДокумент7 страницVOL 1 0.1 Index-MYLMNaveen NagisettiОценок пока нет

- VOL 1 0.0 Cover Page MYLMДокумент10 страницVOL 1 0.0 Cover Page MYLMNaveen NagisettiОценок пока нет

- Vol 1 2.0 Itb-MylmДокумент50 страницVol 1 2.0 Itb-MylmNaveen NagisettiОценок пока нет

- 06 Part A-1 CIVIL WORKS PR PDFДокумент104 страницы06 Part A-1 CIVIL WORKS PR PDFNaveen Nagisetti100% (1)

- TUNNEL II - BOQ (Part1)Документ16 страницTUNNEL II - BOQ (Part1)Naveen Nagisetti75% (4)

- Technical Specification Canal - 02Документ203 страницыTechnical Specification Canal - 02Naveen Nagisetti100% (1)

- Please Enable Macros To View Boq InformationДокумент2 страницыPlease Enable Macros To View Boq InformationNaveen NagisettiОценок пока нет

- RCC-DI-AC PipeДокумент10 страницRCC-DI-AC PipeNaveen NagisettiОценок пока нет

- Boq1 268515Документ32 страницыBoq1 268515Naveen NagisettiОценок пока нет

- Existing Drain LevelsДокумент1 страницаExisting Drain LevelsNaveen NagisettiОценок пока нет

- "Mekastar/Jhalani/Taparia/ Mitutoyo Make "T & P" For Water System in 1X500 MW KTPS-VI Stage"Документ4 страницы"Mekastar/Jhalani/Taparia/ Mitutoyo Make "T & P" For Water System in 1X500 MW KTPS-VI Stage"Naveen NagisettiОценок пока нет

- Item Rate Boq: Validate Print HelpДокумент7 страницItem Rate Boq: Validate Print HelpNaveen NagisettiОценок пока нет

- Schedule - 6 Schedule of General Terms and Conditions (To Be Enclosed in The Part-I Pre-Qualification Bid)Документ2 страницыSchedule - 6 Schedule of General Terms and Conditions (To Be Enclosed in The Part-I Pre-Qualification Bid)Naveen NagisettiОценок пока нет

- S.No. Name of The Material Qty (No's) E-Procurement CodeДокумент2 страницыS.No. Name of The Material Qty (No's) E-Procurement CodeNaveen NagisettiОценок пока нет

- Percentage Boq: Validate Print HelpДокумент12 страницPercentage Boq: Validate Print HelpNaveen NagisettiОценок пока нет

- Quality Assurance PlanДокумент4 страницыQuality Assurance PlanNaveen NagisettiОценок пока нет

- Quality Assurance Plan: Product Name: Hdpe PipesДокумент3 страницыQuality Assurance Plan: Product Name: Hdpe PipesNaveen NagisettiОценок пока нет

- Quality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing PlanДокумент2 страницыQuality Assurance Plan: For Manufacture of Ductile Iron Pipes, Inspection and Testing PlanNaveen NagisettiОценок пока нет

- QAP CI Flsnged PipesДокумент11 страницQAP CI Flsnged PipesNaveen NagisettiОценок пока нет

- Government of Odisha: Office of The Engineer-In-Chief, Public Health Odisha, BhubaneswarДокумент1 страницаGovernment of Odisha: Office of The Engineer-In-Chief, Public Health Odisha, BhubaneswarNaveen NagisettiОценок пока нет

- 39MLD STP at Daulatganj - Survey, Investigation, Design, Supply, ConstructionДокумент56 страниц39MLD STP at Daulatganj - Survey, Investigation, Design, Supply, ConstructionNaveen NagisettiОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- FortiManager Study Guide-OnlineДокумент398 страницFortiManager Study Guide-OnlineFelipe Gabriel Nieto Concha25% (4)

- Antiphon - Caritas - Habundat - in - Omnia - Hildegard Von BingenДокумент3 страницыAntiphon - Caritas - Habundat - in - Omnia - Hildegard Von BingenGStarkОценок пока нет

- À Bout de Souffle (Breathless) : Treatment by François TruffautДокумент10 страницÀ Bout de Souffle (Breathless) : Treatment by François TruffautAlex KahnОценок пока нет

- Guidelines For Mental Care Onboard Merchant Ships: ContentДокумент12 страницGuidelines For Mental Care Onboard Merchant Ships: ContentSona NarulaОценок пока нет

- TestingДокумент116 страницTestingAkarsh LОценок пока нет

- ZF 2000 Series: Product DetailsДокумент4 страницыZF 2000 Series: Product DetailsJhonAlexRiveroОценок пока нет

- 34 / Architecture: Form, Space, & OrderДокумент5 страниц34 / Architecture: Form, Space, & Ordersusmita waghmareОценок пока нет

- Module 7 - Badminton - Fundamental SkillsДокумент45 страницModule 7 - Badminton - Fundamental SkillsJoshua AltamiranoОценок пока нет

- Company Profile Bureau Veritas ThailandДокумент13 страницCompany Profile Bureau Veritas ThailandPitichai PakornrersiriОценок пока нет

- Thermostability of PVC and Related Chlorinated Polymers: Application Bulletin 205/2 eДокумент3 страницыThermostability of PVC and Related Chlorinated Polymers: Application Bulletin 205/2 eAnas ImdadОценок пока нет

- Industrial Automation Lab: Project ProposalДокумент3 страницыIndustrial Automation Lab: Project ProposalAmaan MajidОценок пока нет

- Kamal Din - Trainer Profile-2019 PDFДокумент2 страницыKamal Din - Trainer Profile-2019 PDFChoy Hau Yan100% (1)

- Internet BillДокумент2 страницыInternet Billshiva ramОценок пока нет

- HR-Security Profile OptionДокумент1 страницаHR-Security Profile Optionnil77Оценок пока нет

- WordДокумент48 страницWordenkelene.zulfajОценок пока нет

- Icbc Songs Line-Up 2Документ118 страницIcbc Songs Line-Up 2paolojaspiras89% (9)

- Substantive Testing in The Revenue CycleДокумент3 страницыSubstantive Testing in The Revenue CycleGeorgia FlorentinoОценок пока нет

- Passed 1489-13-21MELCS Ifugao The Mole Concept and Mass of SubstancesДокумент28 страницPassed 1489-13-21MELCS Ifugao The Mole Concept and Mass of SubstancesPowerBob TVОценок пока нет

- Obstetric & Gynaecological NursingДокумент30 страницObstetric & Gynaecological NursingSanthosh.S.U100% (1)

- Aakash ADV Full Tests MERGEDДокумент486 страницAakash ADV Full Tests MERGEDAnirudh100% (1)

- Sita's RamayanaДокумент2 страницыSita's RamayanaAnonymous dSuPcxyn0% (1)

- Revenge, Hypnotism, and Oedipus in OldboyДокумент13 страницRevenge, Hypnotism, and Oedipus in OldboyAdrián PiqueroОценок пока нет

- Notes Microwave Engineering Unit 5 PDFДокумент14 страницNotes Microwave Engineering Unit 5 PDFKujur RebecaОценок пока нет

- Doors & People ManualДокумент32 страницыDoors & People ManualOscar Ayala100% (1)

- Am Coverage Mapping & PredictionДокумент6 страницAm Coverage Mapping & PredictionJoyce HencelОценок пока нет

- Behavior Intervention PlanДокумент22 страницыBehavior Intervention Planapi-343163369100% (1)

- Safety EducationДокумент5 страницSafety EducationOwen Silva NaldozaОценок пока нет

- Chapter 1Документ17 страницChapter 1Nari KangОценок пока нет

- 10.1007@s10157 020 01867 yДокумент6 страниц10.1007@s10157 020 01867 yGin RummyОценок пока нет

- Gas Rating Summary 2010Документ2 страницыGas Rating Summary 2010ahmadhadraniОценок пока нет