Академический Документы

Профессиональный Документы

Культура Документы

(Colageno) Indrani Et Al., 2016 PDF

Загружено:

André Zamith SelvaggioОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

(Colageno) Indrani Et Al., 2016 PDF

Загружено:

André Zamith SelvaggioАвторское право:

Доступные форматы

Journal of International Dental and Medical Research ISSN 1309-100X Effect of Gamma-ray Irradiation on Bacterial Penetration

http://www.ektodermaldisplazi.com/journal.htm Decky Joesiana Indrani, and et al

Effect of Gamma-ray Irradiation on Bacterial Penetration Power of

Chitosan/Collagen Blend Membranes for Wound Dressing

Decky Joesiana Indrani1*, Fajar Lukitowati2,3, Darmawan Darwis2

1. Department of Dental Materials Science, Faculty of Dentistry, Universitas Indonesia.

2. Postgraduate Programmes of Biomedical Engineering, Multidiciplinary Study, Universitas Indonesia.

3. Center for the Application of Isotopes and Radiation, National Nuclear Agency, Indonesia.

Abstract

The aim of this study is to investigate the effects of gamma-ray irradiation on the bacterial

penetration power of chitosan/collagen blend membranes. For this study, commercially available

chitosan, and collagen extracted from bovine tendon were made into solution using a modified acid-

solution method. This solution is then used to prepare the chitosan, collagen and chitosan/collagen

blend membranes via solution casting on a plastic plate. Each of the membranes are exposed to

gamma-ray irradiation (0, 15 or 25 kGy), placed on an agar medium and immediately inoculated

with Staphylococcus aureus. The bacterial penetration power of the irradiated specimens are

determined by inspecting the growth of colony-forming units on the agar medium. Observations of

the bacterial penetration power of each type of membrane are as follows: the collagen membranes

displayed colony-forming units on the agar medium, the chitosan membranes had the colony-

forming units encircling the membranes, while the chitosan/collagen membranes showed spots of

colony-forming units. After exposure to the gamma-ray irradiation, a reduction in the colony-forming

units was observed for each of the membranes. In addition, increasing the dose of the gamma-ray

irradiation was shown to reduce the number of the colony-forming units on the agar medium for

each membrane type.

In conclusion, the collagen membranes were able to prevent penetration of S. areus, whereas,

the membranes containing chitosan were penetrable to the bacteria. The number of the colony-

forming units shown in the agar medium depended on the the gamma-ray doses.

Experimental article (J Int Dent Med Res 2016; 9: (3), pp. 202-206)

Keywords: bacterial penetration, chitosan, collagen, gamma-ray, wound dressing.

Received date: 01 August 2016 Accept date: 24 October 2016

Introduction dressings. Traditional wound care products tend

to address the wound’s macroenvironment,

An increase in the number of patients including moist wound environment control, fluid

suffering from wounds and burns over the recent management, and controlled transpiration of

years has been linked to the passage of bacteria wound fluids. The newer class of biomaterials

through dressing membranes and has become a and wound-healing agents, such as collagen and

potential avenue of wound contamination. To growth factors, targets specific defects in the

prevent bacterial passage through a wound chronic wound environment with the possibility

dressing, the wound should be covered with a that they benefit the wound healing process at a

suitable biomaterial. Wound dressings prepared biochemical level1-4. Recently, attention has

from biomaterials are studied intensively because been focused on employing natural polymers for

they can offer alternatives to traditional wound medical applications, such as gelatin,5-7

hyaluronic acid,8-10 collagen3,11-13 or

14,15

*Corresponding author:

chitosan .

Decky Joesiana Indrani Chitosan is derived from chitin, through a

Department of Dental Materials Science, deacetylation process to obtain a linear structure

Faculty of Dentistry, of N-acetyl glucosamine polysaccharide, which is

Universitas Indonesia.

found in the exoskeletons of marine crustaceans

E-mail: deckyji@gmail.com such as shrimps and crabs, as well as in insects

and the cell walls of fungi.16,17 Apart from these,

Volume ∙ 9 ∙ Number ∙ 3 ∙ 2016 Page 202

Journal of International Dental and Medical Research ISSN 1309-100X Effect of Gamma-ray Irradiation on Bacterial Penetration

http://www.ektodermaldisplazi.com/journal.htm Decky Joesiana Indrani, and et al

there are many factors present in the chitosan or collagen due to the cleavage of the glycosidic

molecule that can influence its antimicrobial bonds.27

properties, (which can be beneficial in biomedical Therefore, testing the bacterial

applications) and the physical state of the penetration power of wound dressing

chitosan, e.g. whether it is present in the form of chitosan/collagen blend membranes with

hydrogels, powders, films, gamma-ray irradiation is necessary as

membranesmicro/nanoparticles and coatings. membrane dressings should serve as a barrier

According to past reports, the most important between the wound and microbes from the

medical application of chitosan’s makes use of its outside environment. This study aims to

capability to act as an artificial skin for humans investigate the effect of gamma-ray irradiation on

with extensive burns18 and as wound dressings.14 the bacterial penetration power of

The use of the chitosan was found to promote chitosan/collagen blend membranes.

wound healing and induce cell migration and

proliferation. Materials and methods

Collagen is the major protein of the

extracellular matrix mostly found in connective Specimen preparation

tissue. Collagen is usually originated from Chitosan powder, with 90% degree of

bovine,19 avian ,20 or porcine21 connective tissue, deacetylation, was purchased from Kimia Farma

as collagen is the most abundant protein found in (Jakarta, Indonesia), and used without further

mammals. Among the above mentioned natural treatment. Whereas, bovine tendons were

polymers, collagen in its natural state is obtained from a local market in Jakarta,

abundantly available, for instance, as a by- Indonesia. Staphylococcus aureus was obtain

product in the meat industry. Due to its negligible from Microbiology Laboratorium of Faculty of

immunogenicity, excellent biocompatibility, Medicine - Universitas Indonesia and tryptic soy

mechanical stability and its ability to be involved agar from Merck (Darmstadt, Germany). The

in all 3 phases of the wound-healing cascade, reagents used were glacial acetic acid (100%

studies have examined the use of collagen, for purity) and sodium chloride (Merck, Darmstadt,

example, in periodontal reconstruction and Germany).

wound dressing. Collagen can be prepared in

forms of its binary or ternary blends; one of the Chitosan, collagen and chitosan/collagen

reasons for using chitosan/collagen blends as a membrane preparation

candidate for wound dressing is due to its Chitosan membranes were prepared following

potential to have extraordinary properties. the method used by Montoya MHU, et al28. In

For effective crosslinking of proteins and brief, chitosan dispersions were prepared in 0.7

polysaccharides such as , chitosan/collagen M acetic acid aqueous and stirred at 700 rpm for

blends to improve their mechanical properties, approximately 2h at room temperature (25±1 °C)

physical methods including UV and gamma-ray and allowed to stand without stirring for 12h. To

irradiation have been applied. 22-24 On the other obtain a chitosan membrane, the resulting

hand, the use of non-sterilized dressing is solution was cast onto a plastic plate (15x10

associated with the risk of infectious disease mm2) and dried at room temperature for 48h.

transmission. As the dressing comes in contact These dried chitosan membranes were peeled

with the open wounds, it needs to be perfectly off and were immediately kept in a polyethylene

sterile to avoid the transmission of disease. plastic bag prior to using. Collagen was

Gamma radiation is the most reliable and extractedfrom the bovine tendons the modified

effective method for sterilization of medical and acid-soluble method as prepared by Ramasamy

health care products22, although very few studies P and Shanmugan A29 and Gopinath 30. For

consider gamma-ray irradiation techniques as preparation of the collagen and chitosan/collagen

solvent free and environmentally processes.24-26 blend membranes, with a mixture with equal

According to ISO 11137, gamma-ray irradiation parts of chitosan and collagen for approximately

of 15–25 kGy, should be used for the 12h at room temperature (25±1 °C). The collagen

sterilization of biomedical devices. However, and the blends were then made into membranes

relatively high irradiation doses lead to the using the method described above.

degradation of polysaccharides such as chitosan

Volume ∙ 9 ∙ Number ∙ 3 ∙ 2016 Page 203

Journal of International Dental and Medical Research ISSN 1309-100X Effect of Gamma-ray Irradiation on Bacterial Penetration

http://www.ektodermaldisplazi.com/journal.htm Decky Joesiana Indrani, and et al

Irradiation Applications

Prior to irradiation, each membrane was

packaged under in polyethylene film to prevent

oxidation during the process and maintain an

aseptic environment. The membranes (chitosan,

collagen and chitosan/collagen) were then

irradiated. The irradiation process was conducted

using a linear electron accelerator of gamma-

rays generated from a Co-60 source carrying 2.2

MeV of energy at a dose rate of 0.002 kGy/sec.

The required doses were 15 and 25 kGy at room

temperature (25±1 °C). The un-irradiated

membranes that were used as controls.

Bacterial penetration test

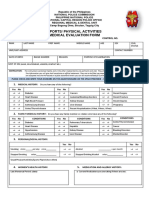

Three round agar plates, 90 mm in diameter, Figure 2. Bacterial penetration power in collagen

were filled with tryptic soy agar medium. Each membranes with gamma-ray irradiations doses of

membrane was sterilized using of irradiation of 0, (a) 0 kGy, (b) 15 kGy, and (c) 25 kGy showing

15 or 25 kGy. Then membrane samples with the colony-forming units on the agar medium.

diameters of 19±1 mm were placed on the agar

of each plate. Subsequently, the sample was

inoculated with a suspension (0,1 ml) of an

overnight culture of Staphylococcus aureus (108

bacteria/ml) in its center. After one night of

incubation at 37oC, the membranes were

removed and the agar below the membranes

were checked immediately for bacterial

penetration power by observing any growth of

colony-forming units on the agar medium.

Results

After one night of incubation, the bacterial

penetration power of the irradiated membranes

are displayed in Figure. 1, 2 and 3. Figure 3. Bacterial penetration power in

chitosan/collagen blend membranes with

gamma-ray irradiations doses of (A) 0 kGy, (B)

15 kGy, and (C) 25 kGy showing the colony-

forming units on the agar medium.

As seen in Figure. 1, the agar medium

with chitosan membranes irradiated by (A) 0 kGy,

(B) 15 kGy, and (C) 25 kGy showed colony-

forming units, which indicate that they were

penetrable by S. areus. The collagen membranes

showed colony-forming units around the

circumference of each membrane sample, as can

be seen in Figure 2. When the membranes were

removed, however, no colony-forming units on

the agar medium below the membranes were

Figure 1. Bacterial penetration power in chitosan seen. In terms of the blend membranes of

membranes with gamma-ray irradiations doses of chitosan/collagen, in Figure. 3, very small

(a) 0 kGy, (b) 15 kGy, and (c) 25 kGy showing numbers of penetrable colony-forming units were

the colony-forming units on the agar medium. detected on the agar medium. In general, the

Volume ∙ 9 ∙ Number ∙ 3 ∙ 2016 Page 204

Journal of International Dental and Medical Research ISSN 1309-100X Effect of Gamma-ray Irradiation on Bacterial Penetration

http://www.ektodermaldisplazi.com/journal.htm Decky Joesiana Indrani, and et al

agar medium that contained un-irradiated from contact with the acidic environment of the

membranes (A) showed more colony-forming agar medium. Similarly, the chitosan membrane

units than those irradiated with 15 kGy (B), and was probably more easily ruptured when in

those exposed to 25 kGy (C) showed the fewest contact with the agar medium.

colony-forming units. The typical decreased vertical facial

height of this patient resulted from the congenital.

Discussion

Conclusions

There were visible colony-forming units

on the agar mediums after removal of the It is concluded that the collagen

membranes, with irradiation gamma ray doses of membranes demonstrated the ability to prevent

0, 15 or 25 kGy (Figure. 1). This probably due to the bacterial penetration power of S. aureus,

the acidic nature (pH <7) of the agar medium whereas the chitosan membranes were

which may have caused swelling of the sensitive penetrated by the S. areus. The chitosan/

chitosan, as chitosan is soluble at pH values of collagen blend membranes showed minimal

lower than 5.5. The acidic conditions may have penetration of the S. areus, as shown by the

damaged the chitosan membrane , enabling the occurrence of colony-forming units on each agar

inouculated S.aureus bacteria to freely penetrate medium. When gamma-rays were applied, the

the ruptured chitosan membrane and grow on the higher doses resulted in fewer colony-forming

agar medium as colony-forming units. units on the agar medium.

Absence of growth below the collagen

membranes (Figure. 2) showed that the bacteria Acknowledgements

was unable to penetrate the membranes. This

can be explained by the braid peptide bond This study was supported by the grant

occurring within the collagen structure that gives from the Ministry of Research, Technology and

it a relatively dense membrane. Collagen could Higher Education, Republic of Indonesia, through

also have be crosslinked by the gamma-ray Universitas Indonesia. The authors would also

irradiation. Crosslinks are introduced by the like to thank the Gamma-ray Irradiator Plant of

bonding of radicals.31 Therefore, the colony- National Nuclear Energy Agency, Indonesia, for

forming units occurred outside the membranes the irradiation process.

with a circular shape which followed the

circumference of the membrane. Declaration of Interest

The blend membranes also displayed

colony-forming units on the agar medium (Figure. The authors report no conflict of interest.

3), although they were relatively small in number.

This can be explained by the braid peptide bond References

mentioned above that gives the collagen a 1. Martin C., Low W.L., Amin M.C.I.M., et al. Current Trends In

relatively dense membrane with crosslinks The Development of Wound Dressings, Biomaterials and

Devices. Pharmaceutical Patent Analyst 2013;2(3):341-59.

between the chitosan and collagen. This made 2. Aramwit P. Introduction to Biomaterials for Wound Healing.

the membrane impenetrable to colony forming Wound Healing Biomaterial, Chp: 1. Bangkok, Thailand.

units. In addition, scanning electron micrographs 2016:3-38.

3. Fleck C.A and Simman R. Modern Collagen Wound Dressing:

obtained from the chitosan/collagen blend Function and Purpose. Journal of The American College of

membranes irradiated with doses of 15 and 25 Certified Wound 2011;2(3):50-4.

kGy showed pore sizes of around 297-344 nm 4. Murphy P.S and Evans G.R.D. Advances In Wound Healing: A

Review of Current Wound Healing Products.. Plastic Surgery

and 826 nm, respectively, as was shown in our International 2012:1-9.

previous study. As S. aureus is of around 800- 5. Rujitanaroj P., Pimpha N., and Supaphol P. Wound-dressing

1,000 μm in size, it may have been difficult for Materials with Antibacterial Activity from Electrospun Gelatin

Fiber Mats Containing Silver Nanoparticles. Polymer

the bacterium to penetrate through the 2008;49(21):4723-32.

membranes. Nevertheless, a few colony-forming 6. Kanokpanont S., Damrongsakkul S., Ratanavarapon J., et al.An

Innovative Bi-Layered Wound Dressing Made of Silk and

units were still seen showing that the bacteria Gelatin For Accelerated Wound Healing. International Journal

was able to penetrate the blend membranes. of Pharmaceutical 2012;436(1-2):141-53.

This was likely due to the chitosan content in the 7. Wang T., Zhu X., Xue X., et al. Hydrogel Sheets of Chitosan,

Honey and Gelatin As Burn Wound Dressing. Carbohydrate

blend membranes that were easily damaged Polymer 2012;88(1):75-3.

Volume ∙ 9 ∙ Number ∙ 3 ∙ 2016 Page 205

Journal of International Dental and Medical Research ISSN 1309-100X Effect of Gamma-ray Irradiation on Bacterial Penetration

http://www.ektodermaldisplazi.com/journal.htm Decky Joesiana Indrani, and et al

8. Uppal R., Ramaswamy G.N., Arnold C., et al. Hyaluronic Acid 28. Montoya. M., Moscoso J., Jatomea M., et al. Jumbo Squid

Nanofiber Wound Dressing-Production, Characterization and In (Dosidicus Gigas) Mantle Collagen: Extraction, Characterization,

Vivo Behaviour. Journal of Biomedical Materials Research Part and Potential Application In Preparation of Chitosan-Collagen

B: Applied Biomaterials 2011;97B(1):20-9. Biofilms. Journal Bioresource Technology 2010;101:4212-9.

9. Matsumoto Y and Kuroyanagi Y. Development of A Wound 29. Ramasamy P. and Shanmugam A. International Journal of

Dressing Composed of Hyaluronic Acid Sponge Containing Biological Macromolecules Characterization and Wound

Arginine and Epidermal Growth Factor. Journal of Biomaterials Healing Property of Collagen–Chitosan Film from Sepia

Science, Polymer Edition 2012;21(6-7):715-26. kobiensis ( Hoyle , 1885 ). Int. J. Biol. Macromol 2015;74:93-2.

10. Kondo S and Kuroyanagi Y. Development of A Wound Dressing 30. Gopinath D., Ahmed M.R., Gomathi K., et al. Dermal Wound

Composed of Hyaluronic Acid and Collagen Sponge With Healing Processes with Curcumin Incorporated Collagen Films.

Epiddermal Growth Factor. Journal of Biomaterials Science, Biomaterials 2004;25(10):1911-17.

Polymer Edition 2012;23(5):629-643. 31. Makuuchi K., a n d S. Cheng. Radiation Processing of

11. Liu S., Kau Y., Chou C., et al. Electrospun PLGA/Collagen Polymer Materials and Its Industrial Application. John Wiley &

Nanofibrous Membrane As Early Stage Wound Dressing. Sons, Inc 2012:2-20.

Journal of Membrane Science 2010;355(1-2):53-9.

12. Akturk O., tezcaner A., Bilgili H., et al. Evaluation of

Sericin/Collagen Membranes As Prospective Wound Dressing

Biomaterial. Journal of Bioscience and Bioengineering

2011;112(3):279-8.

13. Rastogi S., Modi M., and Sathian B. The Efficacy of Collagen

Membrane As A Biodegradable Wound Dressing Material For

Surgical Defects of Oral Mucosa: A Prospective Study. Journal

of Oral and Maxillofacial Surgery 2009;67(8):1600-6.

14. Jayakumar R., Prabaharan M., Kumar P.T.S., et al.

Biomaterials Based On Chitin and Chitosan In Wound Dressing

Applications 2011;29(3):322-37.

15. Ong S., Wu J., Moochhala S.M., Tan M., et al. Development of

A Chitosan-Based Wound Dressing With Improved Hemostatic

and Antimicrobial Properties. Biomaterials 2008;29(32):4323-32.

16. Yeul V and Rayalu S.S. Unprecedented Chitin and Chitosan: A

Chemical Overview. Journal of Polymers and The Environment

2012;21(2):606-14.

17. Ko H., Sfeir C., and Kumta P.N. Novel Synthesis Strategies For

Natural Polymer and Composite Biomaterials As Potential

Scaffolds For Tissue Engineering. Philosophical Transactions of

The Royal Society 2010;368:1981-97.

18. Lin W., Lien C., Yeh H., et al. Bacterial Cellulose and Bacterial

Cellulose-Chitosan Membranes For Wound Dressing

Applications. Carbohydrate Polymers 2013;94(1):603-11.

19. Byun E.H., Kim J.H., Sung N.K., et al. Effects of Gamma

Irradiation on The Physical and Structural Properties of β-

Glucan. Rad. Phys. Chem 2008;77:781–6.

20. Sailaksmi G., Mitra T., Gnananmani A., et al. Bonding

Interactions and Stability Asessment of Biopolymer Material

Prepared Using Type III Collagen of Avian Intestine and Anionic

Polysaccharides. Journal of Materials Science: Materials in

Medicine 2011;22(6):1419-29.

21. Wang C., Ma Z., Lan W., et al. Comparasion Study on

Extraction of Collagen From Porcine Skin By Different Enzymes.

Food Science 2007,01.

22. Jo C., Kang H., Lee N.Y., et al. Pectin- And Gelatin-Based Film:

Effect of Gamma Irradiation On The Mechanical Properties and

Biodegradation. Radiation Physics and Chemistry

2005;72(6):745-50.

23. Ryzhkova A., Jarzak U., Schafer A., et al. Modification of

Surface Properties of Thin Polysaccharide Films By Low-

Energy Electron Exposure. Carbohydrate Polymers

2011;83(2):608-15.

24. Wihodo M and Moraru C.I. Physical and Chemical Methods

Used To Enhance The Structure and Mechanical Properties of

Protein Films: A Review. Journal of Food Engineering

2012;114(3):292-3.

25. Lacroix C., Le T.C., Quattara B., et al. Use of Gamma

Irradiation To Produce Films From Whey, Casein and Soy

Proteins: Structure and Functional Characteristics. Radiation

Physics and Chemistry 2002;63:827-32.

26. Lee S.L., Lee M.S., and Song K.B. Effect of Gamma-Irradiation

On The Physicochemical Properties of Soy Protein Isolates

Films. Radiation Physics and Chemistry 2004;72:35-40.

27. Prashanth K.V.H and Tharanathan R.N. Chitin/Chitosan;

Modifications and Their Unlimited Application Potential-An

Overview. Trends in Food Science and Technology

2007;18(3):117-31.

Volume ∙ 9 ∙ Number ∙ 3 ∙ 2016 Page 206

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- SILVA METHOD The Five Rules For MindДокумент5 страницSILVA METHOD The Five Rules For MindVesna Radojevic100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Biostat 2020 62 QДокумент270 страницBiostat 2020 62 Q'محمد علي' محمد لافيОценок пока нет

- Learning Medicine - 1.0Документ206 страницLearning Medicine - 1.0Henry Leroy Lewis BatresОценок пока нет

- Pre Medical Evaluatiom Form PFT 1 PDFДокумент2 страницыPre Medical Evaluatiom Form PFT 1 PDFAIEN WENDELEIH Q. CAPINPIN100% (2)

- The Last Days of Quaid e AzamДокумент5 страницThe Last Days of Quaid e AzamQurrat Ul Ain100% (1)

- Carol Rivers'board Review FlashcardsДокумент440 страницCarol Rivers'board Review FlashcardsJennelle CadoganОценок пока нет

- Past Papers:MICROBIOLOGYДокумент6 страницPast Papers:MICROBIOLOGYMalavikaN100% (3)

- Role of A Nurse in COVID-19 PandemicДокумент6 страницRole of A Nurse in COVID-19 PandemicMARYAM AL-KADHIM100% (3)

- Case Study On GynaeДокумент22 страницыCase Study On GynaeJay PaulОценок пока нет

- CB Insights - Digital Health 150 2020Документ15 страницCB Insights - Digital Health 150 2020nikhil karthikeyanОценок пока нет

- Aclidinium Bromide 340mcg + Formoterol Fumarate 11.8mcg (Duaklir Genuair Inhalation Powder)Документ22 страницыAclidinium Bromide 340mcg + Formoterol Fumarate 11.8mcg (Duaklir Genuair Inhalation Powder)ddandan_2Оценок пока нет

- Kasus Psi TraumaДокумент17 страницKasus Psi TraumaWulanОценок пока нет

- Obe PDFДокумент6 страницObe PDFjaycee_evangelistaОценок пока нет

- NCP Step 1: Nutrition Assessment: SnapshotДокумент2 страницыNCP Step 1: Nutrition Assessment: SnapshotBushra KainaatОценок пока нет

- Endodontic Steps For Endo Tech Spring 2021Документ9 страницEndodontic Steps For Endo Tech Spring 2021Ramiz FareedОценок пока нет

- ANAPHY Lec Session #19 - SAS (Agdana, Nicole Ken)Документ7 страницANAPHY Lec Session #19 - SAS (Agdana, Nicole Ken)Nicole Ken AgdanaОценок пока нет

- Of Of: National HeadquartersДокумент5 страницOf Of: National Headquarterschitobarba19726762Оценок пока нет

- DW - SRX - Optex High Complexity Epidemic Mathematical ModelingДокумент1 страницаDW - SRX - Optex High Complexity Epidemic Mathematical ModelingJuan Carlos RodriguezОценок пока нет

- Kuliayada CaafimaadkaДокумент50 страницKuliayada CaafimaadkaKhalid Abdiaziz AbdulleОценок пока нет

- Vet Obst Lecture 1 Pregnancy in Domestic AnimalsДокумент53 страницыVet Obst Lecture 1 Pregnancy in Domestic AnimalsgnpobsОценок пока нет

- End of Life CareДокумент19 страницEnd of Life CareArjumand ZargarОценок пока нет

- Motor System ExaminationДокумент57 страницMotor System ExaminationSoma wahidОценок пока нет

- Assessment of Knowledge Sharing For Prevention of Hepatitis Viral Infection Among Students of Higher Institutions of Kebbi State, NigeriaДокумент9 страницAssessment of Knowledge Sharing For Prevention of Hepatitis Viral Infection Among Students of Higher Institutions of Kebbi State, NigeriaInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Literature Review On Breaking Bad NewsДокумент5 страницLiterature Review On Breaking Bad Newseeyjzkwgf100% (2)

- Chapter 6 - Pest and Disease Management in Plant Propagation and NurseryДокумент22 страницыChapter 6 - Pest and Disease Management in Plant Propagation and NurserySheena Jane SegalesОценок пока нет

- SARS: The Inside Story: Where Did SARS Come From?Документ6 страницSARS: The Inside Story: Where Did SARS Come From?ZauzaОценок пока нет

- Allen John B. Manlapaz Las 3 STEM 12 - Rutherford: VI. AssessmentДокумент2 страницыAllen John B. Manlapaz Las 3 STEM 12 - Rutherford: VI. AssessmentKawaguchi OerkeОценок пока нет

- Ayad Et Al - Antibacterial.efficiency - PomeloДокумент5 страницAyad Et Al - Antibacterial.efficiency - PomeloJesus NavaОценок пока нет

- Higher FunctionДокумент181 страницаHigher FunctionMeilisa OngОценок пока нет

- Zee Bedside ExamДокумент20 страницZee Bedside Examhikmat sheraniОценок пока нет