Академический Документы

Профессиональный Документы

Культура Документы

Copper Conductor Test - Shrinkage Test & Heat Shock Test

Загружено:

vijay waghАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Copper Conductor Test - Shrinkage Test & Heat Shock Test

Загружено:

vijay waghАвторское право:

Доступные форматы

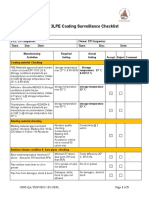

Copper Conductor Test Shrinkage Test & Heat shock Test

Shrinkage Test Heat Shock Test Thermal stability of PVC Insulation & Sheath

Date : 31/08/2019 Date : 31/08/2019 Date : 31/08/2019

Machine : Extrusion 65 mm Machine : Extrusion 65 mm Machine : Extrusion 65 mm

Sample Size= 7/36 - 3 Core sheathed cable Sample : 7/36 - 3 Core sheathed cable of 4.5 mm Dia Sample : 7/36 - 3 Core sheathed cable of 4.5 mm Dia

Type of Conductor Tinned Copper wire Type of conductor Tinned copper wire Type of conductor Tinned copper wire

O.D. ( in mm ) 4.48 4.44 4.42 Apparatus : Hot Air oven Apparatus : Thermal stability tester

Sample length= 260 mm Set Temperature : 150° C Set Temperature : 150° C

Holding Time in 1. Sheath

Length After 60 Minutes

striping & Before Oven

219 Sheath colour : Grey

Keeping it in oven

( mm ) Observation: None marks & cracks found on specimen

Holding Time in

Thermal stability

Set temperature 150° C 40 Minutes

Examine sample visually for any cracks after tester ( For

cooling it off at room temperature for 1 hour. If no Sheath )

Holding Time at Requirement

15 Minutes crack found on specimen the sample has passed Mass of Sheath 49 mg

set temperature the test

Observation: No colour change of pH paper

Sample length Result: Sample has passed the test

after taking out of 215 Result : Sample passed the test 2. Insulation

oven ( mm )

Insulation colour : Red/Black/ Green

Shrinkage in Holding Time in

1.83 thermal stability

percentage (%)

tester ( For 80 Minutes

If shrinkage found more than 4% , the specimen fails insulation )

If shrinkage found less than 4% , sample has passed the test

Result : Specimen passed the test Mass of all sheath 47 mg, 52mg , 56 mg

Requirement: No colour change of pH paper for minimum 40 Mins

Observation No colour change of insulation

Result Sample has passed the test

8/31/2019 18:15:55 1

Вам также может понравиться

- Protective Clothing Requirements for FirefightersДокумент2 страницыProtective Clothing Requirements for FirefightersGMОценок пока нет

- Test Reports - NBRДокумент105 страницTest Reports - NBRImtiyaz KhanОценок пока нет

- Color Index Story PDFДокумент4 страницыColor Index Story PDFAsim khandual50% (2)

- Twad Board Sor 2017-18Документ294 страницыTwad Board Sor 2017-18Nagarjuna KunchamОценок пока нет

- Pedestal Burn TestДокумент1 страницаPedestal Burn TestPauly HerreraОценок пока нет

- Steripleat Vent: Sterile Tank Vent FiltrationДокумент3 страницыSteripleat Vent: Sterile Tank Vent FiltrationPraful IngleОценок пока нет

- 3M VHB Adhesive Transfer Tape F9469PCДокумент8 страниц3M VHB Adhesive Transfer Tape F9469PCSaravanabhavan ChandrasekarОценок пока нет

- Syncure™ S1054A Natural: Crosslinked PolyethyleneДокумент2 страницыSyncure™ S1054A Natural: Crosslinked PolyethyleneHomero RamosОценок пока нет

- HT Process Validation-AshishДокумент9 страницHT Process Validation-Ashishashish mishraОценок пока нет

- 3M Polyurethane Sealant 540Документ7 страниц3M Polyurethane Sealant 540vivek jayswalОценок пока нет

- 3M Polyurethane Sealant 540Документ7 страниц3M Polyurethane Sealant 540vivek jayswalОценок пока нет

- DELRIN 150 Series Nat Acetal Homopolymer 14Документ1 страницаDELRIN 150 Series Nat Acetal Homopolymer 14kgrier8966Оценок пока нет

- Mouser EpoxyДокумент2 страницыMouser EpoxyChen josephОценок пока нет

- Data Sheet Multi-Channel Duct: Doc. No. DIPL-M/QA/PDS/FPF/693 Rev. 00, Issue: 1 - Issue Date: 09 - Aug, 2017Документ2 страницыData Sheet Multi-Channel Duct: Doc. No. DIPL-M/QA/PDS/FPF/693 Rev. 00, Issue: 1 - Issue Date: 09 - Aug, 2017Murali KrishnaОценок пока нет

- Celanyl Product-Pdf-345596Документ1 страницаCelanyl Product-Pdf-345596Rafael CastroОценок пока нет

- Instrument Cable Test MethodsДокумент3 страницыInstrument Cable Test MethodsParesh Ghodasara100% (1)

- Advanced Barrier Protection: 3M Personal SafetyДокумент4 страницыAdvanced Barrier Protection: 3M Personal Safetylucky414Оценок пока нет

- FG 2120Документ3 страницыFG 2120Mohit AggarwalОценок пока нет

- FORMUL Product-Catalogue PDFДокумент84 страницыFORMUL Product-Catalogue PDFADARA SARLОценок пока нет

- 3M™ Adhesive Transfer Tape 966_20231209Документ10 страниц3M™ Adhesive Transfer Tape 966_20231209Son NguyenОценок пока нет

- Northern India Textile Research Association, Ghaziabad: Polymer & Technical Textiles LaboratoryДокумент4 страницыNorthern India Textile Research Association, Ghaziabad: Polymer & Technical Textiles LaboratoryNitraNtcОценок пока нет

- 3M™ VHB™ Tape RP+040GF - 20230121Документ8 страниц3M™ VHB™ Tape RP+040GF - 20230121tripathi prashantОценок пока нет

- TDS BorSafe ME3444 (E115026)Документ2 страницыTDS BorSafe ME3444 (E115026)charlesОценок пока нет

- Lecture26 PDFДокумент67 страницLecture26 PDFBinayak KumarОценок пока нет

- 3M™ Adhesive Transfer Tape 950 - 20240112Документ8 страниц3M™ Adhesive Transfer Tape 950 - 20240112qualityОценок пока нет

- Azeeta PP-R Hot & Cold Water Plumbing System Catalogue VisualДокумент8 страницAzeeta PP-R Hot & Cold Water Plumbing System Catalogue VisualSyed HusseinОценок пока нет

- PT100Документ1 страницаPT100aneleyОценок пока нет

- Jotun Adhesion Test Report Pull-Off Test ResultsДокумент7 страницJotun Adhesion Test Report Pull-Off Test Resultsudin cupuОценок пока нет

- Araldite Av138 hv998Документ7 страницAraldite Av138 hv998Nautique SolutionsОценок пока нет

- Soaking Time Validation - Heat Treatment[1] [Read-Only]Документ6 страницSoaking Time Validation - Heat Treatment[1] [Read-Only]ashish mishraОценок пока нет

- Eccoh 5836 TDS01 2018-10Документ2 страницыEccoh 5836 TDS01 2018-10bobОценок пока нет

- Santoprene™ 121-75M100: Thermoplastic VulcanizateДокумент3 страницыSantoprene™ 121-75M100: Thermoplastic VulcanizateBrian García AguirreОценок пока нет

- Technical Data SheetДокумент1 страницаTechnical Data SheetNiko SwandanaОценок пока нет

- Coating Mill Surveillance ChecklistДокумент3 страницыCoating Mill Surveillance ChecklistlincinkrishnanОценок пока нет

- UL Test ProcedureДокумент3 страницыUL Test ProcedureParagОценок пока нет

- UL94 Flammability Test ProceduresДокумент3 страницыUL94 Flammability Test ProceduresAn TranОценок пока нет

- Tabulized Data For StatДокумент4 страницыTabulized Data For StatJohn Phillipp MacaraigОценок пока нет

- Elastomer testing guideДокумент5 страницElastomer testing guideEric FernandesОценок пока нет

- Quality TestДокумент3 страницыQuality TestsijogeorgeofficialОценок пока нет

- Hoja-Tecnica-3m Scotch-Weld Epoxy Adhesive DP460 Off WhiteДокумент15 страницHoja-Tecnica-3m Scotch-Weld Epoxy Adhesive DP460 Off WhiteJOEL EZEQUIEL PACHECO MENAОценок пока нет

- Testo 104 Data SheetДокумент2 страницыTesto 104 Data SheetpradipОценок пока нет

- 3M™ Double Coated Tissue Tape 9448A - 20230321Документ12 страниц3M™ Double Coated Tissue Tape 9448A - 20230321Ghenal RiveraОценок пока нет

- 3M Adhesive Transfer Tape 467MPДокумент7 страниц3M Adhesive Transfer Tape 467MPNerissa CastilloОценок пока нет

- 3M VHB Tape 5952Документ9 страниц3M VHB Tape 5952Vivek JayswalОценок пока нет

- Neltex PPR PN 20Документ3 страницыNeltex PPR PN 20ChrisОценок пока нет

- Hot Set OvenДокумент2 страницыHot Set OvenDebasis MallickОценок пока нет

- Rolling Thin Film Oven Accurately Simulates Asphalt AgingДокумент1 страницаRolling Thin Film Oven Accurately Simulates Asphalt AgingHuda MahdiОценок пока нет

- 3M™ VHB™ Tape 5962 - 20231024Документ10 страниц3M™ VHB™ Tape 5962 - 20231024energyengineerestОценок пока нет

- Hanwha Total PP FH44Документ3 страницыHanwha Total PP FH44Nguyễn Hồng NamОценок пока нет

- Ignitability Test ProcedureДокумент5 страницIgnitability Test ProcedureAlief AnggaОценок пока нет

- WT 1205 16 Feb 2019Документ6 страницWT 1205 16 Feb 2019smtplvikasОценок пока нет

- 3M™ Scotch-Weld™ Epoxy Adhesive DP460 Off White - 20230718Документ10 страниц3M™ Scotch-Weld™ Epoxy Adhesive DP460 Off White - 20230718arthurms325Оценок пока нет

- 035 Test Record Fire Resistant Rev DGKДокумент1 страница035 Test Record Fire Resistant Rev DGKSyauqy AlfarakaniОценок пока нет

- 3M™ Adhesive Transfer Tape 9471 - 20231201Документ8 страниц3M™ Adhesive Transfer Tape 9471 - 20231201dsfasdfafsОценок пока нет

- SDS Es EsДокумент2 страницыSDS Es EsJuan David Guerrero MurciaОценок пока нет

- Inspection CertДокумент1 страницаInspection CertVICTORI AОценок пока нет

- CPVC Geon PM280Документ1 страницаCPVC Geon PM280angelokyoОценок пока нет

- TECAPEEK Natural Polyetheretherketone 14Документ2 страницыTECAPEEK Natural Polyetheretherketone 14kgrier8966Оценок пока нет

- Material Safety Data Sheet For PVC CompoundДокумент1 страницаMaterial Safety Data Sheet For PVC CompoundmaxОценок пока нет

- Remaclave 60 2017 eДокумент5 страницRemaclave 60 2017 eAlejandro Victor Estremadoyro CuevaОценок пока нет

- SeraConP ARДокумент5 страницSeraConP ARArbab SkunderОценок пока нет

- CodeДокумент13 страницCodeKamlesh Steel industriesОценок пока нет

- 3 Marks (Metals and Non-Metals)Документ13 страниц3 Marks (Metals and Non-Metals)simrannehraa2Оценок пока нет

- Setting Time For ggbs-2019Документ12 страницSetting Time For ggbs-2019Yara MounaОценок пока нет

- Sa 4820M00450 00001 01 - 00Документ1 страницаSa 4820M00450 00001 01 - 00mohdfaridabubakarОценок пока нет

- NEET/JEE 2020-21 DPP - Don't Solve This Periodic Properties Practice PaperДокумент3 страницыNEET/JEE 2020-21 DPP - Don't Solve This Periodic Properties Practice Papershantinath123gmailcoОценок пока нет

- Part 3 Chapter2Документ33 страницыPart 3 Chapter2Mahmoud AlnaserОценок пока нет

- Childers PDS CP 70 R0719Документ2 страницыChilders PDS CP 70 R0719Maikol Cedeño CerdasОценок пока нет

- Greenhouse homework on plant cellsДокумент5 страницGreenhouse homework on plant cellsMadhav ManjulalОценок пока нет

- Linda - Review W CKI - 04mar20 - Increasing 10percent of Contract Unit RateДокумент54 страницыLinda - Review W CKI - 04mar20 - Increasing 10percent of Contract Unit RateoktianaОценок пока нет

- Pumps Aeration Steering Controls.122212108 PDFДокумент149 страницPumps Aeration Steering Controls.122212108 PDFpngchanhОценок пока нет

- QA FLOW CHARTДокумент1 страницаQA FLOW CHARTAnkurОценок пока нет

- OSOS OMBLIGO AmigurumiДокумент12 страницOSOS OMBLIGO AmigurumiANDREA ULTENGOОценок пока нет

- Mitsubishi Process of Copper MakingДокумент23 страницыMitsubishi Process of Copper MakingSwarnaRakshitОценок пока нет

- Process Control LДокумент23 страницыProcess Control Ltariq fareedОценок пока нет

- SteelДокумент6 страницSteelJ LorbelОценок пока нет

- Staircase DetailДокумент1 страницаStaircase DetailsadafОценок пока нет

- Armacell 168158 Data Spec Sheet PDFДокумент2 страницыArmacell 168158 Data Spec Sheet PDFCarlos Gustavo Gámez VillegasОценок пока нет

- Dehyton AB 30Документ2 страницыDehyton AB 30dedeteОценок пока нет

- 01-50-911 en Soldadura MIG y TIGДокумент24 страницы01-50-911 en Soldadura MIG y TIGjuliae194Оценок пока нет

- CSWIP 3.2 Multiple ChoiceДокумент10 страницCSWIP 3.2 Multiple Choicerandhir kumar jha0% (1)

- Formosa Ldpe Data SheetДокумент5 страницFormosa Ldpe Data SheetBasant AGarwalОценок пока нет

- Sustainable TextilesДокумент23 страницыSustainable TextilesGupta KiraОценок пока нет

- Brochure Poliver March 2014Документ2 страницыBrochure Poliver March 2014NayBonitaОценок пока нет

- Bejs Bridge Expansion Joint System Tech Data Sheet EmsealДокумент3 страницыBejs Bridge Expansion Joint System Tech Data Sheet EmsealrenandОценок пока нет

- 5070 w17 QP 42 PDFДокумент14 страниц5070 w17 QP 42 PDFdR SHAMMIR AHMEDОценок пока нет

- Abrasion Resistance of High-Strength Concrete in Hydraulic StructuresДокумент8 страницAbrasion Resistance of High-Strength Concrete in Hydraulic StructuresEjaz RahimiОценок пока нет

- ASME B31.3 Process Piping Wall Thickness CalculationДокумент27 страницASME B31.3 Process Piping Wall Thickness CalculationJesus Magallanes SОценок пока нет

![Soaking Time Validation - Heat Treatment[1] [Read-Only]](https://imgv2-1-f.scribdassets.com/img/document/720530292/149x198/b39c102e87/1712388457?v=1)