Академический Документы

Профессиональный Документы

Культура Документы

Size of Battery

Загружено:

Pelis CloneИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Size of Battery

Загружено:

Pelis CloneАвторское право:

Доступные форматы

PL BATTERY 8A - 1

BATTERY

CONTENTS

page page

GENERAL INFORMATION CHARGING COMPLETELY DISCHARGED

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1 BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DESCRIPTION AND OPERATION VISUAL INSPECTION . . . . . . . . . . . . . . . . . . . . . 7

BATTERY IGNITION OFF DRAW (IOD) . . . . . . . . 1 REMOVAL AND INSTALLATION

CHARGING TIME REQUIRED . . . . . . . . . . . . . . . 1 BATTERY TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DIAGNOSIS AND TESTING BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BATTERY BUILT-IN TEST INDICATOR . . . . . . . . 2 FRESH AIR INLET TUBE REMOVAL . . . . . . . . . . 9

BATTERY IGNITION OFF DRAW (IOD) . . . . . . . . 3 SPECIFICATIONS

BATTERY LOAD TEST . . . . . . . . . . . . . . . . . . . . . 5 BATTERY SPECIFICATIONS . . . . . . . . . . . . . . . 10

BATTERY OPEN CIRCUIT VOLTAGE TEST . . . . . 6 TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

BATTERY TEMPERATURE SENSOR . . . . . . . . . . 6

SERVICE PROCEDURES

BATTERY CHARGING . . . . . . . . . . . . . . . . . . . . . 6

GENERAL INFORMATION must be cleaned before diagnostic procedures are per-

formed.

INTRODUCTION

The battery stores, stabilizes, and delivers electri-

DESCRIPTION AND OPERATION

cal current to operate various electrical systems in

the vehicle. The determination of whether a battery

BATTERY IGNITION OFF DRAW (IOD)

is good or bad is made by its ability to accept a

A completely normal vehicle will have a small

charge. It also must supply high-amperage current

amount of current drain on the battery with the key

for a long enough period to be able to start the vehi-

out of the ignition. It can range from 4 to 10 milli-

cle. The capability of the battery to store electrical

amperes after all the modules time out. If a vehicle

current comes from a chemical reaction. This reac-

will not be operated for approximately a 20 days, the

tion takes place between the sulfuric acid solution

IOD fuse should be disconnected to minimize the

(electrolyte) and the lead +/- plates in each cell of the

vehicle electrical drain on the battery. The IOD fuse

battery. As the battery discharges, the plates react

is located in the Power Distribution Center (PDC).

with the acid from the electrolyte. When the charging

Refer to the PDC to locate the cover proper fuse.

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

CHARGING TIME REQUIRED

in the electrolyte is measured as specific gravity

using a hydrometer. The original equipment (OE) WARNING: NEVER EXCEED 20 AMPS WHEN

battery is equipped with a hydrometer (test indica- CHARGING A COLD -1°C (30°F) BATTERY. PER-

tor) built into the battery cover. The specific gravity SONAL INJURY MAY RESULT.

indicates the battery’s state-of-charge. The OE bat-

tery is sealed and water cannot be added. The time required to charge a battery will vary

The battery is vented to release gases that are cre- depending upon the following factors.

ated when the battery is being charged and dis-

charged. The battery top, posts, and terminals should SIZE OF BATTERY

be cleaned when other under hood maintenance is A completely discharged large heavy-duty battery

performed. may require more recharging time than a completely

When the electrolyte level is below the top of the discharged small capacity battery. Refer to Battery

plates, Yellow/Clear in the test Indicator, the battery Charging Timetable for proper charging times.

must be replaced. The battery must be completely

charged, and the battery top, posts, and cable clamps

8A - 2 BATTERY PL

DESCRIPTION AND OPERATION (Continued)

BATTERY CHARGING TIMETABLE DIAGNOSIS AND TESTING

Charging 5 10 20 BATTERY BUILT-IN TEST INDICATOR

Amperage Amperes Amperes Amperes

USING TEST INDICATOR

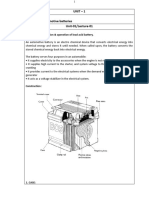

Open Circuit The Test Indicator (Fig. 1), (Fig. 2) and (Fig. 3)

Hours Charging at 21°C (70°F)

Voltage measures the specific gravity of the electrolyte. Spe-

12.25 to 6 hours 3 hours 1.5 hours cific Gravity (SG) of the electrolyte will show state-

12.39 of-charge (voltage). The test indicator WILL NOT

show cranking capacity of the battery. Refer to Bat-

12.00 to 8 hours 4 hours 2 hours

tery Load Test for more information. Look into the

12.24

sight glass (Fig. 1), (Fig. 3) and note the color of the

11.95 to 12 hours 6 hours 3 hours indicator. Refer to the following description of colors:

11.99

10.00 to 14 hours 7 hours 3.5 hours NOTE: GREEN = 75 to 100% state-of-charge

11.94

less than See Charging Completely Discharged

10.00 Battery

TEMPERATURE

A longer time will be needed to charge a battery at

-18°C (0°F) than at 27°C (80°F). When a fast charger

is connected to a cold battery, current accepted by

battery will be very low at first. In time, the battery

will accept a higher rate as battery temperature

warms.

CHARGER CAPACITY

A charger which can supply only five amperes will

require a much longer period of charging than a

charger that can supply 20 amperes or more. Fig. 2 Battery Construction and Test Indicator

STATE OF CHARGE

A completely discharged battery requires more

charging time than a partially charged battery. Elec-

trolyte is nearly pure water in a completely dis-

charged battery. At first, the charging current

amperage will be low. As water is converted back to

sulfuric acid inside the battery, the current amp rate

will rise. Also, the specific gravity of the electrolyte

will rise, bringing the green ball (Fig. 1) into view at

approximately 75 percent state-of-charge.

Fig. 3 Test Indicator

The battery is adequately charged for further test-

ing and may be returned to use. If the vehicle will

not crank for a maximum 15 seconds, refer to BAT-

TERY LOAD TEST in this Group for more informa-

tion.

Fig. 1 Reading Test Indicator

PL BATTERY 8A - 3

DIAGNOSIS AND TESTING (Continued)

NOTE: BLACK OR DARK = 0 to 75% state-of-charge be checked. To determine if a high current draw con-

The battery is INADEQUATELY charged and must dition exists first check the vehicle with a test lamp.

be charged until green dot is visible, (12.4 volts or (1) Verify that all electrical accessories are OFF.

greater) before the battery is tested or returned to • Remove key from ignition switch

use. Refer to Causes of Battery Discharging in this • Turn off all lights

Group for more information. • Trunk lid is closed

• Engine compartment hood lamp is disconnected

NOTE: CLEAR COLOR = Replace Battery or lamp removed

• Glove box door is closed

• Sun visor vanity lights are OFF

WARNING: DO NOT CHARGE, ASSIST BOOST,

• All doors are closed

LOAD TEST, OR ADD WATER TO THE BATTERY

• Allow the ignition key lamp system to time out

WHEN CLEAR COLOR DOT IS VISIBLE. PERSONAL

in approximately 30 seconds, if equipped.

INJURY MAY OCCUR.

(2) Disconnect battery negative cable (Fig. 4).

A clear color dot shows electrolyte level in battery (3) Connect a 12 Volt test lamp, with a cold resis-

is below the test indicator (Fig. 1). Water cannot be tance of 5-7 ohms, between the battery negative cable

added to a maintenance free battery. The battery clamp and the negative post (Fig. 5). If test lamp

must be replaced. A low electrolyte level may be goes out system is OK. If test lamp lights and stays

caused by an over charging condition. Refer to Gen- ON, go to Test Lamp Stays ON procedure.

erator Test Procedures on Vehicle.

TEST LAMP STAYS ON

CAUSES OF BATTERY DISCHARGING There is either a short circuit or a fault in an elec-

It is normal to have a small 5 to 25 milliamperes tronic module. Two fuses in the Power Distribution

continuous electrical draw from the battery. This Center (PDC) feed the modules with ignition off

draw will take place with the ignition in the OFF draw.

position, and the courtesy, dome, storage compart- • Interior lamps fuse (10 Amp) (IOD) PDC.

ments, and engine compartment lights OFF. The con- • Fuel pump fuse (20 Amp) in PDC

tinuous draw is due to various electronic features or (1) Remove interior lamp and fuel pump fuses. By

accessories that require electrical current with the removing these fuses all ignition off draw from the

ignition OFF to function properly. When a vehicle is vehicle electronics will be disconnected. The test

not used over an extended period of approximately 20 lamp should go out. If test lamp goes out go to Step

days the IOD fuse should be pulled. The fuse is 2. If test lamp does not go out there is a current

located in the power distribution center. removal of draw or short circuit. Refer to Group 8W, Wiring Dia-

this fuse will reduce the level of battery discharge. grams.

Refer to the Battery Diagnosis and Testing Table for (2) Install the fuel pump fuse. If test lamp lights,

proper diagnosis. there is a current draw or short circuit in the A14

wiring circuit feed.

ABNORMAL BATTERY DISCHARGING (a) Disconnect Powertrain Control Module.

• Corroded battery posts, cables or terminals. (b) If test lamp goes out, replace Powertrain

• Loose or worn generator drive belt. Control Module.

• Electrical loads that exceed the output of the (c) If test lamp does not go out, there is a cur-

charging system due to equipment or accessories rent draw or short circuit in the A14 circuit feed.

installed after delivery. Refer to Group 8W, Wiring Diagrams.

• Slow driving speeds in heavy traffic conditions (3) Install the interior lamp fuse. If test lamp

or prolonged idling with high-amperage electrical lights, there is a current draw or short circuit in the

systems in use. M01 circuit. Refer to Group 8W, Wiring Diagrams. If

• Defective electrical circuit or component causing test lamp stays out, go to Step 4

excess Ignition Off Draw (IOD). Refer to Battery (4) Use a multi-meter that has at least a range of

Ignition Off Draw (IOD). 200 milliamperes. Install meter between the battery

• Defective charging system. negative cable and battery negative post (Fig. 6).

• Defective battery. Carefully remove the test lamp without disconnecting

the meter. After all modules time-out the total vehi-

BATTERY IGNITION OFF DRAW (IOD) cle IOD should be less than 10 milliamperes. If igni-

High current draw on the battery with the ignition tion off draw is more than 10 milliamperes go to Step

OFF will discharge a battery. After a dead battery is 5.

recharged, the vehicle ignition off draw (IOD) should (5) Remove both fuses from the Power Distribution

Center:

8A - 4 BATTERY PL

DIAGNOSIS AND TESTING (Continued)

BATTERY DIAGNOSIS AND TESTING

STEPS POSSIBLE CAUSE CORRECTION

VISUAL INSPECTION (1) Loose battery post, Cracked (1) Replace Battery

Check for possible damage to battery cover or case, Leaks or Any (2) Check state of charge. Refer to

battery and clean battery. other physical Test Indicator.

(2) Battery OK.

TEST INDICATOR (1) GREEN (1) Battery is charged. Perform

Check Charge Eye Color (2) BLACK Battery 0pen Circuit Voltage Test

(3) CLEAR (2) Perform Battery Charging

procedure.

(3) Replace Battery.

BATTERY OPEN CIRCUIT (1) Battery is above 12.40 Volts (1) Perform the Battery Load Test.

VOLTAGE TEST (2) Battery is below 12.40 Volts. (2) Perform Battery Charging

procedure.

BATTERY CHARGING (1) Battery accepted Charge. (1) Ensure that the indicator eye is

(2) Battery will not accept charge GREEN and perform Battery 0pen

Circuit Voltage Test

(2) Perform Charging a Completely

Discharged Battery.

BATTERY LOAD TEST (1) Acceptable minimum voltage. (1) Battery is OK to put in use,

(2) Unacceptable minimum voltage perform Battery Ignition Off Draw

Test.

(2) Replace Battery and perform

Battery Ignition Off Draw Test.

CHARGING A COMPLETELY (1) Battery accepted charge. (1) Ensure that the indicator eye is

DISCHARGED BATTERY (2) Battery will not accept charge. GREEN and perform Battery 0pen

Circuit Voltage Test.

(2) Replace Battery.

IGNITION OFF DRAW TEST (1) IOD is 5-25 Milliamperes. (1) Vehicle is normal.

(2) IOD Exceeds 25 Milliamperes. (2) Eliminate excess IOD draw.

out the reading should not exceed 8 milliamperes. If

NOT OK go to Step 8. If OK go to Step 9.

• Ignition key lamp system

• Radio

• Remote keyless entry module, if equipped

(8) Disconnect radio and ignition switch key lamp

one component at time, to see if any component is at

fault. If the high reading is not eliminated there is a

short circuit in the wiring. Refer to Group 8W, Wir-

ing Diagrams.

CAUTION: Always disconnect the meter before

Fig. 4 Disconnect Battery Negative Cable opening a door.

• Fuel pump fuse (20 Amp)

(9) Remove interior lamps fuse and install the fuel

• Interior lamps fuse (10 Amp)

pump fuse. The reading should be between 1-3 milli-

(6) If there is any reading with fuses removed

amperes. If reading is higher than 3 milliamperes:

there is a current draw or short circuit in the wiring.

(a) Disconnect Powertrain Control Module.

Refer to Group 8W, Wiring Diagrams. If OK go to

(b) If reading drops to zero, replace Powertrain

Step 7.

Control Module.

(7) Install interior lamp fuse. After installing fuse,

(c) If reading remains the same there is a cur-

the current can reach 250 milliamperes. After time-

rent draw or short circuit in the A14 circuit. Refer

to Group 8W, Wiring Diagrams.

PL BATTERY 8A - 5

DIAGNOSIS AND TESTING (Continued)

LOW ELECTROLYTE LEVEL, DO NOT TEST. ACID

BURNS OR AN EXPLOSIVE CONDITION MAY

RESULT.

(1) Remove both battery cables, negative cable

first. The battery top, cables and posts should be

clean. If green dot is not visible in indicator, charge

the battery. Refer to Battery Charging Procedures.

(2) Connect a Volt/Ammeter/Load tester to the bat-

tery posts (Fig. 7). Rotate the load control knob of the

Carbon pile rheostat to apply a 300 amp load. Apply

this load for 15 seconds to remove the surface charge

from the battery, and return the control knob to off

(Fig. 8).

Fig. 5 Ignition OFF (IOD) Test

Fig. 7 Volt-Ammeter Load Tester Connections

Fig. 8 Remove Surface Charge From Battery

Fig. 6 Milliampere Meter Connection

(3) Allow the battery to stabilize for 2 minutes,

BATTERY LOAD TEST and then verify open circuit voltage.

A fully charged battery must have cranking capac- (4) Rotate the load control knob on the tester to

ity, to provide the starter motor and ignition system maintain 50% of the battery cold crank rating for 15

enough power to start the engine over a broad range seconds (Fig. 9). Record the loaded voltage reading

of ambient temperatures. A battery load test will ver- and return the load control to off. Refer to the Bat-

ify the actual cranking capability of the battery. tery Specifications at the rear of this Group.

(5) Voltage drop will vary according to battery

WARNING: IF BATTERY SHOWS SIGNS OF FREEZ- temperature at the time of the load test. Battery

ING, LEAKING, LOOSE POSTS, OR EXCESSIVELY temperature can be estimated by the temperature of

8A - 6 BATTERY PL

DIAGNOSIS AND TESTING (Continued)

Carbon pile rheostat to apply a 300 amp load. Apply

this load for 15 seconds to remove the surface charge

from the battery, and return the control knob to off

(Fig. 8).

(3) Allow the battery to stabilize for 2 minutes,

and then verify the open circuit voltage (Fig. 10).

(4) This voltage reading will approximate the state

of charge of the battery. It will not reveal battery

cranking capacity. Refer to Battery Open Circuit

Voltage Table.

Fig. 9 Load 50% Cold Crank Rating

exposure over the preceding several hours. If the bat-

tery has been charged or boosted a few minutes prior

to the test, the battery would be slightly warmer.

Refer to Battery Load Test Temperatures Table for

proper voltage/temperature reading:

BATTERY LOAD TEST TEMPERATURES

Minimum Temperature

Voltage °F °C Fig. 10 Testing Open Circuit Voltage

9.6 volts 70° and above 21° and above BATTERY OPEN CIRCUIT VOLTAGE

9.5 volts 60° 16°

9.4 volts 50° 10° Open Circuit Volts Charge Percentage

9.3 volts 40° 4° 11.7 volts or less 0%

9.1 volts 30° -1° 12.0 volts 25%

8.9 volts 20° -7° 12.2 volts 50%

8.7 volts 10° -12° 12.4 volts 75%

8.5 volts 0° -18° 12.6 volts or more 100%

(6) If battery passes load test, it is in good condi- BATTERY TEMPERATURE SENSOR

tion and further tests are not necessary. If it fails For Battery Temperature Sensor refer to Group 8C

load test, it should be replaced. Generator.

BATTERY OPEN CIRCUIT VOLTAGE TEST

SERVICE PROCEDURES

An open circuit voltage no load test shows the

state of charge of a battery and whether it is ready

BATTERY CHARGING

for a load test at 50 percent of the battery’s cold

A battery is considered fully charged when it will

crank rating. Refer to Battery Load Test. If a battery

meet all the following requirements.

has open circuit voltage reading of 12.4 volts or

• It has an open circuit voltage charge of at least

greater, and will not pass the load test, replace the

12.4 volts.

battery because it is defective. To test open circuit

• It passes the 15 second load test. Refer to Bat-

voltage, perform the following operation.

tery Load Test.

(1) Remove both battery cables, negative cable

• The built in test indicator dot is GREEN (Fig.

first. Battery top, cables and posts should be clean. If

1).

green dot is not visible in indicator, charge the bat-

tery. Refer to Battery Charging Procedures. NOTE: The battery cannot be refilled with water, it

(2) Connect a Volt/Ammeter/Load tester to the bat- must be replaced.

tery posts (Fig. 7). Rotate the load control knob of the

PL BATTERY 8A - 7

SERVICE PROCEDURES (Continued)

WARNING: DO NOT CHARGE A BATTERY THAT BATTERY CHARGING RATE

HAS EXCESSIVELY LOW ELECTROLYTE LEVEL.

BATTERY MAY SPARK INTERNALLY AND Voltage Hours

EXPLODE. EXPLOSIVE GASES FORM OVER THE 16.0 volts maximum up to 4 hours

BATTERY. DO NOT SMOKE, USE FLAME, OR CRE-

ATE SPARKS NEAR BATTERY. DO NOT ASSIST 14.0 to 15.9 volts up to 8 hours

BOOST OR CHARGE A FROZEN BATTERY. BAT- 13.9 volts or less up to 16 hours

TERY CASING MAY FRACTURE. BATTERY ACID IS

POISON, AND MAY CAUSE SEVERE BURNS. BAT- (1) Measure the voltage at battery posts with a

TERIES CONTAIN SULFURIC ACID. AVOID CON- voltmeter accurate to 1/10 volt (Fig. 11). If below 10

TACT WITH SKIN, EYES, OR CLOTHING. IN THE volts, charge current will be low, and it could take

EVENT OF CONTACT, FLUSH WITH WATER AND some time before it accepts a current in excess of a

CALL PHYSICIAN IMMEDIATELY. KEEP OUT OF few milliamperes. Such low current may not be

REACH OF CHILDREN. detectable on amp meters built into many chargers.

CAUTION: Disconnect the battery NEGATIVE cable

first, before charging battery to avoid damage to

electrical systems. Lift the red battery boot cover

from the positive cable clamp. Do not exceed 16.0

volts while charging battery. Refer to the instruc-

tions supplied with charging equipment

Battery electrolyte may bubble inside of battery

case while being charged properly. If the electrolyte

boils violently, or is discharged from the vent holes

while charging, immediately reduce charging rate or

turn off charger. Evaluate battery condition. Battery

damage may occur if charging is excessive.

Some battery chargers are equipped with polarity

Fig. 11 Voltmeter Accurate to 1/10 Volt (Connected)

sensing devices to protect the charger or battery from

being damaged if improperly connected. If the bat- (2) Connect charger leads. Some chargers feature

tery state of charge is too low for the polarity sensor polarity protection circuitry that prevents operation

to detect, the sensor must be bypassed for charger to unless charger is connected to battery posts correctly.

operate. Refer to operating instructions provided A completely discharged battery may not have

with battery charger being used. enough voltage to activate this circuitry. This may

happen even though the leads are connected properly.

CAUTION: Charge battery until test indicator (3) Battery chargers vary in the amount of voltage

appears green. Do not overcharge. and current they provide. For the time required for

the battery to accept measurable charger current at

It may be necessary to jiggle the battery or vehicle various voltages, refer to the Battery Charging Rate

to bring the green dot in the test indicator into view. table. If charge current is still not measurable after

After the battery has been charged to 12.4 volts or charging times, the battery should be replaced. If

greater, perform a load test to determine cranking charge current is measurable during charging time,

capacity. Refer to Battery Load Test in this Group. If the battery may be good, and charging should be

the battery passes the load test, the battery is OK to completed in the normal manner.

use. If battery will not pass the load test, it must be

replaced. Properly clean and inspect battery hold VISUAL INSPECTION

downs, tray, terminals, cables, posts, and top before

completing service. CAUTION: Do not allow baking soda solution to

enter vent holes, as damage to battery can result.

CHARGING COMPLETELY DISCHARGED BATTERY

The following procedure should be used to recharge (1) Clean top of battery with a solution of warm

a completely discharged battery. Unless procedure is water and baking soda.

properly followed, a good battery may be needlessly (2) Apply soda solution with a bristle brush and

replaced. Refer to Battery Charging Rate Table for allow to soak until acid deposits loosen (Fig. 12).

proper charging time.

8A - 8 BATTERY PL

SERVICE PROCEDURES (Continued)

Fig. 12 Cleaning Battery Fig. 13 Cleaning Battery Post

(3) Rinse soda solution from battery with clear

water and blot battery dry with paper toweling. Dis-

pose of toweling in a safe manner. Refer to the

WARNINGS on top of battery.

(4) Inspect battery case and cover for cracks, leak-

age or damaged hold down ledge. If battery is dam-

aged replace it.

(5) Inspect battery tray for damage caused by acid

from battery. If acid is present, clean area with bak-

ing soda solution.

(6) Clean battery posts with a battery post clean-

ing tool (Fig. 13).

(7) Clean battery cable clamps with a battery ter-

minal cleaning tool (Fig. 14). Replace cables that are

frayed or have broken clamps.

REMOVAL AND INSTALLATION

BATTERY

REMOVAL

(1) Make sure ignition switch is in OFF position

and all accessories are OFF. Fig. 14 Cleaning Battery Cable Terminal

(2) Remove battery negative cable then the posi- (4) Remove battery hold down clamp (Fig. 16) and

tive cable (Fig. 4). battery from vehicle.

(3) Remove battery thermoguard cover (Fig. 15).

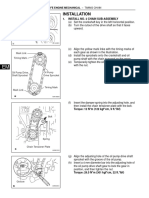

INSTALLATION

WARNING: TO PROTECT THE HANDS FROM BAT- (1) Install battery in vehicle making sure that it is

TERY ACID, A SUITABLE PAIR OF HEAVY DUTY properly positioned on battery tray.

RUBBER GLOVES, NOT THE HOUSEHOLD TYPE,

SHOULD BE WORN WHEN REMOVING OR SERVIC-

ING A BATTERY. SAFETY GLASSES ALSO SHOULD

BE WORN.

PL BATTERY 8A - 9

REMOVAL AND INSTALLATION (Continued)

(4) Connect battery cable clamps to battery posts

and making sure top of clamp is flush or below with

top of post (Fig. 18). Install battery positive cable

first.

(5) Tighten clamp nuts securely.

Fig. 17 Battery Tray Removal

Fig. 15 Battery Thermoguard

Fig. 18 Remove and Install Battery Cables

BATTERY TRAY

REMOVAL

(1) Remove battery, refer to Battery Removal.

(2) Remove battery tray pencil strut. Remove bat-

tery tray, refer to (Fig. 17).

INSTALLATION

For installation reverse above procedures.

Fig. 16 Battery Hold-Down FRESH AIR INLET TUBE REMOVAL

(2) Install battery hold down clamp, making sure

REMOVAL

that it is properly positioned on battery.

(1) Ensure that the ignition switch and all acces-

(3) Place thermoguard cover over the battery and

sories are OFF

snap it together with battery tray (Fig. 17). The bat-

(2) Remove battery negative cable first then the

tery tray pencil strut may have to be loosened on one

positive cable (Fig. 4).

end to install the thermoguard cover. After the ther-

(3) Remove battery thermoguard cover (Fig. 15).

moguard cover is in place, tighten pencil strut as

necessary.

8A - 10 BATTERY PL

REMOVAL AND INSTALLATION (Continued)

WARNING: TO PROTECT THE HANDS FROM BAT- INSTALLATION

TERY ACID, A SUITABLE PAIR OF HEAVY DUTY For installation reverse above procedures. Ensure

RUBBER GLOVES, NOT THE HOUSEHOLD TYPE, that the lock tabs are properly seated in the radiator

SHOULD BE WORN WHEN REMOVING OR SERVIC- panel and to the bottom of battery tray (Fig. 19).

ING A BATTERY. SAFETY GLASSES ALSO SHOULD Ensure that the tube opening is properly aligned

BE WORN. with hole before pulling on strap.

(4) Squeeze the sides of the tube at the pull strap

lock tabs and push down through the hole in the bat- SPECIFICATIONS

tery tray (Fig. 19). DO NOT push directly down on

the pull strap itself. BATTERY SPECIFICATIONS

(5) Remove the tube from the radiator closure

Load Test Cold Reserve

panel by squeezing the lock tabs and pushing from

Cranking

the front side (Fig. 16).

(Amps) Rating @ Capacity

-18°C (0°F)

225 Amp 450 Amp 85 Minutes

COLD CRANK RATING

The current battery can deliver for 30 seconds and

maintain a terminal voltage of 7.2 volts or greater at

–18° C (0° F).

RESERVE CAPACITY RATING

The length of time a battery can deliver 25 amps

and maintain a minimum terminal voltage of 10.5

volts at 27°C (80°F).

TORQUE

DESCRIPTION TORQUE

Fig. 19 Air Inlet Tube Pull Strap Battery Hold Down Bolt

Clamp Bolt. . . . . . . . . . . . . . . . .9 N·m (75 in. lbs.)

Вам также может понравиться

- Epl 8aДокумент10 страницEpl 8aapi-3777439Оценок пока нет

- Group 3 Electric Components: 1. Functions of Battery Forklift Truck and Electric ComponentsДокумент76 страницGroup 3 Electric Components: 1. Functions of Battery Forklift Truck and Electric ComponentsJorge RojasОценок пока нет

- Battery TestingДокумент27 страницBattery TestingAriel AdriaticoОценок пока нет

- Chrysler Dakota Part7Документ24 страницыChrysler Dakota Part7Sašo Brunšek-BrunoОценок пока нет

- Electrical: Group GroupДокумент24 страницыElectrical: Group GroupderekrichnerОценок пока нет

- 2 BatteriesДокумент32 страницы2 BatteriesNguyen Minh TienОценок пока нет

- BU-903 - Measuring State-Of-Charge (2017)Документ3 страницыBU-903 - Measuring State-Of-Charge (2017)Hugh Ell - auОценок пока нет

- Battery Specs by SHDДокумент7 страницBattery Specs by SHDKEDARNATH SASTRY SUSARLAОценок пока нет

- Diagrama Del Sistema Electrico de Carga Grand Cherokee Laredo 95Документ22 страницыDiagrama Del Sistema Electrico de Carga Grand Cherokee Laredo 95ALONSO GONZALEZ DURANОценок пока нет

- UNIT 1 Moodle Lecture 1Документ9 страницUNIT 1 Moodle Lecture 1aryanОценок пока нет

- BRJ 7 PDFДокумент117 страницBRJ 7 PDFCamilo TorresОценок пока нет

- RET Practical No13Документ10 страницRET Practical No13Prasad KulkarniОценок пока нет

- 6 3 PDFДокумент77 страниц6 3 PDFAndré SantosОценок пока нет

- Battery HandbookДокумент7 страницBattery Handbookcheguevara2010100% (1)

- 94XJ 8A ElectricalДокумент20 страниц94XJ 8A ElectricalFurRelKTОценок пока нет

- Hawker Batt ManualДокумент58 страницHawker Batt ManualSusan Gebhard0% (1)

- Battery Sizing - Open ElectricalДокумент10 страницBattery Sizing - Open ElectricalSAIОценок пока нет

- Chapter 10 Electrical System: ContentДокумент19 страницChapter 10 Electrical System: ContentFabian Carrasco NaulaОценок пока нет

- VRLA BatteryДокумент23 страницыVRLA BatteryAlexander Mccormick100% (1)

- Battery Sizing WikiДокумент10 страницBattery Sizing Wikiศิษย์เก่า ทีเจพีОценок пока нет

- NSB Blue Battery ManualДокумент13 страницNSB Blue Battery ManualSahand ArasОценок пока нет

- Care and Maintenance of Lead-Acid BatteriesДокумент11 страницCare and Maintenance of Lead-Acid BatteriesBalakrishnan Pedda GovindierОценок пока нет

- The Hotchek: Expanded Scale Voltmeter and Battery TesterДокумент12 страницThe Hotchek: Expanded Scale Voltmeter and Battery TesterCSEngineerОценок пока нет

- Automotive Electrical and Electronics EngineeringДокумент5 страницAutomotive Electrical and Electronics EngineeringKarthik SwaminathanОценок пока нет

- Battery How To Measure State of ChargeДокумент6 страницBattery How To Measure State of ChargeGuillermo Lopez-FloresОценок пока нет

- Battery Testing: Keysight TechnologiesДокумент10 страницBattery Testing: Keysight Technologieswahlgren9483Оценок пока нет

- GMDSS Battery Test NotesДокумент14 страницGMDSS Battery Test NotesRavinder SinghОценок пока нет

- Electrical and Ignition: Battery, Charging and Starting SystemДокумент15 страницElectrical and Ignition: Battery, Charging and Starting SystemBaxter LoachОценок пока нет

- Battery Charging Guide - 2 VoltДокумент4 страницыBattery Charging Guide - 2 VoltR.ArumugamОценок пока нет

- How To Maintain The BatteryДокумент5 страницHow To Maintain The BatteryNaghul PranavОценок пока нет

- Cbhd1 2 ManualДокумент8 страницCbhd1 2 ManualDino NecciОценок пока нет

- 32battery O&M1Документ16 страниц32battery O&M1Sunil SinghОценок пока нет

- Objective 2. Rference 3. Pre-Requisites 4. Precaution and Notes 5. Test Equipment 6. Commissioning and Testing Procedure 7. ChecklistДокумент11 страницObjective 2. Rference 3. Pre-Requisites 4. Precaution and Notes 5. Test Equipment 6. Commissioning and Testing Procedure 7. ChecklistsureshnfclОценок пока нет

- 12V - 24 V Lead-Acid Battery State of Charge Indicator: Group 9: Voltage & CurrentДокумент27 страниц12V - 24 V Lead-Acid Battery State of Charge Indicator: Group 9: Voltage & CurrentAyuguОценок пока нет

- Battery User Manu: CautionДокумент24 страницыBattery User Manu: Cautionbenbekreti amineОценок пока нет

- Murray Electrical From MA-S-1612 2004 Quick ReferenceДокумент35 страницMurray Electrical From MA-S-1612 2004 Quick ReferenceleowccheungОценок пока нет

- Batterie TestingДокумент27 страницBatterie TestingalfredmaticyengОценок пока нет

- Maintenance - Free Secondary Cells (Vrla) General: BSNL Power-PlantДокумент15 страницMaintenance - Free Secondary Cells (Vrla) General: BSNL Power-PlantNiranjanОценок пока нет

- Bat 5Документ15 страницBat 5Paul OñaОценок пока нет

- Battery Test Procedures 1997Документ7 страницBattery Test Procedures 1997Tara P. PradhanОценок пока нет

- Ex 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleДокумент23 страницыEx 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleKunal TanwarОценок пока нет

- Applied Wh3-Manual PDFДокумент24 страницыApplied Wh3-Manual PDFsaul rosalesОценок пока нет

- Getting Familiar With VRLA BatteriesДокумент5 страницGetting Familiar With VRLA BatteriesSushil SharmaОценок пока нет

- Battery Sizing: From Open ElectricalДокумент11 страницBattery Sizing: From Open ElectricalBADRI VENKATESHОценок пока нет

- Battery Sizing - Open ElectricalДокумент11 страницBattery Sizing - Open ElectricalJoseph GuzmanОценок пока нет

- Battery SizingДокумент10 страницBattery SizingmerebookОценок пока нет

- 220V Main Plant BatteryДокумент12 страниц220V Main Plant BatteryVikrant DeshmukhОценок пока нет

- Test, Charge and Replace Batteries and Jump-Start VehiclesДокумент11 страницTest, Charge and Replace Batteries and Jump-Start Vehiclesajay100% (1)

- PG PDFДокумент145 страницPG PDFacero1508Оценок пока нет

- Uninterruptible Power Supply Battery Acceptance/Capacity Test ProcedureДокумент9 страницUninterruptible Power Supply Battery Acceptance/Capacity Test Proceduresjaveeds2003Оценок пока нет

- Daily On Load / Off Load TestДокумент8 страницDaily On Load / Off Load TestFlexiОценок пока нет

- Batteries: Tests and Checks Mariners Must KnowДокумент11 страницBatteries: Tests and Checks Mariners Must KnowKalaivani PeriyasamyОценок пока нет

- BatteriesДокумент83 страницыBatteriesShubham DawleОценок пока нет

- GMDSS Batteries: Tests and Checks Mariners Must Know: Written by On January 31, 2016Документ22 страницыGMDSS Batteries: Tests and Checks Mariners Must Know: Written by On January 31, 2016larina20049273Оценок пока нет

- TRJN0109 UsersGuide PDFДокумент24 страницыTRJN0109 UsersGuide PDFBijuОценок пока нет

- Marine Electrics Made Simple or How to Keep the Batteries ChargedОт EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedОценок пока нет

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaОт EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaОценок пока нет

- Boatowner's Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential SystemsОт EverandBoatowner's Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential SystemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Fig. 1 Vehicle Identification NumberДокумент10 страницFig. 1 Vehicle Identification NumberPelis CloneОценок пока нет

- Transaxle: NV T350 (A-578) Manual TransaxleДокумент120 страницTransaxle: NV T350 (A-578) Manual TransaxlePelis CloneОценок пока нет

- Transaxle: Description and Operation Brake Transmission Shift Interlock (Btsi) SystemДокумент4 страницыTransaxle: Description and Operation Brake Transmission Shift Interlock (Btsi) SystemPelis CloneОценок пока нет

- Epl 22 PDFДокумент14 страницEpl 22 PDFPelis CloneОценок пока нет

- PL Electrically Heated Systems 8N - 1Документ4 страницыPL Electrically Heated Systems 8N - 1Pelis CloneОценок пока нет

- Epl 8f PDFДокумент6 страницEpl 8f PDFPelis CloneОценок пока нет

- Lamps: Lamp DiagnosisДокумент14 страницLamps: Lamp DiagnosisPelis CloneОценок пока нет

- PL Charging System 8C - 1Документ12 страницPL Charging System 8C - 1Pelis CloneОценок пока нет

- PL Heating and Air Conditioning 24 - 1Документ30 страницPL Heating and Air Conditioning 24 - 1Pelis CloneОценок пока нет

- PL Instrument Panel and Systems 8E - 1Документ14 страницPL Instrument Panel and Systems 8E - 1Pelis CloneОценок пока нет

- PL Horns 8G - 1Документ4 страницыPL Horns 8G - 1Pelis CloneОценок пока нет

- Power Door LocksДокумент6 страницPower Door LocksPelis CloneОценок пока нет

- PL Cooling 7 - 1Документ24 страницыPL Cooling 7 - 1Pelis CloneОценок пока нет

- Windshield Wipers and WashersДокумент10 страницWindshield Wipers and WashersPelis CloneОценок пока нет

- General Service InformationДокумент52 страницыGeneral Service InformationPelis CloneОценок пока нет

- PL Differential and Driveline 3 - 1Документ16 страницPL Differential and Driveline 3 - 1Pelis CloneОценок пока нет

- PL Clutch 6 - 1Документ12 страницPL Clutch 6 - 1Pelis CloneОценок пока нет

- Epl 5 PDFДокумент90 страницEpl 5 PDFPelis CloneОценок пока нет

- Epl 8m PDFДокумент12 страницEpl 8m PDFPelis CloneОценок пока нет

- PL Ignition System 8D - 1Документ20 страницPL Ignition System 8D - 1Pelis CloneОценок пока нет

- Epl 14 PDFДокумент58 страницEpl 14 PDFPelis CloneОценок пока нет

- Lamps: Lamp DiagnosisДокумент8 страницLamps: Lamp DiagnosisPelis CloneОценок пока нет

- Emission Control Systems: On-Board DiagnosticsДокумент22 страницыEmission Control Systems: On-Board DiagnosticsPelis CloneОценок пока нет

- Clutch: Fig. 1 Clutch Pedal ComponentsДокумент10 страницClutch: Fig. 1 Clutch Pedal ComponentsPelis CloneОценок пока нет

- PL Starting 8B - 1Документ8 страницPL Starting 8B - 1Pelis CloneОценок пока нет

- PL Vehicle Speed Control System 8H - 1Документ10 страницPL Vehicle Speed Control System 8H - 1Pelis CloneОценок пока нет

- Frame and BumpersДокумент10 страницFrame and BumpersPelis CloneОценок пока нет

- Engine: Standard Service ProceduresДокумент100 страницEngine: Standard Service ProceduresPelis Clone100% (1)

- Steering: General InformationДокумент42 страницыSteering: General InformationPelis CloneОценок пока нет

- PL Exhaust System and Intake Manifold 11 - 1Документ12 страницPL Exhaust System and Intake Manifold 11 - 1Pelis CloneОценок пока нет

- Light Combat AircraftДокумент5 страницLight Combat AircraftUtsav NiroulaОценок пока нет

- Principles of Accounting, Volume 2: Managerial AccountingДокумент59 страницPrinciples of Accounting, Volume 2: Managerial AccountingVo VeraОценок пока нет

- Definitions - NFPAДокумент365 страницDefinitions - NFPAAnand KrishnaОценок пока нет

- Fire Protection Engineering Summer 2001Документ33 страницыFire Protection Engineering Summer 2001Hany RifaatОценок пока нет

- Catalogo de Oleohidraulica AGVДокумент73 страницыCatalogo de Oleohidraulica AGVadjime3Оценок пока нет

- Waste Management in Selected Hotels in GoaДокумент11 страницWaste Management in Selected Hotels in GoaSyna SoaresОценок пока нет

- Whirlpool SPIW318A2WF Air ConditionerДокумент324 страницыWhirlpool SPIW318A2WF Air ConditionerAxxОценок пока нет

- Appendix I - AirДокумент155 страницAppendix I - AirTown of Colonie LandfillОценок пока нет

- PC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensДокумент2 страницыPC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensSarah JenkinsОценок пока нет

- Sincronizacion de Motor Toyota 2az-FeДокумент12 страницSincronizacion de Motor Toyota 2az-FeWilliams NavasОценок пока нет

- Global Cardiac Catheters - 2012-2018Документ4 страницыGlobal Cardiac Catheters - 2012-2018Axis Research MindОценок пока нет

- Sanjay ProjectДокумент41 страницаSanjay ProjectPrynka RawatОценок пока нет

- Ch2 Snapshot 20 LightingДокумент4 страницыCh2 Snapshot 20 Lightinggarych72Оценок пока нет

- INTEC 2019 User Manual PDFДокумент30 страницINTEC 2019 User Manual PDFshriramsusindarОценок пока нет

- Dilg-Mbcrpp Isf Q2 2023Документ2 страницыDilg-Mbcrpp Isf Q2 2023Mallari GabrielОценок пока нет

- SAP BW Basic Configuration SettingsДокумент29 страницSAP BW Basic Configuration SettingsSIKANDARОценок пока нет

- HVAC Water TreatmentДокумент7 страницHVAC Water TreatmentDuxToyОценок пока нет

- CAM Charges Working For The Month of May 2023Документ1 страницаCAM Charges Working For The Month of May 2023adnandani2882Оценок пока нет

- GCash OrientationДокумент27 страницGCash OrientationArmiel SarmientoОценок пока нет

- Starter MP EecДокумент21 страницаStarter MP EecIshan 96Оценок пока нет

- Yuli's PPT FloralДокумент28 страницYuli's PPT FloralYuli MyeshaОценок пока нет

- Training Form PDFДокумент2 страницыTraining Form PDFZurika WarniОценок пока нет

- Media and Information Literacy: ACTIVITY 1: Forget Me NotДокумент5 страницMedia and Information Literacy: ACTIVITY 1: Forget Me NotShaina Fe RabaneraОценок пока нет

- 08L76 HR3 A21Документ6 страниц08L76 HR3 A21liebofreakОценок пока нет

- Module Tes Answer Key: Student B Student AДокумент2 страницыModule Tes Answer Key: Student B Student AKremena KoevaОценок пока нет

- Pressure Flow and Temperature SwitchesДокумент16 страницPressure Flow and Temperature SwitchesMD SAMANОценок пока нет

- Serial Index CaterpillarДокумент260 страницSerial Index CaterpillarRamón Mangles90% (10)

- 200+ Network Management Tools - Open Source, Free and Commercial SoftwareДокумент29 страниц200+ Network Management Tools - Open Source, Free and Commercial SoftwarenscintaОценок пока нет

- The Dilemma of The Last FilipinoДокумент12 страницThe Dilemma of The Last FilipinoEunice Delos SantosОценок пока нет

- Dialogues in French and EnglishДокумент62 страницыDialogues in French and Englishmiki1222Оценок пока нет