Академический Документы

Профессиональный Документы

Культура Документы

Jsa For Scaffolding Erection & Dismentling

Загружено:

sanath adhikaryОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Jsa For Scaffolding Erection & Dismentling

Загружено:

sanath adhikaryАвторское право:

Доступные форматы

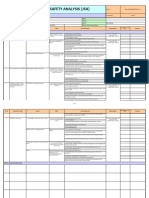

`Job Safety Analysis Page 1

JOB SAFETY ANALYSIS (JSA)

Associated industrial JSA Number:

Company name: Date

furnaces Pvt. Ltd. HZL/FUMER/SCAFFOLDIING- 00

Supervisor name :Mr.

Site name: FUMER Project Permit to work required? :Yes

Plant / Area: HZL ,Fumer/STG Location: :

Scope of JSA :

1. To find out all hazards associated with each activity

2. To fix control measures to mitigate the hazard

3. To follow proper engineering / OHS guidelines to complete the job in safe manner to prevent any incident and property loss.

JSA team member names:

Sign. By AIFL/UNI7 Sign. By NFC Sign. BY CBRE

Version 1.0, April 2016

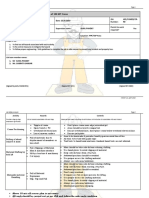

`Job Safety Analysis Page 2

Activity Hazards Controls

Provide a step-by-step List all hazards associated with each Measures that need to be taken to eliminate or minimise the risk associated with each

breakdown of the task step hazard

Use Cut Resistance hand Gloves level-4.

1.1 Cut injury.

1. Area inspection and Wear dust mask.

1.2 Dust inhalation.

levelling. Area must be cleared of any obstacle.

1.3 Slip trip & falls.

Proper housekeeping should be done before starting the job.

Job specific TBT before starting the job.

Material should be stored properly & not obstructed the passage.

1.1 Slippage of material.

Proper barrier should be present to prevent slippage.

1.2 Cut injury by sharp edges.

2. Material Shifting and Wears hand gloves. Use shoulder pad during Manual shifting.

Storage.

1.3 Fall of materials.

Ensure Proper material handling procedure when shifting material manually.

1.4 Ergonomic Hazard.

Don’t allow to shift excess load manually.

Shift material using gin wheel or pull up / lower the material with rope & sack.

3.1 Scaffold may topple due to Surface should be levelled & compacted.

uneven surface.

Job Specific tool box meeting to be conducted before commence of the work.

3.2 Fall of materials. Materials to be lift by certified rope pulley if required.

Follow the sequence of scaffolding erection.

3. Scaffolding Erection.

Right body position must be ensure while material handling

Place tools in sack / toolbox.

Tools to be tied with string.

3.3 Fall of person.

Job specific PPE (safety harness with shock absorber if 6 meter &above) must be

Version 1.0, April 2016

`Job Safety Analysis Page 3

Activity Hazards Controls

Provide a step-by-step List all hazards associated with each Measures that need to be taken to eliminate or minimise the risk associated with each

breakdown of the task step hazard

provided to all workers involved with scaffolding erection.

Proper anchorage point or if required life line to be provided.

Only medically fit for height and trained worker must be deployed for erection work.

Retractable fall arrestor to be used if required.

Area must be barricaded and warning board will be displayed.

Line of fire must be followed strictly.

3.4 Hit by scaffolding materials.

3.5 Collapse of scaffold.

Scaffolding erection work should be maintained as per scaffolding standard and

certified scaffolder.

During Erection Red Tag Should Be Displayed.

Area must be barricaded and warning board will be displayed.

Scaffolding height above 15meter, approved designed drawing should be available at

site before starting the job.

3.6 Overhead power cable. Don’t use rusted & damaged material.

Authorized and trained scaffolder for erected of scaffold.

Avoid overhead cable area/zone.

3.7 Collapse of Mobile Scaffold.

Parallel Job is not allowed during scaffolding Erection.

Insure Lock the wheel of Mobile Scaffold to Avoid any sudden Move.

Insure to fix out legs of mobile scaffold & Proper lock with Pin.

4.1 Fall of material. Job specific Tool box Talk to be conducted before commence of the work.

Dismantling scaffolding pipes should be bringing down by rope pulley.

Using rope pulley/ chain pulley block must have TPIC with load test.

4. Dismantling of scaffolding.

Use joint free PP rope with 19mm thickness.

Place tools in sack / toolbox.

Tools to be tied with string.

Version 1.0, April 2016

`Job Safety Analysis Page 4

Activity Hazards Controls

Provide a step-by-step List all hazards associated with each Measures that need to be taken to eliminate or minimise the risk associated with each

breakdown of the task step hazard

Job specific PPE (safety harness with shock absorber if 6 meter &above) must be

provided to all workers involved with scaffolding erection.

Only medically fit and trained worker must be deployed for dismantling work.

Scaffolding dismantling work should be carried out in the presence of job supervisor

from top to bottom area also barricading with stand by person.

Proper anchorage point or if required life line to be provided.

4.2 Fall of person. Retractable fall arrestor to be used if required.

Area must be barricaded and warning board will be displayed.

4.3 Hit by scaffolding material.

Line of fire must be followed strictly, do not walk under suspended load.

Red tag must be displayed at the time of dismantling.

Follow the dismantling sequence of scaffolding.

4.4 Collapse scaffold. Area must be barricaded and Cautionary board will be displayed.

4.5 Over head cable. Don’t stand inside line of fire.

Avoid over head cable area/zone.

Version 1.0, April 2016

`Job Safety Analysis Page 5

Activity Hazards Controls

Provide a step-by-step List all hazards associated with each Measures that need to be taken to eliminate or minimise the risk associated with each

breakdown of the task step hazard

5. Housekeeping/stacking of 5.1 Slip, trip & Fall injury. 5.1 Material should be stored properly & not obstructed the passage.

dismantled material. 5.2 Proper barrier should be present to prevent slippage.

5.3 Ensure Proper material handling procedure when shifting material manually.

5.2 Cut injury by sharp edges.

5.2 Use Cut Resistance (level-4) hand gloves.

1. Usage of job specific PPE’S.

1. Burn injury. 2. All electrical tools to be tested.

2. Cut injury. 3. All electrical tools connection through ELCB.

3. Fire. 4. Area to be free from combustible material.

4.Electric shock by Raining or 5. Wearied cutting and binding area to be barricaded.

Machine in open yard 6 .Fire extinguisher to be ensured at site.

7. Cutting and binding area to be barricaded.

8. Remove the scrap material.

Cutting and binding of TMT. 9. Electrical Machine and its accessories shall be keep under shade and protect these

by Raining.

10. Use specific Hand Gloves while handling and cutting/bending the Reinforcement

Bars to avoid the Electric Shock by Wet Reinforcement in Monsoon.

Version 1.0, April 2016

`Job Safety Analysis Page 6

11. Only Authorized Operator Must Operate the cutting and bending machine.

1. All workers on site shall wear proper PPE’S.

1. Slip of material. 2. Area Proper housekeeping.

2. Cut injury. 3. Safe access provided.

3. Tripping. 4. Area should be free from any inessential objects.

5. Shuttering material should not be in loose condition.

De-shuttering work 6. After removing of shuttering from height, it should not be thrown freely from

height.

7. People should not work under the scaffolding where de-shuttering work in

progress at height for Walls/Columns.

8. Area should be barricaded at ground level where de-shuttering work is going on at

height.

1.Fall injury - Specific tool box talk to be undertaken prior to work at height activities.

-Scaffolding inspection as per defined standards to ensured.

2.Cut injury

- Use of long handled tools where appropriate.

3.Slippage of material - Full body harness without shock absorber should be used upto 6.0 m height

and over 6.0 m full body harness with shock absorber should be used.

-Life line/Anchor point to be ensured to anchor safety harness.

Falls from height. - Close supervision to be ensured during the work.

- Consider use of fall arrest systems depending on nature of task, equipment

and duration.

-Walk platform to be secured.

-Safety nets should be used if working above 8.0 m.

- Adequate and appropriate signs in place to warn of hazards below work area.

- Ensure operatives trained to work at height.

-Area should be barricaded at ground level.

Version 1.0, April 2016

`Job Safety Analysis Page 7

1. Cut Injury 1. Wear cut resistant(LVL IV) hand gloves while manually shifting only.

Manually Material 2. Do not carry over load against man strength. Only carry suitable load.

2. Slipping

Shifting at site 3. Maintain safe distance from all workers while carrying.

4. Keep the area barricaded.

Version 1.0, April 2016

Вам также может понравиться

- JSA For Diesel Filling at Del CampДокумент6 страницJSA For Diesel Filling at Del CampMohammed Minhaj60% (5)

- JSA-for Lifting Activity by CraneДокумент13 страницJSA-for Lifting Activity by CraneRival Lino85% (13)

- Jsa For Drilling.Документ3 страницыJsa For Drilling.Belsyah Nofriyan75% (4)

- TEIPL-JSA-058 Carpentry Wood WorkДокумент3 страницыTEIPL-JSA-058 Carpentry Wood Workba ratnaparkheОценок пока нет

- Up Dated Job Safety Analysis-Gypsum Plastering WorksДокумент12 страницUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- Jsa For Scaffolding ErectionДокумент7 страницJsa For Scaffolding Erectionnoorul IslamОценок пока нет

- Job Safety Analysis For Scaffolding 1Документ3 страницыJob Safety Analysis For Scaffolding 1nasar_mahsood71% (34)

- JSA Ladders Working at Heights 001Документ2 страницыJSA Ladders Working at Heights 001Raman SawОценок пока нет

- JSA-006 Shuttering & Deshuttering Form WorkДокумент3 страницыJSA-006 Shuttering & Deshuttering Form Workba ratnaparkhe83% (12)

- JSA-Working at HeightДокумент2 страницыJSA-Working at Heightsubhanmusadiq83% (109)

- JSA For Working at HeightДокумент2 страницыJSA For Working at HeightXUE JIANОценок пока нет

- JSA For Concrete, Brecking, ExavationДокумент6 страницJSA For Concrete, Brecking, ExavationBinay0% (1)

- JSA Concrete WorksДокумент8 страницJSA Concrete Worksfrancis_e_tan93% (27)

- JSA WeldingДокумент2 страницыJSA WeldingSigint Sides0% (3)

- JSA For Rebar Works Includes Working in ScaffoldingДокумент4 страницыJSA For Rebar Works Includes Working in Scaffoldingyc safetyОценок пока нет

- Jsa For Applying Bituminous Roof Treatment On BuildingsДокумент3 страницыJsa For Applying Bituminous Roof Treatment On BuildingsMohammed Minhaj100% (1)

- Jsa Scaffolding Erection Maintenance InspectionДокумент3 страницыJsa Scaffolding Erection Maintenance InspectionAli50% (2)

- Scaffolding JSA (General)Документ5 страницScaffolding JSA (General)Panchdev KumarОценок пока нет

- JSA For Brick WorkДокумент3 страницыJSA For Brick Workwahyu nugroho83% (6)

- JSA G20 Scaffolding (Erection, Dismantling)Документ4 страницыJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- JSA Roof Sheeting V3 16 July 06Документ6 страницJSA Roof Sheeting V3 16 July 06Walt Flowers80% (5)

- 9.JSA For Night Work Activity - Rev 01Документ7 страниц9.JSA For Night Work Activity - Rev 01ibrahim80% (10)

- Jsa For Tile FixingДокумент4 страницыJsa For Tile FixingMohammed Minhaj100% (1)

- ULSADO-JSA-Demolation Existing Concrete FoundationДокумент2 страницыULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- Jsa For Road WorksДокумент11 страницJsa For Road Worksyc safety75% (12)

- Column Lifting & Erection JSAДокумент7 страницColumn Lifting & Erection JSAAli Mohsin100% (3)

- JSA - SK-erection & DismantlingДокумент1 страницаJSA - SK-erection & DismantlingEngr Tahir UL Haq100% (3)

- JOB SAFETY ANALYSIS Grout Placement, Curing and CoatingДокумент5 страницJOB SAFETY ANALYSIS Grout Placement, Curing and Coatingmuhammad zaman50% (2)

- JSA For Cutting, Grinding and WeldingДокумент4 страницыJSA For Cutting, Grinding and Weldingyc safety100% (3)

- RA - 018 01 Scaffolding Erection and DismantlingДокумент14 страницRA - 018 01 Scaffolding Erection and DismantlingVuong Bui95% (63)

- Mobile - Scaffolds JSAДокумент10 страницMobile - Scaffolds JSABojie Abogadie100% (1)

- Area Hard Barrication JsaДокумент7 страницArea Hard Barrication JsaJanakiramanОценок пока нет

- JSA # 3 Column ErectionДокумент6 страницJSA # 3 Column ErectionRaghava Richhu100% (2)

- JSA For WrappingДокумент6 страницJSA For WrappingMohammed Minhaj100% (2)

- JSA-Manual Lifting of MaterialsДокумент3 страницыJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- JSA FORMAT For Materials LoadingДокумент2 страницыJSA FORMAT For Materials LoadingVikky KumarОценок пока нет

- Steel Heat Treatment HandbookДокумент832 страницыSteel Heat Treatment HandbookSiampol Feepakphor100% (2)

- JSA For Cement Plaster at Office ExtensionДокумент4 страницыJSA For Cement Plaster at Office ExtensionMohammed Minhaj50% (2)

- JSA ScaffoldingДокумент2 страницыJSA ScaffoldingHrishikesh UnnikrishnanОценок пока нет

- Crane Jsa TGPДокумент2 страницыCrane Jsa TGPSuryakant SurajОценок пока нет

- JSA For RCC, Foundation & Generator Installation (R-00)Документ14 страницJSA For RCC, Foundation & Generator Installation (R-00)Suju RajanОценок пока нет

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedДокумент12 страницCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- JSA Installation of PumpsДокумент6 страницJSA Installation of Pumpsyc safety100% (2)

- Jobs Safety Analysis (JSA)Документ9 страницJobs Safety Analysis (JSA)uttam mishra100% (1)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteДокумент5 страницJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANОценок пока нет

- JSA of Pipe Unloading.Документ2 страницыJSA of Pipe Unloading.vijay kumar singh100% (1)

- Jsa For ScaffoldingДокумент3 страницыJsa For Scaffoldingsoubhagya100% (4)

- Jsa For Operating A BobcatДокумент2 страницыJsa For Operating A Bobcatsoubhagya100% (2)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Reinforcement WorkДокумент2 страницыJob Safety Analysis (Jsa) : Title of Activity / Work: Reinforcement Workba ratnaparkhe67% (3)

- JSA For Lifting of RebarsДокумент5 страницJSA For Lifting of RebarsNiraОценок пока нет

- Form JSA Lifting CraneДокумент6 страницForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JHA 08 On Erection of Roofing SheetsДокумент3 страницыJHA 08 On Erection of Roofing SheetsAkhilesh KumarОценок пока нет

- JSA Lifting OperationsДокумент4 страницыJSA Lifting OperationsCristina Rican100% (1)

- Safe Work Method Statement: (See Below)Документ6 страницSafe Work Method Statement: (See Below)Siddharth P100% (1)

- Jsa For Steel ErectionДокумент7 страницJsa For Steel ErectionRajuОценок пока нет

- Job Safety Analysis: Page 1 of 4Документ4 страницыJob Safety Analysis: Page 1 of 4RakeshkasarlaОценок пока нет

- JSA SK Erection DismantlingДокумент1 страницаJSA SK Erection DismantlingSamuel Hugos100% (4)

- JSA GroutingДокумент2 страницыJSA GroutingSyazWyn100% (5)

- 04) ZEEPod & Other Project ExperienceДокумент72 страницы04) ZEEPod & Other Project Experiencebapaobao100% (1)

- The Weathering - Aircraft - 20 - BASESДокумент74 страницыThe Weathering - Aircraft - 20 - BASESjose vivarОценок пока нет

- NEC Vs JCT ContractsДокумент36 страницNEC Vs JCT ContractsYash Tohooloo100% (3)

- IJ GIS en - CompressedДокумент24 страницыIJ GIS en - CompressedpopaminoОценок пока нет

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisДокумент5 страницThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarОценок пока нет

- Jsa Slip FormДокумент5 страницJsa Slip Formputrasejahtra50% (2)

- 12 Scaffolding WorkДокумент5 страниц12 Scaffolding WorkKoneti JanardhanaraoОценок пока нет

- Dual Stack Ip-Mpls and MPLS-TPДокумент6 страницDual Stack Ip-Mpls and MPLS-TPFelipe A. PérezОценок пока нет

- Total Quality Management: PCTI Limited - A Unique Name For Quality EducationДокумент296 страницTotal Quality Management: PCTI Limited - A Unique Name For Quality Educationrajesh_vuОценок пока нет

- Welcome To Oracle Business Intelligence Tools 10g (10.1.2) : Quick TourДокумент2 страницыWelcome To Oracle Business Intelligence Tools 10g (10.1.2) : Quick TourtejukmОценок пока нет

- RДокумент59 страницRChristopher AndersonОценок пока нет

- Primer 1 PDFДокумент3 страницыPrimer 1 PDFTomislav JovanovicОценок пока нет

- Flight Training Instruction: Naval Air Training CommandДокумент118 страницFlight Training Instruction: Naval Air Training CommandSteve JeffОценок пока нет

- Powder Actuated ToolsДокумент1 страницаPowder Actuated ToolsJayvee Baradas ValdezОценок пока нет

- Air-Breathing Engines Unit 4Документ22 страницыAir-Breathing Engines Unit 4ganeshkumarbemech0% (1)

- Boiler 5Документ4 страницыBoiler 5Shams TabrezОценок пока нет

- 2023 Product Catalog - 5.2Документ22 страницы2023 Product Catalog - 5.2Zulfikar BladeОценок пока нет

- An Study On Kort and ProppellerДокумент129 страницAn Study On Kort and ProppellerLong NguyenОценок пока нет

- Apcorise Program Book 2019Документ74 страницыApcorise Program Book 2019huria nusantaraОценок пока нет

- SAP ABAP Interview QuestionsДокумент9 страницSAP ABAP Interview QuestionsJo MallickОценок пока нет

- Masa ProfileДокумент20 страницMasa ProfileTasleem HabiОценок пока нет

- 09574099710805556Документ50 страниц09574099710805556heartback100% (2)

- Systems Design: C H A P T E RДокумент39 страницSystems Design: C H A P T E Reve2495Оценок пока нет

- D46 Seam3 5 3 05Документ3 страницыD46 Seam3 5 3 05James SilvozaОценок пока нет

- Customer Relationship ManagementДокумент4 страницыCustomer Relationship ManagementWebster CarrollОценок пока нет

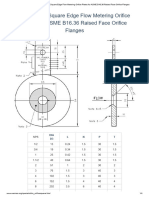

- Wermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice FlangesДокумент4 страницыWermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice Flangestechnicalei sulfindoОценок пока нет

- DFD ExamplesДокумент20 страницDFD Examplesasadahmedkhan129611Оценок пока нет

- 2.what Are Fundamental Stages of Data Warehousing?: WikipediaДокумент7 страниц2.what Are Fundamental Stages of Data Warehousing?: WikipediaRajan SinghОценок пока нет

- Aliens Colonial Marines ManualoptimizationguideДокумент4 страницыAliens Colonial Marines ManualoptimizationguideMax LuxОценок пока нет

- Project ReportДокумент18 страницProject ReportManish RawatОценок пока нет

- UNITRONICS V200-18-E1Документ10 страницUNITRONICS V200-18-E1eddieipenzaОценок пока нет

- Arch WiresДокумент38 страницArch WireskirmaniОценок пока нет