Академический Документы

Профессиональный Документы

Культура Документы

Stress Relief PDF

Загружено:

Rajesh KumarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stress Relief PDF

Загружено:

Rajesh KumarАвторское право:

Доступные форматы

Stress Relief

by:

Daniel H. Herring Stress relief is a simple heat-treating operation for

“The Heat Treat Doctor”®, President

The HERRING GROUP, Inc.

wire products that depends strongly on the proper

P.O. Box 884 selection of temperature and time at temperature

Elmhurst, IL 60126-0884 USA

www.heat-treat-doctor.com as well as a proper cooling rate for success.

Stress relief is one of the most common heat-treating Cycle Times

processes used in spring manufacturing. Like any Temperature, time and time at temperature are key

manufacturing step, if not performed properly this process variables (Table 1). In general, heating steel to

simple operation can have disastrous consequences. a temperature of about 165°F (75°C) below the transfor-

Drawing, forming and machining induce stresses in mation temperature (Ac1) for an hour (or until the entire

all wire products. part reaches the temperature), will allow for removal of

These stresses can cause loss of tolerance, cracking most internal stresses. Typical temperature ranges are:

and distortion, and contribute to in-service failures. •1025°F to 1200°F (55°C to 650°C) for unalloyed

For these reasons, stress relieving is often necessary, and low-alloy steels.

and in some cases, mandatory. •1115°F to 1300°F (600°C to 700°C) for hot-work

A stress relief operation is typically used to remove and high-speed tool steels.

internal (residual) stresses that have accumulated in For many alloy steels, little or no stress relief occurs at

the material. The stress relief process is performed by temperatures less than approximately 500°F (260°C),

heating in an oven (as seen in Figure 1) or furnace to while approximately 90% of the stress is relieved by

a temperature (for steel wire) below the lower critical 1000°F (540°C). The maximum temperature for stress

temperature (Ac1) and holding at that temperature relief is limited to 55°F (30°C) below the tempering

long enough to achieve the desired reduction in re- temperature used after quenching from the hardening

sidual stresses. process. After removing from the furnace or oven, the

wire must be cooled in still air. If cooled in any other

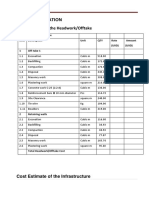

Table 12. Oven Stress Relief Temperatures

& Times for Wire.

Fig. 1 — Typical stress relief oven for wire coils

(photo courtesy of Wisconsin Oven).

The steel is then cooled at a sufficiently slow rate

to avoid formation of excessive thermal stresses.

No microstructural changes occur during the stress

relief process.

In addition to removing stresses, the stress relief

process returns the material to a strength level

approximately equivalent to where it was prior to

forming. Studies have shown1 that the interstitial ele-

ments pin the lattice defects in the atomic structure

of the metal, resulting in this increase in mechanical

strength.

xx Wire Forming Technology International/Summer 2010

manner, stresses are reintroduced into the part.

Note: it is reported2 that rapid stress-relieving tech-

nology reduces total stress relieving time for many

materials. For example, tests on 0.630" (16 mm) di-

ameter chrome-silicon wire have shown that time at

temperature can be reduced from approximately 60

minutes to 10 minutes or less.

Process Examples

To completely eliminate residual stresses in helical

springs through stress relief, the material must be

heated high enough to fully recrystallize. This is not

practical in spring manufacturing since the recrystal-

lization process significantly reduces the material’s

strength and therefore its usefulness in spring ap-

plications.

On the other hand, an elevated temperature recovery

process (for example, stress relief) can eliminate the

majority of residual stresses without significantly

deteriorating the material’s strength (as seen in

Figure 2).

Fig. 2 — Effects of recovery and recrystallization

The temperature required to accomplish the recovery on grain structure.

process depends on the material type and process-

ing history (i.e., carbon steel versus alloy steel, cold in the oven and material type. It is important to antici-

drawn versus oil tempered, etc.). Additional recom- pate these changes so final product specifications are

mendations for proper recovery are found in the SMI met. In general, the following is true:

Encyclopedia of Spring Design3. •Extension springs: reduction in initial

In another example4, stress relief yields maximum me- tension; change in hook position; change in

chanical properties in 302 stainless steel wire between spring diameter.

600°F (315°C) and 900°F (480°C). The fatigue properties

•Compression springs: reduction in initial

of the wire are optimum at a stress relief temperature

tension; change in spring diameter.

of 1200°F (650°C). However, mechanical properties

such as yield strength, modulus of resilience, modulus •Torsion springs: reduction in initial tension;

of toughness and ultimate strength are reduced as low temperature stabilizes position of ends.

much as 30% when compared to similar properties at In general, if you change a wire diameter by 1%, the

600°F (315°C).

Also, the capacity of 302 stainless steel wire Table 2 . Process Induced Residual Stress

5

to stretch elastically continuously decreases Benefits for Torsion Springs.

at room temperature as the stress relief tem-

perature is increased beyond 600°F (315°C).

Not all springs, however, require stress relief

to improve properties. For example, torsion

springs loaded in bending are subject to a

number of different residual stresses (see

Table 2) only some of which are harmful.

Other parts that benefit from stress relief are

complex shapes, parts with tight dimension-

al tolerances and machined parts that have

had a lot of stock removal performed.

Dimensional Changes

Stress relief will change spring dimensions

as a function of temperature, length of time

Summer 2010/Wire Forming Technology International xx

Stress Relief ...continued

spring rate will change by 4%. So an increase in wire steel (grade 321 or 347) or an extra-low-carbon type

size by 1% will result in a 4% stronger spring. The (304L or 316L) be used, particularly when a lengthy

converse is also true. A decrease in wire size of 1% will stress relieving operation is required.

result in a 4% weaker spring. In addition, it is common

to see up to a 3% change in torsional stress.

In Conclusion

Stress relief is a simple heat-treating operation for

Corrosion Resistance wire products that depends strongly on the proper

Corrosion resistance is another important considera- selection of temperature and time at temperature for

tion in certain wire products, especially those con- its success. A proper cooling rate is also a surprisingly

structed of stainless steel. The corrosion resistance important factor.

in these alloys is primarily a function of stress relief So, the next time that your products need stress relief,

temperature. be sure that your heat treater fully understands what

Stress relief at temperatures below 750°F (400°C) is it is that you are trying to achieve.

an acceptable industry practice, but results in only www.heat-treat-doctor.com WFTI

a modest level of stress reduction. Stress relieving

at 800°F to 1700°F (425°C to 925°C) significantly re- References:

duces residual stresses that otherwise might lead to 1

Bartel, Terry, Heat Treating, SPRINGS, October 2007.

stress corrosion cracking or dimensional instability in 2

Grenier, Mario and Gingras, Roger, Rapid Tempering and

service. One hour at a temperature of 1600°F (870°C) Stress Relief Via High-Speed Convection Heating, Industrial

Heating, May 2003.

typically relieves about 85% of the residual stresses. 3

Sebastian, D. et al., Fundamentals of Spring Design, SMI, Oak

However, stress relieving in this temperature level

Brook Illinois, 2000, p. SM-5.

can also precipitate grain boundary carbides, result- 4

Bhonsle, S.R. and C.D. Van Karsen, Mechanical and Fatigue

ing in sensitization that severely impairs corrosion Properties of Stress Relieved Type 302 Stainless Steel Wire,

resistance in many media. To minimize these effects, Journal of Materials Engineering and Performance, Volume

it is strongly recommended that a stabilized stainless 1, Issue 3, pp. 363-369.

xx Wire Forming Technology International/Summer 2010

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- CHE421Документ1 страницаCHE421Eko SuherОценок пока нет

- Effect of Density On Mechanical Properties of Sinter Hardened P/M MaterialsДокумент8 страницEffect of Density On Mechanical Properties of Sinter Hardened P/M Materialsjoko setiawanОценок пока нет

- How To Improve The Glass Curtain Wall FlatnessДокумент3 страницыHow To Improve The Glass Curtain Wall FlatnessHan JoeОценок пока нет

- TECHNICALДокумент48 страницTECHNICALPuneeth KumarОценок пока нет

- Reclaimed Asphalt Pavement (R Pavement (Rrap) Rap)Документ28 страницReclaimed Asphalt Pavement (R Pavement (Rrap) Rap)Biprajit SahaОценок пока нет

- Teja Mahendra Sai KommuriДокумент8 страницTeja Mahendra Sai Kommurisai srinivasОценок пока нет

- Loc Corr SS Weldments SummaryДокумент52 страницыLoc Corr SS Weldments SummarySatheesh KumarОценок пока нет

- Melt Blown TechnologyДокумент15 страницMelt Blown TechnologyKalyan Ray Gupta100% (2)

- TDS - Texture GC1540 TMP GeocellДокумент1 страницаTDS - Texture GC1540 TMP GeocellWiraОценок пока нет

- TLE (5) - Carpentry and MasonryДокумент12 страницTLE (5) - Carpentry and MasonryJezel PlazaОценок пока нет

- Linear Thermal Expansion CoefficientsДокумент4 страницыLinear Thermal Expansion CoefficientsputriОценок пока нет

- FYP Proposal Edited)Документ26 страницFYP Proposal Edited)Cheah Woi Leong100% (1)

- Material Schedule For Housing Development at Barnawa KadunaДокумент5 страницMaterial Schedule For Housing Development at Barnawa KadunaAliyu Shehu100% (2)

- Astm C884C884M-16Документ3 страницыAstm C884C884M-16adolfo camayoОценок пока нет

- Aircraft Materials and Processes PDFДокумент392 страницыAircraft Materials and Processes PDFIris Garcia100% (1)

- Metal Equivalent StandardДокумент7 страницMetal Equivalent StandardN D Senthil Ram0% (1)

- Cables MCQsДокумент11 страницCables MCQsAbhishek Kumar SahОценок пока нет

- Byk - Garamite 1958 TDS (En) PDFДокумент6 страницByk - Garamite 1958 TDS (En) PDFsudhir5441Оценок пока нет

- 2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeДокумент13 страниц2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeGonzalo MazaОценок пока нет

- All Ceramic Classification.Документ3 страницыAll Ceramic Classification.Yasmeena SbeihОценок пока нет

- Aalco Metals LTD - Stainless Steel 14016 430 Sheet and Plate - 95Документ3 страницыAalco Metals LTD - Stainless Steel 14016 430 Sheet and Plate - 95bhushansalunkeОценок пока нет

- Materials Today Communications: S. Deniz Varsavas, Cevdet KaynakДокумент10 страницMaterials Today Communications: S. Deniz Varsavas, Cevdet KaynakbnechitaОценок пока нет

- Ardex CA20PДокумент4 страницыArdex CA20PHarsa VardhanОценок пока нет

- 400 MtrsДокумент79 страниц400 MtrsCarl Malone TolentinoОценок пока нет

- Steady Load Failure TheoriesДокумент17 страницSteady Load Failure Theoriesapi-3710585Оценок пока нет

- Bill of Quantities (BoQ)Документ3 страницыBill of Quantities (BoQ)Mohamoud AbdulahiОценок пока нет

- People. Passion. Possibilities.: .30 .11 Thread Relief As RequiredДокумент40 страницPeople. Passion. Possibilities.: .30 .11 Thread Relief As RequiredFranciscoОценок пока нет

- FiIllers and Additives of Plastics PDFДокумент53 страницыFiIllers and Additives of Plastics PDFAnishMendisОценок пока нет

- C4.tension Member Compatibility ModeДокумент45 страницC4.tension Member Compatibility ModejojomarbunОценок пока нет

- Innovation in Concrete TechnologyДокумент9 страницInnovation in Concrete TechnologyGirish YumnamОценок пока нет