Академический Документы

Профессиональный Документы

Культура Документы

100kw TSP Agenitor-404b Biogas 60-hz 480v En-827879

Загружено:

Julian BarreraОригинальное название

Авторское право

Доступные форматы

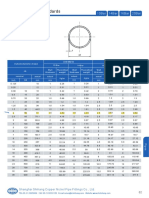

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

100kw TSP Agenitor-404b Biogas 60-hz 480v En-827879

Загружено:

Julian BarreraАвторское право:

Доступные форматы

Technical specification

agenitor 404b BG

Design:

100 kW el.

60 Hz / 480 V

biogas (50% CH4, 50% CO2)

Calorific Value = 481 BTU/ft³

NOx < 1.0 g/BHP-h

Exhaust cooling to 356 °F

Altitude 0 ft

Technical specification agenitor 404b BG 2G Energy AG 1/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

1. Genset 3

1.1 Engine 3

1.2 Generator (utility planning data) 4

2 Mixture composition 4

2.1 Combustion air 4

2.2 Fuel 5

3 Integrated heat extraction 5

3.1 Customer Heat Recovery Circuit 5

3.2 Engine circuit 5

3.3 Mixture cooling water circuit - low temperature (LT) 5

4. Exhaust system 6

5 Ventilation 6

6 Operating fluids 6

7 Electronics and software 6

8 Interfaces 7

8.1 Dimensions and weights 7

8.2 Mechanical Connections 8

8.3 Electrical connections / utility interface 8

8.4 Data interfaces 8

9 Technical boundary conditions 9

H4, 50% CO2)

< 1.0 g/BHP-h

Subject to technical changes!

Note: Figure on cover page may differ

Technical specification agenitor 404b BG 2G Energy AG 2/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

1. Genset

50 % 75 % 100 % Load

(5)

Electrical power 50 75 100 kW

Useful thermal power 257.728 332.969 405.385 MBTU/hr ⁽²⁾

Fuel cosumption 549.526 735.032 921.591 MBTU/hr ⁽¹⁾

Efficiency Electrical 31.0 34.8 37.0 % (1)

Efficiency Thermal 46.9 45.3 44.0 % (1), (2)

Efficiency Combined (el. + th.) 77.9 80.1 81.0 % (1), (2)

(1), (2)

CHP coefficient 0.66 0.77 0.84

NOx CO VOC ⁽⁸⁾

< 1.0 < 2.4 < 0.7 g/BHP-h

Exh. emissions without catalytic converter

< 91 < 300 #WERT! ppm ⁽⁴⁾’⁽⁶⁾

< 1.0 < 0.7 < 0.7 g/BHP-h

Exh. emissions with catalytic converter

< 91 < 90 < 11 ppm ⁽⁴⁾’⁽⁶⁾

Engine surface noise ** 104 dB(A) (7)

Engine surface noise with sound enclosure (optional) *** 70 dB(A) (7)

1.1 Engine

Engine manufacturer 2G

Engine type agenitor 404b

Type row

No. of cylinders 4

Operating method 4-stroke

Engine displacement 8000 ccm

Bore 5.12 in

Stroke 5.91 in

RPM 1800 1/min

ISO standard power (mech.) 141 bhp

compression ratio 13,6 : 1

average effective pressure 127.4 psi

average piston speed 29.5 ft/s

body of balance wheel SAE 1

Direction of rotation (based on balance wheel) left

tooth rim with number of teeth 167

Engine dead weight 1940 lbs

Mixture cooling to 176 °F

* Reffered to MAN data sheet

** Total sound power level at full engine load in accordance with DIN EN ISO 3746

*** Average sound pressure level under open area conditions at distance of 1 m in accordance with DIN 45635

An increased noise load must be taken into account with fresh air intake from the installation room.

Technical specification agenitor 404b BG 2G Energy AG 3/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

1.2 Generator (utility planning data)

Manufacturer Leroy Somer

Type LSA 44.3 L10/4p

Generator type Synchronous, directly coupled

Voltage regualtor (AVR) D510C

Rated speed 1800 1/min

Frequency 60 Hz

Effective electrical power 100 kW

Apparent electrical power (cos φ 0.8) 125 kVA

Apparent electrical power (cos φ 1.0) 100 kVA

Rated generator current (cos φ 0.8) 150 A

Rated generator current (cos φ 1.0) 120 A

Rated generator voltage (± 10 %) 480 V

Subtransient reactance X"d 10.2 %

Short-circuit current lk"3 2.5 kA

Power factor cos φ (lagging / leading) 0.8 / 0.95

Generator circuit breaker 250 A

Additional section switch (VDE-AR-N 4105) 250 A

Efficiency (full load) at Cos φ = 1 94.9 %

Mass moment of inertia 32.04 lb · ft²

Ambient air temperature 104 °F

Stator circuit star

Protection class IP 23

Generator weight 968 lbs

Compensation not available

Engine startup not available

2 Mixture composition

2.1 Combustion air

Combustion air mass flow 1101 lbs/hr

Combustion air volume flow (25 °C, 1013 mbar) 248 SCFM

2.2 Fuel

Fuel requirements in accordance with 'TA-004 Gas'

Reference methane number - minimum methane number 150 / 130

Combustible mass flow 161.0 lbs/hr ⁽¹⁾

Combustible volume flow 31.9 SCFM ⁽⁶⁾’⁽¹⁾

Gas pressure at rated load min. * 0.435 psig

Gas flow pressure at rated load max. * 1.015 psig

Gas regulation line safety pressure 7.252 psig

* At the inlet to the gas regulation line

Technical specification agenitor 404b BG 2G Energy AG 4/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

3 Integrated heat extraction

3.1 Customer Heat Recovery Circuit

Heating water requirements in accordance with 'TA-002 Heating circuit'

Heating water volume flow (at ∆t = 15 K) 30.0 gpm

Internal pressure loss in heating circuit (approx.) * 4.35 psig

Pressure reserve (approx.) * 16.75 ft

Heating water return temperature (max) 158 °F

Heating water flow temperature (max) ** 194 °F

Safety valve 87.02 psi

3.2 Engine circuit

Coolant requirements in accordance with 'TA-001 Coolant'

Jacket Water Heat 188.994 MBTU/hr

Exhaust Gas Heat up to 356°F 209.562 MBTU/hr

Engine inlet temperature (min.) 176 °F

Engine outlet temperature (max.) 190 °F

Differential inlet / outlet (max.) 10.8 °F

Engine jacket water flow (min.) 40.6 gpm

Total cooling water circulation volume 40.6 gpm

Operating pressure (max.) 29.0 psi

Safety valve 43.5 psi

Safety temperature limiter 230 °F

Intercooler heat high temperature circuit 6.828 MBTU/hr

Intercooler inlet high water temperature (max.) 180 °F

Intercooler coolant flow high temperatue circuit (min.) 2.9 gpm

3.3 Mixture cooling water circuit - low temperature (LT)

Coolant requirements in accordance with 'TA-001 Coolant'

Intercooler heat low temperature circuit not available

Intercooler inlet low water temperature (max.) not available

Intercooler outlet low water temperature (max.) not available

Intercooler coolant flow low temperature circuit (min.) not available

Safety valve not available

Druckreserve ca.** - mbar

* Up to / from module interface

** Heating water supply temperature in partial load operation < 90°C

Technical specification agenitor 404b BG 2G Energy AG 5/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

4. Exhaust system

Exhaust gas temperature after turbo charger 964 °F ⁽³⁾

Exhaust temperature after exhaust heat exchanger 356 °F

exhaust gas volume flow wet 257 SCFM ⁽⁶⁾

exhaust gas volume flow dry 227 SCFM ⁽⁶⁾

exhaust gas mass flow wet 1262 lbs/hr

exhaust gas mass flow dry 1165 lbs/hr

Exhaust back pressure downstream of turbine max. 0.73 psig

Pressure reserve approx. (with catalytic converter) * 0.55 (0.46) psig

Exhaust outlet noise ** 121 dB (7)

5 Ventilation

Radiation heat of engine and generator (approx.) 69.519 MBTU/hr

Supply air volume flow min. (at ∆t = 15 K) 2667 SCFM

6 Operating fluids

Lubricating oil approvals, see 'TA-003 Lubricating oil'

Lubrication oil consumption (max.) 0.30 g/kWh

Filling capacity lubricant (max.) 6.34 gallons

Lubricating oil filling tank fill capacity *** 9.25 gallons

Lubricating oil volume extension tank (optional) 18.49 gallons

Coolant approvals, see 'TA-001 Coolant'

7 Electronics and software

Generator Protection Relay Deif GPC 3 | optional redundant Relay SEL 700GT

Touchscreen display 10 "

Protection class Control cabinet Type 12

Protection class Power switch cabinet Type 1

Switch cabinet environmental temperature 32 - 95 °F

Switch cabinet relative air humidity (max.) 65 %

* From module interface (exhaust heat exchanger / catalytic converter in standard version and new condition)

** Total sound power level at full engine load in accordance with DIN 45635-11 Annex A

*** Filling tank omitted with installation of a lubricating oil volume auxiliary tank

Technical specification agenitor 404b BG 2G Energy AG 6/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

8 Interfaces

8.1 Dimensions and weights

(Figures may differ)

Length Module X 121.65 in

Width Module Y 46.06 in

Height Module Z 72.24 in

Weight Module 7496 lbs

Weight Module with sound enclosure (optional) 8774 lbs

Powder-coated CHP frame RAL 6002

Width Control cabinet X 39.37 in

Depth Control cabinet Y 23.62 in

Height Control cabinet Z 82.68 in

Weight Control cabinet 441 lbs

Control cabinet powder coated RAL 7035

Width Power switch cabinet X 23.62 in

Depth Power switch cabinet Y 19.69 in

Height Power switch cabinet Z 78.74 in

Weight Power switch cabinet 331 lbs

Power switch cabinet powder coated RAL 7035

8.2 Mechanical Connections

Interface Gas 40 / 10 DN / PN

Interface Exhaust 100 / 10 DN / PN

Interface Heating circuit 40 / 16 DN / PN

Interface Emergency cooling circuit 50 / 16 DN / PN

Interface Mixture cooling circuit LT / DN / PN

Technical specification agenitor 404b BG 2G Energy AG 7/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

8.3 Electrical connections / utility interface

Grid connection with pre-fuse (customer-provided) 60 Hz / 480 V

Grid system Y

Short-circuit proof Icc (max.) 50 kA

8.4 Data interfaces

Remote maintenance access (optional) * DSL / UMTS (SIM)

Interfaces / Data interfaces (optional): - Profibus

- Profinet

- Modbus RTU

- Modbus TCP

- Ethernet IP

- Hardware signals

Access virtual power plant (optional) Possible after technical

clarification (bus or hardware

signals)

* Access for remote maintenance must be provided by the customer

Technical specification agenitor 404b BG 2G Energy AG 8/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

9 Technical boundary conditions

Unless otherwise specified, all data is based on full engine load with the respective indicated media

temperatures and subject to technical improvements. The generator output measured at the generator

terminals serves as the basis for the delivered electrical power. All power and efficiency specifications are

gross specifications. The fuel gas quality must conform to the specifications of 'TA-004 Gas'. The operating

fluids and plant system layout must conform to the 'Technical instructions' of 2G.

(1)

Performance conditions in accordance with DIN ISO 3046. Tolerance for specific fuel use

amounts to + 5% of nominal performance. Efficiency specifications are based on an engine in

new condition. An abatement in efficiency over the service life is reduced with observance of

the maintenance requirements.

(2) The tolerance for usable heat output is +/- 8 % under normal load.

(3) The tolerance for the exhaust temperature is +/- 8 %.

(4) Corresponding to a residual oxygen concentration in the exhaust of 15 %.

(5) Electrical generator terminal power at cos φ = 1.0

(6) Volume specifications for normal status:

Pressure 14.69 psig

Temperature 32 °F

(7) Standard deviation of reproducibility 4 dB in accordance with DIN EN ISO 3746

(8) Assumed gas composition (VOC calculated as NMHC):

CH4=50 %, CO2=50 %

Power specifications in this document relate to standard reference conditions.

Standard reference conditions in accordance with DIN ISO 3046-1:

Air pressure 14.50 psig

Air temperature 77 °F

Relative air humidity 30 %

Power reduction

Power reduction due to installation at altitude > 958ft a.s.l. and/or air suction temperature > 77°F shall be

determined specifically for each project according "TI-049 Load reduction".

Technical specification agenitor 404b BG 2G Energy AG 9/9

Rev.: B , 16.01.2017 www.2-g.com

Doc.-ID.: 810900

Вам также может понравиться

- Waukesha Gas Engines VGF F18Gl: 310 - 440 BHP (230 - 330 KWB)Документ2 страницыWaukesha Gas Engines VGF F18Gl: 310 - 440 BHP (230 - 330 KWB)Javier F Pacheco PuentesОценок пока нет

- AQ10T-BFM, 363PL 2335kWДокумент2 страницыAQ10T-BFM, 363PL 2335kWLiviu ConstantinОценок пока нет

- Emergency Generator CoolingДокумент7 страницEmergency Generator CoolingJay JayОценок пока нет

- How To Calculate Motor Service FactorsДокумент6 страницHow To Calculate Motor Service Factorsabdulyunus_amirОценок пока нет

- PDS Ga-401Документ1 страницаPDS Ga-401wahyuОценок пока нет

- JMS 620 GS-N.L: Technical SpecificationДокумент4 страницыJMS 620 GS-N.L: Technical SpecificationjoellopezzОценок пока нет

- Application Guide Sludge Mixers en Rev 1Документ8 страницApplication Guide Sludge Mixers en Rev 1gazwang478Оценок пока нет

- Gei 41004Документ10 страницGei 41004Ivan Poma MontesОценок пока нет

- Engine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringДокумент20 страницEngine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringSean Chen GyarinoОценок пока нет

- Deka Avr 95Документ4 страницыDeka Avr 95Miguel Angel Perez EstradaОценок пока нет

- HYDRUS 2 Bulk - Specifications FW1.0.8 - ENДокумент44 страницыHYDRUS 2 Bulk - Specifications FW1.0.8 - ENManuel Alejandro Espinosa FarfanОценок пока нет

- Generator Set and System Spec Review - 05!12!2016Документ38 страницGenerator Set and System Spec Review - 05!12!2016Hai LeОценок пока нет

- D 6728 - 01 - Rdy3mjg - PDFДокумент7 страницD 6728 - 01 - Rdy3mjg - PDFPRASANTH PRASANTHОценок пока нет

- Capacitor Information (PT 2) PDFДокумент18 страницCapacitor Information (PT 2) PDFwillchamОценок пока нет

- S10K Chlorinator EvoquaДокумент4 страницыS10K Chlorinator EvoquameloszОценок пока нет

- Copper Nickel Pipe Din86089 Eemua145Документ1 страницаCopper Nickel Pipe Din86089 Eemua145Araby GamalОценок пока нет

- Engine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringДокумент22 страницыEngine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringRaka Adhwa MaharikaОценок пока нет

- J416V06 enДокумент4 страницыJ416V06 enMartin KratkyОценок пока нет

- Technical Specification: JMS 620 GS-N.LДокумент3 страницыTechnical Specification: JMS 620 GS-N.LHoseinKhodadadyОценок пока нет

- Transformer Room Ventilation Calculation 20170310xlsx - CompressДокумент1 страницаTransformer Room Ventilation Calculation 20170310xlsx - CompressMuhammad Ali TariqОценок пока нет

- Brochure ERKДокумент19 страницBrochure ERKAri BinukoОценок пока нет

- 2015 12 SCM EngДокумент33 страницы2015 12 SCM EngkqОценок пока нет

- Dhanalakshmi Srinivasan College of Engineering and TechnologyДокумент21 страницаDhanalakshmi Srinivasan College of Engineering and TechnologySAJU UTHUPPANОценок пока нет

- Pulsation Damper Sizing RevДокумент13 страницPulsation Damper Sizing RevFrancesca CoattiОценок пока нет

- Tedom CHP UnitsДокумент2 страницыTedom CHP UnitsMadhav RathourОценок пока нет

- Determination of Critical Speed of Whirling Shafts AimДокумент3 страницыDetermination of Critical Speed of Whirling Shafts AimLoka RakeshОценок пока нет

- Assignment 1Документ2 страницыAssignment 1nimishk92100% (1)

- Automatic Water Flow ControlДокумент18 страницAutomatic Water Flow ControlssgjmlimОценок пока нет

- Pump MathsДокумент10 страницPump MathsSakib RafeeОценок пока нет

- Pump Power Calculator PDFДокумент6 страницPump Power Calculator PDFDjalel la Parole100% (1)

- ST-124 New Gear Train PDFДокумент21 страницаST-124 New Gear Train PDFPopa MihaiОценок пока нет

- Flygt PumpsДокумент56 страницFlygt PumpsThe_RainmakerОценок пока нет

- 1.HSK78 2MW DatasheetДокумент6 страниц1.HSK78 2MW Datasheetnunukidsshop 0869478221Оценок пока нет

- Blackbear C HoistДокумент8 страницBlackbear C Hoistex5dreamОценок пока нет

- Avk Saudi National Price ListДокумент46 страницAvk Saudi National Price Listjanpaul2481Оценок пока нет

- HydroHelp1 4lockedДокумент63 страницыHydroHelp1 4lockedkorayayhanОценок пока нет

- Suction Strainer Boxes: Standard Specification ForДокумент5 страницSuction Strainer Boxes: Standard Specification ForKevin JosueОценок пока нет

- PVsyst ReportДокумент13 страницPVsyst ReportPranjal BagalОценок пока нет

- N2 Generator CalculationДокумент9 страницN2 Generator CalculationBagus PrambudiОценок пока нет

- Value of Lost LoadДокумент7 страницValue of Lost LoadLuis AntonioОценок пока нет

- A.3 Sequence of Operation Fuel SystemДокумент9 страницA.3 Sequence of Operation Fuel SystemPLC Swa100% (2)

- PMRC Mar Va 140Документ6 страницPMRC Mar Va 140Dwayne YiiОценок пока нет

- Cruisair Seawater PumpsДокумент2 страницыCruisair Seawater PumpsorlandoОценок пока нет

- Desalination Plant Feed Water ArrangementsДокумент11 страницDesalination Plant Feed Water ArrangementsSooraj Surendran SugathaОценок пока нет

- Jgs616 Ds Preliminary DataДокумент4 страницыJgs616 Ds Preliminary DataEdutamОценок пока нет

- Pump Sizing Calculation (Photo)Документ25 страницPump Sizing Calculation (Photo)anto3harrish3fdoОценок пока нет

- 2300-1101 Ion Ip-man-Vnx Rev eДокумент45 страниц2300-1101 Ion Ip-man-Vnx Rev epicolin78Оценок пока нет

- Section 3 Table 3.01 - Jahra Pumping Station - Odor Control CalculationsДокумент9 страницSection 3 Table 3.01 - Jahra Pumping Station - Odor Control CalculationsHRK65Оценок пока нет

- Heat Balance DiagramДокумент2 страницыHeat Balance DiagramprasalaОценок пока нет

- Boiler Design DataДокумент8 страницBoiler Design Dataramnath008100% (1)

- NPSH Improvement PDFДокумент28 страницNPSH Improvement PDFPUMPSОценок пока нет

- Hydropneumatic TanksДокумент7 страницHydropneumatic Tankstimka1910Оценок пока нет

- Fuel Flow MetersДокумент7 страницFuel Flow MetersAMIYA SHANKAR PANDAОценок пока нет

- Room ACis.1391.2.1992Документ36 страницRoom ACis.1391.2.1992Ajay MenonОценок пока нет

- High Head Drainage PumpsДокумент9 страницHigh Head Drainage PumpsEnrique MurgiaОценок пока нет

- Heat Balance Test On Computerised Single Cylinder Diesel Engine Fitted With Eddy Current DynamometerДокумент4 страницыHeat Balance Test On Computerised Single Cylinder Diesel Engine Fitted With Eddy Current DynamometerNagaraj MuniyandiОценок пока нет

- JGS 320 GS-B.L: Technical Description GensetДокумент11 страницJGS 320 GS-B.L: Technical Description GensetAmir QayyumОценок пока нет

- 20V4000 L33 FN Technical Data SheetДокумент2 страницы20V4000 L33 FN Technical Data SheetB-ENERGY INVESTMENTОценок пока нет

- Ficha Tecnica Equipo Gas CAT G3516Документ5 страницFicha Tecnica Equipo Gas CAT G3516MarioAndrésRamirezC.Оценок пока нет

- TS J420 E900 at BMEP 12bar, Pure H2Документ12 страницTS J420 E900 at BMEP 12bar, Pure H2d_macuraОценок пока нет

- Econom Ic in D Ica To RS: CepciДокумент2 страницыEconom Ic in D Ica To RS: CepciJulian BarreraОценок пока нет

- Indicators: Cpi Output Index Cpi Output Value Cpi Operating RateДокумент2 страницыIndicators: Cpi Output Index Cpi Output Value Cpi Operating RateJulian BarreraОценок пока нет

- Effective Writing - Learn Science at ScitableДокумент6 страницEffective Writing - Learn Science at ScitableJulian BarreraОценок пока нет

- 2017 - A Quick Start For The Python Interface To LINGO APIДокумент5 страниц2017 - A Quick Start For The Python Interface To LINGO APIJulian BarreraОценок пока нет

- Important Dates (PG Students View) Semester 1, 2022-2023 - All Campus (As of 2 October 2022)Документ4 страницыImportant Dates (PG Students View) Semester 1, 2022-2023 - All Campus (As of 2 October 2022)AFHAM JAUHARI BIN ALDI (MITI)Оценок пока нет

- Marine Products: SL-3 Engine ControlsДокумент16 страницMarine Products: SL-3 Engine ControlsPedro GuerraОценок пока нет

- PIL HANDOUT in TextДокумент173 страницыPIL HANDOUT in Textbhargavi mishraОценок пока нет

- Tire Size ComparisonДокумент1 страницаTire Size ComparisonBudi DarmawanОценок пока нет

- SMB Marketing PlaybookДокумент18 страницSMB Marketing PlaybookpramodharithОценок пока нет

- Turn Pet1 Plastic Bottles Into 3d Filament With The Recreator 3d Mk5kit Ender3 b7936987 A5e5 4b10 80fa 8754423f3ee8Документ11 страницTurn Pet1 Plastic Bottles Into 3d Filament With The Recreator 3d Mk5kit Ender3 b7936987 A5e5 4b10 80fa 8754423f3ee8Meet MehtaОценок пока нет

- MEETING 12 - Additional CasesДокумент25 страницMEETING 12 - Additional CasesJohn Michael VidaОценок пока нет

- Moon Chae-Won - AsianWiki - 1606832167285Документ6 страницMoon Chae-Won - AsianWiki - 1606832167285CESHОценок пока нет

- MC1413 D PDFДокумент8 страницMC1413 D PDFAnonymous oyUAtpKОценок пока нет

- Dislocations and StrenghteningДокумент19 страницDislocations and StrenghteningAmber WilliamsОценок пока нет

- Microeconomics Theory and Applications 12th Edition Browning Solutions ManualДокумент5 страницMicroeconomics Theory and Applications 12th Edition Browning Solutions Manualhauesperanzad0ybz100% (26)

- CollectionsДокумент42 страницыCollectionsNaveen KumarОценок пока нет

- NV 2Документ2 страницыNV 2Joshua ApongolОценок пока нет

- Compatibility Matrix For Cisco Unified Communications Manager and The IM and Presence Service, Release 12.5 (X)Документ31 страницаCompatibility Matrix For Cisco Unified Communications Manager and The IM and Presence Service, Release 12.5 (X)Flavio AlonsoОценок пока нет

- Nammcesa 000010 PDFДокумент1 543 страницыNammcesa 000010 PDFBasel Osama RaafatОценок пока нет

- Catalogo AMF Herramientas para AtornillarДокумент76 страницCatalogo AMF Herramientas para Atornillarabelmonte_geotecniaОценок пока нет

- Megohmmeter: User ManualДокумент60 страницMegohmmeter: User ManualFlavia LimaОценок пока нет

- E2 Lab 2 8 2 InstructorДокумент10 страницE2 Lab 2 8 2 InstructorOkta WijayaОценок пока нет

- Apogee 3800 Service ManualДокумент56 страницApogee 3800 Service ManualGauss Medikal Sistemler100% (1)

- Surname 1: Why Attend To WMO? Who Would Not Trust The Brand That Their Friends Strongly Recommend? It IsДокумент4 страницыSurname 1: Why Attend To WMO? Who Would Not Trust The Brand That Their Friends Strongly Recommend? It IsNikka GadazaОценок пока нет

- Document 3Документ6 страницDocument 3Nurjaman SyahidanОценок пока нет

- Indian Chief Motorcycles, 1922-1953 (Motorcycle Color History)Документ132 страницыIndian Chief Motorcycles, 1922-1953 (Motorcycle Color History)Craciun Sabian100% (6)

- Data Structures and Algorithms Made Easy-Narasimha KarumanchiДокумент228 страницData Structures and Algorithms Made Easy-Narasimha KarumanchiPadmalatha Ragu85% (40)

- Good Quality Practices at NTPC KudgiДокумент8 страницGood Quality Practices at NTPC KudgisheelОценок пока нет

- 2012 Brochure Keltan Final en PDFДокумент20 страниц2012 Brochure Keltan Final en PDFJorge Zegarra100% (1)

- Unit I Lesson Ii Roles of A TeacherДокумент7 страницUnit I Lesson Ii Roles of A TeacherEvergreens SalongaОценок пока нет

- APUS Court Cases: Escobedo V IllinoisДокумент4 страницыAPUS Court Cases: Escobedo V Illinoisapi-3709436100% (1)

- Hydrostatic Pressure Test Safety ChecklistДокумент3 страницыHydrostatic Pressure Test Safety ChecklistJerry Faria60% (5)

- I. Characteristics of WastewaterДокумент59 страницI. Characteristics of WastewaterEljay VinsonОценок пока нет

- Lucrare de DiplomaДокумент99 страницLucrare de DiplomarashcapurОценок пока нет