Академический Документы

Профессиональный Документы

Культура Документы

Aço 1.4301 - INOX 304

Загружено:

Rhani NogueiraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aço 1.4301 - INOX 304

Загружено:

Rhani NogueiraАвторское право:

Доступные форматы

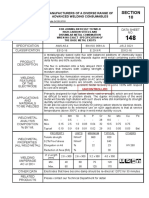

Edition 3.

01 - 2006/08

Steel 1.4301

Page 1/3

EN UNS AISI LMSA

Designation X5CrNi18-10 1.4301 S30400 304 D110

Chemical composition (Weight %)

Fe C Cr Ni Si Mn P S N

Balance max 0.07 17.0 – 19.5 8.0-10.5 <=1.0 <=2.0 <=0.045 <=0.015 <=0.110

In order to achieve maximum homogeneity and consistent quality, the actual tolerances on both alloy components and impurities are

significantly tighter and more precisely defined than the standard composition indicated.

Main technical properties and features

Ãustenitic stainless steels are amongst the most popular and most widely used of the stainless steel family. They

have a chromium content of around 17% and comprise nickel and possibly other additives such as molybdenum,

titanium or niobium. It is the nickel content which enables the austenitic structure that supports corrosion

resistance. In fact, the absence of a second phase, such as strain induced martensite or ferrite promotes the

corrosion resistance. Austenitic stainless steel 1.4301, X5CrNi18-8, is very widely used because of its excellent

intercrystalline corrosion resistance, very good cold deformability, good deep drawing capability and its good

aptitude for welding. The 1.4301, X5CrNi18-8, preserves its excellent corrosion resistance up to 300°C but can

also be used at very low temperatures for cryogenic applications. In the soft temper, alloy 1.4301, X5CrNi18-8, is

practically non-magnetic. The work hardening effect during cold deformation is rather weak, For example, it does

not reach the spring properties of stainless steel 1.4310, X10CrNi18-8. Lamineries MATTHEY can produce the

1.4301, X5CrNi18-8, in various tempers ranging from dead soft to extra hard rolled.

Typical manufacturing range

Thickness (mm) Width (mm) Length (mm)

1)

Rolled products Strip in coils 0.010 - 2.000 1.5 - 200.0 -

1)

Strip as sheets 0.015 - 1.500 10.0 - 200.0 100 - 3000

1) Not all our production possibilities are presented here. Other dimensions or other product forms available upon request.

Certain combinations of thicknesses and widths are not possible.

Mechanical properties of strips

Temper Tensile strength, Rm Hardness

(N/mm2) HV

1), 2)

C500 soft 500-700 150-200

C700 1) , 2) soft 650-850 190-250

C850 1) ¼ hard 680-1000 200-300

C1000 1) ½ hard 950-1150 250-390

C1150 1) hard 1100-1300 310-420

C1300 1) extra hard 1250-1550 380-500

1) These tempers do not correspond exactly to the EN 10151 and EN 10088 standards and are only indicative.

2) Temper C500, soft is only available for thicknesses higher or equal to 0.1 mm. For thicknesses < 0.1mm, soft corresponds to the C700

temper.

Lamineries MATTHEY SA Tél +41 (0)32 752 32 32 E-mail CH: sales@matthey.ch

Route de Neuchâtel 6 Fax +41 (0)32 752 32 00 E-mail Export: salesexport@matthey.ch

CH - 2520 La Neuveville www.matthey.ch

Edition 3.01 - 2006/08

Steel 1.4301

Page 2/3

EN UNS AISI LMSA

Designation X5CrNi18-10 1.4301 S30400 304 D110

Physical properties

Modulus of elasticity kN/mm2 200 (180 à 300°C, 165 à 500°C))

Poisson ratio 0.3

Density kg/dm3 7.9

Melting point / Melting range °C 1420-1470

Linear dilatation coefficient (20-300°C) / °C 0,000016 (0,000017 à 300°C, 0,000018 à 500°)

Thermal conductivity at 20°C W/m °K 15

Electrical resistivity μΩcm 0.73

Electrical conductivity MS/m 1.4

Specific heat at 20°C J/(kg K) 500

Magnetic properties Can be slightly magnetic in soft temper. Its magnetism

increases with work hardening (also with its hardness

and its tensile strength).

Typical uses

Thanks to its corrosion resistance, the 1.4301 is widely used in the chemical industry, cutlery, watches and clocks,

medical devices, appliances etc. The 1.4301, X5CrNi18-10, as delivered by Lamineries MATTHEY SA is

frequently used to manufacture parts such as spring components, pressure membranes, various watch

components, deep drawn parts, connectors etc

Lamineries MATTHEY SA Tél +41 (0)32 752 32 32 E-mail CH: sales@matthey.ch

Route de Neuchâtel 6 Fax +41 (0)32 752 32 00 E-mail Export: salesexport@matthey.ch

CH - 2520 La Neuveville www.matthey.ch

Edition 3.01 - 2006/08

Steel 1.4301

Page 3/3

EN UNS AISI LMSA

Designation X5CrNi18-10 1.4301 S30400 304 D110

Tolerances

Thickness Thickness (mm) Lamineries MATTHEY SA

LMSA LMSA LMSA

≥ < Standard Precision Extreme

0.025 - - ± 0.001

0.025 0.050 ± 0.003 ± 0.002 ± 0.0015

0.050 0.065 ± 0.004 ± 0.003 ± 0.002

The table shown is an outline of our

typical thickness tolerances available. 0.065 0.100 ± 0.006 ± 0.004 ± 0.003

They are tighter than industry 0.100 0.125 ± 0.008 ± 0.006 ± 0.003

standards. 0.125 0.150 ± 0.008 ± 0.006 ± 0.004

0.150 0.250 ± 0.010 ± 0.008 ± 0.004

Our "Precision" and "Extreme" 0.250 0.300 ± 0.012 ± 0.008 ± 0.005

tolerances are available upon request.

0.300 0.400 ± 0.012 ± 0.009 ± 0.005

0.400 0.500 ± 0.015 ± 0.010 ± 0.006

0.500 0.600 ± 0.020 ± 0.012 ± 0.007

0.600 0.800 ± 0.020 ± 0.014 ± 0.007

0.800 1.000 ± 0.025 ± 0.015 ± 0.009

1.000 1.200 ± 0.025 ± 0.018 ± 0.0012

1.200 1.250 ± 0.030 ± 0.020 ± 0.0012

1.250 1.500 ± 0.035 ± 0.025 ± 0.0014

Width Our width tolerance is + 0.2 -0.0 mm (or ± 0.1 mm upon request). They are available

for slit widths < 125 mm and thicknesses < 1.00 mm. Special tolerances upon request.

Camber Width (mm) Camber max. (mm/m)

LMSA standard LMSA extreme

> ≤ ≤ 0.5 mm > 0.5 mm ≤ 0.5 mm > 0.5 mm

Our tolerance "standard" respects the 3 6 12 - 6 -

EN Standard 1654 (Length of 6 10 8 10 4 5

measurement 1000 mm). 10 20 4 6 2 3

Other tolerances upon request. 20 250 2 3 1 1.5

Surface Special surface qualities upon request

Flatness Special requirement on the longitudinal or transversal flatness upon request

Lamineries MATTHEY SA Tél +41 (0)32 752 32 32 E-mail CH: sales@matthey.ch

Route de Neuchâtel 6 Fax +41 (0)32 752 32 00 E-mail Export: salesexport@matthey.ch

CH - 2520 La Neuveville www.matthey.ch

Вам также может понравиться

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)От EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)Оценок пока нет

- 1.4435 - C Stainless Steel DetailsДокумент3 страницы1.4435 - C Stainless Steel DetailsmeenakshiОценок пока нет

- SUPRA50®: Chemical Composition (Weight %)Документ3 страницыSUPRA50®: Chemical Composition (Weight %)malaya tripathyОценок пока нет

- Mild Non-Alloy Steels For Direct Cold-Forming: Available Dimensions Mechanical PropertiesДокумент1 страницаMild Non-Alloy Steels For Direct Cold-Forming: Available Dimensions Mechanical PropertiesHemachandra ShrotriОценок пока нет

- Mild Non-Alloy Steels For Direct Cold-Forming: Available Dimensions Mechanical PropertiesДокумент1 страницаMild Non-Alloy Steels For Direct Cold-Forming: Available Dimensions Mechanical PropertiesHemachandra ShrotriОценок пока нет

- CuNi18Zn20 M18 CДокумент3 страницыCuNi18Zn20 M18 CJORDAN JUNOR ELLAОценок пока нет

- Stainless Steel 1.4462 Sheet & PlateДокумент3 страницыStainless Steel 1.4462 Sheet & PlatePaulОценок пока нет

- Soft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdДокумент10 страницSoft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdMohammadehsan SalarpourОценок пока нет

- Hot-Rolled - Plate: Data SheetДокумент2 страницыHot-Rolled - Plate: Data SheetRichard Vica CalvoОценок пока нет

- Dogal 600 and 780 CP: Advanced High Strength SteelДокумент2 страницыDogal 600 and 780 CP: Advanced High Strength SteelMartin O'NeillОценок пока нет

- Docol 1300M: General Product DescriptionДокумент2 страницыDocol 1300M: General Product DescriptionAnonymous wR1jrmpYAОценок пока нет

- C7025 (英文) ver1 6Документ11 страницC7025 (英文) ver1 6顏健軒Оценок пока нет

- Grade 301 Stainless Steel Data SheetДокумент2 страницыGrade 301 Stainless Steel Data SheetGovind RaoОценок пока нет

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Документ3 страницыAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouОценок пока нет

- Data Sheet Raex 450Документ3 страницыData Sheet Raex 450Amit GauravОценок пока нет

- 316 Tubeing TrisДокумент1 страница316 Tubeing Triscenter steel110Оценок пока нет

- S275JR PDFДокумент1 страницаS275JR PDFEmrahCayboylu100% (1)

- SF-1 Flux-cored wire for mild steel and 490N/mm2 steelДокумент1 страницаSF-1 Flux-cored wire for mild steel and 490N/mm2 steelHoque AnamulОценок пока нет

- Armox 370T Class 1: General Product DescriptionДокумент2 страницыArmox 370T Class 1: General Product DescriptionSuneelОценок пока нет

- DD11 Mild Steel for Cold FormingДокумент1 страницаDD11 Mild Steel for Cold FormingHemachandra ShrotriОценок пока нет

- Strenx 700 MC: Advanced High Strength SteelДокумент2 страницыStrenx 700 MC: Advanced High Strength SteeldbaОценок пока нет

- 30mnb5 Specificationa IneternationalДокумент3 страницы30mnb5 Specificationa IneternationalMohammed AliОценок пока нет

- En-Gjs-400-15 - GGG40 PDFДокумент2 страницыEn-Gjs-400-15 - GGG40 PDFDylkanWingsОценок пока нет

- 300 SeriesДокумент29 страниц300 SeriesShashank SaxenaОценок пока нет

- CSF-71T en 2014Документ1 страницаCSF-71T en 2014HoangОценок пока нет

- CSF-71T en 2014Документ1 страницаCSF-71T en 2014Yousab CreatorОценок пока нет

- Cu - of - Cw008aДокумент2 страницыCu - of - Cw008ap.designОценок пока нет

- Low Hydrogen High Tensile Welding RodДокумент1 страницаLow Hydrogen High Tensile Welding Rodmohamed AdelОценок пока нет

- SAF 2205 DatasheetДокумент11 страницSAF 2205 DatasheetNitinОценок пока нет

- Mat 07000-07149 200411Документ5 страницMat 07000-07149 200411Ronaldo Bandeira RodriguesОценок пока нет

- Datasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1Документ5 страницDatasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1aceinsteinОценок пока нет

- 1414059256wpdm - Stainless Steel Grade AISI 310Документ2 страницы1414059256wpdm - Stainless Steel Grade AISI 310Riian ApriansyahОценок пока нет

- Eurocw617n ST enДокумент4 страницыEurocw617n ST endrgilleОценок пока нет

- Stabilized Ferritic Stainless Steel for Automotive Exhaust SystemsДокумент37 страницStabilized Ferritic Stainless Steel for Automotive Exhaust SystemsShashank SaxenaОценок пока нет

- Stabilized Ferritic Stainless Steel: General CharacteristicsДокумент37 страницStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaОценок пока нет

- An DL001Документ12 страницAn DL001maggamОценок пока нет

- General CapabilitiesДокумент1 страницаGeneral CapabilitiesBenito LópezОценок пока нет

- Data Sheet 2008 Strenx 700 MC 20170420 254 371857150 enДокумент2 страницыData Sheet 2008 Strenx 700 MC 20170420 254 371857150 enmarkoОценок пока нет

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Документ6 страницINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezОценок пока нет

- Jed-050m 008 eДокумент5 страницJed-050m 008 egsuoagОценок пока нет

- Alloy 34MnB5Документ2 страницыAlloy 34MnB5Javo RodriguezОценок пока нет

- Data Sheet Strenx 700 MCДокумент3 страницыData Sheet Strenx 700 MCRoger BandeiraОценок пока нет

- CDC - Meehanite - Tuyauterie Acid SulfuriqueДокумент3 страницыCDC - Meehanite - Tuyauterie Acid SulfuriqueAyoub LaouinateОценок пока нет

- Datasheet BOHLER DCMS-IG TIGДокумент1 страницаDatasheet BOHLER DCMS-IG TIGDaniele DuarteОценок пока нет

- Ok 68.55Документ1 страницаOk 68.55Sadashiva sahooОценок пока нет

- Stainless Steel 1.4401 Material Data SheetДокумент3 страницыStainless Steel 1.4401 Material Data SheetLuis LoayzaОценок пока нет

- ER-410NiMo MIG Wire Data SheetДокумент2 страницыER-410NiMo MIG Wire Data SheetAnonymous skBAwexОценок пока нет

- Aluminium Honeycomb Seminar ReportДокумент28 страницAluminium Honeycomb Seminar Report123CineWorld Com0% (1)

- Metal-Coated - Galvsteel: Data SheetДокумент2 страницыMetal-Coated - Galvsteel: Data SheetjcvalenciaОценок пока нет

- Enqno 29160138-1470996854Документ2 страницыEnqno 29160138-14709968543024 Jangam Sunny KiranОценок пока нет

- GALVSTEEL® G300 SteelДокумент2 страницыGALVSTEEL® G300 SteelTulus Ztx ZaputroОценок пока нет

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMДокумент1 страница3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarОценок пока нет

- Electrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetДокумент4 страницыElectrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetEvka AkováОценок пока нет

- 1 4571 PDFДокумент7 страниц1 4571 PDFSiis IngenieriaОценок пока нет

- European Steel and Alloy GradesДокумент3 страницыEuropean Steel and Alloy Gradesfarshid KarpasandОценок пока нет

- Web Datasheet b4.1Документ3 страницыWeb Datasheet b4.1Reza Khatibi NasabОценок пока нет

- CoCr MP1 M270 Material Data SheetДокумент6 страницCoCr MP1 M270 Material Data Sheetgpiprototype.comОценок пока нет

- Stainless Steel 1.4404 Material Data SheetДокумент3 страницыStainless Steel 1.4404 Material Data SheetDilipSinghОценок пока нет

- Stainless Steel 1.4404 316lДокумент3 страницыStainless Steel 1.4404 316lDilipSinghОценок пока нет

- GC6000-2-4 Selection of Bearing SizeДокумент5 страницGC6000-2-4 Selection of Bearing SizeFrancisco AlessandriОценок пока нет

- TemperatureДокумент6 страницTemperatureNur Khairiah Daimah SanupinОценок пока нет

- DPW G2 Multi Pole Spec SheetДокумент2 страницыDPW G2 Multi Pole Spec SheetlОценок пока нет

- Reactive Wetting, Evolution of Interfacial and Bulk IMCs and Their Effect On Mechanical PDFДокумент32 страницыReactive Wetting, Evolution of Interfacial and Bulk IMCs and Their Effect On Mechanical PDFeid elsayedОценок пока нет

- 2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions HyderabadДокумент4 страницы2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions Hyderabadnithish0% (1)

- 34crnimo6: Steel GradeДокумент4 страницы34crnimo6: Steel Gradeanu swamiОценок пока нет

- Arandelas Hill Side A325Документ1 страницаArandelas Hill Side A325Oscar SanabriaОценок пока нет

- CSR July August 2014 DigitalДокумент60 страницCSR July August 2014 Digitalolger huancara gasparaОценок пока нет

- Design and Manufacturing of Water Chiller For Proc PDFДокумент17 страницDesign and Manufacturing of Water Chiller For Proc PDFzoom_999Оценок пока нет

- Safety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228Документ5 страницSafety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228sergio.lopezОценок пока нет

- QBДокумент18 страницQBMudrikaОценок пока нет

- Calculation Sheet For Spit Anchors: TAPCON XTREM HFL Min. Anchorage 10x120/65-35Документ6 страницCalculation Sheet For Spit Anchors: TAPCON XTREM HFL Min. Anchorage 10x120/65-35abdallah badrОценок пока нет

- Internet Standards for Irrigation EquipmentДокумент19 страницInternet Standards for Irrigation EquipmentHarindu VyasОценок пока нет

- Mro Products and Oem Adhesives Catalog 2021Документ44 страницыMro Products and Oem Adhesives Catalog 2021piyush1124Оценок пока нет

- SAKLA - Eccentrically-Loaded Single Angle StrutsДокумент10 страницSAKLA - Eccentrically-Loaded Single Angle StrutsmarinamoviaОценок пока нет

- Lab Report EnviroДокумент19 страницLab Report EnviroThinesh BoltОценок пока нет

- Chemical Proces-WPS OfficeДокумент58 страницChemical Proces-WPS OfficeMuhammad Ahmed50% (2)

- Neutrophiles and ElectrophilesДокумент2 страницыNeutrophiles and Electrophileswhydaspam joeОценок пока нет

- 3rd Summative TestДокумент8 страниц3rd Summative TestAngelica ValdezОценок пока нет

- MIDC UNITSДокумент16 страницMIDC UNITSSatej SatyanОценок пока нет

- SOP On LMO Tank 20210401 - USAID RISEДокумент25 страницSOP On LMO Tank 20210401 - USAID RISEBoke BelayОценок пока нет

- Lecture 3 Coagulation and FlocculationДокумент53 страницыLecture 3 Coagulation and FlocculationAbo-Khaled Mohammed100% (1)

- Hans OerstedДокумент17 страницHans OerstedseialuwisОценок пока нет

- Advanced Lab Course 50: PhotovoltaicsДокумент18 страницAdvanced Lab Course 50: PhotovoltaicsHamza OuerfelliОценок пока нет

- MEPDG Manual of PracticesДокумент209 страницMEPDG Manual of PracticesSri RamyaОценок пока нет

- Carbofill Dec08Документ4 страницыCarbofill Dec08Cristian Andres Araya CisternasОценок пока нет

- Heraklith CatalogueДокумент54 страницыHeraklith CatalogueN P SrinivasaraoОценок пока нет

- ZOLLERN-Broschuere ZGF Legierungen ENGДокумент16 страницZOLLERN-Broschuere ZGF Legierungen ENGPablo PadillaОценок пока нет

- The Effectiveness of Cassava (Manihot Esculenta) Starch in Creating Biodegradable PlasticДокумент3 страницыThe Effectiveness of Cassava (Manihot Esculenta) Starch in Creating Biodegradable PlasticKimi Annika VillarealОценок пока нет

- Sample Problem Mod 3 CPCДокумент6 страницSample Problem Mod 3 CPCAman PratikОценок пока нет