Академический Документы

Профессиональный Документы

Культура Документы

Frame and Bumpers

Загружено:

Pelis CloneОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Frame and Bumpers

Загружено:

Pelis CloneАвторское право:

Доступные форматы

PL FRAME AND BUMPERS 13 - 1

FRAME AND BUMPERS

CONTENTS

page page

BUMPERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 FRAMES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

BUMPERS

INDEX

page page

REMOVAL AND INSTALLATION REAR BUMPER FASCIA . . . . . . . . . . . . . . . . . . . 1

FRONT BUMPER FASCIA . . . . . . . . . . . . . . . . . . 1 REAR BUMPER REINFORCEMENT . . . . . . . . . . . 2

FRONT BUMPER REINFORCEMENT . . . . . . . . . . 1

REMOVAL AND INSTALLATION INSTALLATION

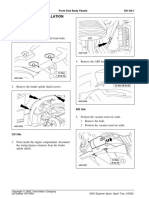

(1) Position fascia on vehicle.

FRONT BUMPER FASCIA (2) Install bolts holding fascia to bottom of bumper

reinforcement.

REMOVAL (3) Install bolts holding fascia to bumper reinforce-

(1) Remove nuts holding front bumper fascia ment forward of radiator (Fig. 1).

bracket to bottom of fender forward of front wheels. (4) Install screws holding front fascia to inner

(2) Remove screws holding front fascia to inner wheelhouse.

wheelhouse. (5) Install radiator grille, refer to Group 23, Body

(3) Remove bolts holding fascia to bumper rein- for proper procedures.

forcement forward of radiator (Fig. 1).

(4) Remove bolts holding fascia to bottom of FRONT BUMPER REINFORCEMENT

bumper reinforcement.

(5) Separate fascia from vehicle. REMOVAL

(1) Remove front fascia.

(2) Support bumper reinforcement on a suitable

lifting device.

(3) Remove nuts holding reinforcement to radiator

closure panel (Fig. 2).

(4) Separate bumper reinforcement from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR BUMPER FASCIA

REMOVAL

(1) Release trunk lock and open trunk lid.

(2) Remove bolts holding fascia to tail closure

panel.

(3) Remove push–in fasteners holding fascia to

Fig. 1 Front Bumper Fascia bottom of rear bumper reinforcement (Fig. 3).

13 - 2 FRAME AND BUMPERS PL

REMOVAL AND INSTALLATION (Continued)

Fig. 2 Front Bumper Reinforcement

Fig. 3 Rear Bumper Fascia

(4) Remove bolts holding fascia bracket to lower

quarter panels. (4) Separate bumper reinforcement from vehicle.

(5) Separate fascia from vehicle.

INSTALLATION

(1) Position fascia on vehicle.

(2) Install bolts holding fascia bracket to lower

quarter panels.

(3) Install push–in fasteners holding fascia to bot-

tom of rear bumper reinforcement (Fig. 3).

(4) Install bolts holding fascia to tail closure panel.

REAR BUMPER REINFORCEMENT

REMOVAL

(1) Remove rear fascia.

(2) Support bumper reinforcement on a suitable

lifting device.

(3) Remove nuts holding reinforcement to rear clo- Fig. 4 Rear Bumper Reinforcement

sure panel (Fig. 4).

INSTALLATION

Reverse the preceding operation.

PL FRAME AND BUMPERS 13 - 3

FRAMES

INDEX

page page

REMOVAL AND INSTALLATION TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . 10

FRONT SUSPENSION CROSSMEMBER . . . . . . . 3

SPECIFICATIONS

STRUCTURAL DIMENSIONS . . . . . . . . . . . . . . . . 4

REMOVAL AND INSTALLATION (3) Remove front wheels from vehicle.

(4) Remove pinch bolts holding front ball joints to

FRONT SUSPENSION CROSSMEMBER spindles.

(5) Separate ball joints from spindles.

WARNING: IF SUSPENSION CROSSMEMBER IS (6) Position a suitable lifting device under the

REPLACED DUE TO COLLISION DAMAGE, INSPECT crossmember.

THE STEERING COLUMN TO STEERING GEAR (7) Remove bolts holding suspension crossmember

COUPLING FOR DAMAGE. REFER TO GROUP 19, to frame rails above lower control arms (Fig. 1).

STEERING FOR INSTRUCTIONS. (8) Remove bolts holding crossmember to frame

torque boxes and allow front of crossmember to

Before removing front suspension crossmem- swing down.

ber, index mark location of crossmember on (9) Remove bolts holding steering gear to cross-

frame to aid installation. member.

The front suspension crossmember must be prop- (10) Separate steering gear from crossmember.

erly installed to achieve design camber, caster set- (11) Tie steering gear to a suitable structure above

tings and wheel stagger. The crossmember can be to support gear after crossmember is removed.

installed out of position on the frame rails due to its (12) Separate front suspension crossmember from

design. Bolts and cage nuts hold the rear of the vehicle.

crossmember to the frame torque boxes. Bolts and

J-nuts hold the front of the crossmember to the

frame rails. No designed in locating device is used to

position the crossmember in the vehicle. Before

removing the crossmember mark the frame torque

box around the rear mounting location to aid instal-

lation. A crossmember that is removed during service

must be installed in the same position from which it

was removed. To verify that crossmember is in the

proper position, refer to the dimensions provided.

Front end dimensions are gauged from the principal

locating point (PLP) holes located under the frame

torque boxes rearward of the front wheels. After

removal and installation of the crossmember is per-

formed, verify that front suspension alignment is

within specifications. If camber, caster settings and

wheel stagger is not within specifications, loosen and

Fig. 1 Front Suspension Crossmember

reposition crossmember to bring suspension within

specifications. Refer to Group 2, Front Suspension INSTALLATION

and Driveshaft for additional information. If a new crossmember is to be installed, transfer

stabilizer bar and lower control arms from original

REMOVAL crossmember. Refer to Group 2, Suspension and

(1) Hoist and support vehicle on safety stands. Driveshaft for proper procedures.

(2) Using a suitable marking device, mark the out- (1) Place front suspension crossmember in position

line of the suspension crossmember on the frame on vehicle.

torque box around the rear mounting location. (2) Remove tie device supporting steering gear.

13 - 4 FRAME AND BUMPERS PL

REMOVAL AND INSTALLATION (Continued)

(3) Place steering gear in position on crossmember. (14) Install front wheels on vehicle.

(4) Install bolts to hold steering gear to crossmem- (15) Lower vehicle and verify front suspension

ber. alignment. If camber, caster settings and wheel stag-

(5) Position lifting device under the crossmember. ger is not within specifications, loosen and reposition

(6) Lift crossmember to frame rails. crossmember to bring suspension within specifica-

(7) Engage bolts to hold crossmember rear mounts tions. Refer to Group 2, Front Suspension and Drive-

into cage nuts in the frame torque boxes. Do not shaft for additional information.

tighten bolts.

(8) Install bolts to hold crossmember to frame rails

above lower control arms. SPECIFICATIONS

(9) Lower and remove lifting device.

(10) Align crossmember to index marks. Verify STRUCTURAL DIMENSIONS

that crossmember is at the specified dimensions from Structural dimensions are listed in metric mea-

the PLPs (Fig. 2). surements. All dimensions are from center to center

(11) Tighten bolts to hold suspension crossmember of Principal Locating Point (PLP), or from center to

to frame rails and torque boxes. center of PLP and fastener location (Fig. 3), (Fig. 4),

(12) Insert ball joints into spindles. (Fig. 5), (Fig. 6), (Fig. 7), and (Fig. 8).

(13) Install pinch bolts to hold front ball joints to

spindles.

Fig. 2 Forward Frame and Suspension Crossmember

PL FRAME AND BUMPERS 13 - 5

SPECIFICATIONS (Continued)

Fig. 3 Engine Compartment Top View

13 - 6 FRAME AND BUMPERS PL

SPECIFICATIONS (Continued)

Fig. 4 Engine Compartment Side and Bottom View

PL FRAME AND BUMPERS 13 - 7

SPECIFICATIONS (Continued)

Fig. 5 Rear Frame Section Side and Bottom View

13 - 8 FRAME AND BUMPERS PL

SPECIFICATIONS (Continued)

Fig. 6 Door and Windshield Openings—4 Door

PL FRAME AND BUMPERS 13 - 9

SPECIFICATIONS (Continued)

Fig. 7 Door and Windshield Openings—2 Door

13 - 10 FRAME AND BUMPERS PL

SPECIFICATIONS (Continued)

Fig. 8 Rear Window and Trunk Openings

TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Front Bumper Reinforcement

Nut. . . . . . . . . . . . . . . . . . . . .156 N·m (115 ft. lbs)

Rear Bumper Reinforcement

Nut. . . . . . . . . . . . . . . . . . . . .156 N·m (115 ft. lbs)

Front Crossmember To Body

Mounting Bolts . . . . . . . . . . .163 N·m (120 ft. lbs)

Вам также может понравиться

- 182 185Документ4 страницы182 185jharl100% (1)

- Camaro High Performance Suspension TuningДокумент5 страницCamaro High Performance Suspension TuningSarawoot Watechagit100% (1)

- Wheel Alignment Guide for Front and Rear SuspensionДокумент54 страницыWheel Alignment Guide for Front and Rear SuspensionGuillermo UcОценок пока нет

- Tr35cum - 7881 Allison PDFДокумент274 страницыTr35cum - 7881 Allison PDFErick Domínguez CansecoОценок пока нет

- MonroeCatalogue PDFДокумент398 страницMonroeCatalogue PDFDiego AguirreОценок пока нет

- Design and Analysis of A Suspension Coil Spring PDFДокумент7 страницDesign and Analysis of A Suspension Coil Spring PDFCiobanu MihaiОценок пока нет

- Air Brake System For Railway CoachesДокумент40 страницAir Brake System For Railway CoachesShashwat SamdekarОценок пока нет

- Transaxle: NV T350 (A-578) Manual TransaxleДокумент120 страницTransaxle: NV T350 (A-578) Manual TransaxlePelis CloneОценок пока нет

- Kac 860e-1k PDFДокумент16 страницKac 860e-1k PDFdpomahОценок пока нет

- Neon 2000Документ16 страницNeon 2000Roberto VazquezОценок пока нет

- 1999 Jeep TJ Wrangler Service Manual - 13. Frame and BumpersДокумент12 страниц1999 Jeep TJ Wrangler Service Manual - 13. Frame and Bumpersbfranklin33Оценок пока нет

- Epl 13a PDFДокумент2 страницыEpl 13a PDFPelis CloneОценок пока нет

- 93FWD 13Документ18 страниц93FWD 13Christian MartinezОценок пока нет

- Daewoo M-150 Bumper and Fascia Removal GuideДокумент8 страницDaewoo M-150 Bumper and Fascia Removal GuidesheoОценок пока нет

- Rear Brake2Документ7 страницRear Brake2jeremih alhegnОценок пока нет

- Frame and Bumpers 13 - 1Документ18 страницFrame and Bumpers 13 - 1Sry SantosОценок пока нет

- RA Removing and Installing Front Bumper Trim (From 09 - 2006Документ3 страницыRA Removing and Installing Front Bumper Trim (From 09 - 2006Byron Jose Zambrano QuinterosОценок пока нет

- Bumpers and Fascias: Section 9OДокумент14 страницBumpers and Fascias: Section 9OJarry PotterОценок пока нет

- Tightening Torque 51 71 2AZ. Refer To Gap Dimensions, Body.: InstallationДокумент1 страницаTightening Torque 51 71 2AZ. Refer To Gap Dimensions, Body.: Installationapi-3744308Оценок пока нет

- Frame and BumpersДокумент12 страницFrame and BumpersAshif IqubalОценок пока нет

- Frame and BumpersДокумент16 страницFrame and BumpersMike KrothОценок пока нет

- REAR SUSPENSION AND DRIVELINE Chrysler Voyaguer 1994Документ48 страницREAR SUSPENSION AND DRIVELINE Chrysler Voyaguer 1994juanОценок пока нет

- Body ComponentДокумент44 страницыBody ComponentZamrizal ZakariaОценок пока нет

- Tilt Steering Column Removal and Disassembly GuideДокумент12 страницTilt Steering Column Removal and Disassembly GuideNicolás CastiblancoОценок пока нет

- 05 Upper Struck-CabДокумент60 страниц05 Upper Struck-Cabkampungsaya79Оценок пока нет

- Exterior TrimДокумент9 страницExterior TrimSebastian SirventОценок пока нет

- 501-02 Front-End Body Plate PICKUP JMCДокумент6 страниц501-02 Front-End Body Plate PICKUP JMCRusonegroОценок пока нет

- Overhaul Front Brake of 2004 Toyota CorollaДокумент5 страницOverhaul Front Brake of 2004 Toyota Corollajeremih alhegnОценок пока нет

- Power Train: Procedures and Suggestions For Removal and InstallationДокумент11 страницPower Train: Procedures and Suggestions For Removal and InstallationPepe AlОценок пока нет

- Exterior Mitsubishi GalantДокумент24 страницыExterior Mitsubishi Galantsabrani branОценок пока нет

- Eee PDFДокумент10 страницEee PDFDillet BuchananОценок пока нет

- BMW F 800 R K73 Bajar-Subir MotorДокумент7 страницBMW F 800 R K73 Bajar-Subir MotorGustavo FajardoОценок пока нет

- SM - 29 - Fenders, Engine Hood - BMW M3 1992-1998Документ6 страницSM - 29 - Fenders, Engine Hood - BMW M3 1992-1998Hermawan 0103Оценок пока нет

- INJECTION PUMP DISASSEMBLYДокумент6 страницINJECTION PUMP DISASSEMBLYDavid QuispeОценок пока нет

- Fiat Barchetta: BodyworkДокумент16 страницFiat Barchetta: BodyworkHallex OliveiraОценок пока нет

- Install Rear Seat BackrestДокумент1 страницаInstall Rear Seat BackrestRyszard KotОценок пока нет

- Seat Belt, Srs AirbagДокумент16 страницSeat Belt, Srs AirbagJipsonCuevaОценок пока нет

- Rear Strut: A: RemovalДокумент3 страницыRear Strut: A: RemovalmiguelОценок пока нет

- Fender Splash Shield Removal and Installation PDFДокумент2 страницыFender Splash Shield Removal and Installation PDFMichael HernandezОценок пока нет

- Steering Column2Документ7 страницSteering Column2Clever Raul Mamani CcajmaОценок пока нет

- 2-FRAME BODY PANALS - EXHAUST SYSTEM Honda Rebel 500Документ14 страниц2-FRAME BODY PANALS - EXHAUST SYSTEM Honda Rebel 500Good weedОценок пока нет

- AR91.10-P-1911EC Remove/install Front Backrest Cover Frame 17.5.11 MODEL 204.3, 207Документ2 страницыAR91.10-P-1911EC Remove/install Front Backrest Cover Frame 17.5.11 MODEL 204.3, 207danny wongОценок пока нет

- Remove Tilt Steering Column in Lexus IS200Документ2 страницыRemove Tilt Steering Column in Lexus IS200Moh DeBrОценок пока нет

- PL Differential and Driveline 3 - 1Документ16 страницPL Differential and Driveline 3 - 1Pelis CloneОценок пока нет

- 2C-2&3 Rear Shock Absorber Removal and InstallationДокумент3 страницы2C-2&3 Rear Shock Absorber Removal and InstallationPaulo SergioОценок пока нет

- 2 Touring Rear Cargo BMW TIS. View DocumentДокумент3 страницы2 Touring Rear Cargo BMW TIS. View DocumentdarkcraveОценок пока нет

- ExteriorДокумент73 страницыExteriorMirceaОценок пока нет

- Disassembly: Front SeatДокумент5 страницDisassembly: Front SeatThar KyiОценок пока нет

- 3-1. Tools For Disassembly and ReassemblyДокумент19 страниц3-1. Tools For Disassembly and ReassemblyMhooMOoChaappHteenОценок пока нет

- New Holland 100hp - 115hp - 135hp - 160hp Power Take-Off Part2Документ13 страницNew Holland 100hp - 115hp - 135hp - 160hp Power Take-Off Part2Drag TrakОценок пока нет

- 5 - Manual Trans Removal PDFДокумент3 страницы5 - Manual Trans Removal PDFEduardo SantosОценок пока нет

- Power Train: Procedure and Suggestions For Removal and InstallationДокумент11 страницPower Train: Procedure and Suggestions For Removal and InstallationIvaylo PetkovОценок пока нет

- Ремни и Подушки безопасности LGSRS-WE-0552Документ117 страницРемни и Подушки безопасности LGSRS-WE-0552Dmitry BondarОценок пока нет

- AssemblyДокумент8 страницAssemblyGregory YoungОценок пока нет

- How to Replace Headlight Bulbs and Fog LampsДокумент8 страницHow to Replace Headlight Bulbs and Fog LampsPelis CloneОценок пока нет

- M SR 0008 PDFДокумент2 страницыM SR 0008 PDFMoh DeBrОценок пока нет

- Air Conditioning Kit CX135SRДокумент10 страницAir Conditioning Kit CX135SRBaris TuranОценок пока нет

- Removal: 2Uz-Fe Engine Mechanical - Timing BeltДокумент4 страницыRemoval: 2Uz-Fe Engine Mechanical - Timing BeltmarranОценок пока нет

- Install or Remove Power Brake Booster RHDДокумент2 страницыInstall or Remove Power Brake Booster RHDRuhu royОценок пока нет

- FR564HR NaДокумент22 страницыFR564HR Nausaussr52Оценок пока нет

- Front Suspension PDFДокумент28 страницFront Suspension PDFtavi2meОценок пока нет

- Removal: 1. Remove Rear WheelsДокумент1 страницаRemoval: 1. Remove Rear WheelssalusfrankОценок пока нет

- Remo 62Документ1 страницаRemo 62salusfrankОценок пока нет

- BMW Installation Instructions - Hand-Brushed Tail-Hump Cover - 02.2021Документ9 страницBMW Installation Instructions - Hand-Brushed Tail-Hump Cover - 02.2021aviaqualОценок пока нет

- Service Manual SM17 - 002 - 083.00: Latching Boom Mechanism RetrofitДокумент24 страницыService Manual SM17 - 002 - 083.00: Latching Boom Mechanism RetrofitErissonОценок пока нет

- Removal: Torx Screw Screw CaseДокумент2 страницыRemoval: Torx Screw Screw CasejuanОценок пока нет

- SC5357Документ3 страницыSC5357tzОценок пока нет

- Undercariagge HITACHI ZX 850Документ108 страницUndercariagge HITACHI ZX 850januar arieОценок пока нет

- PL Electrically Heated Systems 8N - 1Документ4 страницыPL Electrically Heated Systems 8N - 1Pelis CloneОценок пока нет

- Fig. 1 Vehicle Identification NumberДокумент10 страницFig. 1 Vehicle Identification NumberPelis CloneОценок пока нет

- Transaxle: Description and Operation Brake Transmission Shift Interlock (Btsi) SystemДокумент4 страницыTransaxle: Description and Operation Brake Transmission Shift Interlock (Btsi) SystemPelis CloneОценок пока нет

- Epl 8w PDFДокумент322 страницыEpl 8w PDFPelis CloneОценок пока нет

- MANUFACTURER PLATE - . - . - . - . - . - . - . - . - . 2 Vehicle Identification Number - . - . - . - . - 1Документ2 страницыMANUFACTURER PLATE - . - . - . - . - . - . - . - . - . 2 Vehicle Identification Number - . - . - . - . - 1CARLOSОценок пока нет

- Lamps: Lamp DiagnosisДокумент14 страницLamps: Lamp DiagnosisPelis CloneОценок пока нет

- Epl 22 PDFДокумент14 страницEpl 22 PDFPelis CloneОценок пока нет

- PL Instrument Panel and Systems 8E - 1Документ14 страницPL Instrument Panel and Systems 8E - 1Pelis CloneОценок пока нет

- Audio System Diagnostics and Repair GuideДокумент6 страницAudio System Diagnostics and Repair GuidePelis CloneОценок пока нет

- PL Horns 8G - 1Документ4 страницыPL Horns 8G - 1Pelis CloneОценок пока нет

- PL Heating and Air Conditioning 24 - 1Документ30 страницPL Heating and Air Conditioning 24 - 1Pelis CloneОценок пока нет

- PL Charging System 8C - 1Документ12 страницPL Charging System 8C - 1Pelis CloneОценок пока нет

- Chrysler Neon 99 - Immobiliser SystemДокумент4 страницыChrysler Neon 99 - Immobiliser SystemeephantomОценок пока нет

- PL Differential and Driveline 3 - 1Документ16 страницPL Differential and Driveline 3 - 1Pelis CloneОценок пока нет

- How to Replace Headlight Bulbs and Fog LampsДокумент8 страницHow to Replace Headlight Bulbs and Fog LampsPelis CloneОценок пока нет

- Power Door Lock and Remote Keyless Entry Troubleshooting GuideДокумент6 страницPower Door Lock and Remote Keyless Entry Troubleshooting GuidePelis CloneОценок пока нет

- Optimize Your Braking KnowledgeДокумент90 страницOptimize Your Braking KnowledgePelis CloneОценок пока нет

- Guide to Clutch System Components, Diagnosis, and RepairДокумент12 страницGuide to Clutch System Components, Diagnosis, and RepairPelis CloneОценок пока нет

- Body Component Removal and Installation GuideДокумент52 страницыBody Component Removal and Installation GuidePelis CloneОценок пока нет

- Epl 14 PDFДокумент58 страницEpl 14 PDFPelis CloneОценок пока нет

- Emission Control Systems Guide for Diagnosing On-Board DiagnosticsДокумент22 страницыEmission Control Systems Guide for Diagnosing On-Board DiagnosticsPelis CloneОценок пока нет

- Epl 8m PDFДокумент12 страницEpl 8m PDFPelis CloneОценок пока нет

- PL Ignition System 8D - 1Документ20 страницPL Ignition System 8D - 1Pelis CloneОценок пока нет

- Windshield Wipers and WashersДокумент10 страницWindshield Wipers and WashersPelis CloneОценок пока нет

- Battery Charging Guide and Diagnosis TipsДокумент10 страницBattery Charging Guide and Diagnosis TipsPelis CloneОценок пока нет

- PL Starting 8B - 1Документ8 страницPL Starting 8B - 1Pelis CloneОценок пока нет

- PL Cooling 7 - 1Документ24 страницыPL Cooling 7 - 1Pelis CloneОценок пока нет

- Bose SuspensionДокумент7 страницBose SuspensionRajan GuptaОценок пока нет

- Civic 2014 BrochureДокумент11 страницCivic 2014 BrochureIsko AtilanoОценок пока нет

- Airstroke AirmountДокумент112 страницAirstroke Airmountvinay8464Оценок пока нет

- FSW Technical HandbookДокумент27 страницFSW Technical HandbookAnand Kumar MandalОценок пока нет

- Trailer Parts - Rocket Trailers - Body ComponentsДокумент7 страницTrailer Parts - Rocket Trailers - Body ComponentsRocket TrailersОценок пока нет

- BE Mechanical Engineering CBCGS Syllabus 2016 OnwardsДокумент9 страницBE Mechanical Engineering CBCGS Syllabus 2016 OnwardsShubhamJangleОценок пока нет

- Toyota Tundra TRD Lowering Kit Installation InstructionsДокумент9 страницToyota Tundra TRD Lowering Kit Installation InstructionsJason LancasterОценок пока нет

- Bufori La Joya.: Be UniqueДокумент34 страницыBufori La Joya.: Be Uniqueapi-25938659Оценок пока нет

- BMW's Dynamic DriveДокумент3 страницыBMW's Dynamic DrivesnikkillОценок пока нет

- Jaguar XF Sportbrake R-Sport 2.0L Diesel - Scheda TecnicaДокумент1 страницаJaguar XF Sportbrake R-Sport 2.0L Diesel - Scheda TecnicaBlogo MotoriОценок пока нет

- Need StoДокумент31 страницаNeed StoG S SARAVANA KUMARОценок пока нет

- Terex Franna 20t BrochureДокумент2 страницыTerex Franna 20t BrochureKin Siang YapОценок пока нет

- Catia DesignДокумент9 страницCatia DesignBejai Alexander MathewОценок пока нет

- Jaguar XE Brochure 1X7601804SSSBGBEN01P - tcm76 386866 PDFДокумент32 страницыJaguar XE Brochure 1X7601804SSSBGBEN01P - tcm76 386866 PDFjohnleeОценок пока нет

- Ship's Hull Theory II, Stability (Module 1)Документ17 страницShip's Hull Theory II, Stability (Module 1)ScarletRahadyanОценок пока нет

- en de 170630Документ24 страницыen de 170630JESUSCALVILLOОценок пока нет

- Static and Dynamic Analysis of Space FrameДокумент6 страницStatic and Dynamic Analysis of Space Frameanand007krishnanОценок пока нет

- 33 34 Manual Yerf DogДокумент24 страницы33 34 Manual Yerf DogJohn CaravalhoОценок пока нет

- Course Plan (Ae) Me ViiiДокумент15 страницCourse Plan (Ae) Me ViiiManjunatha EikilaОценок пока нет

- Electromagnetic SuspensionДокумент16 страницElectromagnetic Suspensionaciddrops100% (1)

- L1-CHE-GDL-004 - 54 Hour Service Suspension Contaminated Rail CleaningДокумент1 страницаL1-CHE-GDL-004 - 54 Hour Service Suspension Contaminated Rail Cleaning4493464Оценок пока нет

- STRENGTH OF MATERIALS SOLUTIONSДокумент2 страницыSTRENGTH OF MATERIALS SOLUTIONSJerick MadrileñoОценок пока нет