Академический Документы

Профессиональный Документы

Культура Документы

Hi Ride Mud Hopper

Загружено:

Anonymous VNu3ODGavОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hi Ride Mud Hopper

Загружено:

Anonymous VNu3ODGavАвторское право:

Доступные форматы

Product Bulletin

HIRIDE Hopper

High-Speed, Rapid-Induction, Dynamic Eductor

The HIRIDE* Hopper integrates a proprietary Minimum

Pressure Drop (MPD) 175 nozzle and unique TriMix Diffuser

(TMD) into an easily installed, rugged, stainless steel frame

which has been designed to an optimal height for improved

ergonomics. The unit is available in three configurations: FE,

SE and EA.

The HIRIDE Hopper Model 175 FE unit’s dynamic-

positioning design offers the unique ability to rotate the

MPD/ TMD eductor assembly up to 180° while utilizing up to

3 in. (76 mm) of vertical travel, creating unparalleled flexibility

for new installs or retrofits on offshore or land rigs. The propri-

Features

etary eductor design minimizes pressure loss, provides consis-

• Rapid, complete mixing of

tently higher vacuum, requires less energy, maintains a rapid

dry or liquid additives into the

rate of induction and reduces “fish eyes.” The ability to maintain fluid system

high productivity under consistently low or variable circulating- • Lowest comparable pressure loss

pump pressures makes the HIRIDE Hopper unit the leader in

• Creates high shear rates in a

rapid mixing technology. circulating loop

• Compact design with

Features small footprint

• Unique dynamic eductor assembly offers unparalleled 180° of • Dust-free dry-product mixing

rotation and 3 in. (76 mm) of vertical travel (Model 175 FE)

• The patent-pending, combination Minimum Pressure Drop Benefits

(MPD) 175 nozzle and TriMix Diffuser (TMD) are made of • Minimizes “fish eyes” in

durable polyurethane hard-to-mix products

• 2,790 in.3 (45.7 L) hopper (equal to a 100-lb [45.4-kg] sack • Requires less energy

of barite) • Flexible design eliminates

• Standard 2-in. (51-mm) bulk-liquids induction port extra equipment

• 2-in. (51-mm) cam lock quick connect provides compatibility • Ideal for rigs where space is at

with bulk tanks a premium

• Consistent 26.8-in (681-mm) Hg vacuum • A greater degree of

• Lowest comparable pressure loss at 48 psi (3.3 bar) worker safety

• Lowest comparable energy requirement at 0.47 hp/gph

(92 kW/m3/hr)

• 25,992 lb/hr (11,790 kg/hr) rate of solids induction for bentonite

• Grooved pipe connections for quick installation and removal

• Consistent mixing performance between 30 and 60 psi

(2 and 4 bar)

• Durable, weather-resistant, stainless steel construction

• 600-GPM (136.2 m3/min) circulation can vacuum water

through 33 ft (10 m) of 2-in. (51-mm) hose and a vertical rise

of 20 ft (6.1 m) at 80 GPM (302.8 L/min)

• Reduced dimensions and weight with adjustable profile

Benefits

HIRIDE Hopper Model 175 FE

• Bulk solids induction without costly additional equipment

• Dynamic eductor allows rapid adjustment of eductor height

and hopper orientation for customized installation onshore

or offshore

• Smaller dimensions ensure suitability for all locations

requiring minimal modifications to rig spaces or the unit itself

• Unique nozzle/diffuser design ensures mixing performance

that is not affected by variable service pressure

• Combination of advanced MPD nozzle and TMD design

ensure efficient entrainment of solids and elimination of

“fish eyes” in less than 5 min, with hydrophobic polymers

• No spillage or hopper bridging

• Cleanouts are faster with no equipment disassembly required HIRIDE Hopper Model 175 SE

• Cleaner work site reduces potential for slip and fall injuries

• More tank turnovers

• Three configurations available including:

– Model 175 FE — Features adjustable eductor piping

– Model 175 SE — Standard model with eductor piping

fixed in position

– Model 175 EA — An eductor-only option to be coupled

with a dust-free system

HIRIDE Hopper Model 175 EA

How It Works

The HIRIDE Hopper unit is an improved means of introducing

liquid, powdered or granular additives into drilling, reservoir

drill-in or completion fluids on the rig. The mixing hopper facili-

tates the manual addition of small volumes of material supplied

in individual 50- or 100-lb (22- or 44-kg) sacks.

Fluids enter the unit via a 6-in. (152-mm) line, and the MPD

nozzle constricts the flow to a 1.75-in. (45-mm) orifice in the

nozzle via a downstream, inwardly sloping conical shape. The

flow exits the downstream side of the MPD nozzle at high

velocity into a void space. The mixing hopper or other flowline

opens into this void space via a manual butterfly valve. With

the valve open, the high-velocity flow creates a zone of relative

low pressure, which creates suction, drawing the material into

the void space.

The powdered material drawn into the void space is then

carried by the high-velocity flow into the mouth of the TMD

diffuser where the geometry promotes turbulence and thus mix-

ing. Flow moves through the throat of the diffuser into a sec-

ondary void space, which again changes velocity, creating more

turbulence and recirculation zones. The flow then enters the sec-

ond throat of the TMD and exits into the 6-in. (152-mm) pipe

which again changes the flow velocity creating more recircu-

lation and turbulence and further encouraging mixing. At this

stage, all material is effectively entrained in the fluid.

There is also a 2-in. (51-mm) angled port installed directly

below the 4-in. (102-mm) butterfly valve on the inlet to the educ-

tor. This port is used for the addition of liquid products from

drum, bulk tank or tanker. Liquids with a viscosity similar to

water can be added at a rate of up to 108 GPM (410 L/min).

Induction rates will vary depending on the temperature and

viscosity of the fluid added.

Y-Z plane Diffuser –1 inlet Diffuser –1 outlet

Diffuser –2 inlet Diffuser –2 outlet X/D = 2.0 from

Diffuser –2 outlet

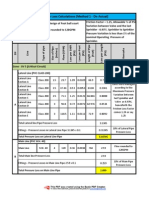

Specifications

Pipe Spool

Length Width Height Length (F-F) Pipe Spool Elevation

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

HIRIDE Hopper 49 (1,244.6) 29.6 (751.8) 39.3 (998.2) 42.2 (1,071.9) Typical 8 (203.2), varies 3 (76.2) on 175 FE

• Table and hopper: 304/304L stainless steel plate 1⁄4-in.

(6.35-mm) thick

• Legs: 304/304L stainless steel

• Victaulic couplings: ASTM A395/A536 and 316 stainless

• Valves: ASTM A395/A536 and 316 stainless (ASTM A743)

• Piping: 316/316L stainless steel

• Standard: B31.3 ANSI/ASME Code for Pressure Piping —

Chemical Plant and Refinery Piping

• Weights: Standard table 420 lb (190.5 kg)

Eductor only 162 lb (73.5 kg)

Flexible unit 390 lb (176.9 kg)

Engineering Drawing: HIRIDE Hopper

All dimensions are expressed in inches (millimeters).

29.6

(751.8)

49 (1,244.6)

39.3

(998.2)

8

(203.2)

42.2 (1,071.9)

Вам также может понравиться

- D-GASSERS Orizontal + Vertical PDFДокумент2 страницыD-GASSERS Orizontal + Vertical PDFciucalata880% (1)

- Cobra Kcobra MCДокумент2 страницыCobra Kcobra MCEd CalheОценок пока нет

- Back PoshtДокумент2 страницыBack Poshtmhn yОценок пока нет

- 450╦«┴·═╖╦╡├≈╩Θ003ok engДокумент27 страниц450╦«┴·═╖╦╡├≈╩Θ003ok engGabriel IbarraОценок пока нет

- Drilling Junk Sub: Operation & Maintenance ManualДокумент8 страницDrilling Junk Sub: Operation & Maintenance ManualShag ShaggyОценок пока нет

- BHDecat072013_bu0930Lexar_From080607 10/3/14 12:15 Am Page 12Документ1 страницаBHDecat072013_bu0930Lexar_From080607 10/3/14 12:15 Am Page 12Prime Energy Warehouse-YemenОценок пока нет

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopДокумент34 страницыTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanОценок пока нет

- Hi Kal Catalogue New OptДокумент16 страницHi Kal Catalogue New Optask101Оценок пока нет

- Xq114-6yx Manual PDFДокумент55 страницXq114-6yx Manual PDFFredy NavasОценок пока нет

- Torque Chart: 700hp Caterpillar C18 HXI Top Drive With D4P-700 Power UnitДокумент10 страницTorque Chart: 700hp Caterpillar C18 HXI Top Drive With D4P-700 Power UnitAlejandro Alejandre100% (1)

- English CatalogДокумент10 страницEnglish Catalogcorsini999Оценок пока нет

- Manual Farr 14-50Документ166 страницManual Farr 14-50JAVIER EDUARDO MANTILLA BUITRAGO100% (1)

- INSTRUMENT - AUTODRILLER - AOI - TECH MANUAL - IOM-111 Automatic Drilling Control SystemДокумент53 страницыINSTRUMENT - AUTODRILLER - AOI - TECH MANUAL - IOM-111 Automatic Drilling Control SystemKapil AgarwalОценок пока нет

- Skidding SystemДокумент6 страницSkidding Systemjesus alfonso fragozo calderonОценок пока нет

- Swivel National Series PДокумент1 страницаSwivel National Series Pluis sarmientoОценок пока нет

- Demco Gate Valve PDFДокумент56 страницDemco Gate Valve PDFyacine3516100% (1)

- 1976-77 Koomey General CatalogДокумент152 страницы1976-77 Koomey General CatalogNicasio AlonzoОценок пока нет

- Iron Roughnecks BrochureДокумент9 страницIron Roughnecks BrochureMahmoud MorsiОценок пока нет

- Manual Operation HCUДокумент27 страницManual Operation HCUSon DDarrellОценок пока нет

- Onshore Product Reference Guide PDFДокумент44 страницыOnshore Product Reference Guide PDFPedro RiveraОценок пока нет

- Automated Power CatwalkДокумент6 страницAutomated Power CatwalkianherzogОценок пока нет

- TDS 93 1 Pib PDFДокумент6 страницTDS 93 1 Pib PDFMohamed HashemОценок пока нет

- National Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALДокумент37 страницNational Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALariel feОценок пока нет

- Group Annexures 2017-18Документ45 страницGroup Annexures 2017-18rajesh_rathОценок пока нет

- Charles Rig Supplies, Inc.: Instruction ManualДокумент9 страницCharles Rig Supplies, Inc.: Instruction Manualashad100% (1)

- HHF-1600L Drilling Pump Set Parts ListДокумент21 страницаHHF-1600L Drilling Pump Set Parts ListAhmed SaeedОценок пока нет

- Erifon HD603HP hydraulic fluidДокумент2 страницыErifon HD603HP hydraulic fluidVictor RomeroОценок пока нет

- Preventive Maintenance System: It's A Marriage - Man and Machine - and They Have To Get AlongДокумент27 страницPreventive Maintenance System: It's A Marriage - Man and Machine - and They Have To Get Alongsrinath saiОценок пока нет

- Berkeley Ownwes ManualДокумент28 страницBerkeley Ownwes ManualMoses Alvarado100% (1)

- TM 80 Daily and Weekly Inspection and Maintenance TasksДокумент25 страницTM 80 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoОценок пока нет

- Bem-650-Shale - Shaker PDFДокумент8 страницBem-650-Shale - Shaker PDFWilliamОценок пока нет

- FKQ50-2 Use R ManualДокумент56 страницFKQ50-2 Use R ManualMuthia AstriОценок пока нет

- Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Документ7 страницInstructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Heri VillaОценок пока нет

- Bilco Bde User ManualДокумент11 страницBilco Bde User ManualRaymond ChuОценок пока нет

- LEWA Ecoflow Variable Eccentric Pump Drive Type LDC: PerformanceДокумент2 страницыLEWA Ecoflow Variable Eccentric Pump Drive Type LDC: PerformancesanthoshkumarplОценок пока нет

- Farr KT7585Документ132 страницыFarr KT7585wfcenda2603Оценок пока нет

- Model D Tech Unit Stripper Packer SpecsДокумент14 страницModel D Tech Unit Stripper Packer SpecsДудла Станіслав100% (1)

- RCH 4 - Williams Model 7100 PDFДокумент2 страницыRCH 4 - Williams Model 7100 PDFChris Alfa PalaОценок пока нет

- F-500 Mud Pump Parameters: CAT C15 Engine ParametersДокумент1 страницаF-500 Mud Pump Parameters: CAT C15 Engine ParametersFahirОценок пока нет

- ABS Fire and Safety Features For MODU - Part5Документ40 страницABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- W-440 Manual - CN-EN (2ND V)Документ39 страницW-440 Manual - CN-EN (2ND V)ADM MTCОценок пока нет

- Auto DrillerДокумент2 страницыAuto DrillersrpadronОценок пока нет

- Drill Pipe Make/Break Machines and Spinners by Hawk IndustriesДокумент3 страницыDrill Pipe Make/Break Machines and Spinners by Hawk IndustriesShandiPrasetyoОценок пока нет

- M60es44 NX449L Man 001Документ24 страницыM60es44 NX449L Man 001Riski KurniawanОценок пока нет

- D352004107 MKT 001 PDFДокумент20 страницD352004107 MKT 001 PDFEloy Lardet LafiОценок пока нет

- Westco Product Catalog 2019Документ16 страницWestco Product Catalog 2019DiegoCaicedo1982100% (2)

- West Oberon 87263Документ3 страницыWest Oberon 87263Arturo Treviño MedinaОценок пока нет

- Top Drive Actuator Maintenance GuideДокумент34 страницыTop Drive Actuator Maintenance Guidefelipe EstradaОценок пока нет

- LCI 550SpecSheetДокумент3 страницыLCI 550SpecSheetandy131078Оценок пока нет

- IND Drawworks DLS 163Документ11 страницIND Drawworks DLS 163Jose Luis MazzoniОценок пока нет

- Model pl5 Service Manual PDFДокумент31 страницаModel pl5 Service Manual PDFingcalderonОценок пока нет

- D399 Testing and AdjustingДокумент73 страницыD399 Testing and AdjustingNOUR ZAIN100% (1)

- Degasser CD-1400Документ3 страницыDegasser CD-1400Ruslan ZakirovОценок пока нет

- WWW - Incar.tw-Kelly Spinner ManualДокумент6 страницWWW - Incar.tw-Kelly Spinner ManualSachin KumarОценок пока нет

- Williams Model 7100: DescriptionДокумент2 страницыWilliams Model 7100: Descriptionfauzan kartiyasaОценок пока нет

- 2013 Us Shop Tech BrochureДокумент16 страниц2013 Us Shop Tech Brochurefollowjesus100% (1)

- HH 102 SemitrailerДокумент6 страницHH 102 SemitrailerleoОценок пока нет

- McCoyDrillingCompletionsCatalog LowResДокумент65 страницMcCoyDrillingCompletionsCatalog LowResAlvin Garcia PalancaОценок пока нет

- Perforadora Sobre OrugaДокумент28 страницPerforadora Sobre OrugaHenrry RVОценок пока нет

- MD6240 2 PDFДокумент28 страницMD6240 2 PDFWill WeinsoffОценок пока нет

- Photon Resin SettingДокумент4 страницыPhoton Resin SettingAnonymous VNu3ODGav57% (7)

- Responsibilities of Rig Superintendent StudyДокумент7 страницResponsibilities of Rig Superintendent StudyAnonymous VNu3ODGavОценок пока нет

- SPE 110805 Use of Advanced Optimization Techniques To Manage A Complex Drilling ScheduleДокумент9 страницSPE 110805 Use of Advanced Optimization Techniques To Manage A Complex Drilling ScheduleAnonymous VNu3ODGavОценок пока нет

- Octoparse V8.1 Release NotesДокумент1 страницаOctoparse V8.1 Release NotesAnonymous VNu3ODGavОценок пока нет

- Composite Frac Tree System PsДокумент1 страницаComposite Frac Tree System PsAnonymous VNu3ODGavОценок пока нет

- Activity Report Workshop eДокумент5 страницActivity Report Workshop eAnonymous VNu3ODGavОценок пока нет

- Activity Report Workshop eДокумент5 страницActivity Report Workshop eAnonymous VNu3ODGavОценок пока нет

- 4 Week Project Timeline: Week 1 Week 2 Week 3 Week 4Документ1 страница4 Week Project Timeline: Week 1 Week 2 Week 3 Week 4Mile VasilicОценок пока нет

- Ensco 80Документ1 страницаEnsco 80Anonymous VNu3ODGavОценок пока нет

- Si047data Sheetgate Valve 1051100619 PDFДокумент2 страницыSi047data Sheetgate Valve 1051100619 PDFAnonymous VNu3ODGavОценок пока нет

- Dittrich Et Al Supplementary MaterialДокумент5 страницDittrich Et Al Supplementary MaterialAnonymous VNu3ODGavОценок пока нет

- Woodhouse Stock Jan 2019Документ720 страницWoodhouse Stock Jan 2019Anonymous VNu3ODGav100% (2)

- Medium Voltage Cable Inspection Digital PDFДокумент4 страницыMedium Voltage Cable Inspection Digital PDFAnonymous VNu3ODGavОценок пока нет

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsДокумент3 страницыEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsjacquesmayolОценок пока нет

- Woodhouse Stock Jan 2019Документ720 страницWoodhouse Stock Jan 2019Anonymous VNu3ODGav100% (2)

- Weiss TR Ringindexeertafel Handleiding EN 2016 PDFДокумент84 страницыWeiss TR Ringindexeertafel Handleiding EN 2016 PDFMai Văn ĐịnhОценок пока нет

- Im 805Документ51 страницаIm 805Anonymous VNu3ODGavОценок пока нет

- 4 Week Project Timeline: Week 1 Week 2 Week 3 Week 4Документ1 страница4 Week Project Timeline: Week 1 Week 2 Week 3 Week 4Mile VasilicОценок пока нет

- ProHeat 35 TC Calibration Verification Procedure 232169BДокумент3 страницыProHeat 35 TC Calibration Verification Procedure 232169BAnonymous VNu3ODGavОценок пока нет

- Arc Welding Equipment Monthly ChecklistДокумент1 страницаArc Welding Equipment Monthly ChecklistAnonymous VNu3ODGav40% (5)

- Welding Electrode Classifications 123Документ2 страницыWelding Electrode Classifications 123Unnikrishnan RajanОценок пока нет

- Im 862Документ54 страницыIm 862Anonymous VNu3ODGavОценок пока нет

- Landmark - Drilling and Completions Portfolio PDFДокумент1 страницаLandmark - Drilling and Completions Portfolio PDFAnonymous VNu3ODGavОценок пока нет

- Calibration ValidationДокумент12 страницCalibration Validationelmira100% (2)

- Columbia Model 234 Chinook Helicopter SpecsДокумент2 страницыColumbia Model 234 Chinook Helicopter SpecsAnonymous VNu3ODGavОценок пока нет

- Vantage 500 Code 11467 Ingles PDFДокумент76 страницVantage 500 Code 11467 Ingles PDFamerica1591100% (1)

- Weld Cracking PDFДокумент5 страницWeld Cracking PDFjuanОценок пока нет

- 3512B Engine-Maintenance IntervalsДокумент56 страниц3512B Engine-Maintenance IntervalsAnonymous VNu3ODGavОценок пока нет

- IC Asset Tracking 8566 V3Документ4 страницыIC Asset Tracking 8566 V3juharieОценок пока нет

- Fleet - CH 47d ChinookДокумент2 страницыFleet - CH 47d ChinookAnonymous VNu3ODGavОценок пока нет

- Problem Set 2 - Fluid MachineryДокумент1 страницаProblem Set 2 - Fluid MachineryRonard Pa–aОценок пока нет

- DimplesДокумент20 страницDimplesrajuОценок пока нет

- A2K5D8 - CNRL Pipeline Specifications 2009Документ241 страницаA2K5D8 - CNRL Pipeline Specifications 2009MamacintОценок пока нет

- PISCO PLANT LINE LISTДокумент33 страницыPISCO PLANT LINE LISTFCTОценок пока нет

- 08 Co 178 Realiance Saf Val 2 LRДокумент2 страницы08 Co 178 Realiance Saf Val 2 LRAli AliОценок пока нет

- Learn Basic Hydraulics Concepts in 40 CharactersДокумент85 страницLearn Basic Hydraulics Concepts in 40 CharactersRamesh Babu K KОценок пока нет

- Presentation 1Документ9 страницPresentation 1Fatimə MəhərrəmovaОценок пока нет

- 10 819 Astro Express LF Valve IOДокумент2 страницы10 819 Astro Express LF Valve IOHary FadlyОценок пока нет

- SCI Ductile Iron Flanged FittingДокумент12 страницSCI Ductile Iron Flanged FittingJose Angel GonzalezОценок пока нет

- Influence of Flow Coefficient Stagger Angle and Tip Clearance On Tip Vortex in Axial CompressorsДокумент7 страницInfluence of Flow Coefficient Stagger Angle and Tip Clearance On Tip Vortex in Axial Compressorsmehrzad rahdarОценок пока нет

- Fluid Mechanics Lab ManualДокумент41 страницаFluid Mechanics Lab ManualrajmaljatОценок пока нет

- Advantages of Bladder Surge TanksДокумент8 страницAdvantages of Bladder Surge TanksChrisHogbenОценок пока нет

- Problem SetДокумент4 страницыProblem SetR SuyaoОценок пока нет

- Flow Through An OrificeДокумент27 страницFlow Through An Orificejochem_ligthartОценок пока нет

- Compressibility Effects on Airfoil LiftДокумент9 страницCompressibility Effects on Airfoil LiftSahil JadiaОценок пока нет

- Ce 15 LX 3Документ4 страницыCe 15 LX 3Lester JayОценок пока нет

- Hydraulic Systems Design GuidelinesДокумент29 страницHydraulic Systems Design Guidelinesrajesh09100% (2)

- R0404-MT - Rev - 0 DF Da Bateria de CicloneДокумент2 страницыR0404-MT - Rev - 0 DF Da Bateria de CiclonecaapasaОценок пока нет

- API 6A Hydraulic Actuator Operation InstructionДокумент7 страницAPI 6A Hydraulic Actuator Operation InstructionSrikanth Bammhide100% (1)

- Hydraulic Equipment for Industrial MachinesДокумент4 страницыHydraulic Equipment for Industrial MachinesFerney LaraОценок пока нет

- Friction Loss Calculations of Irrigation Design A Foot Ball CourtДокумент13 страницFriction Loss Calculations of Irrigation Design A Foot Ball Courtmathewmanjooran100% (2)

- Lec 3. Centfg - Compressor ExДокумент30 страницLec 3. Centfg - Compressor ExmichaelОценок пока нет

- J4011 - PNEUMATIC & HYDRAULIC (Hydraulic Basic)Документ43 страницыJ4011 - PNEUMATIC & HYDRAULIC (Hydraulic Basic)Boy LiverpoolОценок пока нет

- HHM Unit-1 PDFДокумент66 страницHHM Unit-1 PDFAchyutha AnilОценок пока нет

- Presentacion Sellos DoblesДокумент33 страницыPresentacion Sellos DoblesRolando Felipe Tapia MoyanoОценок пока нет

- Preparation and RequirementДокумент2 страницыPreparation and RequirementAdy FardyОценок пока нет

- Design of Circular Liquid or Gas PipesДокумент6 страницDesign of Circular Liquid or Gas PipessereutyОценок пока нет

- Hydro Pneumatic SystemДокумент8 страницHydro Pneumatic SystemAlvaajid SaleemОценок пока нет

- Presentation On Hydraulic TurbineДокумент32 страницыPresentation On Hydraulic TurbineMudrika PatelОценок пока нет

- Saudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 PipeДокумент10 страницSaudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 Pipesuresh100% (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (50)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationОт EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationРейтинг: 4 из 5 звезд4/5 (18)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Understanding Automotive Electronics: An Engineering PerspectiveОт EverandUnderstanding Automotive Electronics: An Engineering PerspectiveРейтинг: 3.5 из 5 звезд3.5/5 (16)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationОт EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationРейтинг: 1 из 5 звезд1/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansОт EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerРейтинг: 4 из 5 звезд4/5 (1)

- Control of Power Electronic Converters and Systems: Volume 1От EverandControl of Power Electronic Converters and Systems: Volume 1Рейтинг: 5 из 5 звезд5/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsОт EverandDesign for How People Think: Using Brain Science to Build Better ProductsРейтинг: 4 из 5 звезд4/5 (8)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryОт EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryРейтинг: 4 из 5 звезд4/5 (5)

- Design of Foundations for Offshore Wind TurbinesОт EverandDesign of Foundations for Offshore Wind TurbinesРейтинг: 5 из 5 звезд5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsОт EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsОценок пока нет