Академический Документы

Профессиональный Документы

Культура Документы

Oil Facility: Main Process

Загружено:

Raghavan VenkatramanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Oil Facility: Main Process

Загружено:

Raghavan VenkatramanАвторское право:

Доступные форматы

Join SPE Log in About Help

Search Search

Oil facility

An oil facility encompasses the equipment between the oil

wells and the pipeline or other transportation system. The

purpose of an oil facility is to make the oil ready for sale to

the purchaser's standards (maximum allowable water,

salt, and other impurities). This article describes the key

equipment and functions found in an oil facility.

Contents [hide]

1 Overview

2 Function of a facility

2.1 Main process

2.2 Secondary process

2.3 Auxiliary systems

3 Separation

4 Oil treating

5 Produced-water treating

6 References

7 Noteworthy papers in OnePetro

8 External links

9 See also

10 Category

Overview

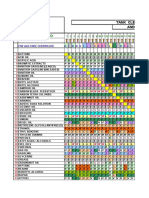

Fig. 1 is a block diagram of a simple oil facility. Each of

the blocks is described here, except for gas dehydration,

which is covered in Gas Facilities.

Fig. 1—Typical oil facility.

Function of a facility

Main process

The main function of an oil facility is to:

separate the oil, gas, water, and solids

treat the oil to meet sales specifications (e.g.,

BS&W, salt content, vapor pressure)

measure and sample the oil to determine its value

deliver it to the transportation system (i.e., the

pipeline, truck, ship, or railroad car)

The gas must be treated for sales or disposal. In the past,

disposal sometimes meant flaring or venting, but now gas

that can’t be transported is usually compressed for

reinjection into the reservoir. Gas treating may involve

only separation from the liquids, or it may include

additional processes such as:

compression

dehydration

removing H2S and CO2

gas processing to condense heavier components

that can be transported as a liquid

Secondary process

In addition to processing the oil for sale, the produced

water and solids must be treated for disposal. For

produced water, treating usually includes removal of

dispersed and dissolved hydrocarbons and, in addition to

separation or oil skimming, may include:

filtration

deionization

pumping

If treating of solids is required, it may include water

washing and agitating the solids to remove the oil and

then separating the water from them.

Auxiliary systems

In addition to the process systems, auxiliary process

heating and cooling may be required. Process heat is

usually needed for oil treating.

While, if necessary, facilities can be run without electric

power, power generation and electrical systems will

usually be included for a facility that is large or complex or

for living quarters that are provided for personnel.

All facilities require safety systems, including:

safety instrumentation and shutdown system

fire and gas detection

fire-fighting equipment

a means of evacuation, such as life rafts and

escape capsules for offshore

other equipment, depending on the location and

complexity of the facility and whether it is manned

Separation

The first step in the process is separating the gas from the

liquid and the water from the oil. This is usually done in a

separator—a pressure vessel into which the wellstream

flows to allow the gas, oil, and water to separate because

of gravity. To aid separating the streams, separators may

contain:

inlet diverters

outlet vortex breakers

buckets

weirs

mist extractors

A separator may be either of the following:

two-phase: separating gas from liquids

three-phase: separating gas, oil, and water, which

are removed through three outlets

The first separator in a facility that receives fluid from the

wells is called a production, or high-pressure (HP),

separator. If the production is at high pressure, (e.g., 500

to 1,200 psig) and if the oil from the separator is put

directly into a pipeline, gas will flash as the pressure

decreases owing to friction losses in the pipeline. Gas

takes up a much larger volume than its equivalent mass

of oil, so a pipeline sized for liquid flow will be undersized

if some of the liquid flashes into gas, resulting in

excessive velocities and pressure drop. For this reason,

oil pipeline owners generally specify a maximum vapor

pressure allowed to prevent the lighter components in the

oil from flashing into gas. The process of reducing the

vapor pressure in the oil to meet oil-pipeline specifications

is called “stabilization.”

For the simplest form of stabilization, the oil is put into an

atmospheric tank for storage. This allows the gas to flash

from the liquid in the tank when the pressure is reduced to

atmospheric. This process would get the true vapor

pressure of the oil down to atmospheric, or even lower if

some heating were added in addition to the pressure

reduction, and could be used to make the oil meet

pipeline specifications for vapor pressure. The gas that

flashes in the tank must then be compressed back to the

original pressure of the separator and combined with the

separator gas.

If the oil is sent to an intermediate pressure (IP) separator

instead of going directly into an atmospheric tank, the gas

that flashes in the IP separator will be at a higher

pressure, requiring less compression horsepower. In

addition, the total amount of oil stabilized in the

atmospheric tank is greater with an intermediate

separation stage than with a single flash to atmospheric

pressure. This is because of the gas/liquid equilibrium for

the higher-pressure flash and the altered composition of

the oil that is flashing in the tank.

While there still would be gas flashed as the liquid flowed

from the IP separator to the tank, the quantity would be

much smaller than in the first case in which liquid goes

directly from the HP separator to the tank. Thus, adding a

second stage of separation has two benefits:

first, the horsepower required to compress the gas

is lower because some of the gas flashes at higher

pressure

second, more stabilized oil will be produced

If we add a third, low-pressure (LP) stage of separation,

the total liquid in the tank increases even further, with

additional gas flashing at a higher pressure, reducing

compressor horsepower. Fig. 2 shows a typical three-

stage separation with flash-gas compression. Adding

additional stages of separation and compression would

increase liquids and reduce compression horsepower

further; however, at this point, the capital cost of adding

additional separation stages is generally not worth the

small increase in hydrocarbon value.

Fig. 2—Three-stage separation.

A typical separation train might have a well producing into

an HP separator at 1,100 psig, with the oil to an IP

separator at 450 psig, an LP separator at 150 psig, and

possibly an oil treater at 50 psig (see Oil Treating) before

storage in an atmospheric tank. The separator pressures

are chosen so that the flash gas from each stage of

separation feeds into a stage of compression with

reasonable compression ratios for each stage of the

compressor. (See page: Compressors)

Oil treating

No separation is perfect, there is always some water left

in the oil. Water content can range from less than 1%

water to more than 20% water in the oil by volume. The

lower the American Petroleum Institute (API) gravity (i.e.,

the higher the molecular weight and the oil viscosity), the

less efficient the separation.

To get the last of the water out of the oil, the oil is

processed through an oil treater or a treating system, as

described in the page of Emulsion Treating. A treater is

similar to a separator, but with special features to help

separate the water from the oil. Treaters or treating

systems usually provide heat to reduce oil viscosity and

large settling sections to allow the water time to settle

from the oil, and may provide an electrostatic grid to

promote coalescing of the water droplets. Conventional

treaters usually have a front section with a heater in which

the emulsion is heated and initial separation of the “free

water” takes place. The oil then flows to a second section

of the vessel, where additional coalescence and settling

of the water droplets takes place. Gas is flashed (i.e.,

liberated) from the emulsion as the pressure is lowered

and the temperature is raised from the upstream

separator. For a conventional treater with a heater, free-

water knockout section, and settling section, the water

content in the oil can be reduced to less than 1%. An

electrostatic treater, which is a conventional treater with

an electrostatic grid in the settling section, can reduce the

water content to 0.3 to 0.5% by volume.

The contract between the oil seller, who is normally the

producer and the purchaser and who may be a pipeline

company, specifies the allowable water content and may

specify the maximum salt content in the crude oil. High

water content can make corrosion problems worse in

pipelines and other transportation systems and can cause

problems with downstream processing. High salt content,

which is caused by the salinity of the produced water left

in the oil, may cause a refining problem when the water is

boiled off in the refinery distillation unit.

The oil from the treater is usually sent into a dry oil tank,

from which it is pumped through a sales meter for custody

transfer and then into a pipeline for transportation. For

additional information, see the pages on Storage tanks

and Pumps.

Produced-water treating

As mentioned previously, separation is not perfect, and

the amount of oil left in the water from a separator is

normally between 100 and 2,000 ppm by mass. This oil

must be removed to acceptable levels before the water

can be disposed of. The regulatory requirements for oil-in-

water content for overboard water disposal vary from

place to place, and some locations do not allow any

discharge of produced water. As an example, in the Gulf

of Mexico outer continental shelf (U.S. federal waters),

producers are limited to a maximum measurement of 42

ppm for any one sample and no more than 29 ppm

average for a given month. In contrast, on shore, no

discharge of produced water is permitted. In the case in

which discharge is not permitted, produced water is

usually injected into disposal wells.

Various types of equipment for water treating are

described in the page of Water treating facilities.

Equipment types used in this case include:

water skimmers

plate coalescers

gas flotation devices

hydrocyclones

Additional equipment, including desanders and filters,

may be needed to remove solids before injection.

Hydrocyclones require a pressure drop in excess of 100

psi to work well and would usually be placed between a

separator and its water-level control valve. In addition to

removing oil from the water, hydrocyclones have a

tendency to coalesce the remaining oil droplets in the

water streams, making the droplets easier to separate

with the downstream equipment. Water skimmers use

gravity separation to remove the remaining oil from

produced water and are usually placed downstream of

separators or hydrocyclones.

A good rule of thumb is to use two types of water-treating

equipment for a gas facility and three types for an oil

facility in which the oil may be more difficult to separate.

For example, a water-treating system might consist of a

hydrocyclone, followed by a water skimmer and a gas

flotation cell.

References

Noteworthy papers in OnePetro

Use this section to list papers in OnePetro that a reader

who wants to learn more should definitely read

External links

Use this section to provide links to relevant material on

websites other than PetroWiki and OnePetro

See also

PEH:Oil_and_Gas_Processing

PEH:Water-

Treating_Facilities_in_Oil_and_Gas_Operations

Water treating facilities

Oil and gas processing

Gas facility

Storage tanks

Pumps

Emulsion Treating

Compressors

Oil and gas separators

Category

Categories:

4 Facilities design, construction, and operation NR

Help Read

Main page Random page

Interaction Tools Print

Founding Sponsor

Gold Sponsor

Gold Sponsor

Silver Sponsor

10 Tweet

6

Like

Share

This page was last modified on 6 July 2015, at 08:58.

Privacy policy About Disclaimer Help

Copyright 2012-2018, Society of Petroleum Engineers

Вам также может понравиться

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaОт EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaОценок пока нет

- Petroleum Refinery EngineeringДокумент9 страницPetroleum Refinery EngineeringMahtab SajnaniОценок пока нет

- SRS - New Edit On 11 09 2020Документ12 страницSRS - New Edit On 11 09 2020Rida ChОценок пока нет

- Professor Email SampleДокумент1 страницаProfessor Email SamplemehtabОценок пока нет

- Gas Business in IndiaДокумент42 страницыGas Business in IndiaSparshy Saxena75% (4)

- SLIDE7-Gas Condst ResДокумент14 страницSLIDE7-Gas Condst ResAnonymous nztG1AGvОценок пока нет

- 5092-2009 CNG Refuelling StationsДокумент44 страницы5092-2009 CNG Refuelling StationsTim WilsonОценок пока нет

- List of Terminals in The Country-UpdatedДокумент2 страницыList of Terminals in The Country-Updatedokey obiОценок пока нет

- LPG - Jilal EnterprisesДокумент18 страницLPG - Jilal EnterpriseshaidersarwarОценок пока нет

- Microbial DesulfurizationДокумент34 страницыMicrobial DesulfurizationMiguel RazquinОценок пока нет

- World LNG Plants & Terminals PDFДокумент3 страницыWorld LNG Plants & Terminals PDFlulut falaОценок пока нет

- Reservoir Potential EvaluationДокумент19 страницReservoir Potential EvaluationahouaОценок пока нет

- 1467 - 01 - Attachment 1 To Form 1 - QaqДокумент11 страниц1467 - 01 - Attachment 1 To Form 1 - QaqturboОценок пока нет

- SLIDE7-Gas Condst ResДокумент14 страницSLIDE7-Gas Condst Resolaseye100% (1)

- Liquefied Petroleum GasДокумент2 страницыLiquefied Petroleum GasjacuzzisОценок пока нет

- CHE353 Industrial Training - Final ReportДокумент18 страницCHE353 Industrial Training - Final ReportNishanth GuptaОценок пока нет

- Characteristics of LPGasДокумент8 страницCharacteristics of LPGasAnkita KulshreshthaОценок пока нет

- Presentation Michael HackingДокумент29 страницPresentation Michael HackingpoupoularyОценок пока нет

- Gas Breakthrough Control GBCДокумент1 страницаGas Breakthrough Control GBCamjath584Оценок пока нет

- Oil and Gas ProductionДокумент38 страницOil and Gas ProductionArun Kumar PОценок пока нет

- XtraView Installation Manual V2 0bДокумент35 страницXtraView Installation Manual V2 0bmgalosОценок пока нет

- Oil & Gas Industry ConversionsДокумент9 страницOil & Gas Industry ConversionsWagus GinanjarОценок пока нет

- Annual Report HELLENIC PETROLEUM 2010Документ77 страницAnnual Report HELLENIC PETROLEUM 2010AbdelmotelbElbannaОценок пока нет

- Kerangka Kerja Imtermal AuditДокумент5 страницKerangka Kerja Imtermal AuditkaranziaОценок пока нет

- Flaring and Venting Reduction Guideline (October Release)Документ71 страницаFlaring and Venting Reduction Guideline (October Release)Behnam HosseinzadehОценок пока нет

- IMANI Ghana Gas Initial Report 2013 AprilДокумент7 страницIMANI Ghana Gas Initial Report 2013 AprilIMANI Center for Policy and EducationОценок пока нет

- Petronas Pressol: Premium Grade Air Compressor OilsДокумент1 страницаPetronas Pressol: Premium Grade Air Compressor OilsMujeeb SiddiqueОценок пока нет

- Machines and Gadgets Used in Process Industries PDFДокумент15 страницMachines and Gadgets Used in Process Industries PDFAhmed H. ShehataОценок пока нет

- Reservoir Engineering Lecture Notes: G.C.EnyiДокумент39 страницReservoir Engineering Lecture Notes: G.C.EnyiRaimundoОценок пока нет

- Dragon OilДокумент34 страницыDragon OilDavinОценок пока нет

- RasGas Sustainability Report 2011 PDFДокумент78 страницRasGas Sustainability Report 2011 PDFjameskagomeОценок пока нет

- Questor Training Example 1Документ2 страницыQuestor Training Example 1Gary NgОценок пока нет

- Assignment 1Документ9 страницAssignment 1TejasОценок пока нет

- LPG Business StudiesДокумент56 страницLPG Business StudiesAubrey MothibiОценок пока нет

- Module 2.1 - Basic Flow Assurance PDFДокумент13 страницModule 2.1 - Basic Flow Assurance PDFAyuku KidaОценок пока нет

- Cost Premise - 2011Документ17 страницCost Premise - 2011Olusegun OyebanjiОценок пока нет

- Guidelines For National Gas Expansion Programme FinalДокумент11 страницGuidelines For National Gas Expansion Programme FinalEguono OmonighoОценок пока нет

- Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerДокумент6 страницDesign of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerHoàng KakaОценок пока нет

- Excel Tips Tricks Ebook DLДокумент30 страницExcel Tips Tricks Ebook DLSiamОценок пока нет

- CV of Res EngДокумент5 страницCV of Res Engyasir_irfan01Оценок пока нет

- LPG Energy IntegrationДокумент6 страницLPG Energy IntegrationBandaru KiranОценок пока нет

- Job Analysis: A Prelude To Recruitment and PlacementДокумент76 страницJob Analysis: A Prelude To Recruitment and PlacementJapjiv SinghОценок пока нет

- Gas Processing UnitsДокумент5 страницGas Processing UnitsBashirОценок пока нет

- LPG Presentation SlidesДокумент19 страницLPG Presentation SlidesLeed ENОценок пока нет

- MySep Software Brochure PDFДокумент7 страницMySep Software Brochure PDFoverlord5555Оценок пока нет

- Fuel Dispensing Pump TestingДокумент4 страницыFuel Dispensing Pump TestingAnonymous FW5PVUp50% (2)

- Cover Sheet For Individual Assignments: September'2009Документ19 страницCover Sheet For Individual Assignments: September'2009Povenesan Krishnan100% (1)

- ESD DiscussionДокумент4 страницыESD DiscussionNazim SalehОценок пока нет

- Project of MPOL LPGДокумент24 страницыProject of MPOL LPGroihyОценок пока нет

- BAT - 2 Ton LPG Tank at ThikaДокумент3 страницыBAT - 2 Ton LPG Tank at ThikamusewejamesoumaОценок пока нет

- Nigeria Factories Act, 1987Документ56 страницNigeria Factories Act, 1987Ethelbert AkwuruahaОценок пока нет

- Gas Pre TreatmentДокумент12 страницGas Pre TreatmentAnonymous bHh1L1100% (4)

- Data Sheet of Bitumen 10/20Документ1 страницаData Sheet of Bitumen 10/20Iqra Angels100% (1)

- Gas Processing Plant OperationsДокумент15 страницGas Processing Plant OperationschineduОценок пока нет

- Air Separation Unit QRAДокумент109 страницAir Separation Unit QRALi QiОценок пока нет

- Uniformance Process Studio PINДокумент4 страницыUniformance Process Studio PINM Sigit A MaskarebetОценок пока нет

- The Nigerian Gas Master Plan As Presented by NNPC in 2008Документ39 страницThe Nigerian Gas Master Plan As Presented by NNPC in 2008Adedire FisayoОценок пока нет

- Equipment Catalogue API Oil SeparatorДокумент2 страницыEquipment Catalogue API Oil Separatorbesant vargheesОценок пока нет

- 4-dmsg-14-2-g2 Questionnaire Subcontractors SmallДокумент4 страницы4-dmsg-14-2-g2 Questionnaire Subcontractors SmallRaghavan VenkatramanОценок пока нет

- RX Marine International: Ferroxyl Test Kit For Free IRONДокумент2 страницыRX Marine International: Ferroxyl Test Kit For Free IRONRaghavan VenkatramanОценок пока нет

- Key Changes in API 571-2020 Part 1Документ66 страницKey Changes in API 571-2020 Part 1Raghavan Venkatraman100% (4)

- Vacuum Relief Valve: Product Literature & Maintenance GuidelinesДокумент17 страницVacuum Relief Valve: Product Literature & Maintenance GuidelinesRaghavan VenkatramanОценок пока нет

- Raghavan.V: Skype Id: Raghavan - Venkatraman1Документ15 страницRaghavan.V: Skype Id: Raghavan - Venkatraman1Raghavan VenkatramanОценок пока нет

- 0901b80380959cc7 PDFДокумент2 страницы0901b80380959cc7 PDFRaghavan VenkatramanОценок пока нет

- 021 - Naptha Hydrotreating Unit (NHT)Документ6 страниц021 - Naptha Hydrotreating Unit (NHT)Raghavan VenkatramanОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 023 - Isomerization Unit (ISOM)Документ5 страниц023 - Isomerization Unit (ISOM)Raghavan VenkatramanОценок пока нет

- Questions For RBI Engineer InterviewДокумент1 страницаQuestions For RBI Engineer InterviewRaghavan VenkatramanОценок пока нет

- Qualified Welders ListДокумент3 страницыQualified Welders ListRaghavan VenkatramanОценок пока нет

- Welder Qualification MatrixДокумент1 страницаWelder Qualification MatrixRaghavan VenkatramanОценок пока нет

- Most Important Terms & Conditions: Schedule of ChargesДокумент11 страницMost Important Terms & Conditions: Schedule of ChargesRaghavan VenkatramanОценок пока нет

- Api 571 Questions PDFДокумент18 страницApi 571 Questions PDFRaghavan Venkatraman100% (1)

- 0901b80380959cc7 PDFДокумент2 страницы0901b80380959cc7 PDFRaghavan VenkatramanОценок пока нет

- API-571 Chart - UdayДокумент11 страницAPI-571 Chart - UdayRaghavan Venkatraman100% (1)

- CuproBraze 34Документ2 страницыCuproBraze 34Vinod SaleОценок пока нет

- 2007 LE Mayer TwleveДокумент5 страниц2007 LE Mayer TwleveVictor ZhicayОценок пока нет

- Computer Simulation of Intelligent Building FacadesДокумент291 страницаComputer Simulation of Intelligent Building FacadesDobri StefОценок пока нет

- CH 0 Cleaning Cross Refference Table DREW AMEROIDДокумент36 страницCH 0 Cleaning Cross Refference Table DREW AMEROIDPavel ViktorОценок пока нет

- Worksheet Cellular Respiration#2 - Ch9 PDFДокумент6 страницWorksheet Cellular Respiration#2 - Ch9 PDFTaniaBarrios-ChongОценок пока нет

- Complex Systems in Finance and EconometricsДокумент19 страницComplex Systems in Finance and EconometricsJuliana TessariОценок пока нет

- Neraca MassaДокумент15 страницNeraca MassaFrengky Akmil PutraОценок пока нет

- Condorled Reflector Technical SheetДокумент2 страницыCondorled Reflector Technical SheetDiseño Lexu LightОценок пока нет

- Chemistry Education in The 21st CenturyДокумент106 страницChemistry Education in The 21st CenturyAbhishek BansalОценок пока нет

- Question Paper CodeДокумент4 страницыQuestion Paper CodeBalaji ArunОценок пока нет

- Mechanical Properties of MaterialsДокумент3 страницыMechanical Properties of MaterialsTiras Ngugi0% (1)

- ARMENANTE Ny Adsorption With Granular Activated Carbon PDFДокумент103 страницыARMENANTE Ny Adsorption With Granular Activated Carbon PDFpippo2378793Оценок пока нет

- Alat (GPT) Fs (Ifcc Mod.) : Mindray BS300Документ1 страницаAlat (GPT) Fs (Ifcc Mod.) : Mindray BS300armasfernandoОценок пока нет

- Chemical Analysis of Red Lead: Standard Test Methods ofДокумент4 страницыChemical Analysis of Red Lead: Standard Test Methods ofAmer AmeryОценок пока нет

- Module 6 - Ash, Water, Extractive and Crude Fiber Content DeterminationДокумент23 страницыModule 6 - Ash, Water, Extractive and Crude Fiber Content DeterminationPRINCESS NOELLEE TRAYVILLAОценок пока нет

- Unit 6 - Introduction To Volumetric Analysis - Subjects 0 PDFДокумент92 страницыUnit 6 - Introduction To Volumetric Analysis - Subjects 0 PDFSiti AmirahОценок пока нет

- StereochemistryДокумент52 страницыStereochemistryTimmyОценок пока нет

- ChemicalsДокумент72 страницыChemicalsMrudulaОценок пока нет

- HY10 1630US 5 2012-Diaphragm AccumulatorsДокумент6 страницHY10 1630US 5 2012-Diaphragm AccumulatorsAlejandro GilОценок пока нет

- Void Swelling StraalsundДокумент7 страницVoid Swelling StraalsundAzif Ali MoothantevileyilОценок пока нет

- Factors Influencing ToxicityДокумент7 страницFactors Influencing ToxicityderrickОценок пока нет

- Pharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)Документ13 страницPharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)wangzahОценок пока нет

- Mil-B-007883 Brazing - Cancelled - See Cancellation NoteДокумент26 страницMil-B-007883 Brazing - Cancelled - See Cancellation NoteChris NenovОценок пока нет

- Essential Variables API 1104Документ4 страницыEssential Variables API 1104Madidj_2014Оценок пока нет

- Four Steps To Effective Pigment Dispersions Jadel Baptista DCC LanscoДокумент5 страницFour Steps To Effective Pigment Dispersions Jadel Baptista DCC LanscoEyad AlsheiikhОценок пока нет

- Fuel Cells Article in ISOFT by Inderraj GulatiДокумент6 страницFuel Cells Article in ISOFT by Inderraj GulatiInderraj_Gulati100% (1)

- Gate 2011Документ8 страницGate 2011Bhuva_janaОценок пока нет

- Standard Enthalpy of HCLДокумент3 страницыStandard Enthalpy of HCLGarvit ChopraОценок пока нет

- How To Eliminatdadde Outgassing, The Powder Coating Faux PasДокумент2 страницыHow To Eliminatdadde Outgassing, The Powder Coating Faux PasSandra ArianaОценок пока нет

- Alkaline Ionised Water BookletДокумент25 страницAlkaline Ionised Water Bookletmichelle_wong_6Оценок пока нет