Академический Документы

Профессиональный Документы

Культура Документы

71-00-00-710-006-B - Minimum Idle Check

Загружено:

Eder LucianoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

71-00-00-710-006-B - Minimum Idle Check

Загружено:

Eder LucianoАвторское право:

Доступные форматы

Customer : AZU Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 051-051

Rev. Date : Aug 01, 2018

71-00-00-710-006-B - Minimum Idle Check

** ON A/C 051-100

TASK 71-00-00-710-006-B

Minimum Idle Check

WARNING: MAKE SURE THAT ALL ENGINE OPERATING AREAS ARE AS CLEAN AS POSSIBLE. ALL

RAMPS, TAXIWAYS, RUNWAYS AND OTHER OPERATING AREAS MUST BE VERY CLEAN

TO PREVENT BAD DAMAGE TO THE ENGINE, AIRCRAFT AND PERSONS IN THE AREA.

WARNING: DO NOT TRY TO STOP THE FAN FROM TURNING BY HAND. THIS CAN CAUSE INJURY TO

THE PERSONS AND DAMAGE TO THE EQUIPMENT.

WARNING: MAKE SURE THAT THE LANDING GEAR GROUND SAFETIES AND THE WHEEL CHOCKS

ARE IN POSITION. MOVEMENT OF THE AIRCRAFT CAN BE DANGEROUS.

WARNING: DO NOT DO AN ENGINE RUN-UP WITH THE THRUST REVERSER COWLS OPEN. DO NOT

DO AN ENGINE RUN-UP WITH THE FAN COWLS OPEN AND SAFETIED BY THE HOLD-OPEN

ROD IF YOU OPERATE THE ENGINE AT POWER HIGHER THAN IDLE.

WARNING: - ENGINE OPERATION MUST NOT EXCEED MINIMUM IDLE WHEN PERSONNEL ARE IN

ENTRY/EXIT CORRIDOR.

- POSITIVE COMMUNICATION BETWEEN THE FLIGHT COMPARTMENT AND PERSONNEL

IN ENTRY EXIT CORRIDOR IS NECESSARY.

- INLET AND EXHAUST HAZARD AREAS MUST BE STRICTLY OBSERVED BY PERSONNEL

IN ENTRY/EXIT CORRIDOR.

WARNING: MAKE SURE THAT:

- THE PASSENGER DOORS ARE CLOSED AND THE PASSENGER LOADING STAIRS ARE

REMOVED WHEN AT LEAST ONE ENGINE IS OPERATED ABOVE IDLE POWER.

- THE CARGO DOORS ARE CLOSED AND CARGO LOADING EQUIPMENT IS REMOVED

WHEN:

. ENGINE 2 IS OPERATED AT IDLE OR ABOVE

. AT LEAST ONE ENGINE IS OPERATED ABOVE IDLE POWER

IF YOU DO NOT OBEY THESE PRECAUTIONS INJURY TO THE PERSONNEL AND DAMAGE

TO THE AIRCRAFT AND/OR EQUIPMENT CAN OCCUR.

CAUTION: - SEE THE APPLICABLE FIGURE FOR WIND LIMIT RESTRICTIONS WHEN THE ENGINE OP-

ERATES.

- NATURAL WINDS AND IRREGULAR FORCES FROM SUDDEN GUSTS INCREASE THE

DANGEROUS AREA.

- DO NOT GO ABOVE OPEN COWLING LIMITATIONS WHEN YOU DO THE TESTS.

- THE OPERATOR MUST FULLY KNOW ALL THE OPERATING LIMITS AND PROCEDURES

BEFORE THE ENGINE OPERATES.

CAUTION: OPERATION AT MINIMUM IDLE IN ICING CONDITIONS IS PERMITTED FOR EXTENDED PERI-

ODS. IF THE CONDITION CONTINUES FOR MORE THAN 30 MINUTES , OR IF IMPORTANT

ENGINE VIBRATION OCCURS; YOU MUST INCREASE THE ENGINE SPEED TO 70 PER-

CENT N1 MINIMUM FOR APPROXIMATELY 15 SECONDS BEFORE YOU SELECT A HIGHER

THRUST OPERATION.

1. Reason for the Job

The idle check gives instructions to make sure that the engine connections do not leak.

Print Date: September 17, 2018 Page 1 of 6

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AZU Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 051-051

Rev. Date : Aug 01, 2018

71-00-00-710-006-B - Minimum Idle Check

It also permit you to make sure that noise from engine operation is normal and that all engine instruments give

the correct indications.

NOTE: Do a visual leak check if disconnected without engine plumbing static pressure check after installation:

NOTE: For a visual leak check after replacement of a component, it is not necessary to record parameters.

2 Job Set-up Information

A. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

FOR 1000EM1 (ENGINE-1)

437AL, 438AR, 451AL, 452AR

FOR 1000EM2 (ENGINE-2)

447AL, 448AR, 461AL, 462AR

B. Referenced Information

REFERENCE DESIGNATION

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

(Ref. 71-00-00-710-003-B). Engine Automatic Start

(Ref. 71-00-00-710-028-B). Engine Shutdown

(Ref. 71-00-00-790-002-B). Fuel or Hydraulic or Oil Leakage Limits

(Ref. 71-00-00-869-003-A). Wind Limitations During Engine Ground Operations

(Ref. 71-13-00-010-040-B). Opening of the Fan Cowl Doors

(Ref. 71-13-00-410-040-B). Closing of the Fan Cowl Doors

(Ref. 78-30-00-081-041-B). Make the Thrust Reverser Serviceable after Maintenance

(Ref. 78-30-00-481-041-B). Make the Thrust Reverser Unserviceable for Maintenance

(Ref. 78-36-00-010-040-B). Opening of the Thrust Reverser Doors

(Ref. 78-36-00-410-040-B). Closing of the Thrust Reverser Doors

(Ref. 79-00-00-210-003-A). Visual Inspection of the Oil System

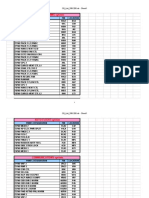

Oil Pressure Versus Engine Core Speed SHEET 1

Print Date: September 17, 2018 Page 2 of 6

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AZU Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 051-051

Rev. Date : Aug 01, 2018

71-00-00-710-006-B - Minimum Idle Check

CAUTION.

MAINTENANCE ACTION IS REQUIRED PRIOR TO NEXT FLIGHT

IF ENGINE OIL PRESSURE LEVELS ARE REPORTED TO BE IN AREA 1.

OPERATION IN AREAS 1 AND 3 REQUIRES CLOSE

MONITORING OF OTHER OIL SYSTEM PARAMETERS.

KPA PSID

DIFF

(2068) 300 COLD START BY-PASS VALVE

OPENS AT 305 PSID

(2102 KPA DIFF.)

(689) 100

3

(621) 90

MAXIMUM NORMAL

(552) 80

OIL PRESSURE

(483) 70

(414) 60

2

(345) 50

MINIMUM NORMAL NORMAL OPERATING

GROUND OIL PRESSURE OIL PRESSURE RANG

(276) 40

(207) 30

1

(138) 20

(76)

10 MINIMUM ACCEPTABLE PRESSURE: 13 PSID (90 KPA DIFF.)

(69)

LESS THAN MINIMAL OIL PRESSURE REQUIRES ENGINE SHUT DOWN.

0

40 50 60 70 80 90 100 105

INDICATED

OIL PRESSURE CORE ENGINE SPEED N2/PERCENT

S-M56-MM-00244-00-B

N_MM_710000_5_RLM0_01_00

Figure 71(CFMB)-00-00-991-30900-06-A / SHEET 1/1 - Oil Pressure Versus Engine Core Speed

** ON A/C 051-100

Print Date: September 17, 2018 Page 3 of 6

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AZU Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 051-051

Rev. Date : Aug 01, 2018

71-00-00-710-006-B - Minimum Idle Check

3. Job Set-up

Subtask 71-00-00-010-062-A

A. Open the fan cowl doors (Ref. AMM TASK 71-13-00-010-040) :

(1) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(2) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

Subtask 71-00-00-869-107-A

B. Preparation for Test

(1) Obey the wind limitations during Engine Ground Operations (Ref. AMM TASK 71-00-00-869-003) .

(2) Make sure that the engine inlet and exhaust covers have been removed. Make sure that these areas

are clear of any foreign objects.

(3) Make a visual check of the temperature sensors, fan inlet, and exhaust areas. If snow or ice has

collected in the fan duct, make sure that the fan turns freely. Also, make sure that the engine inlet,

inlet lip, fan, spinner, and fan exhaust duct are clear of ice or snow. If the fan does not turn freely,

melt the ice or snow with hot air before an engine operation.

(4) Look at the general condition of the fan spinner and fan blades, core exhaust nozzle, LPT and

external surfaces of the cowls.

(5) Check oil quantity. Make a check of the drain ports for fuel, oil and hydraulic leaks. Also make sure

that fuel drained from the engine does not cause a fire.

Subtask 71-00-00-861-062-A

C. Energize the aircraft electrical circuits (Ref. AMM TASK 24-41-00-861-002) .

Subtask 71-00-00-869-103-A

D. Do the EIS start procedure (upper ECAM display unit only) (Ref. AMM TASK 31-60-00-860-001) .

Subtask 71-00-00-710-079-A

E. Start the engine (Ref. AMM TASK 71-00-00-710-003) .

4. Procedure

Subtask 71-00-00-710-080-A

A. Do this procedure:

(1) Let the engine become stable at minimum idle for 3 minutes and make sure that the parameters

below are in the limits:

(a) N2 speed should not be below 58.3 percent N2.

(b) Oil pressure

(Ref. Fig. Oil Pressure Versus Engine Core Speed SHEET 1)

(c) The EGT is approximately at 440 deg.C (824 deg.F) (normal temperature) for an ambient

temperature T12 of 15 deg.C (59 deg.F).

NOTE: All engines have an EGT that is different. The EGT will increase as an engine collects

time. The condition and bleed configuration of each engine can cause EGT differences

between engines. If N1, N2 and fuel flow are satisfactory at minimum idle, you can have

EGT differences as much as 60 Deg.C or larger.

Print Date: September 17, 2018 Page 4 of 6

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AZU Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 051-051

Rev. Date : Aug 01, 2018

71-00-00-710-006-B - Minimum Idle Check

(2) Make a visual inspection of the fuel and pneumatic lines, fittings and accessories for leaks.

For oil leakage, staining or wetting from/on the oil system tubes, hoses and components

(Ref. AMM TASK 79-00-00-210-003) .

WARNING: DO NOT LET THE HMU TEMPERATURE EXCEED 100 DEG.C (212 DEG.F).

(3) Safety precaution :

NOTE: Hydromechanical Units (HMUs) that have fluorocarbon (Viton) external seals (SB 73-015) can

leak fuel for a short time when they are below 0 deg.C (32.00 deg.F) (Modification 1 and 2)

(Ref. AMM TASK 71-00-00-790-002) . If the ambient temperature is below -40 deg.C (-40.00

deg.F) it is recommended to heat the HMU (modification 1 and 2) to minimize leakage during

starts per the following procedure :

(a) Heat the HMU housing with a suitable hot air blower (Keco GH100, Aerotech BT400-45 or

equivalent) operating at 140 deg.C (284.00 deg.F) until the HMU housing temperature is greater

than 25 deg.C (77.00 deg.F).

NOTE: The HMU should be warm to the touch but not hot.

· If the fuel leakage stops in less than 5 minutes at idle, continue operation of the engine.

· If the fuel leakage continues after 5 minutes at idle, shut down the engine and repair the

source of the leakage.

(4) Stop the engine (Ref. AMM TASK 71-00-00-710-028) .

(5) Do the EIS stop procedure (Ref. AMM TASK 31-60-00-860-002)

Subtask 71-00-00-040-057-A

B. Make the thrust reverser unserviceable (Ref. AMM TASK 78-30-00-481-041) .

Subtask 71-00-00-010-063-A

C. Open the thrust-reverser doors (Ref. AMM TASK 78-36-00-010-040) to do a visual inspection for fuel and

oil leaks:

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR

5. Close-up

Subtask 71-00-00-410-065-A

A. Close the thrust-reverser doors (Ref. AMM TASK 78-36-00-410-040) :

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR

Subtask 71-00-00-440-057-A

B. Make the thrust reverser serviceable (Ref. AMM TASK 78-30-00-081-041) .

Subtask 71-00-00-410-069-A

C. Close the fan cowl doors: (Ref. AMM TASK 71-13-00-410-040)

(1) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

Print Date: September 17, 2018 Page 5 of 6

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AZU Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 051-051

Rev. Date : Aug 01, 2018

71-00-00-710-006-B - Minimum Idle Check

(2) FOR 1000EM2 (ENGINE-2)

447AL, 448AR

Subtask 71-00-00-862-062-A

D. De-energize the aircraft electrical circuits (Ref. AMM TASK 24-41-00-862-002) .

End of document

Print Date: September 17, 2018 Page 6 of 6

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Вам также может понравиться

- Ee6900 Fms 07 DatabasesДокумент56 страницEe6900 Fms 07 Databasesforumid2697100% (1)

- Service Bulletin Atr72: Transmittal Sheet Revision No. 12Документ16 страницService Bulletin Atr72: Transmittal Sheet Revision No. 12Pradeep K sОценок пока нет

- Fast27 PDFДокумент32 страницыFast27 PDFsudarshan111990Оценок пока нет

- BTK - A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - J. AIDS MCDU FunctionsДокумент44 страницыBTK - A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - J. AIDS MCDU FunctionsIrfan05Оценок пока нет

- Vapor Cycle System (VCS) : Effectivity:AllДокумент16 страницVapor Cycle System (VCS) : Effectivity:AllclebersjcОценок пока нет

- ECS Report 19Документ11 страницECS Report 19Suman BajracharyaОценок пока нет

- 31 36 00002Документ16 страниц31 36 00002ryan liaoОценок пока нет

- 4-5 - Airbus presentation-ICAO Aeronautical Surveillance Systems WorshopДокумент31 страница4-5 - Airbus presentation-ICAO Aeronautical Surveillance Systems WorshopMargaret Meporo100% (1)

- Airbus Commercial Aircraft AC A320 PDFДокумент399 страницAirbus Commercial Aircraft AC A320 PDFTania AriasОценок пока нет

- ADS-B Out in and GNSS ReqmentДокумент20 страницADS-B Out in and GNSS ReqmentanantiaОценок пока нет

- EE6900 Flight Management Systems: "Aircraft Communications and Reporting System"Документ20 страницEE6900 Flight Management Systems: "Aircraft Communications and Reporting System"Faraz KhanОценок пока нет

- A330 Easa Tcds A.004 - Issue 50Документ64 страницыA330 Easa Tcds A.004 - Issue 50Pablo CarmonaОценок пока нет

- What Is AirnavXДокумент1 страницаWhat Is AirnavXsithuОценок пока нет

- FOT-999-0130!16!00 Incorrect Characteristic Speeds Computation Due To Absence of The ZFWCG ValueДокумент3 страницыFOT-999-0130!16!00 Incorrect Characteristic Speeds Computation Due To Absence of The ZFWCG ValueGermanTobonОценок пока нет

- Isi 23.28.00028Документ3 страницыIsi 23.28.00028Anonymous SIS1ieОценок пока нет

- FCOM - A320 - Vol1 System DescriptionДокумент1 241 страницаFCOM - A320 - Vol1 System DescriptionduythienddtОценок пока нет

- A320 STD 1.6.0 Service Bulletin (D00621300)Документ11 страницA320 STD 1.6.0 Service Bulletin (D00621300)Bambi513Оценок пока нет

- Airbus Commercial Aircraft AC A330 Jan 2017 PDFДокумент646 страницAirbus Commercial Aircraft AC A330 Jan 2017 PDFMakhou LadoumОценок пока нет

- Erj 190 PDFДокумент2 страницыErj 190 PDFTyrone0% (1)

- 343 Rack 800vuДокумент1 страница343 Rack 800vuMohammad NorouzzadehОценок пока нет

- TRG A340 A320 31 06 Shop 01DДокумент32 страницыTRG A340 A320 31 06 Shop 01DPanneer SelvamОценок пока нет

- Airbus AC A320 Jan16Документ390 страницAirbus AC A320 Jan16simon100% (1)

- TCAS II ChangesДокумент4 страницыTCAS II Changesjunmech-1Оценок пока нет

- Qdoc - Tips Airbus A320Документ14 страницQdoc - Tips Airbus A320Tanay JoshiОценок пока нет

- 14WN Test 2Документ7 страниц14WN Test 2Ahsan AvioniqueОценок пока нет

- A318/A319/A320/A321: Service BulletinДокумент59 страницA318/A319/A320/A321: Service BulletinPradeep K sОценок пока нет

- A320-22-1739 R0 Dated 08.july.2021Документ45 страницA320-22-1739 R0 Dated 08.july.2021Pradeep K sОценок пока нет

- Control Pitch, Roll and Yaw Axis of AircraftДокумент49 страницControl Pitch, Roll and Yaw Axis of AircraftRavi PansheriyaОценок пока нет

- Goodyear AMT MSC-PROPer Tire Spec 2012-001 Rev 1Документ16 страницGoodyear AMT MSC-PROPer Tire Spec 2012-001 Rev 1Muhammad Imran RosadinОценок пока нет

- Fast24 PDFДокумент20 страницFast24 PDFFrancisco Isaac LucenaОценок пока нет

- Jet Shop Training PresentationДокумент28 страницJet Shop Training PresentationGAURAV SINGHОценок пока нет

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidДокумент12 страницHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliОценок пока нет

- A320 A321 P2F Mmel PTC R09 Dec 01 21 PDFДокумент170 страницA320 A321 P2F Mmel PTC R09 Dec 01 21 PDFPiyush SinghalОценок пока нет

- Arinc 450Документ253 страницыArinc 450Tan Nguyen Trong HoangОценок пока нет

- A320 Fam Air Wing Leaks Spurious WRNДокумент8 страницA320 Fam Air Wing Leaks Spurious WRNMCC GoairОценок пока нет

- Cosmetic Condition of Fan Exit Guide VanesДокумент1 страницаCosmetic Condition of Fan Exit Guide VanesRanjit ShawОценок пока нет

- Flight Operations Transmission - Fot: Customer Services DirectorateДокумент4 страницыFlight Operations Transmission - Fot: Customer Services DirectorateVincenzo ParisiОценок пока нет

- A321 Fixed EFB - Laptop Install.Документ9 страницA321 Fixed EFB - Laptop Install.Russ HoweОценок пока нет

- 71 IAE Trouble ShootДокумент22 страницы71 IAE Trouble ShootMarc Covas MartorellОценок пока нет

- A320neo PDFДокумент72 страницыA320neo PDFDinuОценок пока нет

- Lopa A330-202 Version 269pax (7T-VJV-JZ) Rev 03Документ1 страницаLopa A330-202 Version 269pax (7T-VJV-JZ) Rev 03Hache HBОценок пока нет

- Afm A320f 05apr23Документ1 306 страницAfm A320f 05apr23HaeLyong JooОценок пока нет

- Air Conditionning System: CB - List - 330 200.xls Sheet1Документ29 страницAir Conditionning System: CB - List - 330 200.xls Sheet1Sergio SouzaОценок пока нет

- Boeing 7x7 ETOPS FLIGHT CREW GUIDEДокумент24 страницыBoeing 7x7 ETOPS FLIGHT CREW GUIDEericvolmerОценок пока нет

- Cas 67A Tcas Ii System Installation ManualДокумент6 страницCas 67A Tcas Ii System Installation ManualАлександр КорякинОценок пока нет

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationДокумент11 страницService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehОценок пока нет

- Cockpit Display System Interfaces To User Systems: Arinc Specification 661-2Документ308 страницCockpit Display System Interfaces To User Systems: Arinc Specification 661-2fabrizioОценок пока нет

- Exterior Inspection B737-800Документ14 страницExterior Inspection B737-800Me KeenОценок пока нет

- 767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07Документ3 страницы767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07samyghallabОценок пока нет

- SVC A330Документ9 страницSVC A330Maria Amparo Corredor TorresОценок пока нет

- Easa TCDS A.084 - Atr - 42 - Atr - 72 03 17102012Документ35 страницEasa TCDS A.084 - Atr - 42 - Atr - 72 03 17102012mpusОценок пока нет

- Airbus Unreliable Airspeed V 1.1Документ27 страницAirbus Unreliable Airspeed V 1.1rocuetОценок пока нет

- 34070ADIRU MixabilityДокумент9 страниц34070ADIRU MixabilityJános RédeiОценок пока нет

- Vietnam A321 Fleet MBD Se Ip RecommendationДокумент1 страницаVietnam A321 Fleet MBD Se Ip RecommendationLee Nguyen LeОценок пока нет

- Passenger Oxygen Masks PackingДокумент3 страницыPassenger Oxygen Masks PackingpannОценок пока нет

- 3D codes identify aircraftДокумент28 страниц3D codes identify aircraftJorge VillagomezОценок пока нет

- Brake InspectionДокумент5 страницBrake InspectionbillyОценок пока нет

- Kulite Pressure Transducer HandbookДокумент76 страницKulite Pressure Transducer Handbookpmud123Оценок пока нет

- SB - 27 - 1199 - 02 Service BuletinДокумент69 страницSB - 27 - 1199 - 02 Service BuletinKerol MansorОценок пока нет

- 71-00-00-869-001-B - Abnormal Operation and Emergency Procedures PDFДокумент10 страниц71-00-00-869-001-B - Abnormal Operation and Emergency Procedures PDFEder LucianoОценок пока нет

- 71-00-00-710-009-B - Vibration Check PDFДокумент3 страницы71-00-00-710-009-B - Vibration Check PDFEder Luciano100% (1)

- A320 Front Instrument PanelДокумент1 страницаA320 Front Instrument Panelcaptmon3510% (2)

- 71-00-00-710-005-B - Start AbortДокумент2 страницы71-00-00-710-005-B - Start AbortEder LucianoОценок пока нет

- Airbus CommerciaДокумент2 страницыAirbus CommerciaEder LucianoОценок пока нет

- 71-00-00-710-002-B - Wet Motoring CheckДокумент8 страниц71-00-00-710-002-B - Wet Motoring CheckEder Luciano100% (2)

- 71-00-00-869-003-A - Wind Limitations During Engine Ground Operations PDFДокумент3 страницы71-00-00-869-003-A - Wind Limitations During Engine Ground Operations PDFEder LucianoОценок пока нет

- 71-00-00-710-004-B - Engine Manual StartДокумент9 страниц71-00-00-710-004-B - Engine Manual StartEder LucianoОценок пока нет

- ON A/C 051-100: Zone/Access Zone DescriptionДокумент7 страницON A/C 051-100: Zone/Access Zone DescriptionEder LucianoОценок пока нет

- Tfu Leap SystemsДокумент41 страницаTfu Leap SystemsEder Luciano83% (6)

- Boeing Electrical Standard Wiring Practices ManualДокумент6 страницBoeing Electrical Standard Wiring Practices ManualEder Luciano33% (3)

- Airbus Commercial Aircraft AC A320 PDFДокумент397 страницAirbus Commercial Aircraft AC A320 PDFBrayan RobertoОценок пока нет

- NYCO ProductsCatalogue Issue-4Документ70 страницNYCO ProductsCatalogue Issue-4Piyush50% (2)

- Illustrated Parts Catalog - O-235-L2A, - L2C SeriesДокумент83 страницыIllustrated Parts Catalog - O-235-L2A, - L2C SeriesFernando Servian DalmasОценок пока нет

- DirectDriveOverhaul PDFДокумент152 страницыDirectDriveOverhaul PDFEvandro OliveiraОценок пока нет

- Foreign Applicant Checklist + PBR-1Документ2 страницыForeign Applicant Checklist + PBR-1Eder LucianoОценок пока нет

- Rigging and Balancing Helicopter RotorsДокумент48 страницRigging and Balancing Helicopter RotorsEder LucianoОценок пока нет

- AirmanSampleEXP1 2Документ2 страницыAirmanSampleEXP1 2Eder LucianoОценок пока нет

- Computer ResetДокумент12 страницComputer ResetEder LucianoОценок пока нет

- 1) Reminder: MFC72 - 212AДокумент2 страницы1) Reminder: MFC72 - 212AEder LucianoОценок пока нет

- Leap-1a Operating LimitsДокумент16 страницLeap-1a Operating LimitsEder Luciano100% (4)

- Engine Fault CodeДокумент72 страницыEngine Fault CodeEder Luciano100% (1)

- A320 - Ecam System Logic Data (Esld)Документ5 089 страницA320 - Ecam System Logic Data (Esld)Eder Luciano100% (5)

- Engine Fault CodeДокумент72 страницыEngine Fault CodeEder Luciano100% (1)

- A320 Aircraft CharacteristicsДокумент387 страницA320 Aircraft CharacteristicsEder LucianoОценок пока нет

- Section6 18 AutoflightДокумент24 страницыSection6 18 AutoflightEder LucianoОценок пока нет

- Opsmans615 FireprotectionДокумент14 страницOpsmans615 FireprotectionEder LucianoОценок пока нет

- Research Design Elements for ScenariosДокумент25 страницResearch Design Elements for Scenariosrohizal ibrahimОценок пока нет

- Factors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawatДокумент26 страницFactors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawathumeragillОценок пока нет

- Lesson 3 - Materials That Undergo DecayДокумент14 страницLesson 3 - Materials That Undergo DecayFUMIKO SOPHIA67% (6)

- ДСТУ EN ISO 2400-2016 - Калибровочный блок V1Документ11 страницДСТУ EN ISO 2400-2016 - Калибровочный блок V1Игорь ВадешкинОценок пока нет

- Payroll Canadian 1st Edition Dryden Test BankДокумент38 страницPayroll Canadian 1st Edition Dryden Test Bankriaozgas3023100% (14)

- What Role Can IS Play in The Pharmaceutical Industry?Документ4 страницыWhat Role Can IS Play in The Pharmaceutical Industry?Đức NguyễnОценок пока нет

- Intermediate Accounting Testbank 2Документ419 страницIntermediate Accounting Testbank 2SOPHIA97% (30)

- 702190-Free PowerPoint Template AmazonДокумент1 страница702190-Free PowerPoint Template AmazonnazОценок пока нет

- AnswersДокумент3 страницыAnswersrajuraikar100% (1)

- M Series CylindersДокумент61 страницаM Series CylindersAndres SantanaОценок пока нет

- Cantilever Retaining Wall AnalysisДокумент7 страницCantilever Retaining Wall AnalysisChub BokingoОценок пока нет

- Books 2738 0Документ12 страницBooks 2738 0vinoohmОценок пока нет

- Entrepreneurship and EconomicДокумент2 страницыEntrepreneurship and EconomicSukruti BajajОценок пока нет

- Itec 3100 Student Response Lesson PlanДокумент3 страницыItec 3100 Student Response Lesson Planapi-346174835Оценок пока нет

- WM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersДокумент4 страницыWM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersEdgar JimenezОценок пока нет

- Eship 1Документ18 страницEship 1Yash SoniОценок пока нет

- C J L F S: Vinod TiwariДокумент21 страницаC J L F S: Vinod TiwariVinod TiwariОценок пока нет

- Activate Adobe Photoshop CS5 Free Using Serial KeyДокумент3 страницыActivate Adobe Photoshop CS5 Free Using Serial KeyLukmanto68% (28)

- Camera MatchingДокумент10 страницCamera MatchingcleristonmarquesОценок пока нет

- 59 - 1006 - CTP-Final - 20200718 PDFДокумент11 страниц59 - 1006 - CTP-Final - 20200718 PDFshubh.icai0090Оценок пока нет

- Incident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5AДокумент2 страницыIncident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ARocky BisОценок пока нет

- Corena s2 p150 - Msds - 01185865Документ17 страницCorena s2 p150 - Msds - 01185865Javier LerinОценок пока нет

- CONFLICT ManagementДокумент56 страницCONFLICT ManagementAhmer KhanОценок пока нет

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDДокумент6 страницMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaОценок пока нет

- Marketing Management NotesДокумент115 страницMarketing Management NotesKajwangs DanОценок пока нет

- Shubh AmДокумент2 страницыShubh AmChhotuОценок пока нет

- ETP Research Proposal Group7 NewДокумент12 страницETP Research Proposal Group7 NewlohОценок пока нет

- Article 4Документ31 страницаArticle 4Abdul OGОценок пока нет

- VB 2Документ11 страницVB 2Sudhir IkkeОценок пока нет

- BILL OF SALE Pre ApproveДокумент1 страницаBILL OF SALE Pre ApprovedidinurieliaОценок пока нет

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentОт EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentРейтинг: 4.5 из 5 звезд4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyОт EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyОценок пока нет

- Asset Integrity Management for Offshore and Onshore StructuresОт EverandAsset Integrity Management for Offshore and Onshore StructuresОценок пока нет

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successОт EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionОт EverandBuild Your Own Electric Vehicle, Third EditionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeОт EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeРейтинг: 4 из 5 звезд4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureОт EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureРейтинг: 3.5 из 5 звезд3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachОт EverandImplementing an Integrated Management System (IMS): The strategic approachРейтинг: 5 из 5 звезд5/5 (2)

- Handbook on Battery Energy Storage SystemОт EverandHandbook on Battery Energy Storage SystemРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideОт EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideРейтинг: 2 из 5 звезд2/5 (1)

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesОт EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertРейтинг: 3 из 5 звезд3/5 (2)

- The Rare Metals War: the dark side of clean energy and digital technologiesОт EverandThe Rare Metals War: the dark side of clean energy and digital technologiesРейтинг: 5 из 5 звезд5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemОт EverandISO 50001: A strategic guide to establishing an energy management systemОценок пока нет

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyОт EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyРейтинг: 5 из 5 звезд5/5 (3)