Академический Документы

Профессиональный Документы

Культура Документы

Sikaflex - 521 UV: Excellent Adherent, Weathering Resistant Sealant

Загружено:

milanbrasina0 оценок0% нашли этот документ полезным (0 голосов)

112 просмотров2 страницыok

Оригинальное название

SF_521_UV_e_v08_03

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документok

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

112 просмотров2 страницыSikaflex - 521 UV: Excellent Adherent, Weathering Resistant Sealant

Загружено:

milanbrasinaok

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Technical Data Sheet

Version 08 / 2003

Sikaflex®-521 UV

Excellent adherent, weathering resistant sealant

Technical Product Data

1-C polyurethane-

Chemical base

hybrid

Colour (CSQP1) 001-1) White, grey, black

Cure mechanism Humidity-curing

Density (uncured) (CSQP 006-4) 1,4 kg/l approx.

Good, with no

Non-sag properties (CSQP 061-1)

tendency to sag

Application temperature 5°C - 35°C

Tack free time2) (CSQP 019-1) 30 min. approx.

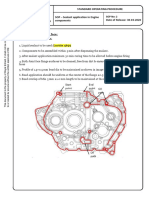

Curing speed (CSQP 049-1) (see diagram)

Shrinkage (CSQP 014-1) 2% approx.

Shore A-hardness (CSQP 023-1 / ISO 868) 40 approx.

2

Tensile strength (CSQP 036-1 / ISO 37) 1,8 N/mm approx.

Industry

Elongation at break (CSQP 036-1 / ISO 37) 400% approx.

Tear propagation resistance (CSQP 045-1 / ISO 34) 5,5 N/mm approx.

Glass transition temperature (CSQP 509-1 / ISO 4663) -60°C approx.

Electrical resistance (CSQP 079-2 / ASTM D 257-99) 1010 Ω cm approx.

Movement accommodation factor 10% approx.

Service temperature (CSQP 513-1) permanent -40°C to +90°C°C

Short term 4 hours 140°C

1 hour 150°C

Shelf life (storage below 25°C) (CSQP 016-1) 9 months

1) 2)

CSQP = Corporate Sika Quality Procedures 23°C / 50% r.h.

Description Product Benefits Areas of Application

Sikaflex®-521 UV is a multi-pur- - 1-C hybrid-formulation Sikaflex®-521 UV bonds well to a

pose non-sag elastic 1-c sealant - Elastic wide variety of substrates and is

based on a polyurethane-hybrid - UV, ageing and weathering suitable for making permanent

compound, which cures on expo- resistant elastic seals of high bonding

sure to atmospheric humidity to - Bonds well to a wide variety of strength. Suitable substrate mate-

form a durable elastomer. substrates without the need for rials are timber, metals, metal

®

Sikaflex -521 UV is manufactured special pre-treatment primers and paint coatings (2-c

in accordance with ISO 9001 / - Can be overpainted systems), ceramic materials and

14001 quality assurance system - Can be sanded plastics.

and with the responsible care - Low odour Seek manufacturer’s advice before

program. - Non-corrosive using on transparent materials that

- High electrical resistance are prone to stress cracking.

- VOC and solvent-free

- Silicone- and PVC-free

Sikaflex® -521 UV 1 / 2

Cure Mechanism Application Further Information

Sikaflex®-521 UV cures by reaction Cartridges: Pierce cartridge Copies of the following publications

with atmospheric humidity. At low membrane. are available on request:

temperatures the water content of Unipacs: Place unipac in the - Material Safety Data Sheets

the air is lower and the curing application gun and snip off the - Sika Primer Chart

reaction proceeds a little more closure clip. - General guidelines for bonding

slowly. Cut off the tip of the nozzle to give and sealing with Sikaflex®

If Sikaflex®-521 UV is used in desired sealant bead geometry. products.

combination with a PUR adhesive, For satisfactory results the sealant

the latter must be fully cured must be applied with a hand- Packaging Information

before seam sealing with operated cartridge gun, piston type

compressed-air gun or pump- Cartridge 300 ml

Sikaflex®-521 UV.

operated bulk dispensing equip- Unipac 600 ml

10 ment. Hobbock (on request) 23 l

Thickness of cure (mm)

8 To ensure satisfactory conditions Drum (on request) 195 l

for curing, do not apply at tempe-

ratures below 5°C or above 35°C.

The optimum temperature for Important

substrate and sealant is between For information and advice regar-

15°C and 25°C. ding transportation, handling, sto-

For advice on selecting and setting rage and disposal of chemical

0

up a suitable pump system, as well products, users should refer to the

Time(days) as on the techniques of pump actual Material Safety Data Sheets

Diagram 1: Curing speed for operated application, please con- containing physical, ecological,

Sikaflex®-521 UV tact the System Engineering De- toxicological and other safety-

partment of Sika Industry. related data.

Chemical Resistance

Tooling and finishing

Sikaflex®-521 UV is resistant to UV Note

Tooling and finishing must be

radiation, fresh water, seawater The information, and, in particular, the

carried out within the tack-free time

and proprietary aqueous cleaning recommendations relating to the

of the sealant. We recommend the application and end-use of Sika

agents; temporarily resistant to ®

use of Sika Tooling Agent N. products, are given in good faith based

fuels, mineral oils, vegetable and

Other products must be tested for on Sika's current knowledge and

animal fats and oils; not resistant

suitability/compatibility prior to use. experience of the products when

to organic acids, concentrated properly stored, handled and applied

mineral acids, caustic solutions or Removal under normal conditions. In practice,

®

solvents. Uncured Sikaflex -521 UV may be the differences in materials, substrates

The above information is offered removed from tools and equipment and actual site conditions are such that

for general guidance only. Advice with Sika® Remover-208 or an- no warranty in respect of

merchantability or of fitness for a

on specific applications will be other suitable solvent. Once cured, particular purpose, nor any liability

given on request. the material can only be removed arising out of any legal relationship

mechanically. whatsoever, can be inferred either from

Method of Application Hands and exposed skin should be this information, or from any written

®

Surface preparation washed immediately using Sika recommendations, or from any other

Handclean Towel or a suitable advice offered. The proprietary rights of

The surfaces must be clean, dry third parties must be observed. All

and free from all traces of grease, industrial hand cleaner and water.

orders are accepted subject to our

oil, and dust. The adhesion of the Do not use solvents! current terms of sale and delivery.

sealant can be improved by wiping Overpainting Users should always refer to the most

the joint faces with ® recent issue of the Technical Data

® Sikaflex -521 UV can be overpain- Sheet for the product concerned,

Sika Hybrid Aktivator (a cleaning ted before tack-free. copies of which will be supplied on

and activating agent) or possibly The paint must be tested for request.

®

applying the appropriate Sika compatibility by carrying out pre-

Primer. liminary trials. It should be

Directions for the preparation and understood that the hardness and

treatment of different substrates film thickness of the paint may

are given in the appropriate Sika impair the elasticity of the sealant

Primer Chart. and lead to cracking of the paint

Advice on specific applications is film.

available from the Technical Ser-

vice Department of Sika Industry.

urther information available at:

www.sika-industry.com

Sikaflex® -521 UV 2 / 2

www.sika.ch

Sika Schweiz AG

Industry

Tüffenwies 16

CH-8048 Zurich

Switzerland

Tel. +41 1 436 40 40

Fax +41 1 436 45 30

CLOSE

Вам также может понравиться

- Sikaflex - 521 UV: Excellent Adherent, Weathering Resistant SealantДокумент2 страницыSikaflex - 521 UV: Excellent Adherent, Weathering Resistant SealantMuruga SriОценок пока нет

- SF 254 Booster GBДокумент2 страницыSF 254 Booster GBmilanbrasinaОценок пока нет

- Sikaflex - 552 AT: High-Performance Assembly AdhesiveДокумент2 страницыSikaflex - 552 AT: High-Performance Assembly AdhesiveRicusОценок пока нет

- Sikaflex 256Документ2 страницыSikaflex 256aboali8686Оценок пока нет

- Sikaflex - 252: Structural AdhesiveДокумент3 страницыSikaflex - 252: Structural AdhesiveRicusОценок пока нет

- Sikaflex-291 - PDSДокумент2 страницыSikaflex-291 - PDSRade PesteracОценок пока нет

- Sikafast 5211 PdsДокумент2 страницыSikafast 5211 PdskonstruksiОценок пока нет

- SIK3287 Sikaflex 221 TDSДокумент2 страницыSIK3287 Sikaflex 221 TDSardabiliОценок пока нет

- Fast-5211 NT PdsДокумент2 страницыFast-5211 NT PdsGino TironiОценок пока нет

- Sikasil AS-60: Industrial Assembly Sealant & AdhesiveДокумент2 страницыSikasil AS-60: Industrial Assembly Sealant & AdhesivedushyantbbaisОценок пока нет

- Sikaflex - Auto: One Component Polyurethane Sealant Exclusively For CBRДокумент2 страницыSikaflex - Auto: One Component Polyurethane Sealant Exclusively For CBRDavid SudarmaОценок пока нет

- Sikaflex - 292iДокумент2 страницыSikaflex - 292iLin LinОценок пока нет

- Pds Sikasil As-770 eДокумент2 страницыPds Sikasil As-770 eArdiansyah ARОценок пока нет

- Sikaflex - 256: The Primerless Windscreen Adhesive System For Direct Glazing in Automotive Glass ReplacementДокумент2 страницыSikaflex - 256: The Primerless Windscreen Adhesive System For Direct Glazing in Automotive Glass ReplacementAlper GmОценок пока нет

- Sikaflex 291 FlyerДокумент2 страницыSikaflex 291 FlyerSholichatul IlmiahОценок пока нет

- Sikaflex-260 N eДокумент2 страницыSikaflex-260 N eTrung Trinh BaoОценок пока нет

- Sil SG-500Документ2 страницыSil SG-500Inggrid P.ChristyОценок пока нет

- Sikatack Panel: Panel Adhesive For Ventilated FaçadesДокумент2 страницыSikatack Panel: Panel Adhesive For Ventilated FaçadeselpibematadorОценок пока нет

- Sikaflex - 221Документ2 страницыSikaflex - 221ESTRELLA MaricelОценок пока нет

- Sikaflex 263Документ2 страницыSikaflex 263Slamet Tri UsadhaОценок пока нет

- Sikaflex - 223Документ2 страницыSikaflex - 223Ahmad HavidОценок пока нет

- TDS Sikasil SG-18 Structural SealantДокумент2 страницыTDS Sikasil SG-18 Structural SealantTuấn Anh NguyễnОценок пока нет

- Sikaflex®-221: Product Data SheetДокумент2 страницыSikaflex®-221: Product Data SheetNurdin YusupОценок пока нет

- Sikasil SG-500: High Performance Structural Silicone AdhesiveДокумент2 страницыSikasil SG-500: High Performance Structural Silicone Adhesivethe enverОценок пока нет

- Sikaflex - 252Документ2 страницыSikaflex - 252oddo_mneОценок пока нет

- PDS SikaPower-492 EnglishДокумент2 страницыPDS SikaPower-492 EnglishpetkoОценок пока нет

- Sikaflex - 221Документ2 страницыSikaflex - 221MarhendraОценок пока нет

- Pds Sikaflex-265 Uk v01-07Документ2 страницыPds Sikaflex-265 Uk v01-07Tomas MoralesОценок пока нет

- Sikaflex®-265: Product Data SheetДокумент2 страницыSikaflex®-265: Product Data Sheetrajneesh thakurОценок пока нет

- Sikasil SG-18: Structural Silicone AdhesiveДокумент2 страницыSikasil SG-18: Structural Silicone AdhesiveMochamad Ardie NoegrohoОценок пока нет

- Sikaflex p2gДокумент2 страницыSikaflex p2goscarjcoОценок пока нет

- Sikatack Drive 60minДокумент2 страницыSikatack Drive 60minVictor GladunОценок пока нет

- Sikasil RTV Gasket PdsДокумент2 страницыSikasil RTV Gasket PdsAhmad Ikhsan KurniantoОценок пока нет

- Sikaflex 255 UltraДокумент2 страницыSikaflex 255 UltraVictor GladunОценок пока нет

- Pds Sikasil Gasket Black e 06-14Документ2 страницыPds Sikasil Gasket Black e 06-14Roger SchvepperОценок пока нет

- Sikaflex - 221Документ2 страницыSikaflex - 221Abdul Wahid PaperwalaОценок пока нет

- Sikacryl® 620 Fire - PDSДокумент3 страницыSikacryl® 620 Fire - PDSMuhammad YasirОценок пока нет

- Sikaflex 252 TDSДокумент3 страницыSikaflex 252 TDSxingobuilderОценок пока нет

- Sika Tack Go4it En12-20171Документ2 страницыSika Tack Go4it En12-20171victorОценок пока нет

- PDS SikaForce-7818 L7 e 2013Документ2 страницыPDS SikaForce-7818 L7 e 2013FBОценок пока нет

- Sika 521Документ3 страницыSika 521Natasha KamalОценок пока нет

- Sikatack® Panel-50: Product Data SheetДокумент2 страницыSikatack® Panel-50: Product Data SheetKhin Sandi KoОценок пока нет

- PDS SikaTherm 4225 eДокумент2 страницыPDS SikaTherm 4225 eMarian ComaniciОценок пока нет

- Sikafast®-555 L05: Product Data SheetДокумент2 страницыSikafast®-555 L05: Product Data SheetAbhi LashОценок пока нет

- Sikatack PanelДокумент2 страницыSikatack PanelFrancsico MeloОценок пока нет

- Sikabond TF PlusrДокумент2 страницыSikabond TF PlusrArda YILDIZEL I Reliant E&CОценок пока нет

- 1-2577 Conformal Coating PDFДокумент3 страницы1-2577 Conformal Coating PDFBrent SchneiderОценок пока нет

- Sika TS Plus PDFДокумент4 страницыSika TS Plus PDFPhuc AnОценок пока нет

- Sika Aktivator 100Документ2 страницыSika Aktivator 100Victor GladunОценок пока нет

- Sikamelt 700Документ2 страницыSikamelt 700Ionut StoicaОценок пока нет

- Sikacem®-711 Elastic: Provisional Product Data SheetДокумент4 страницыSikacem®-711 Elastic: Provisional Product Data SheetDavid V. BaltazarОценок пока нет

- Tds Sikaflex250 PC CДокумент2 страницыTds Sikaflex250 PC CNazar NazarОценок пока нет

- Sikasil® IG-25 HM Plus: Product Data SheetДокумент2 страницыSikasil® IG-25 HM Plus: Product Data SheetKhin Sandi KoОценок пока нет

- Medium Cure Rate, General Purpose Silicone Elastomer: Description ApplicationДокумент3 страницыMedium Cure Rate, General Purpose Silicone Elastomer: Description ApplicationLU CHUNHUIОценок пока нет

- Sikacrete 213F Product Data 1322214Документ3 страницыSikacrete 213F Product Data 1322214chenОценок пока нет

- SikaCor SW-501 - EN - CДокумент4 страницыSikaCor SW-501 - EN - CMark InnesОценок пока нет

- Sikaflex - 295 UV: UV Resistant Adhesive/SealantДокумент3 страницыSikaflex - 295 UV: UV Resistant Adhesive/Sealantmassimo45Оценок пока нет

- Optically Clear Potting and Encapsulating Silicone ElastomerДокумент3 страницыOptically Clear Potting and Encapsulating Silicone ElastomerLU CHUNHUIОценок пока нет

- Geotextiles and Geomembranes HandbookОт EverandGeotextiles and Geomembranes HandbookT.S. IngoldРейтинг: 5 из 5 звезд5/5 (1)

- TL SikaTack UltrafastДокумент2 страницыTL SikaTack UltrafastmilanbrasinaОценок пока нет

- Flange Insulation KitДокумент2 страницыFlange Insulation KitmilanbrasinaОценок пока нет

- Sika Form Oil PDFДокумент2 страницыSika Form Oil PDFmilanbrasinaОценок пока нет

- Sika Decap PDFДокумент2 страницыSika Decap PDFmilanbrasinaОценок пока нет

- Contents CДокумент1 страницаContents CmilanbrasinaОценок пока нет

- Sika Rep Fine PDFДокумент2 страницыSika Rep Fine PDFmilanbrasinaОценок пока нет

- Trafficguard UR200Документ2 страницыTrafficguard UR200milanbrasinaОценок пока нет

- Expancell PDFДокумент2 страницыExpancell PDFmilanbrasinaОценок пока нет

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatДокумент6 страницSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatmilanbrasinaОценок пока нет

- Trafficguard UR100Документ2 страницыTrafficguard UR100milanbrasinaОценок пока нет

- Nitoflor EmeritopДокумент4 страницыNitoflor EmeritopmilanbrasinaОценок пока нет

- Nitoflor DissipativeДокумент4 страницыNitoflor DissipativemilanbrasinaОценок пока нет

- Renderoc LAXtraДокумент2 страницыRenderoc LAXtramilanbrasinaОценок пока нет

- Renderoc PlugДокумент2 страницыRenderoc PlugmilanbrasinaОценок пока нет

- Cemtop 200Документ4 страницыCemtop 200milanbrasinaОценок пока нет

- Trafficguard URДокумент2 страницыTrafficguard URmilanbrasinaОценок пока нет

- Nitofill UR63 : Flexible Polyurethane Injection Resin SystemДокумент4 страницыNitofill UR63 : Flexible Polyurethane Injection Resin SystemmilanbrasinaОценок пока нет

- Cicot ET SlurryДокумент4 страницыCicot ET SlurrymilanbrasinaОценок пока нет

- Renderoc BF2Документ2 страницыRenderoc BF2milanbrasinaОценок пока нет

- Nitofill EPLV : Constructive SolutionsДокумент4 страницыNitofill EPLV : Constructive SolutionsmilanbrasinaОценок пока нет

- Renderoc TGДокумент2 страницыRenderoc TGmilanbrasinaОценок пока нет

- Nitofill WS60 : Crack Injection Resin For Stopping Water FlowДокумент4 страницыNitofill WS60 : Crack Injection Resin For Stopping Water FlowmilanbrasinaОценок пока нет

- Hydroflex Water Isolation ProductsДокумент24 страницыHydroflex Water Isolation ProductssherzodОценок пока нет

- Biocides in Adhesives 2017: Prepared By: Biocide Information Limited EmailДокумент26 страницBiocides in Adhesives 2017: Prepared By: Biocide Information Limited EmailSérgio - ATC do BrasilОценок пока нет

- Spec 079219 - Acoustical Joint SealantsДокумент5 страницSpec 079219 - Acoustical Joint Sealantsداروین پرزОценок пока нет

- Field Guide CCWДокумент253 страницыField Guide CCWRami TarrafОценок пока нет

- Flamex One: Flexible Intumescent SealantДокумент3 страницыFlamex One: Flexible Intumescent SealantBalasubramanian AnanthОценок пока нет

- SIKA Product Information ChartДокумент32 страницыSIKA Product Information ChartPrateek ModyОценок пока нет

- Technical Information ASSET DOC LOC 9447986Документ1 страницаTechnical Information ASSET DOC LOC 9447986Mohammed KabiruddinОценок пока нет

- UntitledДокумент86 страницUntitledAhmed BurekОценок пока нет

- SABA Ecoseal Bio HM PDS ENДокумент2 страницыSABA Ecoseal Bio HM PDS ENArda YILDIZEL I Reliant E&CОценок пока нет

- Dow Corning 991 Product InfoДокумент4 страницыDow Corning 991 Product InfocurlyjockeyОценок пока нет

- Thixoflex Orange & Thixoflex Gray: Product Information SheetДокумент2 страницыThixoflex Orange & Thixoflex Gray: Product Information SheetValerio CadedduОценок пока нет

- ACG Glass Installation - Setting Block, Edge CoverДокумент29 страницACG Glass Installation - Setting Block, Edge CoverDave LiОценок пока нет

- Branz BU481 Timber Windows PDFДокумент6 страницBranz BU481 Timber Windows PDFthom gillОценок пока нет

- TCCL IttihadforPrcrCmntsДокумент22 страницыTCCL IttihadforPrcrCmntshisham1958Оценок пока нет

- Dowsil Warranty ApplicationДокумент4 страницыDowsil Warranty ApplicationKissa DolautaОценок пока нет

- Pittseal CW Sealant: 1. Description and Area of ApplicationДокумент3 страницыPittseal CW Sealant: 1. Description and Area of ApplicationElie AouadОценок пока нет

- Adhesives&Sealants PVCДокумент2 страницыAdhesives&Sealants PVCkaiserasraelОценок пока нет

- SOP 2 - SOP For Sealant Application-1Документ3 страницыSOP 2 - SOP For Sealant Application-1ꯗꯤꯛꯕꯤꯖꯣꯏ ꯂꯨꯋꯥꯡ ꯁꯣꯔꯥꯝОценок пока нет

- SikaFlex-Pro - Data SheetДокумент6 страницSikaFlex-Pro - Data SheetJohn AdamsОценок пока нет

- Silastic 732 RTVДокумент3 страницыSilastic 732 RTVhzq1e100% (1)

- 07 91 26 SealantДокумент10 страниц07 91 26 SealantshajbabyОценок пока нет

- FL - Glazing.agc Glass - Update 1 1Документ44 страницыFL - Glazing.agc Glass - Update 1 1Le Manh CuongОценок пока нет

- Sikaflex® Construction: Product Data SheetДокумент4 страницыSikaflex® Construction: Product Data SheetFritz NatividadОценок пока нет

- AITC, Recommended Practice For Protection of Structural Glued Laminated Timber During Transit, Storage and ErectionДокумент4 страницыAITC, Recommended Practice For Protection of Structural Glued Laminated Timber During Transit, Storage and ErectionCarlos Eduardo Cueva CallerОценок пока нет

- DURAFLEXДокумент2 страницыDURAFLEXتوفيق عبداللهОценок пока нет

- Instructions:: Riverview Polytechnic and Academic School, Inc. (Rpasi)Документ34 страницыInstructions:: Riverview Polytechnic and Academic School, Inc. (Rpasi)Andrei AndoyОценок пока нет

- 7862 enДокумент16 страниц7862 enMarcus NguyễnОценок пока нет

- Dow - 3362 - HD Insulantng Glass SelantДокумент3 страницыDow - 3362 - HD Insulantng Glass SelantmarcosОценок пока нет

- Robotic Vision Dispensing SystemsДокумент2 страницыRobotic Vision Dispensing SystemsSohail KhanОценок пока нет

- PDF Roof Sealant 1Документ7 страницPDF Roof Sealant 1Aj Lyn AlferezОценок пока нет