Академический Документы

Профессиональный Документы

Культура Документы

FRP Itp

Загружено:

HrishikesanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FRP Itp

Загружено:

HrishikesanАвторское право:

Доступные форматы

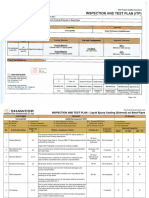

QUALITY PLAN Client: QUALITY PLAN FOR GRP TANKS

PRODUCT Contractor:

Project:

Spec: ; Criticality Rating: PO#:

Identified as category II As per BS4994

Sl. Parameter to be Acceptance Criteria Frequency of Responsibility Record Ref. Standard Client/TPI

No. Inspected / Tested / Verified Check for Check details in

1.0 Pre Inspection Meeting PO, PR, Approved Drawing N/A Sr. Engineer H H

2 Design calculations BS4994 N/A Sr. Engineer BS 4994 H A

3 Tank drawing BS4994 N/A Sr. Engineer BS 4994 H A

4 Lamination Procedure Company internal document N/A Sr. Engineer BS4994 P R

5 Laminators qualification Company internal document N/A Prod. Manager BS4994 P R

6 Calibration of QC Instruments Once a Year QA / QC In-Charge As per Third Party Referencing P R

7 Raw Material Verification :

A.LINER : Vinyl Ester Resin Company METHOD

: Gel Time STATEMENT

: Viscocity P R

Once per batch QA / QC In-Charge

: Volatile Content

: HDT of Cured Resin HDT as per Manufacturer's

As per manufacturers Test Technical Brouchers

certificates/Technical Papers

B. ISO Phthalic Resin : Gel Time Once per batch QA / QC In-Charge Company METHOD

: Viscocity STATEMENT P R

: Volatile Content

: HDT of Cured Resin HDT as per Manufacturer's

As per manufacturers Test Technical Brouchers

certificates/Technical Papers

C. Glass Fibre CSM

: Mass per unit Area per consignment QA / QC In-Charge Company METHOD P R

: % Moisture Content STATEMENT

: % Loss on Ignition

As per manufacturers Test

certificates/Technical Papers

D. Glass Fibre Rovings

: Mass per unit Area per consignment QA / QC In-Charge Company METHOD P R

: % Moisture Content STATEMENT

As per manufacturers Test

certificates/Technical Papers

E. C-Glass Veil

: Mass per unit Area per consignment QA / QC In-Charge Company METHOD P R

: % Moisture Content STATEMENT

: % Loss on Ignition

As per manufacturers Test

certificates/Technical Papers

8 Product Inspection: P W

A. Mould / Patteren Inspection As per Approved Drawing Each mould/mandrel

Dimension tolerence as in Table

5.3.5.1 or 10% as per

B. Dimensions of Vessel As per Approved Drawing Each tank Prodn. Manager & QA manufacturer

C. Visual Inspection Each tank / QC In-Charge ASTM D2563-level-III

i. Tank Shell / bottom / Top

ii. GRP Cage and Ladder

iii. GRP Chair bracket

D. Barcol Hardness 35-45 Every tank ASTM D 2583

E. Laminate Glass Content BS4994 Clause 6.4.1 Each tank shell Prodn. Manager P R

( By weight ) & QA/QC Incharge

F. Lamination Sequence As per approved Each Tank Prodn. Manager BS4994 P R

design

G. Acetone Sensitivity Test BS4994 Each Tank

and on the top coat QA / QC In-Charge App. B clause B.18 P R

of BS 4994

I. Marking Name Plate Details As per approved drawing Each Tank Prodn. Manager REPORT H W

J. Lifting Lug

i. Visual Inspection of Lug Each Component Sr. Engineer H W

Dimensional tolerance of 10% is

ii. Dimensional Inspection of Lug Each Component acceptable

9 Ultimate tensile strength and modulus of BS4994 Once QA/QC Incharge BS2782-Method P W

individual laminates of all the constituent 1003

reinforcing types of glass fibre seperately

prepared and not the cut out from the tank.

10 Lap Shear Strength BS 4994/ Specimen as per Each Tank QA / QC In-Charge BS 4994 P W

(Laminate sequence as per shell design) BS 4994 App.B Clause B9.2 App.B Clause B.9

11 Nozzle Orientation & Manhole Positions As per Approved Drawing every tank Prodn. Manager Approved P W

Drawing

12 i. Laminate thickness and Bond Length As per Approved Drawing Every Tank Prodn. Manager AO Method Statement P R

QA / QC In-Charge QMS/WI/GRP/QC/02

ii. External Protection Layer As per Approved Drawing Every Tank Prodn. Manager P R

QA / QC In-Charge

13 Hydro Test No leakage during test from Every tank Prodn. Manager P W

( Duly filled with Water for 24 hrs) any part of the vessel &

14 i. Visual inpection ( external + internal ) ASTM 2563 QA / QC In-Charge P W

ii. Final Dimensional Inspection Approved drawing QA / QC In-Charge P W

Method Statement

15 Addition of UV Stabilizer As per Vendor Spec Every tank Prodn. Manager P W

(Hostavin N 24)

16 Transportation, Handling, Storage and Each Tank BS 4994 P R

Installation Manual

17 RELEASE OF MATERIAL: P H

Product Release - Product shall be released after completion of all testing and accepting the products as per the acceptance criteria.

+ All test reports, - The delivery note (D.O.) shall accompany test certificate issued by Laboratory and signed by the signatories from production,

results,etc. sales and quality control. With a crated box of spare items like gaskets, nuts and bolts

18 Spare Items, Gasket, MH Cover, Bolts and Material Certificate as per manufacturer. H R

Nuts Visual Inpection of the items as per the approved drawing and a separate report will be submitted along with the delivery note

19 INSPECTION RELEASE NOTE Approved drawing, PO, PR IRN Approved drawing, PO, PR R H

Note : P - Perform, R: Review, W : Witness, H - Hold, A - Approve, R / W - Random Witness

Вам также может понравиться

- Sample FRP Tank SpecificationДокумент8 страницSample FRP Tank Specificationapparaokr100% (1)

- Vertical FRP Tank Spec 11 06Документ9 страницVertical FRP Tank Spec 11 06TECH100% (1)

- Surface Preparation and Painting Procedure Rev 01 PDFДокумент23 страницыSurface Preparation and Painting Procedure Rev 01 PDFNaceur Turki100% (3)

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Документ1 страница201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Specification For FRP TankДокумент10 страницSpecification For FRP TankKyaw Kyaw Aung75% (4)

- Method of Statement For FRP Lining TankДокумент5 страницMethod of Statement For FRP Lining Tankmoytabura96100% (3)

- GRE Pipes Inspection Test PlanДокумент6 страницGRE Pipes Inspection Test PlanMat RidhanОценок пока нет

- RTP 1 A Standard For FRP Storage Tanks PDFДокумент32 страницыRTP 1 A Standard For FRP Storage Tanks PDFDaniel Pagliardini100% (2)

- Structural Wall Bulging IssueДокумент8 страницStructural Wall Bulging IssueJitender Tanwar100% (1)

- Job Procedure For Pipe Line Field Joint Coating-IoclДокумент3 страницыJob Procedure For Pipe Line Field Joint Coating-IoclVineet Khanduri0% (1)

- Amiantit. Field Installation ProcedureДокумент37 страницAmiantit. Field Installation ProcedureABAID ULLAHОценок пока нет

- Astm C 582Документ7 страницAstm C 582Tanktech TanktechОценок пока нет

- There Are Three Main Groups of Resin:: Polyester ResinsДокумент1 страницаThere Are Three Main Groups of Resin:: Polyester ResinsmukeshОценок пока нет

- GRP Bonding ProcedureДокумент19 страницGRP Bonding Proceduremahi1437100% (1)

- Packing Procedure (STEEL STRUCTURE)Документ20 страницPacking Procedure (STEEL STRUCTURE)Abdulrahman AlnasharОценок пока нет

- Test Pack Format: Contents of Hydrostatic Test PackagesДокумент2 страницыTest Pack Format: Contents of Hydrostatic Test PackagesmiteshОценок пока нет

- Method Statement For Application of GRP Lining Inside Water TankДокумент5 страницMethod Statement For Application of GRP Lining Inside Water TankNaveed Ahmed Get-InfoОценок пока нет

- WSM-HIP-06 Hot Insulation Procedure PDFДокумент21 страницаWSM-HIP-06 Hot Insulation Procedure PDFMiky Andrean100% (1)

- MS For Tank Installation - R1Документ6 страницMS For Tank Installation - R1alvinchuan100% (1)

- TDS For Repair Process For Galvanized ItemsДокумент4 страницыTDS For Repair Process For Galvanized ItemsPappu Kishore Kumar100% (2)

- Location Thickness Type of LiningДокумент7 страницLocation Thickness Type of LiningPaul PhiliphsОценок пока нет

- Itp Concrete CoatingДокумент4 страницыItp Concrete Coatingkaml100% (1)

- Field Lamination Method StatementДокумент13 страницField Lamination Method Statementkais rguigui0% (1)

- Welding Procedure PIPE HDPE - Rev.03Документ29 страницWelding Procedure PIPE HDPE - Rev.03DORBANI NedjmeddineОценок пока нет

- Kalseng 2 CFSPP Painting Inspection ReportДокумент2 страницыKalseng 2 CFSPP Painting Inspection ReportKilerz 91100% (2)

- FRP Fabrication ManualДокумент26 страницFRP Fabrication ManualTanmay Majhi100% (1)

- Checklist - Expansion Joint - Non Pressure Parts Drgs.Документ3 страницыChecklist - Expansion Joint - Non Pressure Parts Drgs.Ramalingam Prabhakaran100% (2)

- Tank Specification - Fiberglass Tanks 0408Документ13 страницTank Specification - Fiberglass Tanks 0408shankarkl100% (2)

- Wrapping Coating ProcedureДокумент5 страницWrapping Coating Procedureshantanu kumar100% (1)

- BS 6464 1984 Reinforced Plastics Pipes Fittings and Joints For Process Plants PDFДокумент60 страницBS 6464 1984 Reinforced Plastics Pipes Fittings and Joints For Process Plants PDFDavid FonsecaОценок пока нет

- UG PIPING COATINGДокумент10 страницUG PIPING COATINGcloud23Оценок пока нет

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureДокумент34 страницы000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- FRP Tank Manufacturing MethodsДокумент13 страницFRP Tank Manufacturing Methodsrangabhama9214Оценок пока нет

- Fiberglass Coating SpecДокумент3 страницыFiberglass Coating Specponnivalavans_994423100% (1)

- Holiday TestДокумент2 страницыHoliday TestnationalfoxОценок пока нет

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Документ3 страницыInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0ResearcherОценок пока нет

- MOS-RO Pressure Vessel InstallationДокумент16 страницMOS-RO Pressure Vessel InstallationShams TabrezОценок пока нет

- Method Statement Installation Os Static Equipment and InternalsДокумент24 страницыMethod Statement Installation Os Static Equipment and InternalsAjin SОценок пока нет

- FRP & GRE Inspection Guide Fiber Reinforced PlasticДокумент31 страницаFRP & GRE Inspection Guide Fiber Reinforced PlasticMohd Amani100% (1)

- SA MP LE: Company NameДокумент4 страницыSA MP LE: Company NameAnonymous P8XHEXyIZLОценок пока нет

- Procedure for holiday testingДокумент2 страницыProcedure for holiday testingSaptarshi MandalОценок пока нет

- T-4.896.425 - C01 - MS ITP For Hot Cold Insulation WorksДокумент20 страницT-4.896.425 - C01 - MS ITP For Hot Cold Insulation Worksshahid imamОценок пока нет

- Testing and Commissioning of GRP Water TankДокумент6 страницTesting and Commissioning of GRP Water TankEN ES VH CaliwagОценок пока нет

- Itp For Painting WorksДокумент28 страницItp For Painting WorksAhmed saberОценок пока нет

- Inspection and Test Plan For Above Ground FRP Piping Fabrication & Erection at FieldДокумент3 страницыInspection and Test Plan For Above Ground FRP Piping Fabrication & Erection at FieldGohel100% (1)

- GASOLINE STORAGE TANK INSPECTION AND TEST PLANДокумент1 страницаGASOLINE STORAGE TANK INSPECTION AND TEST PLANAmer Y KОценок пока нет

- Itp-Fbe Pipe CoatingДокумент4 страницыItp-Fbe Pipe CoatingpertmasterОценок пока нет

- Welder and Welder Operator Qualification Record FormДокумент1 страницаWelder and Welder Operator Qualification Record FormNanaba Nanayaw DwomohОценок пока нет

- ASTM D2563 Visual Inspection GRP Laminates PDFДокумент24 страницыASTM D2563 Visual Inspection GRP Laminates PDFbiondimi100% (1)

- WSA Line 5 Anchor Bolt Tightening Inspection ReportДокумент1 страницаWSA Line 5 Anchor Bolt Tightening Inspection ReportMahfudRido'iRonggomaniaОценок пока нет

- Attachment 5 - Painting and Coating System Including Colour CodeДокумент54 страницыAttachment 5 - Painting and Coating System Including Colour CodeVan Anh0% (1)

- Bonstrand PipeДокумент24 страницыBonstrand Pipejayhuacat7743Оценок пока нет

- Inspection and Test Plan For Piping (PP/FRP Piping)Документ2 страницыInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- Itp For Piping QPДокумент4 страницыItp For Piping QPRejoy baby100% (2)

- Protect Industrial Chemical Tanks Under 40 CharactersДокумент16 страницProtect Industrial Chemical Tanks Under 40 CharactersChonTicha'100% (1)

- FRP Above Ground Installation ManualДокумент32 страницыFRP Above Ground Installation ManualCarlos GutierrezОценок пока нет

- Quality Assurance Plan for Metallic Expansion Joint ManufacturingДокумент1 страницаQuality Assurance Plan for Metallic Expansion Joint Manufacturingdemas100% (1)

- Shop Inspection and Test Plan for FRP Water TroughДокумент29 страницShop Inspection and Test Plan for FRP Water TroughEljo AndsОценок пока нет

- BSIBV-ITP-07-2 PP ITP For 3LPP Coating DPE Rev. 0Документ10 страницBSIBV-ITP-07-2 PP ITP For 3LPP Coating DPE Rev. 0AMALENDU PAULОценок пока нет

- BSIBV-ITP-09-1 For Liquid Epoxy Coating On Fittings Rev. 0Документ5 страницBSIBV-ITP-09-1 For Liquid Epoxy Coating On Fittings Rev. 0AMALENDU PAULОценок пока нет

- Lets PDFДокумент20 страницLets PDFAugusto Manuel Inga SánchezОценок пока нет

- ES 49BranchConnections PDFДокумент7 страницES 49BranchConnections PDFprabuharan89Оценок пока нет

- Pickling HandbookДокумент20 страницPickling HandbookRhona100% (1)

- Composites For Wind Energy Applications: National Conference On Recent Advances in CompositesДокумент12 страницComposites For Wind Energy Applications: National Conference On Recent Advances in CompositesHrishikesanОценок пока нет

- Guidance On The Application of ISO/IEC 17020: IAF/ILAC-A4:2004Документ19 страницGuidance On The Application of ISO/IEC 17020: IAF/ILAC-A4:2004certigaseslospatios100% (1)

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsДокумент33 страницыWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsHrishikesanОценок пока нет

- East Coast Fibreglass guide to estimating resin and fiberglass quantitiesДокумент2 страницыEast Coast Fibreglass guide to estimating resin and fiberglass quantitiesben100% (1)

- Development, Manufacturing and Applications of Fiber Reinforced Polymer (FRP) Composite MaterialsДокумент30 страницDevelopment, Manufacturing and Applications of Fiber Reinforced Polymer (FRP) Composite MaterialsdeepakshreeОценок пока нет

- Chemical Resistance Chart FRPДокумент36 страницChemical Resistance Chart FRPHrishikesanОценок пока нет

- East Coast Fibreglass guide to estimating resin and fiberglass quantitiesДокумент2 страницыEast Coast Fibreglass guide to estimating resin and fiberglass quantitiesben100% (1)

- Tech LinksДокумент1 страницаTech LinksHrishikesanОценок пока нет

- General Corrosion Resistance LG CCДокумент20 страницGeneral Corrosion Resistance LG CChycromeОценок пока нет

- Consumables Classification Tables: AS/NZS 1553 Part 1-1995 Covered Electrodes For Welding Low Carbon SteelДокумент15 страницConsumables Classification Tables: AS/NZS 1553 Part 1-1995 Covered Electrodes For Welding Low Carbon SteelelmiraОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Measurement of Weld-Metal FerriteДокумент2 страницыMeasurement of Weld-Metal FerriteHrishikesanОценок пока нет

- Weldability of SteelsДокумент11 страницWeldability of SteelsHrishikesanОценок пока нет

- Atlas Metals HandbookДокумент45 страницAtlas Metals HandbookJim GrayОценок пока нет

- Preparation Instructions For Valves To Be Fire Tested: Southwest Research InstituteДокумент7 страницPreparation Instructions For Valves To Be Fire Tested: Southwest Research InstituteHrishikesanОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Pressure Vessel Fabrication InspectionДокумент82 страницыPressure Vessel Fabrication InspectionHrishikesan100% (3)

- Definitions: - HAZ (Heat Effected Zone) - Heat Input - Residual StressДокумент65 страницDefinitions: - HAZ (Heat Effected Zone) - Heat Input - Residual StressHrishikesanОценок пока нет

- Guidance On The Application of ISO/IEC 17020: IAF/ILAC-A4:2004Документ19 страницGuidance On The Application of ISO/IEC 17020: IAF/ILAC-A4:2004certigaseslospatios100% (1)

- Document No. Cswip-Iso-Ndt-11/93-R Requirements For The Certification of Personnel Engaged in Non-Destructive TestingДокумент12 страницDocument No. Cswip-Iso-Ndt-11/93-R Requirements For The Certification of Personnel Engaged in Non-Destructive TestingHrishikesanОценок пока нет

- BS en 499Документ15 страницBS en 499Hrishikesan100% (2)

- Guidelines For Welding: ZERON 100 Super Duplex Stainless SteelДокумент16 страницGuidelines For Welding: ZERON 100 Super Duplex Stainless SteelHrishikesanОценок пока нет

- HardnessДокумент21 страницаHardnessJerry Man UtdОценок пока нет

- Weld Failure Causes and PreventionДокумент5 страницWeld Failure Causes and PreventionMidhun K ChandraboseОценок пока нет

- Weld Defects PDFДокумент38 страницWeld Defects PDFIshack MohammedОценок пока нет

- Weldability of Steels PDFДокумент40 страницWeldability of Steels PDFHrishikesanОценок пока нет

- Dr. Blyden: Chronic Obstructive Pulmonary Disease (Copd)Документ63 страницыDr. Blyden: Chronic Obstructive Pulmonary Disease (Copd)Blyden NoahОценок пока нет

- Fundamentals of VolleyballДокумент2 страницыFundamentals of VolleyballLawrence CezarОценок пока нет

- Metric Heavy Hex Nuts: ASME B18.2.4.6M-2010Документ16 страницMetric Heavy Hex Nuts: ASME B18.2.4.6M-2010CarlitosОценок пока нет

- SB632B Connecting Rod IdentificationДокумент20 страницSB632B Connecting Rod IdentificationLuisCheukoCheuquianОценок пока нет

- 03.can-Bus and Sae-Bus j1939 - CatДокумент29 страниц03.can-Bus and Sae-Bus j1939 - CatEdison Pfoccori BarrionuevoОценок пока нет

- Chemistry How To Make Stuff PDFДокумент184 страницыChemistry How To Make Stuff PDF2967449CEEОценок пока нет

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaДокумент3 страницыRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesОценок пока нет

- Assignment #1: 1 HgjyygbykvrfДокумент1 страницаAssignment #1: 1 HgjyygbykvrfJuan Sebastian ArangoОценок пока нет

- Gravimetric Analysis Lab ReportДокумент5 страницGravimetric Analysis Lab Reportclaire_miller_16100% (1)

- Data Sheet ID FanДокумент5 страницData Sheet ID FanrudiawanОценок пока нет

- ASIAN LIVESTOCK PERSPECTIVESДокумент18 страницASIAN LIVESTOCK PERSPECTIVESMuadz AbdurrahmanОценок пока нет

- Purification of Morphologically and Functionally Intact Human Basophils To Near HomogeneityДокумент9 страницPurification of Morphologically and Functionally Intact Human Basophils To Near HomogeneitySinaí GutierrezОценок пока нет

- Lab Journal 4 14032023 104921amДокумент8 страницLab Journal 4 14032023 104921amHammad MashwaniОценок пока нет

- Mahindra Powertrain - Market StrategyДокумент4 страницыMahindra Powertrain - Market StrategyEshan KapoorОценок пока нет

- Difference Between AerospaceДокумент2 страницыDifference Between AerospaceSyawalMaulanaОценок пока нет

- Learning To Solve Multiple Partial Differential Equations With DNNДокумент4 страницыLearning To Solve Multiple Partial Differential Equations With DNNVichara PoolsОценок пока нет

- DUB01CB Eng PDFДокумент4 страницыDUB01CB Eng PDFAnonymous hj273CMОценок пока нет

- Shariff NДокумент4 страницыShariff NKruu ChinnuОценок пока нет

- JMJ Marist Brothers Notre Dame of Marbel University Integrated Basic Education Department City of Koronadal, South CotabatoДокумент13 страницJMJ Marist Brothers Notre Dame of Marbel University Integrated Basic Education Department City of Koronadal, South CotabatoNestor Gerotape DiosanaОценок пока нет

- Secretary Birds: Fascinating Hunters of the African SavannahДокумент32 страницыSecretary Birds: Fascinating Hunters of the African Savannahpwint phyu kyawОценок пока нет

- Ghost Events in Optical Time - NewДокумент3 страницыGhost Events in Optical Time - NewsekutunetОценок пока нет

- 1296169395JH 122310 - WebДокумент12 страниц1296169395JH 122310 - WebCoolerAdsОценок пока нет

- Mycotoxin Test ProcedureДокумент3 страницыMycotoxin Test ProcedureKishenthi KerisnanОценок пока нет

- Type 2 Diabetes MellitusДокумент6 страницType 2 Diabetes MellitusJoy NisoladaОценок пока нет

- Larrabee JChem Educ 1990,67,267Документ3 страницыLarrabee JChem Educ 1990,67,267κ.μ.α «— Brakat»Оценок пока нет

- Hyundai Elevator Manual Helmon 2000 InstructionДокумент27 страницHyundai Elevator Manual Helmon 2000 InstructionReynold Suarez100% (1)

- Gold Grade of Epithermal Gold Ore at Lamuntet, Brang Rea, West Sumbawa District, West Nusa Tenggara Province, IndonesiaДокумент10 страницGold Grade of Epithermal Gold Ore at Lamuntet, Brang Rea, West Sumbawa District, West Nusa Tenggara Province, Indonesiasukri arjunaОценок пока нет

- Particle Technology Che Calculations Separation Processes Heat and Mass TransferДокумент1 страницаParticle Technology Che Calculations Separation Processes Heat and Mass TransferAduchelab AdamsonuniversityОценок пока нет

- 2009 ESC Guidelines On EndocarditisДокумент45 страниц2009 ESC Guidelines On EndocarditisDaondy Friarsa SoehartoОценок пока нет

- (Teubner Studienbücher Chemie) Brian R. Eggins (Auth.) - Biosensors - An Introduction (1996, Vieweg+Teubner Verlag) PDFДокумент221 страница(Teubner Studienbücher Chemie) Brian R. Eggins (Auth.) - Biosensors - An Introduction (1996, Vieweg+Teubner Verlag) PDFRicardo PatrickОценок пока нет