Академический Документы

Профессиональный Документы

Культура Документы

Scheduled Oil Sampling Report: Customer Information Unit Information

Загружено:

Heri KiswantoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Scheduled Oil Sampling Report: Customer Information Unit Information

Загружено:

Heri KiswantoАвторское право:

Доступные форматы

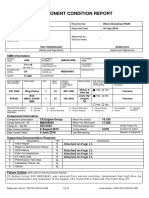

Scheduled Oil Sampling Report

PT. Trakindo Utama S•O•S Fluids Analysis Laboratory

Jl. Jendral Sudirman No.848, Balikpapan 76114, Indonesia

Tel. +62 542 762810, Call Center 1500 228

Customer Information Unit Information

BUKIT MAKMUR MANDIRI UTAMA PT. Category Oil Equip Make Komatsu Received Date: 10/15/2018 8:10:00AM

ATTN: Valuable Customer Lab No B18J163010 Equip Model GD825A-2 Reported Date: 10/17/2018 1:20:43PM

THE HONEY LADY 3RD FLOOR LOT 301-306 Unit Number GDKM82022 Location KIDECO Sample Note

KAWASAN CBD PLUIT,JL.PLUIT SELATAN RAYA Equip Serial 000012302 Jobsite 64 - KDC Evaluation Code C Action Required.

NO.1 PENJARINGAN,JAKARTA UTARA, Indonesia 14440 Compartment Engine Job No BUMA/KDC-PLT/2018/SK

Sample Point Interpreted by: Interpreter / Diyandika (A)

Label No B64

Phone 085273355152

Element Reading (mg/kg = ppm) - ASTM D-5185

Lab No. Sample Date Eval CMU SMU HOO Oil Added Fluid Filter Oil Type Oil Grade

Wear Metal Contaminant Additives

Date Process Chg Chg

Cr Pb Fe Cu Al Sn Ni B K Na Si Ca P Zn Mg Mo

15/Oct/18 C 0 58220 534 0 Y SHELL : RIMULA SAE 15W-40 2 13 75 11 4 2 1 321 1 3 23 4027 1121 1191 11 57

B18J163010 11/Oct/18

R3 MV

25/Sep/18 A 0 57930 244 0 N SHELL : RIMULA SAE 15W-40 1 7 35 8 2 2 0 278 1 2 16 3459 1039 1098 10 56

B18I250638 21/Sep/18

R3 MV

10/Sep/18 C 0 57686 444 0 Y SHELL : RIMULA SAE 15W-40 1 12 35 26 3 4 0 32 1 2 30 3876 1271 1146 13 109

B18I111213 03/Sep/18

R3 MV

14/Aug/18 X 0 57475 233 0 N UNKNOWN SAE 15W-40 47 9 387 13 41 18 1 339 5 3 147 3685 1134 1163 14 45

B18H151502 10/Aug/18

Element Reading (mg/kg = ppm) Oil Condition (JOAP) ASTM E2412 Physical / Chemical Test Particle Count (Counts / ml) - ASTM D 4464

Lab No Ba * Ti * Ag * V* ST OXI NIT SUL FP (P/N) DF (%) * V100 V40 VI * TBN TAN * W (P/N) W(%) PQ * Visual * PC 04 * PC 06 PC 14 ISO 04* ISO 06 ISO 14

(cSt) (cSt) * (idx)

B18J163010 15 13 7 23 N 13.1 7.1 N 17.0 -

B18I250638 8 11 6 20 N 13.0 8.0 N 4.0 -

B18I111213 4 7 5 15 N 11.1 9.9 N 16.0 -

B18H151502 20 13 6 22 N 13.8 7.3 N 291.0 VISIBLE

Lab No. Tendency (5' Tendency (5' Tendency (5' Stability (10' Stability (10' Stability (10' Milipore Sludge

aeration) Seq 1 * aeration) Seq 2 * aeration) Seq 3 * aeration) Seq 1 * aeration) Seq 2 * aeration) Seq 3 * Test *

B18J163010

B18I250638

B18I111213

B18H151502

Recommendation ** Rekomendasi **

FE INCREASED. INDICATE ABNORMAL WEAR OCCURRED ON PUMP, CYLINDER LINERS OR VALVE TRAINS; CHECK VALVE ELEMEN FE MENINGKAT. MENGINDIKASIKAN KEAUSAN ABNORMAL TERJADI PADA PUMP, CYLINDER LINERS ATAU VALVE TRAINS;

MECHANISM, OIL PRESSURE AND UNUSUAL NOISE. MAKE NECESSARY REPAIRS. RE-SAMPLE WHEN HOURS ON OIL REACH 100 PERIKSA VALVE MECHANISM, TEKANAN OLI DAN SUARA YANG TIDAK NORMAL. SEGERALAH LAKUKAN PERBAIKAN. AMBIL SAMPEL

HOURS TO MONITOR. CUT OPEN FILTER AND INSPECT FOR LARGE PARTICLES. Sample Notes: KEMBALI SETELAH PEMAKAIAN OLI MENCAPAI 100 JAM UNTUK MEMONITOR. BUKA POTONGAN FILTER DAN INSPEK PARTIKEL

BESAR.

This analysis provided is indicative of conditions based upon sample information received and the quality of sample supplied. Any decision relating to repair of components is entirely at the descretion of the customer.

B18J163010 Page 1 of 2

* Not Include on scope of Accreditation

** The evaluation / Recommendation made by Equipment Management PT. Trakindo Utama

Glossaries

Elements P=Phosphorus (LoD=0.74) Water Criteria ISO6=ISO Code 6 V100=Viscosity 100°C (WIN.MP.05)

Si-Silicon (LoD=0.26) B=Boron (LoD=0.40) W=Water - ASTM D 4928 / ASTM D 4377 ISO14=ISO Code 14 V40=Viscosity 40°C - ASTM D445

AI=Aluminum (LoD=0.12) Mo=Molybdenum (LoD=0.20) % =Percentage Oil Condition cSt=Centistokes

Cr=Chromium (LoD=0.12) Zn=Zinc (LoD=0.17) N=Negative ST=Soot DF(%) - ASTM D 3524

Fe=Iron (LoD=0.11) Ti=Titanium P=Positive (0.5 - 0.8%) OXI=Oxidation Visual

Pb=Lead (LoD=0.82) V=Vanadium T=Trace (Cloudy but < 0.5%) NIT=Nitration LQ = Low Quantity

Cu=Copper (LoD=0.01) Ag=Silver E=Excessive (> 0.8%) SUL=Sulfation MQ = Medium Quantity

Sn=Tin (LoD=0.25) Note: Results = 0 < LoD (Limit of Detection) Particle Count Physical / Chemical HQ = High Quantity

Ni=Nickel (LoD=0.38) ppm=Parts Per Million (ASTM D 4464 & ASTM D 7596) PQ=Particle Quantifier (Idx=Index) Met = Metallic

Mg=Magnesium (LoD=0.01) FP Criteria PC04=Particle Count at 4 micron TBN=Total Base Number - ASTM D 4739 Non Met = Non Metallic

Ca=Calcium (LoD=0.05) FP=Flash Point (ASTM D 3828 - Method A) PC06=Particle Count at 6 micron (mg KOH /g) F = Fine

K=Potassium (LoD=0.64) P=Positive PC14=Particle Count at 14 micron TAN=Total Acid Number - ASTM D 664 C = Coarse

Na=Sodium (LoD=0.42) N=Negative ISO4=ISO Code 4 (mg KOH /g) Granul = Granular

General Analysis Guide ***

Primary Element Secondary Element Potential Wear Problem area & causes Primary Element Secondary Element Potential Wear Problem area & causes

Si Al Piston, Rings, Liner Air induction, breathers, dirt. Cr Mo Piston ring Blow by, oil consumption

Liner, piston, valve, gear Dirt, abnormal temperature, lack of lubricant, Na Si, B Cooling system Water Pump, Cyl Head, Liner seal, Oil Cooler,

Fe - Anti Freeze

train, crankshaft storage (rust)

Al Cr Piston & Rings Blow-by

Pb, Sn Cu, Al Bearing Dirt contamination, lack of lubricant.

Fe Cr Piston ring Abnormal operating temperature

Al or Cu Sn, Pb Bearing Low or fluctuating oil pressure. Fe Al Liner Restricted air induction system

*** THIS CHARTS ARE FOR GENERAL USE ONLY, AND DO NOT INDICATE DEFINITE LIMITS OF WEAR METALS FOR ANY SPECIFIC MAKE OR MODEL.

TABEL INI HANYA DIGUNAKAN UNTUK ANALISIS SECARA UMUM DAN TIDAK MENGINDIKASIKAN SUATU BATASAN UNTUK MODEL DAN MEREK TERTENTU

KINDLY ADVISED YOU TO CONTACT US PRIOR 7 DAYS AFTER REPORT RELEASE SHOULD YOU NEED FURTHER DISCUSSION ABOUT THIS SAMPLE.

DISARANKAN AGAR DISKUSI LEBIH LANJUT MENGENAI SAMPLE INI HARUS DILAKUKAN SEBELUM 7 HARI DARI TANGGAL LAPORAN DI TERBITKAN

Wear Metal Contaminant Oil Condition Viscosity

400 160 24 14

350 140

12

20

300 120

10

16

250 100

Al K 8

NIT

Cr Na

200 Fe 80 12 OXI V100

Si SUL

Pb ST TBN

PQ 6

150 60

8

4

100 40

4 2

50 20

0 0 0 0

10/11/2018 9/21/2018 9/3/2018 8/10/2018 10/11/2018 9/21/2018 9/3/2018 8/10/2018 10/11/2018 9/21/2018 9/3/2018 8/10/2018 10/11/2018 9/21/2018 9/3/2018 8/10/2018 Approved by

Mukhlisin

Manager S•O•S Laboratory

B18J163010 Page 2 of 2

Вам также может понравиться

- SOS Sampling ReportДокумент2 страницыSOS Sampling ReportAsaisan AsaisanОценок пока нет

- Sos Sampling ReportДокумент2 страницыSos Sampling Reportomar solimanОценок пока нет

- Oil Sampling Report Highlights Key FindingsДокумент2 страницыOil Sampling Report Highlights Key FindingsDharmaNugrahaОценок пока нет

- A20J120618 Valuable Customer 0Документ2 страницыA20J120618 Valuable Customer 0Chandra Hermanto SinagaОценок пока нет

- Scheduled Oil Sampling Report: Customer Information Unit InformationДокумент2 страницыScheduled Oil Sampling Report: Customer Information Unit InformationARI WIJAYANTOОценок пока нет

- Scheduled Oil Sampling Report: Customer Information Unit InformationДокумент2 страницыScheduled Oil Sampling Report: Customer Information Unit InformationKorneliusОценок пока нет

- Laboratorium SOS PT. Trakindo Utama Oil Analysis ReportДокумент1 страницаLaboratorium SOS PT. Trakindo Utama Oil Analysis ReportAhmad ZarkasiОценок пока нет

- Scheduled Oil Sampling Report: Customer Information Unit InformationДокумент2 страницыScheduled Oil Sampling Report: Customer Information Unit InformationMuhammad AriefОценок пока нет

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportДокумент1 страницаIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar AОценок пока нет

- Raja MargaДокумент2 страницыRaja MargaJimmy ChangОценок пока нет

- Purchase Request: Qualitycontrol DepartmentДокумент2 страницыPurchase Request: Qualitycontrol DepartmentValipireddy NagarjunОценок пока нет

- KG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Документ5 страницKG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Madheswaran DharmapuriОценок пока нет

- CCR JN 5646488-Sis-C9 Engine en Mbd09063-High BlowbyДокумент15 страницCCR JN 5646488-Sis-C9 Engine en Mbd09063-High Blowbyahmat ramadaniОценок пока нет

- Modified BitumensДокумент6 страницModified BitumensDonОценок пока нет

- Pdf24 MergedДокумент9 страницPdf24 MergedauliaadyaksaОценок пока нет

- Purchase Request: Qualitycontrol DepartmentДокумент2 страницыPurchase Request: Qualitycontrol DepartmentValipireddy NagarjunОценок пока нет

- 55.JSS GOH PC850-8R1 Ulimanitra 10 Desember 2022Документ21 страница55.JSS GOH PC850-8R1 Ulimanitra 10 Desember 2022doni granadaОценок пока нет

- Al Muaser Petroleum Services PVT LTD Client/Consultant: Indian Oil Corporation Limited Kaspl Pipeline Project Incoming Material Inspection ReportДокумент1 страницаAl Muaser Petroleum Services PVT LTD Client/Consultant: Indian Oil Corporation Limited Kaspl Pipeline Project Incoming Material Inspection ReportsojeckОценок пока нет

- Hyderabad Investment - Machinery Valuation 05092018Документ5 страницHyderabad Investment - Machinery Valuation 05092018R SwethaОценок пока нет

- Preliminary 00122.00023 Pt. Semesta Alam BaritoДокумент2 страницыPreliminary 00122.00023 Pt. Semesta Alam BaritoBayu Araruna NangasОценок пока нет

- Compressor spare parts inventoryДокумент2 страницыCompressor spare parts inventoryShirazUddinSiddiqueОценок пока нет

- Document Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. NumberДокумент4 страницыDocument Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. Numberrajindo1Оценок пока нет

- Reference: Selection No# C25943: EP R 2EB 030A 10,2Y S100M1 F10e I75x550 B51Документ5 страницReference: Selection No# C25943: EP R 2EB 030A 10,2Y S100M1 F10e I75x550 B51Ян Харлакевич 5172мОценок пока нет

- 1714 MirДокумент1 страница1714 MirIftekhar AhmedОценок пока нет

- T7888 FR DPS So#41715258Документ1 страницаT7888 FR DPS So#41715258alwanbagasОценок пока нет

- Scheduled Oil Sampling Report: Eval CodeДокумент1 страницаScheduled Oil Sampling Report: Eval CodePutra JawaОценок пока нет

- Crane hook block arrangement diagramДокумент1 страницаCrane hook block arrangement diagramAbinash NeupaneОценок пока нет

- Pt. Astar Testing & InspectionДокумент2 страницыPt. Astar Testing & InspectionSASIОценок пока нет

- 01 EngineCheckReport802Документ5 страниц01 EngineCheckReport802phutthawongdanchai041215Оценок пока нет

- A545-101-PA-MR-5001-1072-5099-FOA - 905139-LS - 02 - LUBRICATION SCHEDULE - Multiple TagsДокумент3 страницыA545-101-PA-MR-5001-1072-5099-FOA - 905139-LS - 02 - LUBRICATION SCHEDULE - Multiple Tagsmahesh.easwaran3609Оценок пока нет

- Les Codes D'erreur (SNCFT) Error Codes From Page 8Документ58 страницLes Codes D'erreur (SNCFT) Error Codes From Page 8youssefhs957Оценок пока нет

- Quotation / Proforma InvoiceДокумент1 страницаQuotation / Proforma InvoiceSubham DasОценок пока нет

- Type: T1637K11 5272003349 FG/FGS: SERIAL NO.: 5272003349 BOM NO.: T1637K11Документ194 страницыType: T1637K11 5272003349 FG/FGS: SERIAL NO.: 5272003349 BOM NO.: T1637K11Víctor MatíasОценок пока нет

- Mask Fasteners Pvt. Ltd. CertificationДокумент2 страницыMask Fasteners Pvt. Ltd. CertificationGaurav100% (1)

- Failure Analysis of an Engine with Black Smoke IssueДокумент7 страницFailure Analysis of an Engine with Black Smoke IssueFros DiamonОценок пока нет

- 9562 109 Pve P 004 02Документ71 страница9562 109 Pve P 004 02Hariprasath JayaprakashОценок пока нет

- IPRCETECH Final Inspection ReportДокумент3 страницыIPRCETECH Final Inspection ReportAjinkya PatilОценок пока нет

- Final - Pump - 5P0312ABCD - Antico - GAD - Code 1Документ1 страницаFinal - Pump - 5P0312ABCD - Antico - GAD - Code 1Rishabh Verma100% (1)

- Pulley IdlerДокумент1 страницаPulley IdlerLazzarus Az GunawanОценок пока нет

- Industrial: Severity UrgentДокумент2 страницыIndustrial: Severity UrgentNasser AyoubОценок пока нет

- B14B052339 - Hanurata Ahmad Zarkasi (A) - 0Документ1 страницаB14B052339 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiОценок пока нет

- Battery Manufacturers Print-5Документ1 страницаBattery Manufacturers Print-5nbhushan001Оценок пока нет

- Mpi Lube Tank 6000l 05Документ3 страницыMpi Lube Tank 6000l 05Peter StanleyОценок пока нет

- Qatar Shell Maintenance Contract Tools InventoryДокумент1 страницаQatar Shell Maintenance Contract Tools InventoryJoseph PerezОценок пока нет

- Motor Data Sheet (32-Hal-201ab)Документ5 страницMotor Data Sheet (32-Hal-201ab)Ahmad FaujiОценок пока нет

- Final: Equipment Sectional Drawing With Part ListДокумент23 страницыFinal: Equipment Sectional Drawing With Part ListInsertec LtdaОценок пока нет

- PT Petrolab Services: Grease Analysis ReportДокумент1 страницаPT Petrolab Services: Grease Analysis Reportvictor josuaОценок пока нет

- 7test Report of Petroleum Coke Dated 13.07.2020Документ1 страница7test Report of Petroleum Coke Dated 13.07.2020Abhinav BansalОценок пока нет

- KLJ Hdpe BK 9606 Arat AratДокумент1 страницаKLJ Hdpe BK 9606 Arat AratDinesh SinghОценок пока нет

- Plate - AДокумент9 страницPlate - ASumit SinghОценок пока нет

- Vessel's Info Form - BunkerДокумент2 страницыVessel's Info Form - BunkerFilip NikolevskiОценок пока нет

- Inventory Akhir: Engine Model: Rr250-C20B Inventory DateДокумент5 страницInventory Akhir: Engine Model: Rr250-C20B Inventory DateMilhan InsaniОценок пока нет

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedДокумент1 страницаMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech099200Оценок пока нет

- PT. Tekenomiks IndonesiaДокумент4 страницыPT. Tekenomiks IndonesiaAhmat RamadaniОценок пока нет

- Createds PDFДокумент1 страницаCreateds PDFAkshay0% (1)

- 75b2c Fujitsu Amilo PI2530 P55IMXДокумент37 страниц75b2c Fujitsu Amilo PI2530 P55IMXevencio100% (1)

- Echnical Ulletin: Reissued:15-Sep-06 Model: Date: Subject: Firmware Modification History Prepared byДокумент28 страницEchnical Ulletin: Reissued:15-Sep-06 Model: Date: Subject: Firmware Modification History Prepared byNhã BáОценок пока нет

- Mini Excavator-Nov 23Документ1 страницаMini Excavator-Nov 23Akash vimalОценок пока нет

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceОт EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceОценок пока нет

- Compression Pressure Modeling - Comsol 3.4Документ7 страницCompression Pressure Modeling - Comsol 3.4Ionescu ViorelОценок пока нет

- Encyclopedia of Textile Finishing PDFДокумент2 777 страницEncyclopedia of Textile Finishing PDFFERNANDO JOSE NOVAES100% (1)

- Raoult's Law Is A DeceptionДокумент2 страницыRaoult's Law Is A DeceptionCarlos VelascoОценок пока нет

- 1.5 More About Electron Arrangements - TEДокумент43 страницы1.5 More About Electron Arrangements - TEMirnaОценок пока нет

- AD01314M JISKOOT 210P Probe and 210P-HP Probe In-Line Sampler Extractor Data SheetДокумент2 страницыAD01314M JISKOOT 210P Probe and 210P-HP Probe In-Line Sampler Extractor Data SheetMohammad Fahmi Rahmana0% (1)

- Alberty (2002) Thermodynamics of Systems of Biochemical ReactionsДокумент11 страницAlberty (2002) Thermodynamics of Systems of Biochemical ReactionsSultan ShaikhОценок пока нет

- Toolox 44 DatenblattДокумент4 страницыToolox 44 DatenblattJosevi Jiménez MerinoОценок пока нет

- Bahan-Bahan Restorasi: DRG Erma Sofiani, Sp. KGДокумент33 страницыBahan-Bahan Restorasi: DRG Erma Sofiani, Sp. KGMahanani SubagioОценок пока нет

- Halar Ectfe: Powder Coatings For Corrosion ProtectionДокумент4 страницыHalar Ectfe: Powder Coatings For Corrosion ProtectionmaggiorgioОценок пока нет

- Corr21334a Sds Usa (GHS) EnglishДокумент10 страницCorr21334a Sds Usa (GHS) EnglishJosé Eduardo Narváez CampechanoОценок пока нет

- BIO Project On PopulationДокумент17 страницBIO Project On PopulationHasinur Rahman40% (5)

- ES HS QTSteamMaxДокумент4 страницыES HS QTSteamMaxWattsОценок пока нет

- Theoretical Study of Thermodynamics Properties of Landau Levels in Inas Two-Dimensional Electron GasДокумент8 страницTheoretical Study of Thermodynamics Properties of Landau Levels in Inas Two-Dimensional Electron GasIJAR JOURNALОценок пока нет

- Bioprocessing Films: Films For All Your Bioproduction NeedsДокумент2 страницыBioprocessing Films: Films For All Your Bioproduction NeedsCampaign MediaОценок пока нет

- Lecture 16Документ9 страницLecture 16Hardhik GamerОценок пока нет

- Aoac973 31Документ1 страницаAoac973 31jleonardocosaОценок пока нет

- Tank Truck Loading 3 0Документ4 страницыTank Truck Loading 3 0qasqasem100% (1)

- Chapter 12, Problem 9P: CommentДокумент1 страницаChapter 12, Problem 9P: Commentmahdi najafzadehОценок пока нет

- Heat Transfer Review ProblemsДокумент1 страницаHeat Transfer Review ProblemssayanОценок пока нет

- XRF analysis of soil samplesДокумент4 страницыXRF analysis of soil samplesPrimawati RahmaniyahОценок пока нет

- Sonatrach Well ControlДокумент25 страницSonatrach Well ControlUsama Bin Sabir50% (2)

- MSDS+-+Construction+Film+4 20 10Документ3 страницыMSDS+-+Construction+Film+4 20 10Sebastian GutierrezОценок пока нет

- 5070 s09 QP 2Документ16 страниц5070 s09 QP 2Syed AsharОценок пока нет

- Chemistry IGCSE NotesДокумент38 страницChemistry IGCSE NotesRaneem94% (16)

- Determining Density of Liquids Using PycnometerДокумент8 страницDetermining Density of Liquids Using PycnometerGrace N MalikОценок пока нет

- KLINGER top-sil-ML1: Unique Multi-Layer Material Concept - A Milestone For Fibre Reinforced GasketsДокумент8 страницKLINGER top-sil-ML1: Unique Multi-Layer Material Concept - A Milestone For Fibre Reinforced GasketsNenadОценок пока нет

- Klein,: Organic ChemistryДокумент47 страницKlein,: Organic ChemistryMark BakalanОценок пока нет

- Air Pollution Treatment MethodsДокумент64 страницыAir Pollution Treatment Methodssagbvn100% (1)

- Design For Reliability and Quality: IIT, BombayДокумент12 страницDesign For Reliability and Quality: IIT, Bombaytejap314Оценок пока нет

- As 2345-2006 Dezincification Resistance of Copper AlloysДокумент8 страницAs 2345-2006 Dezincification Resistance of Copper AlloysSAI Global - APAC0% (1)