Академический Документы

Профессиональный Документы

Культура Документы

Sop For Flushing Water Pump

Загружено:

SonratОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sop For Flushing Water Pump

Загружено:

SonratАвторское право:

Доступные форматы

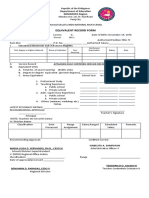

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/FWP/01

Power from knowledge

SOP For Flushing Water Pump

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 1 of 6

STANDARD OPERATING INSTRUCTION

FOR

FLUSHING WATER

PUMP

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/FWP/01

Power from knowledge

SOP For Flushing Water Pump

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 2 of 6

STANDARD OPERATING PROCEDURE FOR FLUSHING WATER PUMP

OBJECTIVE: For Smooth Operation of flushing water pump.

SCOPE: Flushing water pump is required for flushing the slurry discharge line.

INTRODUCTION: It is obtained by 04 nos of flushing water pump for 06 units. For 03 units 01 no flushing

water pump is running and another one is standby).

PRE CHECKS:

FLUSHING WATER PUMP TECHNICAL DATA:-

Make Zhenjiang Auxilary Quantity 04 Nos

Machinery

Type 65ZGB Discharge Capacity 54m³/h

Discharge 0.62mpa Rotating speed r/min

Pressure

Flushing water pump motor

Type Y200L-4 Power 30kW

Voltage 11KV Current

Rotating speed r/min

RESPONSIBILITY: Unit Control Engineer, Field Engineer and Desk Engineer.

SAFTEY PRECAUTIONS:

1. Ensure no permit to work is pending on regarding this system by checking with EE/MRSE.

SAFTEY PPE’s: Ear Plugs, Safety Goggles, Hand Gloves, etc.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/FWP/01

Power from knowledge

SOP For Flushing Water Pump

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 3 of 6

SPECIAL TOOLS/ EQUIPMENTS: NIL

PRECHECKS AND ACTION BY FIELD ENGINEER

S Description Ok Not Ok Remarks

No

1 All permits and cross permits have been returned.

2 Area is clear of any other materials.

3 Check all the foundation bolt should be tight properly.

4 Check whether base frame is grouted properly.

5 Check the coupling bolt should be tight properly.

6 Check coupling guard is not touching with coupling.

7 Check the lubrication of pump & its accessories.

8 Check Pump is not rotate in reverse direction.

9 Check all pipe line flange & coupling nut bolt properly tight.

10 Check water tank discharge valve open.

11 Check pump discharge valve closed.

PRECHECKS AND ACTION BY DESK ENGINEER

S Description Ok Not Ok Remarks

No

1 Check MCC panel feeder is ready.

2 Check control supply is healthy.

4 Check local push button released.

OPERATING PROCEDURE -

Sr. RESPONSIBILITY

No Description UCE DE FE E

. E

PRE- START CHECKS:

1 All permits and cross permits have been returned.

2 Power supply and control power supply available.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/FWP/01

Power from knowledge

SOP For Flushing Water Pump

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 4 of 6

3 Pump suction & discharge valve closed.

4 Buffer water tank level is normal.

START PERMISSIVE :

1 Pump suction & discharge valve closed.

2 Emergency push button is in release condition.

3 Buffer water tank level is normal.

FLUSHING WATER PUMP START UP SEQUENCE :

1 Open the flushing water pump suction valve.

2 Start the flushing water pump.

3 Open the flushing water pump discharge valve.

SHUTDOWN SEQUENCE:

1.PLANNED SHUTDOWN :

1 Insure that stand by flushing water pump is running condition.

2 Stop the flushing water pump, closed the suction & discharge valve.

3 Rectify the probable problem, if any.

2.TRIPPING OF FLUSHING WATER PUMP: If suddenly pump trips

1 Closed the pump suction & discharge valve.

2 Try to start stand by flushing water pump.

3. EMERGENCY SHUT DOWN:

1 There is the apparent abnormal noise after starting the pump.

2 The pump & motor bearing temperature is feeling very high.

3 When discharge line is leakage.

4 When endangering the safety of person and equipment.

INTERLOCKS : Remarks

1 Buffer water tank level is danger low.

2 Pump suction & discharge open feedback.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/FWP/01

Power from knowledge

SOP For Flushing Water Pump

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 5 of 6

ABRIVIATIONS / NOTATIONS:-

o SOP: Standard Operating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o DCS: Distributed Control System

o EE: Electrical Shift Engineer

o MFT: Main Fuel Trip.

o RB : Run Back

DO’s & DONT’s :

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/FWP/01

Power from knowledge

SOP For Flushing Water Pump

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 6 of 6

DO’s :

1. Ensure that Service Water (Buffer Water Tank Make-up) is available.

2. Ensure Discharge is closed before stating of Pump.

3. Before starting, ensure that nozzles are clean and the valves are in open condition.

DONT’s :

1. Don’t run the Pump if Buffer Water Tank level is low.

2. Don’t run the Pump if Cooling Oil level is low.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Вам также может понравиться

- Sop For HCSD PumpДокумент6 страницSop For HCSD PumpSonrat100% (2)

- SMP For Supply Water PumpДокумент13 страницSMP For Supply Water PumpSonratОценок пока нет

- CCCWДокумент7 страницCCCWSonratОценок пока нет

- OCCW Pump SOP-1Документ7 страницOCCW Pump SOP-1SonratОценок пока нет

- Standard Operating Instruction: Sop For Condenser Ball CleaningДокумент6 страницStandard Operating Instruction: Sop For Condenser Ball CleaningSonratОценок пока нет

- EH Oil Pump SOPДокумент8 страницEH Oil Pump SOPSonratОценок пока нет

- Wet Preservation SOPДокумент6 страницWet Preservation SOPShambhu MehtaОценок пока нет

- Sop For LP PumpДокумент5 страницSop For LP PumpSonratОценок пока нет

- Sop For LP PumpДокумент5 страницSop For LP PumpSonratОценок пока нет

- Sop For Eco SystemДокумент6 страницSop For Eco SystemSonratОценок пока нет

- Sop For Vent FilterДокумент6 страницSop For Vent FilterSonratОценок пока нет

- Sop For LP Pump (R1)Документ6 страницSop For LP Pump (R1)SonratОценок пока нет

- Turbine Drains SOPДокумент6 страницTurbine Drains SOPSonratОценок пока нет

- Circulating Water PumpДокумент10 страницCirculating Water PumpsambhuОценок пока нет

- SMP For Vacuum PumpДокумент9 страницSMP For Vacuum PumpSonratОценок пока нет

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpДокумент6 страницKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratОценок пока нет

- Gland Sealing Systeam011Документ6 страницGland Sealing Systeam011SonratОценок пока нет

- SOP for HP water pump operationДокумент6 страницSOP for HP water pump operationSonratОценок пока нет

- Boiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantДокумент11 страницBoiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajОценок пока нет

- JSA - Main Turbine Lub Oil Pumps - OHДокумент2 страницыJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- Sop For Boiler Hydro TestДокумент4 страницыSop For Boiler Hydro TestHardik ThumarОценок пока нет

- SOP Boiler HydrotestДокумент3 страницыSOP Boiler HydrotestSachin nandgaye0% (2)

- Total power failure restoration and cold start up proceduresДокумент8 страницTotal power failure restoration and cold start up proceduresrpshvjuОценок пока нет

- 7 CompressorДокумент2 страницы7 CompressorMithun Singh RajputОценок пока нет

- SOP For Condenser Rubber Ball Cleaning System HBSДокумент8 страницSOP For Condenser Rubber Ball Cleaning System HBSAbeer arifОценок пока нет

- SOP for Turbine Lube Oil SystemДокумент34 страницыSOP for Turbine Lube Oil SystemSonratОценок пока нет

- Commissioning Circulating Pumps at 600MW Power PlantДокумент15 страницCommissioning Circulating Pumps at 600MW Power Plantrohit_me083Оценок пока нет

- Sop For Total Power Failure.Документ4 страницыSop For Total Power Failure.anon_251342212Оценок пока нет

- Duty Pump TestДокумент1 страницаDuty Pump TestMohd Aliff Mohd YunosОценок пока нет

- Sop TurbineДокумент4 страницыSop TurbinesambhuОценок пока нет

- POWER PLANT MAINTENANCE EQUIPMENT CLEANINGДокумент25 страницPOWER PLANT MAINTENANCE EQUIPMENT CLEANINGMariusDragoescuОценок пока нет

- SOP For Closed Cooling Water SystemДокумент16 страницSOP For Closed Cooling Water SystemAbeer arif100% (1)

- Check List Start Up and Comissioning of Fire Pumps 2Документ6 страницCheck List Start Up and Comissioning of Fire Pumps 2ismail_khansОценок пока нет

- NK - 008 Approved Procedure For STEAM BLOWING of North KaranpuraДокумент28 страницNK - 008 Approved Procedure For STEAM BLOWING of North KaranpuraHimanshu ChaturvediОценок пока нет

- Commissioning Steps Power Plant Under 40Документ3 страницыCommissioning Steps Power Plant Under 40ssheart_mind100% (1)

- Testing Schedule For Commissioning of Condensate Extraction PumpsДокумент13 страницTesting Schedule For Commissioning of Condensate Extraction PumpsJackSparrow86100% (1)

- Final AOH Report - TMD 060818Документ15 страницFinal AOH Report - TMD 060818sanmukhaОценок пока нет

- Tandem lifting method at ACC siteДокумент7 страницTandem lifting method at ACC siteHsebepl NkОценок пока нет

- Standard Operating Procedure: Title: Sop For Cooling Water Pump/Tower Section No.: 13Документ2 страницыStandard Operating Procedure: Title: Sop For Cooling Water Pump/Tower Section No.: 13KUSH SHARMAОценок пока нет

- Sop For Oil Purification SystemДокумент8 страницSop For Oil Purification SystemSonrat100% (1)

- Condenser Flood Test 8 of 11Документ14 страницCondenser Flood Test 8 of 11Sara LopezОценок пока нет

- SOP For BFPДокумент2 страницыSOP For BFPsambhuОценок пока нет

- Flushing Procedure For Chilled Water System - Chemical Treatment - Method Statement HQДокумент3 страницыFlushing Procedure For Chilled Water System - Chemical Treatment - Method Statement HQابوزيد عبد الجوادОценок пока нет

- Boiler Commissioning ProcedureДокумент5 страницBoiler Commissioning Procedurekumarmm1234Оценок пока нет

- Submersible Pump InspectionДокумент12 страницSubmersible Pump InspectionTrungVuDinhОценок пока нет

- TEMPORARY POWER PROJECT PANEL INSTALLATIONДокумент18 страницTEMPORARY POWER PROJECT PANEL INSTALLATIONNurdin Sudrajat SasrabahuОценок пока нет

- 6 Esp BlowerДокумент2 страницы6 Esp BlowerMithun Singh RajputОценок пока нет

- DI Pipe Handling and Storage ProcedureДокумент8 страницDI Pipe Handling and Storage ProcedureFrancis DhanarajОценок пока нет

- 18 Air Compressor System Commissioning Procedure-T Säï T +T+ƑF Âf Ò Ä Û+Документ17 страниц18 Air Compressor System Commissioning Procedure-T Säï T +T+ƑF Âf Ò Ä Û+kvsagar0% (1)

- SOP for Starting CEPДокумент8 страницSOP for Starting CEPSaravanan SundararajОценок пока нет

- Jsa Cooling TowerДокумент5 страницJsa Cooling TowerRavi thokalОценок пока нет

- Stage 1 Steam Line Cleaning ProcedureДокумент18 страницStage 1 Steam Line Cleaning ProcedurearuntpeОценок пока нет

- Chemical Dosing Pump SATRДокумент2 страницыChemical Dosing Pump SATRDeshan Sing100% (1)

- Chemical Dosing Pump Checklist Site Acceptance Test ReportДокумент2 страницыChemical Dosing Pump Checklist Site Acceptance Test ReportDeshan Sing100% (1)

- Overhauling Manual PDFДокумент118 страницOverhauling Manual PDFlaloo01Оценок пока нет

- Functional Change of Sac Into Iac: Standard Field Operating ProcedureДокумент7 страницFunctional Change of Sac Into Iac: Standard Field Operating ProcedureMithun Singh RajputОценок пока нет

- FF Water Sprinkler Test ProcedureДокумент2 страницыFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- Sop For Recovery Water Pump (r1) IncompleteДокумент6 страницSop For Recovery Water Pump (r1) IncompleteSonratОценок пока нет

- Vacuum Pump SOPДокумент7 страницVacuum Pump SOPSonratОценок пока нет

- Sop For Eco-Hp Pump (r1)Документ6 страницSop For Eco-Hp Pump (r1)SonratОценок пока нет

- KSK Mahanadi Thermal Power Project Control Write UpДокумент10 страницKSK Mahanadi Thermal Power Project Control Write UpSonratОценок пока нет

- SMP For Agitator (Slurry Sump)Документ9 страницSMP For Agitator (Slurry Sump)SonratОценок пока нет

- Bah ElevationДокумент1 страницаBah ElevationSonratОценок пока нет

- Bah Side ViewДокумент1 страницаBah Side ViewSonratОценок пока нет

- FluidizingДокумент13 страницFluidizingSonratОценок пока нет

- SMP For Slurry PumpДокумент14 страницSMP For Slurry PumpSonrat100% (1)

- SMP For Sealing Water Pump Multi Stage.Документ13 страницSMP For Sealing Water Pump Multi Stage.SonratОценок пока нет

- Part List - BEL0800 PDFДокумент1 страницаPart List - BEL0800 PDFSonratОценок пока нет

- SMP For Ba Overflow PumpДокумент14 страницSMP For Ba Overflow PumpSonratОценок пока нет

- SMP For Dry Ash UnloaderДокумент8 страницSMP For Dry Ash UnloaderSonratОценок пока нет

- PM For Fly Ash Dry SystemДокумент31 страницаPM For Fly Ash Dry SystemSonratОценок пока нет

- SMP For Vacuum PumpДокумент9 страницSMP For Vacuum PumpSonratОценок пока нет

- SMP For Fluidizing Air BlowerДокумент20 страницSMP For Fluidizing Air BlowerSonrat100% (1)

- Sop For Vent FilterДокумент6 страницSop For Vent FilterSonratОценок пока нет

- HCSD PDFДокумент1 страницаHCSD PDFSonratОценок пока нет

- ECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFДокумент1 страницаECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFSonratОценок пока нет

- FluidizingДокумент13 страницFluidizingSonratОценок пока нет

- Water & Slurry BalanceДокумент1 страницаWater & Slurry BalanceSonratОценок пока нет

- Over Flow Pump Concentrator Buffer Tank ModelДокумент1 страницаOver Flow Pump Concentrator Buffer Tank ModelSonratОценок пока нет

- BAH JET PUMP DISCHAGE PIPE LINE-Model PDFДокумент1 страницаBAH JET PUMP DISCHAGE PIPE LINE-Model PDFSonratОценок пока нет

- ASH WATER PUMP HOUSE-Model PDFДокумент1 страницаASH WATER PUMP HOUSE-Model PDFSonratОценок пока нет

- StructureДокумент1 страницаStructureSonratОценок пока нет

- Compressor House ModelДокумент1 страницаCompressor House ModelSonratОценок пока нет

- ESP-FLD. BLOWER-Model PDFДокумент1 страницаESP-FLD. BLOWER-Model PDFSonratОценок пока нет

- Pdi EspДокумент1 страницаPdi EspSonratОценок пока нет

- Silo Unloading ModelДокумент1 страницаSilo Unloading ModelSonratОценок пока нет

- VP To Buffr Hopper-ModelДокумент1 страницаVP To Buffr Hopper-ModelSonratОценок пока нет

- Silo Blower Compressor ModelДокумент1 страницаSilo Blower Compressor ModelSonratОценок пока нет

- SEPCO Electric Power Construction Corporation and NORTHEAST ELECTRIC POWER DESIGN INSTITUTE As Built DrawingДокумент1 страницаSEPCO Electric Power Construction Corporation and NORTHEAST ELECTRIC POWER DESIGN INSTITUTE As Built DrawingSonratОценок пока нет

- Hci01 HumanComputerInteraction OverviewДокумент140 страницHci01 HumanComputerInteraction OverviewAlexSpiridonОценок пока нет

- Linked ListДокумент83 страницыLinked Listshahida18Оценок пока нет

- GDcorrespondencecourselessons 165Документ8 страницGDcorrespondencecourselessons 165olly rathboneОценок пока нет

- ALT Company Introduction 20170524.1Документ51 страницаALT Company Introduction 20170524.1Terence WoonОценок пока нет

- Plate Tectonics LessonДокумент3 страницыPlate Tectonics LessonChristy P. Adalim100% (2)

- Biology 11th Edition Mader Test BankДокумент25 страницBiology 11th Edition Mader Test BankAnthonyWeaveracey100% (44)

- Comparison of AdjectivesДокумент2 страницыComparison of AdjectivesmallxОценок пока нет

- Academic Language Use in Academic WritingДокумент15 страницAcademic Language Use in Academic WritingDir Kim FelicianoОценок пока нет

- School readiness assessmentДокумент10 страницSchool readiness assessmentJave Gene De AquinoОценок пока нет

- Equivalent Record Form: Department of Education MIMAROPA RegionДокумент1 страницаEquivalent Record Form: Department of Education MIMAROPA RegionEnerita AllegoОценок пока нет

- Participatory Assessment of Ragay Gulf Resources and SocioeconomicsДокумент167 страницParticipatory Assessment of Ragay Gulf Resources and SocioeconomicsCres Dan Jr. BangoyОценок пока нет

- PTW QuestionareДокумент63 страницыPTW QuestionareIshtiaq Ahmad100% (2)

- Working Capital Management (2015)Документ62 страницыWorking Capital Management (2015)AJОценок пока нет

- Ezequiel Reyes CV EngДокумент1 страницаEzequiel Reyes CV Engezequiel.rdОценок пока нет

- 11.trouble Shooting For TMДокумент9 страниц11.trouble Shooting For TMfrezgi birhanuОценок пока нет

- Rigor Mortis and Lividity in Estimating Time of DeathДокумент2 страницыRigor Mortis and Lividity in Estimating Time of DeathfunnyrokstarОценок пока нет

- Srimanta Shankardev: Early LifeДокумент3 страницыSrimanta Shankardev: Early LifeAnusuya BaruahОценок пока нет

- CVR College of Engineering: UGC Autonomous InstitutionДокумент2 страницыCVR College of Engineering: UGC Autonomous Institutionshankar1577Оценок пока нет

- Course Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataДокумент61 страницаCourse Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataShekinah Vingno LingcongОценок пока нет

- EMA Guideline on Calculating Cleaning LimitsДокумент4 страницыEMA Guideline on Calculating Cleaning LimitsshivanagiriОценок пока нет

- Facelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger FaceДокумент136 страницFacelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger Faceugur gebologluОценок пока нет

- Austin's Cover Letter Example - Cultivated CultureДокумент1 страницаAustin's Cover Letter Example - Cultivated CultureYash SОценок пока нет

- 3.5 Lonaphala S A3.99 PiyaДокумент9 страниц3.5 Lonaphala S A3.99 PiyaPiya_TanОценок пока нет

- JNTUA Mechanical Engineering (R09) Syllabus BookДокумент147 страницJNTUA Mechanical Engineering (R09) Syllabus Bookslv_prasaad0% (1)

- The Leaders of The NationДокумент3 страницыThe Leaders of The NationMark Dave RodriguezОценок пока нет

- Hazop Recommendation Checked by FlowserveДокумент2 страницыHazop Recommendation Checked by FlowserveKareem RasmyОценок пока нет

- Cult of KUДокумент31 страницаCult of KUEli GiudiceОценок пока нет

- Day 2 TaskДокумент4 страницыDay 2 TaskYaathriganОценок пока нет

- KENDRIYA VIDYALAYA Biology Investigatory ProjectДокумент28 страницKENDRIYA VIDYALAYA Biology Investigatory Projectvishali GОценок пока нет