Академический Документы

Профессиональный Документы

Культура Документы

Sop For Eco System

Загружено:

SonratИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sop For Eco System

Загружено:

SonratАвторское право:

Доступные форматы

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ECOS/01

Power from knowledge

SOP For Eco Ash System

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 1 of 6

STANDARD OPERATING INSTRUCTION

FOR

ECO ASH SYSTEM

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ECOS/01

Power from knowledge

SOP For Eco Ash System

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 2 of 6

STANDARD OPERATING PROCEDURE FOR BOTTOM ASH SYSTEM

OBJECTIVE: For Smooth Operation of Eco Ash System.

SCOPE: This SOP is applicable for 6 nos. of Eco Ash System.

INTRODUCTION: Eco ash system is required to collect the economizer ash particles from boiler and

dispose it to slurry sump. There are 06 nos Eco ash system for 06 units.

ECO ASH SYSTEM TECHNICAL DATA:-

EQUIPMENT CAPACITY MAKE

Eco Ash Hopper Tecpro Systems Limited

Wetting Unit 32 TPH Tecpro Systems Limited

Collector Tank 0.5 m3 Tecpro Systems Limited

Jet Pulsion Pump 176 m3/h Tecpro Systems Limited

ECO HP Pump 220 m3/h Shijiazhuang Kingda Pump

Industry Group Co.Ltd.

Slurry Pump 960 m3/h Shijiazhuang Kingda Pump

Industry Group Co.Ltd.

RESPONSIBILITY: Unit Control Engineer, Field Engineer and Desk Engineer.

SAFTEY PRECAUTIONS:

1. Ensure no permit to work is pending on regarding this system by checking with EE/MRSE.

SAFTEY PPE’s: Ear Plugs, Safety Goggles, Hand Gloves, etc.

SPECIAL TOOLS/ EQUIPMENTS: NIL

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ECOS/01

Power from knowledge

SOP For Eco Ash System

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 3 of 6

PRECHECKS AND ACTION BY FIELD ENGINEER

S No Description Ok Not Ok Remarks

1 All permits and cross permits have been returned.

2 Area is clear of any other materials.

3 Check chain guard/ belt guard/ coupling guard is not touching with

chain/ belt/ coupling.

4 Check all equipment are properly bolted & grouted.

All piping are clamped properly, flange, gasket, valve & nut & bolt

5 should be tightened.

6 Check instrument air is available.

7 Check seal water is available for HP Pump & slurry pump.

8 Check HP Pump is available for Eco de-ashing.

9 Check slurry pump is available for slurry discharge.

10 Check all the local push button is released.

PRECHECKS AND ACTION BY DESK ENGINEER

S No Description Ok Not Ok Remarks

1 All permits and cross permits have been returned.

2 Check all power sources are available.

3 Check instrument air is available for operation of valves.

4 Check seal water pump is running & required pressure is available.

5 Check HP pump is running & required pressure is available.

6 Check slurry sump level is normal.

7 Check slurry sump agitator is running.

OPERATING PROCEDURE -

Sr. RESPONSIBILITY

Description

No. UCE DE FE EE

PRE- START CHECKS:

1 All permits and cross permits have been returned.

2 Power supply and control power supply available.

3 Check instrument air is available for operation of valves.

4 Slurry discharge line pneumatic valve open.

5 HP water pressure normal & all line valves should be open.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ECOS/01

Power from knowledge

SOP For Eco Ash System

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 4 of 6

6 Slurry sump agitator is running.

START PERMISSIVE :

1 HP water pump running.

2 HP water pressure normal.

3 Slurry discharge line valve open.

4 Slurry sump level normal.

ECO SYSTEM START UP SEQUENCE :

1 All seal water line, HP water line & slurry discharge line valve open.

2 Start HP seal water pump & then HP water pump start.

3 Start slurry sump agitator.

4 Start slurry pump seal water pump.

5 Open slurry suction valve.

6 Start slurry pump.

7 Open slurry discharge valve.

SHUTDOWN SEQUENCE:

1.PLANNED SHUTDOWN :

1 After completion of complete de-ashing of Eco ash hopper.

2 Close seal water valve.

3 After flushing the line stop HP water pump if other related system is/are not running.

4 Stop the seal water pump.

2.TRIPPING OF ECO SYSTEM: If suddenly trips

1 If HP water pump is tripped then run the stand by pump.

2 Flush the slurry discharge line & rectify the problem.

3. EMERGENCY SHUT DOWN:

1 If slurry discharge line is chocked then emergency shutdown required.

2 If all HP water pump is in trouble then emergency shutdown required.

3 If all slurry pumps in trouble or slurry line is chocked then emergency shutdown

required.

INTERLOCKS : Remarks

1 If HP water pump is stopped then close the hopper discharge valve.

2 If Seal water pump is tripped then HP water pump will stop & hopper discharge

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ECOS/01

Power from knowledge

SOP For Eco Ash System

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 5 of 6

valve will close

ABRIVIATIONS / NOTATIONS:-

o SOP: Standard Operating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o DCS: Distributed Control System

o EE: Electrical Shift Engineer

o MFT: Main Fuel Trip.

o RB : Run Back

DO’s & DONT’s :

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ECOS/01

Power from knowledge

SOP For Eco Ash System

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 6 of 6

DO’s :

1. During ECO De-ashing, ensure that Ash Intake Valve is fully open.

2. Ensure material flow from ECO Ash Hoppers during ECO de-ashing .

3. During ECO De-ashing, if suction pressure at Jet pump inlet drops down below 6 Bar, close the Ash Intake

Valve immediately.

4. Ensure Discharge is closed before stating the HP Water Pump.

DONT’s :

1. Don’t close the Ash Intake Valve until the ECO Ash Hopper is completely empty.

2. Don’t stop the system until Line Flushing (ECO Hopper to Slurry Sump) is properly done.

3. Don’t stop the HP Water Pump during ECO De-ashing.

4. Don’t close the Suction/Discharge Valve before stopping the HP Water Pump.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Вам также может понравиться

- Sop For Eco-Hp Pump (r1)Документ6 страницSop For Eco-Hp Pump (r1)SonratОценок пока нет

- Sop For Ba-Hp Pump (r1)Документ6 страницSop For Ba-Hp Pump (r1)SonratОценок пока нет

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpДокумент6 страницKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratОценок пока нет

- Sop For Concentrator (r1)Документ5 страницSop For Concentrator (r1)Sonrat100% (1)

- Final KSK Sop Instrument CompressorДокумент10 страницFinal KSK Sop Instrument CompressorSonratОценок пока нет

- Sop For HCSD PumpДокумент6 страницSop For HCSD PumpSonrat100% (2)

- Sop For Dry Ash Pressure Conveying SystemДокумент7 страницSop For Dry Ash Pressure Conveying SystemSonratОценок пока нет

- SMP For Vacuum PumpДокумент9 страницSMP For Vacuum PumpSonratОценок пока нет

- Sop For LP Pump (R1)Документ6 страницSop For LP Pump (R1)SonratОценок пока нет

- Sop For Ash Slurry Pump (r1)Документ6 страницSop For Ash Slurry Pump (r1)SonratОценок пока нет

- Condenser Ball Cleaning SystemДокумент6 страницCondenser Ball Cleaning SystemSonratОценок пока нет

- Sop For LP PumpДокумент5 страницSop For LP PumpSonratОценок пока нет

- SMP For Supply Water PumpДокумент13 страницSMP For Supply Water PumpSonratОценок пока нет

- OCCW Pump SOP-1Документ7 страницOCCW Pump SOP-1SonratОценок пока нет

- Sop For LP PumpДокумент5 страницSop For LP PumpSonratОценок пока нет

- CCCWДокумент7 страницCCCWSonratОценок пока нет

- Sop For Ta CompressorДокумент8 страницSop For Ta CompressorSonratОценок пока нет

- Sop For Dry Ash Vacuum Conveying SystemДокумент8 страницSop For Dry Ash Vacuum Conveying SystemSonratОценок пока нет

- Turbine Drains SOPДокумент6 страницTurbine Drains SOPSonratОценок пока нет

- Gland Sealing Systeam011Документ6 страницGland Sealing Systeam011SonratОценок пока нет

- EH Oil Pump SOPДокумент8 страницEH Oil Pump SOPSonratОценок пока нет

- 6 Esp BlowerДокумент2 страницы6 Esp BlowerMithun Singh RajputОценок пока нет

- Standard Operating Instruction: Sop For CT FanДокумент5 страницStandard Operating Instruction: Sop For CT FanSonratОценок пока нет

- Sop For Vacuum PumpДокумент7 страницSop For Vacuum PumpSonratОценок пока нет

- Condensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantДокумент8 страницCondensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajОценок пока нет

- Sop For Vent FilterДокумент6 страницSop For Vent FilterSonratОценок пока нет

- PM WORK For Fluidizing Blower of Fly Ash SiloДокумент4 страницыPM WORK For Fluidizing Blower of Fly Ash SiloSonratОценок пока нет

- PM FOR FLY ASH Dry SystemДокумент30 страницPM FOR FLY ASH Dry SystemSonratОценок пока нет

- PM Work For Bag Filters of Fly Ash SiloДокумент4 страницыPM Work For Bag Filters of Fly Ash SiloSonrat0% (1)

- SMP For Agitator (Slurry Sump)Документ9 страницSMP For Agitator (Slurry Sump)SonratОценок пока нет

- PM For Bottom Ash Wet System SystemДокумент7 страницPM For Bottom Ash Wet System SystemSonratОценок пока нет

- PM Work For Dry Ash UnloaderДокумент4 страницыPM Work For Dry Ash UnloaderSonratОценок пока нет

- Ash Handling System SOPДокумент18 страницAsh Handling System SOPCo-gen ManagerОценок пока нет

- Stator CW SOP - Docx-1Документ12 страницStator CW SOP - Docx-1SonratОценок пока нет

- Standard Operating InstructionДокумент8 страницStandard Operating InstructionSonratОценок пока нет

- SMP For Dry Ash UnloaderДокумент8 страницSMP For Dry Ash UnloaderSonratОценок пока нет

- MDBFP Sop KSK-1Документ12 страницMDBFP Sop KSK-1SonratОценок пока нет

- Bahp Water PumpДокумент4 страницыBahp Water PumpMithun Singh RajputОценок пока нет

- Cep Sop KSKДокумент11 страницCep Sop KSKSonratОценок пока нет

- Technical Diary: STAGE-I (2 X 500 MW)Документ133 страницыTechnical Diary: STAGE-I (2 X 500 MW)scentpcbarauni BARAUNIОценок пока нет

- Chapter 15 Condensate SystemДокумент11 страницChapter 15 Condensate SystemsambhuОценок пока нет

- 3 Esp .Документ6 страниц3 Esp .Mithun Singh RajputОценок пока нет

- Trip Analysis Recommendation For The FY 2020-21 (660 MW Units)Документ45 страницTrip Analysis Recommendation For The FY 2020-21 (660 MW Units)sudhakarautomatic9940Оценок пока нет

- Sop Ldo Charging r01Документ4 страницыSop Ldo Charging r01jp mishraОценок пока нет

- ACWДокумент9 страницACWrohit_me083Оценок пока нет

- Turbine Lube Oil Cooler ChargingДокумент4 страницыTurbine Lube Oil Cooler Chargingjp mishraОценок пока нет

- Paper 3 Operational Best Practices For ESP Performance Improvement PDFДокумент79 страницPaper 3 Operational Best Practices For ESP Performance Improvement PDFDinoОценок пока нет

- SESI-TSPL-OPN-SOP-BTG-012 (APH Fire)Документ9 страницSESI-TSPL-OPN-SOP-BTG-012 (APH Fire)sourav mahapatraОценок пока нет

- Turbine Working & ItsComponentsДокумент88 страницTurbine Working & ItsComponentsHimanshu spoliaОценок пока нет

- Presentation Outline: Boiler Emergencies Turbine Emergencies Generator Emergencies Grid FailureДокумент17 страницPresentation Outline: Boiler Emergencies Turbine Emergencies Generator Emergencies Grid FailureBabu Aravind100% (1)

- PM Work For Fly Ash Wet System-1Документ15 страницPM Work For Fly Ash Wet System-1Sonrat100% (1)

- 660MW Turbo Generator & Its AuxiliariesДокумент88 страниц660MW Turbo Generator & Its AuxiliariesAshvani ShuklaОценок пока нет

- Valve Inspection ChecklistДокумент1 страницаValve Inspection ChecklistTengku Mohd ImranОценок пока нет

- Tripping Report FD Fan VFD Earth FaultДокумент4 страницыTripping Report FD Fan VFD Earth FaultAnuragОценок пока нет

- Boiler Tube Failure Gyanendra Sharma Npti DelhiДокумент41 страницаBoiler Tube Failure Gyanendra Sharma Npti DelhiNPTIОценок пока нет

- List of BHEL TOP File Handed Over To DocumentationДокумент578 страницList of BHEL TOP File Handed Over To DocumentationNaresh PattanaikОценок пока нет

- Fahp Water PumpДокумент9 страницFahp Water PumpMithun Singh RajputОценок пока нет

- Standard Operating Instruction: Sop For Condenser Ball CleaningДокумент6 страницStandard Operating Instruction: Sop For Condenser Ball CleaningSonratОценок пока нет

- Sop For Recovery Water Pump (r1) IncompleteДокумент6 страницSop For Recovery Water Pump (r1) IncompleteSonratОценок пока нет

- Sop For Flushing Water PumpДокумент6 страницSop For Flushing Water PumpSonratОценок пока нет

- Control Write Up HCSDДокумент10 страницControl Write Up HCSDSonratОценок пока нет

- Sop For Vent FilterДокумент6 страницSop For Vent FilterSonratОценок пока нет

- SMP For Vacuum PumpДокумент9 страницSMP For Vacuum PumpSonratОценок пока нет

- SMP For Dry Ash UnloaderДокумент8 страницSMP For Dry Ash UnloaderSonratОценок пока нет

- SMP For Sealing Water Pump Multi Stage.Документ13 страницSMP For Sealing Water Pump Multi Stage.SonratОценок пока нет

- Pdi EspДокумент1 страницаPdi EspSonratОценок пока нет

- SMP For Agitator (Slurry Sump)Документ9 страницSMP For Agitator (Slurry Sump)SonratОценок пока нет

- SMP For Fluidizing Air BlowerДокумент20 страницSMP For Fluidizing Air BlowerSonrat100% (1)

- SMP For Supply Water PumpДокумент13 страницSMP For Supply Water PumpSonratОценок пока нет

- SMP For Slurry PumpДокумент14 страницSMP For Slurry PumpSonrat100% (1)

- Standard Operating Procedure For Hy-Lp Bypass System: ObjectiveДокумент8 страницStandard Operating Procedure For Hy-Lp Bypass System: ObjectiveSonratОценок пока нет

- Turbine Drains SOPДокумент6 страницTurbine Drains SOPSonratОценок пока нет

- ESP-FLD. BLOWER-Model PDFДокумент1 страницаESP-FLD. BLOWER-Model PDFSonratОценок пока нет

- Silo Blower Compressor ModelДокумент1 страницаSilo Blower Compressor ModelSonratОценок пока нет

- Turbine Drains SOPДокумент6 страницTurbine Drains SOPSonratОценок пока нет

- Buffer Hopper & Air Lock Tank-ModelДокумент1 страницаBuffer Hopper & Air Lock Tank-ModelSonratОценок пока нет

- Stator CW SOP - Docx-1Документ12 страницStator CW SOP - Docx-1SonratОценок пока нет

- State Nodal Officers DS GuidelinesДокумент3 страницыState Nodal Officers DS GuidelinesSonratОценок пока нет

- Stator CW SOP-2Документ12 страницStator CW SOP-2SonratОценок пока нет

- Sop For LP PumpДокумент5 страницSop For LP PumpSonratОценок пока нет

- Sop For LP PumpДокумент5 страницSop For LP PumpSonratОценок пока нет

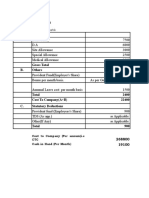

- Salary Structure Siddharth KaushikДокумент1 страницаSalary Structure Siddharth KaushikSonratОценок пока нет

- Sop For Oil Purification SystemДокумент8 страницSop For Oil Purification SystemSonrat100% (1)

- Salary AnnextureДокумент1 страницаSalary AnnextureSonratОценок пока нет

- Seal Oil SopДокумент18 страницSeal Oil SopSonrat100% (1)

- Curriculum Vitae: Nageshwar Prasad RathoreДокумент2 страницыCurriculum Vitae: Nageshwar Prasad RathoreSonratОценок пока нет

- Ossm-Osso IIsec 2.01Документ19 страницOssm-Osso IIsec 2.01Dhenny FarialОценок пока нет

- BHEL Turbine Start-UpДокумент17 страницBHEL Turbine Start-UpSelvakumar SubramanianОценок пока нет

- Mandiri Investa Bersama Company ProfileДокумент16 страницMandiri Investa Bersama Company ProfileIrfan FauzieОценок пока нет

- Application and Analysis in Fluid Power SystemsДокумент288 страницApplication and Analysis in Fluid Power Systemskhursheirani100% (1)

- Axial Piston Pumps: Variable Displacement Worldcup Series P6, 7 & 8W Design BДокумент52 страницыAxial Piston Pumps: Variable Displacement Worldcup Series P6, 7 & 8W Design BSwaminathan KbОценок пока нет

- G T Start Up ProcedureДокумент11 страницG T Start Up ProcedureJJ100% (1)

- Stanadyne Pump Diagnostic TroubleshootingДокумент3 страницыStanadyne Pump Diagnostic TroubleshootingKrishna Pardeshi100% (2)

- EPF4802 - Chapter 5 (Part 1) Utilities and Energy Efficient Design - Video - NotesДокумент14 страницEPF4802 - Chapter 5 (Part 1) Utilities and Energy Efficient Design - Video - NoteshidayantiemОценок пока нет

- Basic Hydraulic Systems and ComponentsДокумент67 страницBasic Hydraulic Systems and Componentsnareshkumaran100% (8)

- MeyleCat TruckAll en b3449Документ868 страницMeyleCat TruckAll en b3449SpicОценок пока нет

- LSM AP Brochure - 02.23Документ8 страницLSM AP Brochure - 02.23pios.helectorОценок пока нет

- Curriculum Vitae: Personal Information Mohamed Nazeer IbrahimДокумент5 страницCurriculum Vitae: Personal Information Mohamed Nazeer IbrahimjennyОценок пока нет

- FLS-pneumatic Transfer From Storage (Tse)Документ22 страницыFLS-pneumatic Transfer From Storage (Tse)Dilnesa EjiguОценок пока нет

- Manual Vertex 70vsДокумент156 страницManual Vertex 70vsbbtnОценок пока нет

- Flowserve PumpsДокумент16 страницFlowserve Pumpsdavidgaro12100% (1)

- BOMBASДокумент4 страницыBOMBASjcrrautocadОценок пока нет

- 330bl NFC AdjustДокумент10 страниц330bl NFC AdjustDaniel Rhasty-ghee AhmanorОценок пока нет

- ITT Lowara Pumps TDBTDVXXXX-BXДокумент92 страницыITT Lowara Pumps TDBTDVXXXX-BXYves AvermateОценок пока нет

- MPR MicroprojectДокумент11 страницMPR MicroprojectNight fadeОценок пока нет

- GX Catalogue2013Документ32 страницыGX Catalogue2013Leobardo DiazОценок пока нет

- Module 3 - Block Diagram For Water SystemДокумент5 страницModule 3 - Block Diagram For Water SystemSatender KumarОценок пока нет

- Diagrama Hidraulico Caterpillar 345cДокумент2 страницыDiagrama Hidraulico Caterpillar 345cJose Miguel Gary Vargas100% (1)

- Lecture On Affinity Laws Pump PerformanceДокумент9 страницLecture On Affinity Laws Pump Performanceanon_697758605Оценок пока нет

- Bukh Diesel Engine Type BBD1105 & BBV1505 Operator's Maintenance ManualДокумент40 страницBukh Diesel Engine Type BBD1105 & BBV1505 Operator's Maintenance ManualmarcusОценок пока нет

- SAMGONG-MITSUBISHI S3037 Purifier Instruction ManualДокумент101 страницаSAMGONG-MITSUBISHI S3037 Purifier Instruction Manualpescarra-167% (3)

- TUTORIAL 3b - Flow in PipesДокумент2 страницыTUTORIAL 3b - Flow in Pipessam19961Оценок пока нет

- Specificatii Tehnice Np3153.091 MTДокумент16 страницSpecificatii Tehnice Np3153.091 MTDaniel CringusОценок пока нет

- CVP Model ManualДокумент28 страницCVP Model ManualvictorОценок пока нет

- PCP0325EДокумент14 страницPCP0325ERizky Riva'iОценок пока нет

- Parallel and Series PumpДокумент1 страницаParallel and Series PumpMary Grace AlmiranezОценок пока нет